Method for removing micro-plastics in water based on graphene material

A graphene and porous graphene technology, applied in the field of environmental pollution research, can solve the problems of incomplete removal of microplastics, microplastics entering rivers and oceans, etc., and achieve the effect of enhanced alkali activation, low cost, and increased wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Provide a kind of preparation method of magnetic porous graphene, comprise the following steps:

[0041]S1. Preparation of graphene oxide: Weigh 2-4g flake graphite and 10-14g potassium permanganate respectively, mix them evenly and pour them into a 200mL reactor liner, then put the reactor liner into a stainless steel reactor jacket ;Quickly add 90-100mL of concentrated sulfuric acid to the inner tank, quickly cover the inner tank lid and rotate the lid of the stainless steel reaction kettle tightly; store the reaction kettle at a temperature of 0-4°C for 3-4h; after the reaction, Quickly put the reaction kettle into an oven at 100-105°C to heat, and perform a rapid oxidation reaction for 1.5-2 hours; after the reaction, take the reaction kettle out of the oven, cool to room temperature and open it; dilute the reactant with 300-400mL deionized water , after cooling again, add 45-55mL 30% hydrogen peroxide drop by drop, stir well until the solution is golden yellow; was...

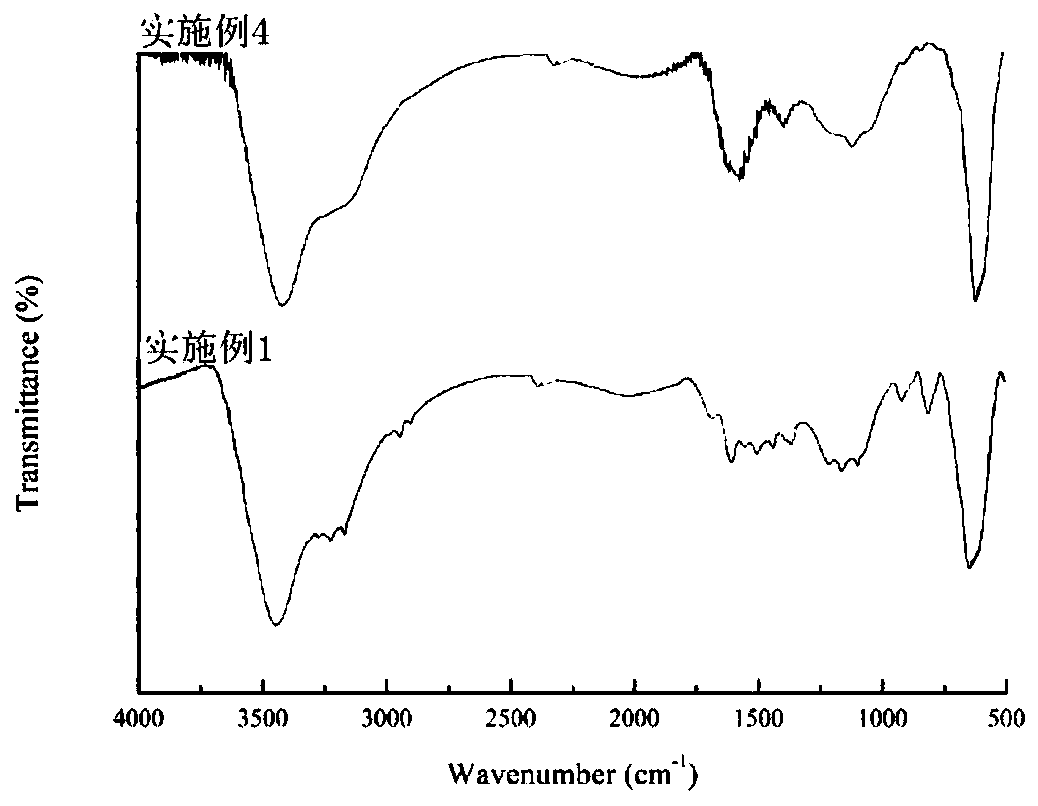

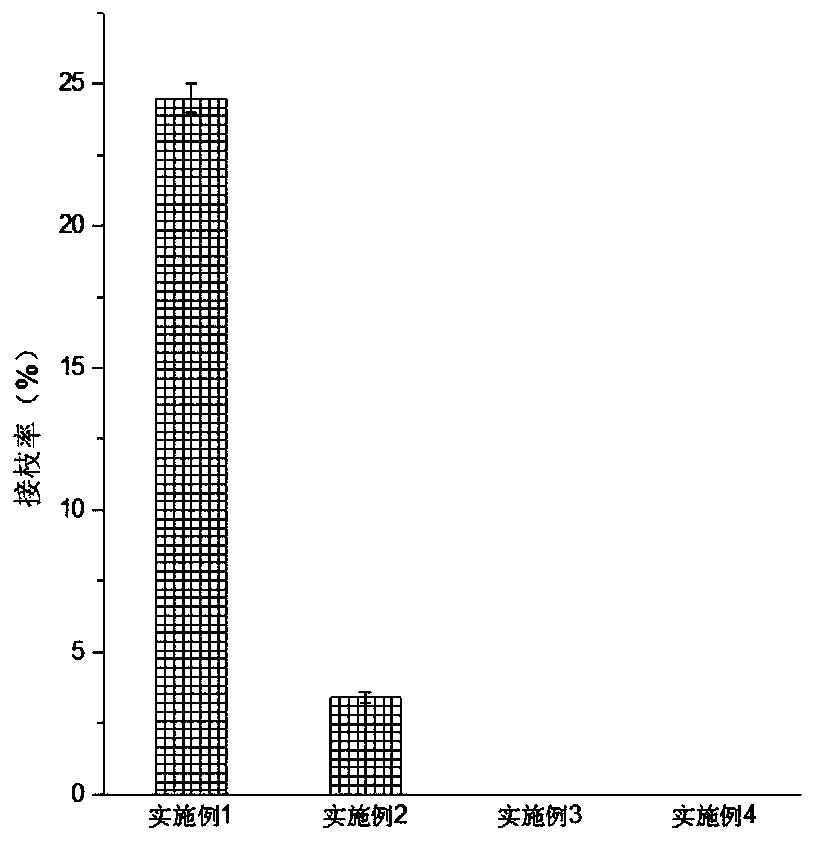

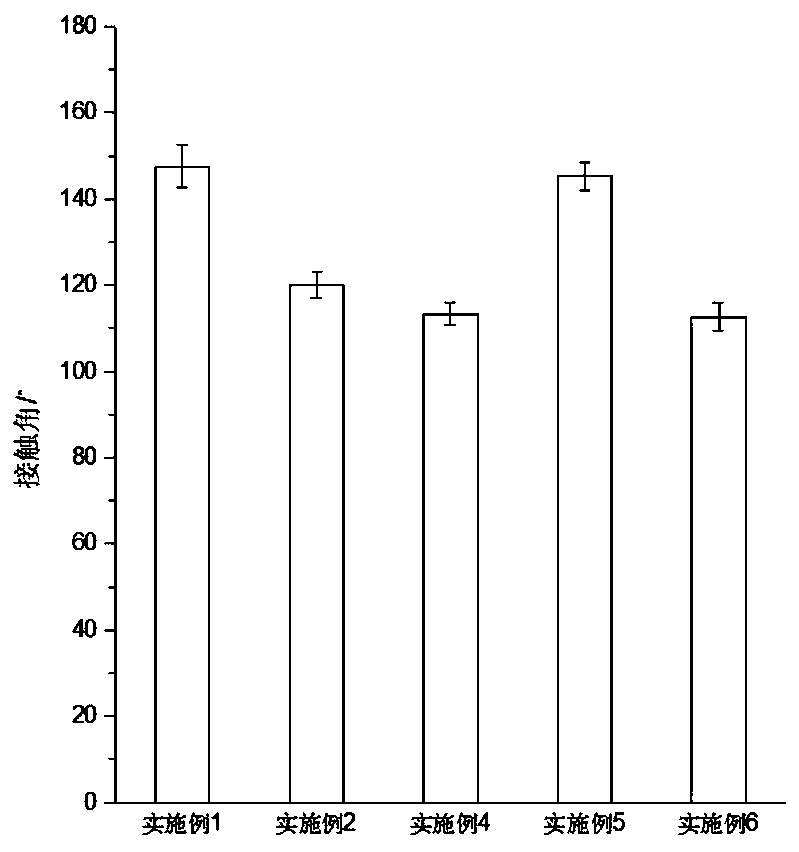

Embodiment 1

[0059] A preparation method of magnetic porous graphene, comprising the following steps:

[0060] S1. Preparation of graphene oxide: Weigh 3g of flake graphite and 12g of potassium permanganate respectively, mix them evenly and pour them into a 200mL reactor liner, then put the reactor liner into a stainless steel reactor jacket; Quickly add 100mL of concentrated sulfuric acid to the tank, quickly cover the lid of the inner container and rotate it tightly to cover the stainless steel reactor lid; store the reactor at 4°C for 4 hours; after the reaction, quickly put the reactor into an oven at 100°C Heating, rapid oxidation reaction for 1.5h; after the reaction, take the reaction kettle out of the oven, cool to room temperature and open it; dilute the reactant with 300mL deionized water, and add 55mL of 30% hydrogen peroxide dropwise after cooling again , fully stirred until the solution was golden yellow; the obtained mixed solution was washed three times with 5% hydrochloric ...

Embodiment 2

[0066] Glycine ethyl ester hydrochloride was not added when modifying graphene oxide, and the rest were exactly the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com