Biomass porous carbon material with high specific surface area as well as preparation method and application thereof

A porous carbon material, high specific surface area technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., to shorten the transmission distance, promote the increase of pore structure, and shorten the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

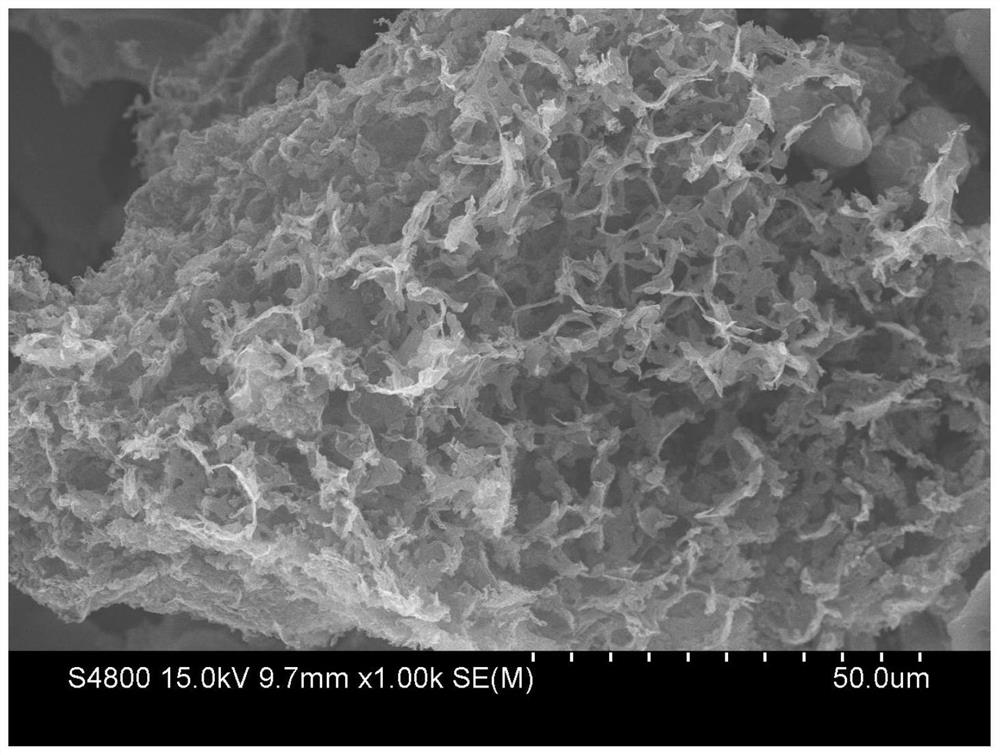

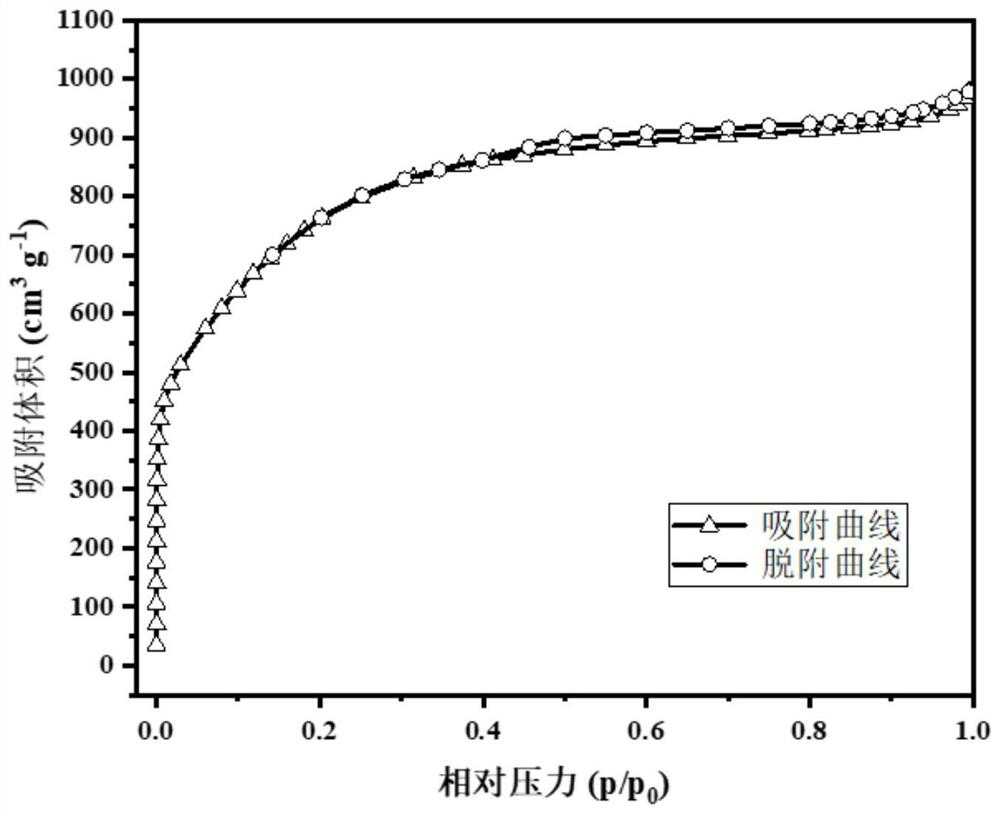

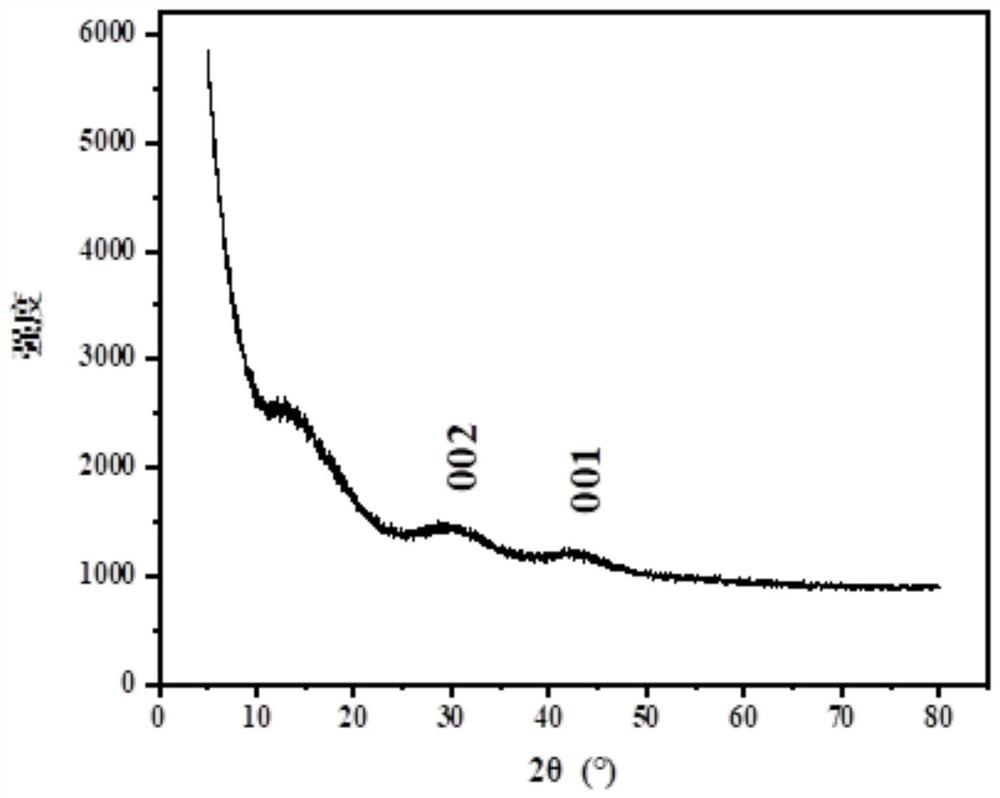

[0041] In this example, under the heating conditions protected by an inert atmosphere, sodium lignosulfonate is used as a carbon precursor, anhydrous potassium carbonate is used as an activator, and a lignin-based porous carbon material is prepared with N dopant urea, including the following steps:

[0042] Step 1, placing the dried sodium lignosulfonate, anhydrous potassium carbonate and N dopant urea in an agate mortar according to the mass ratio of 1:4:0.4, mixing and grinding evenly to obtain a mixed powder;

[0043] Step 2. Put the mixed powder obtained in Step 1 into a corundum porcelain boat, place it in an argon-protected tube furnace, raise the temperature from room temperature to 750°C at a rate of 5°C / min and keep it warm for 1h, then cool naturally to Obtain carbonization product at room temperature;

[0044] Step 3: The carbonized product obtained in Step 2 is repeatedly washed with 0.2 mol / L dilute hydrochloric acid solution and deionized water until neutral, and...

Embodiment 2

[0047] In this example, under the heating conditions protected by an inert atmosphere, sodium lignosulfonate is used as a carbon precursor, anhydrous potassium carbonate is used as an activator, and a lignin-based porous carbon material is prepared with the N dopant dicyandiamide, including The following steps:

