Nano carbon material composite resin hard carbon electrode material as well as preparation method and application thereof

A composite resin and nano-carbon material technology, applied in the field of electrochemical materials, can solve the problems of easy collapse of pore structure, high irreversible capacity loss, and improvement of cycle stability, and achieve environmental pollution-free, controllable pore structure and pore ratio , the effect of inhibiting agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

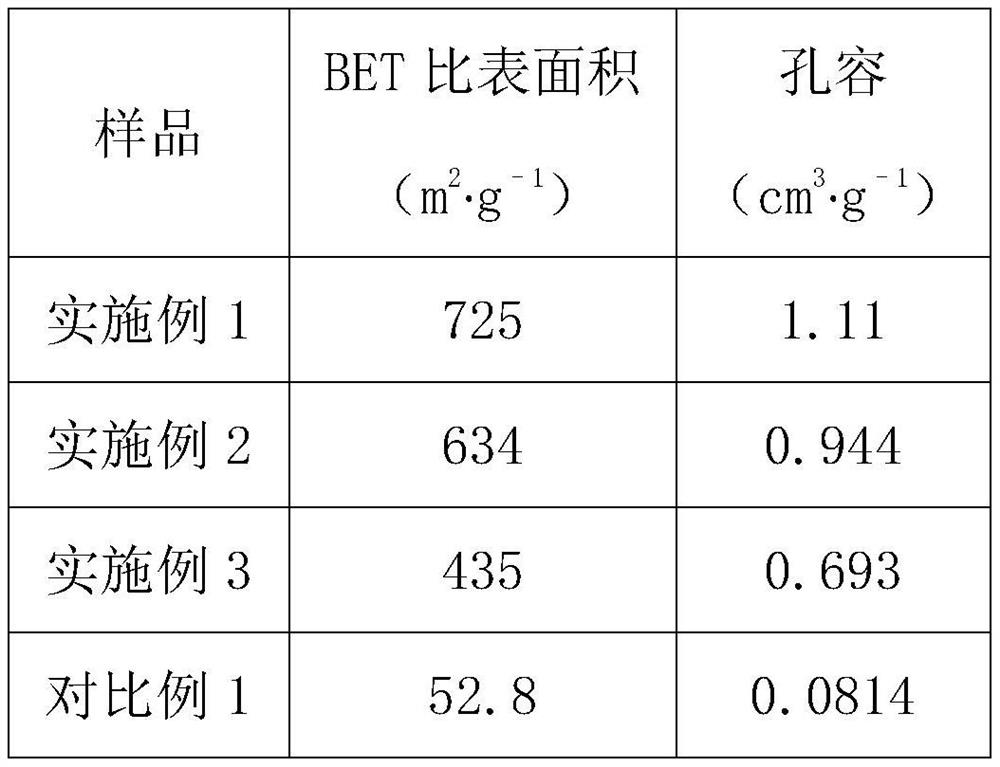

Examples

preparation example Construction

[0028] A kind of preparation method of nano-carbon material composite resin hard carbon electrode material of the present invention, comprises the following steps:

[0029] a. Stir and mix phenolic substances A such as phenol, cresol, xylenol, resorcinol, p-tert-butylphenol, butylphenol and formaldehyde solution B with a phenolic molar ratio of 1:2 to obtain a phenolic mixture liquid;

[0030] b. In the phenolic mixed solution prepared in step a, add a uniformly dispersed aqueous solution C in a weight ratio of 1 to 5:100 by nano-carbon material and phenol, and use mechanical mixing or ultrasonic mixing to obtain a uniformly dispersed mixed solution D. This step The dispersed aqueous solution C in the mixture is a mixed solution of graphene and carbon nanotubes, specifically composed of graphene, carbon nanotubes and surfactant SDS according to the mass ratio of 1 to 10:1 to 10:0.1 to 1, through stirring or ultrasonic mixed in a manner to obtain a homogeneous dispersion C;

...

Embodiment 1

[0039] This embodiment provides a nano-carbon material composite resin hard carbon electrode material, the preparation method is as follows:

[0040] a. Resorcinol A and formaldehyde aqueous solution B are mechanically stirred at a molar ratio of 1:2 for 0.5h and mixed uniformly to obtain a phenolic mixed solution;

[0041] b. Add the dispersed aqueous solution C to the phenolic mixed solution prepared in step a according to the weight ratio of nano-carbon material and phenol at 5:100, and ultrasonicate for 1 hour to obtain a uniformly dispersed mixed solution D. The dispersed aqueous solution C in this step is a mixed aqueous solution of graphene and carbon nanotubes, specifically obtained by graphene, carbon nanotubes and surfactant SDS according to a mass ratio of 10:10:1, and ultrasonic 1h;

[0042] c. Add an alkaline catalyst ammonia solution E to the mixed solution D, stir and mix evenly to obtain a reaction solution F, wherein the amount of ammonia added is 4%wt of phen...

Embodiment 2

[0049] a, phenol A and formaldehyde aqueous solution B are mechanically stirred at a molar ratio of 1:2 for 0.5h and mixed uniformly to obtain a phenolic mixed solution;

[0050] b. Add the dispersed aqueous solution C to the phenolic mixed solution prepared in step a according to the weight ratio of nano-carbon material and phenol at 1:100, and mechanically stir for 2 hours to obtain a uniformly dispersed mixed solution D. The dispersed aqueous solution C in this step is a mixed aqueous solution of graphene and carbon nanotubes, specifically obtained by graphene, carbon nanotubes and surfactant SDS according to a mass ratio of 5:15:1, and mechanical stirring for 10h;

[0051] c, add sodium carbonate aqueous solution E in mixed solution D, stir and mix to obtain reaction solution F, wherein sodium carbonate add-on is 5%wt of phenol;

[0052] d. Put the reaction solution F in a sealed container in a vacuum drying oven, and heat it at a constant temperature of 85° C. for 10 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com