Membrane casting solution, ultrafiltration membrane and preparation method of ultrafiltration membrane

A technology of casting membrane liquid and ultrafiltration membrane, which is applied in the direction of ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve problems that need to be improved, achieve high water flux and rejection rate, good heat resistance, excellent water resistance The effect of pressure performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

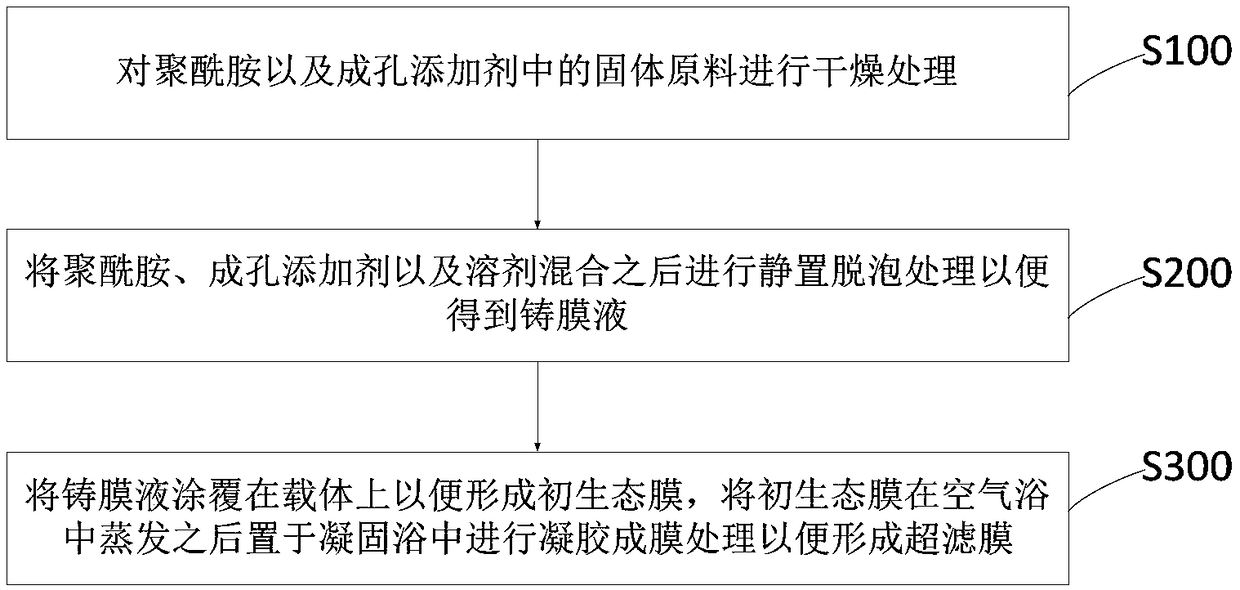

Method used

Image

Examples

Embodiment 1

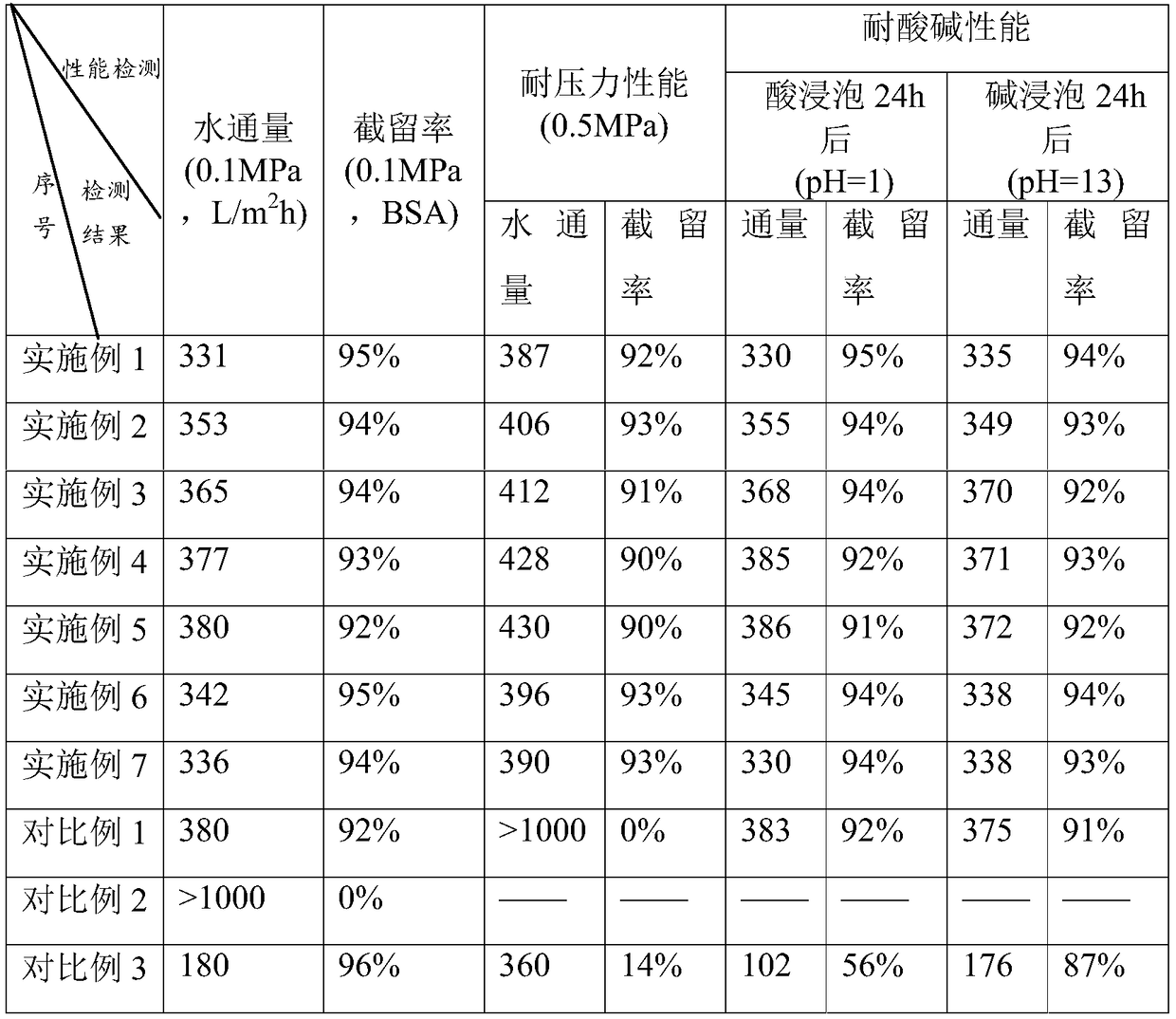

[0067] Weigh dry polym-phenylene isophthalamide (relative molecular mass is 250,000) raw material 15 grams, 4 gram polyethylene glycols (relative molecular mass is 400), join the 81 grams of dimethylacetamide In the solvent, stir and soak at room temperature for 1 hour, then heat up to 80°C and heat and dissolve for 6 hours. The prepared casting solution includes 15 parts by weight of polyamide, 4 parts by weight of additives and the rest of the solvent. After filtering, let it stand defoaming.

[0068] Paste the non-woven fabric flat on a clean glass plate. The humidity in the casting chamber is controlled at 40%, the temperature in the casting chamber is controlled at 25°C, and the completely degassed casting solution is poured into the clean casting chamber. On the woven cloth, use a stainless steel scraper with a thickness of 0.25mm to form a film, evaporate the nascent film in an air bath for 10 seconds, quickly put it into a coagulation bath with a temperature of 25°C, a...

Embodiment 2

[0070] Weigh dry polym-phenylene isophthalamide (relative molecular mass is 250,000) raw material 15 grams, 10 gram polyethylene glycols (relative molecular mass is 400), join in 75 grams of dimethylacetamide In the solvent, stir and soak at room temperature for 1 hour, then heat up to 80°C and heat to dissolve for 6 hours. The prepared casting solution includes 15 parts by weight of polyamide, 10 parts by weight of additives and the rest of the solvent. After filtering, let it stand defoaming.

[0071] The preparation conditions of the ultrafiltration membrane are the same as in Example 1.

Embodiment 3

[0073] Weigh 15 grams of dry polym-phenylene isophthalamide (relative molecular mass is 250,000) raw material, 4 grams of polyvinylpyrrolidone, join in the solvent of dimethylacetamide 81 grams, stir at room temperature Soak for 1 hour, then raise the temperature to 80° C. and heat to dissolve for 6 hours. The prepared casting solution includes 15 parts by weight of polyamide, 4 parts by weight of additives and the rest of the solvent. After filtering, let it stand for defoaming.

[0074] The preparation conditions of the ultrafiltration membrane are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com