[0048] Step 1, placing the dried sodium lignosulfonate, anhydrous potassium carbonate and N dopant dicyandiamide in an agate mortar according to the mass ratio of 1:4:0.6, mixing and grinding evenly to obtain a mixed powder;

[0049] Step 2. Put the mixed powder obtained in step 1 into a corundum porcelain boat, and place it in a nitrogen-protected tube furnace, raise the temperature from room temperature to 850 °C at a rate of 5 °C / min and keep it warm for 3 hours, and then naturally cool to room temperature get carbonized products;

[0050] Step 3: The carbonized product obtained in Step 2 is repeatedly washed with 0.2 mol / L dilute hydrochloric acid solution and de...

Embodiment 3

[0053] In this example, under the heating conditions protected by an inert atmosphere, sodium lignosulfonate is used as a carbon precursor, anhydrous potassium carbonate is used as an activator, and a lignin-based porous carbon material is prepared with N dopant melamine, including the following steps:

[0054] Step 1, placing the dried sodium lignosulfonate, anhydrous potassium carbonate and N dopant melamine in an agate mortar according to the mass ratio of 1:4:0.5, mixing and grinding evenly to obtain a mixed powder;

[0055] Step 2. Put the mixed powder obtained in Step 1 into a corundum porcelain boat, place it in a tube furnace protected by nitrogen and argon, raise the temperature from room temperature to 800°C at a rate of 5°C / min and keep it warm for 2 hours. Cool to room temperature to obtain carbonized product;

[0056] Step 3: The carbonized product obtained in Step 2 is repeatedly washed with 0.2 mol / L dilute hydrochloric acid solution and deionized water until ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com