Composite active medium-green dye

A technology of reactive dyes and dyes, applied in the field of dyes, can solve the problems of poor compatibility of dyeing performance, low rate of first-time genuine products, large difference between hydrophilicity and lipophilicity, etc., to improve washability and washing fastness, and improve application and dyeing performance, the effect of improving the washing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

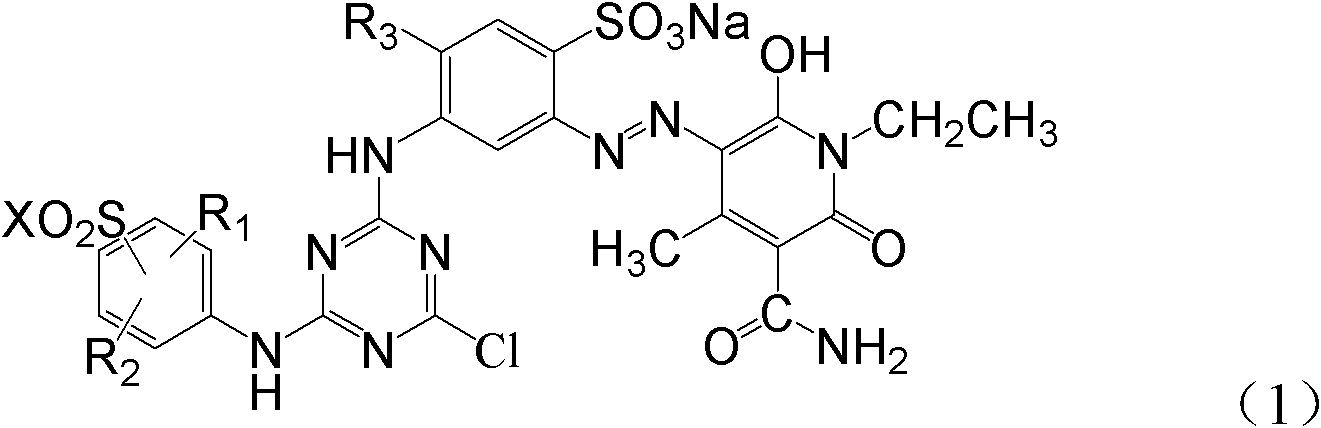

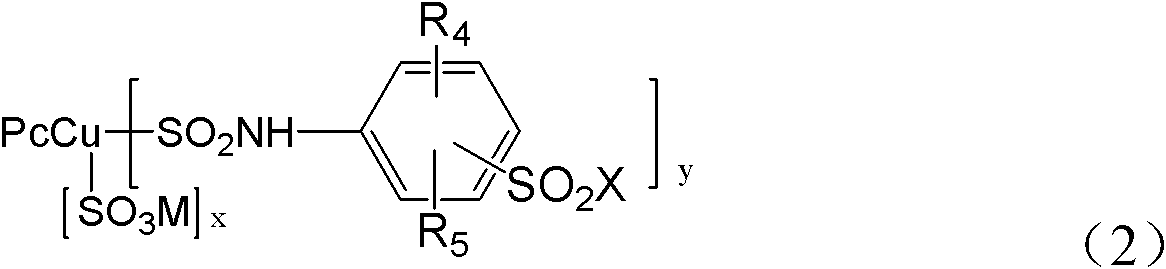

Method used

Image

Examples

Embodiment 1

[0028] Get 35g of dyestuff A shown in formula (4), 30g of dyestuff B shown in formula (10), 48g of dyestuff C shown in formula (14), naphthalenesulfonic acid formaldehyde condensate 20g, dispersant 1g, dustproof agent 0.4 g, 100 g of water are blended, stirred evenly, and then spray-dried to obtain the composite active green dye of the present invention.

[0029] The concrete steps of embodiment 2-9 are as embodiment 1, and specific proportioning is as follows:

[0030]

[0031] In the table, D, E, F, and G represent the following three substituents respectively: D=H, E=OCH 3 , F=SO 3 M,G=CH 3

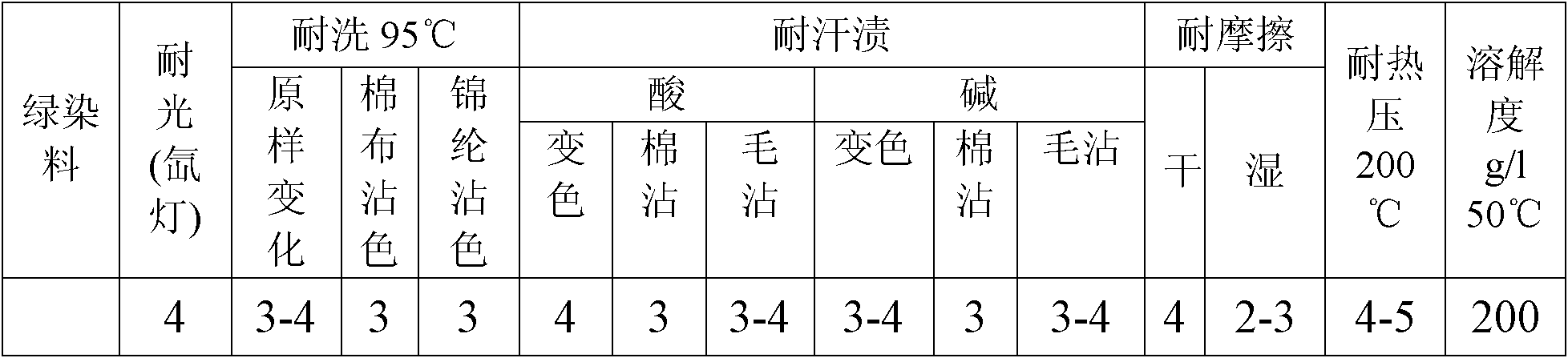

[0032] Among the above Examples 1-9, Embodiment 1-3 is a liquid dye product mixed and spray-dried to obtain a solid product; Embodiment 4-6 is a liquid dye product made by direct mixing; Embodiment 7-9 is a mixture of each dye The solid powder is directly mixed to obtain a solid product. The prepared composite reactive middle green dye is tested for performance, and the results...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com