Method for preparing soilless culture substrate from waste biomass

A technology for soilless culture substrate and waste biomass, which is applied in the directions of botanical equipment and methods, planting substrate, culture medium, etc. Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

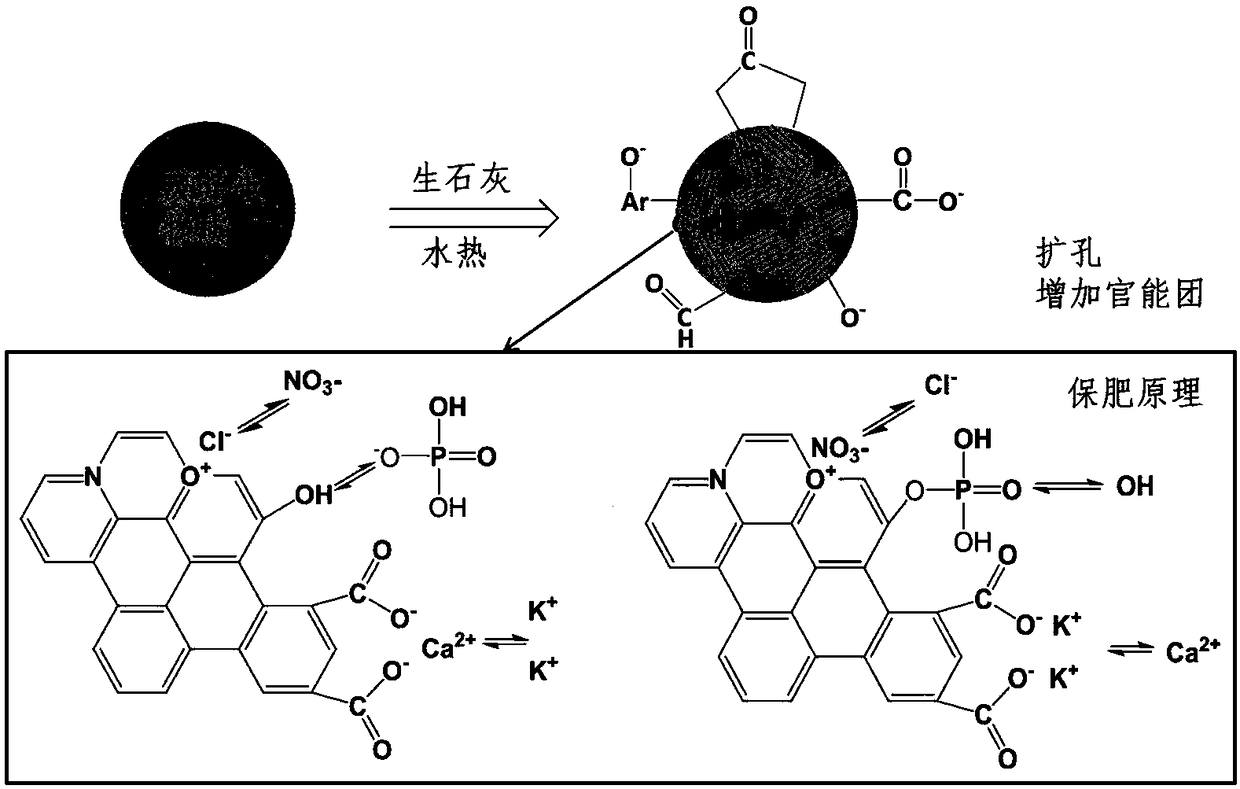

AI Technical Summary

Problems solved by technology

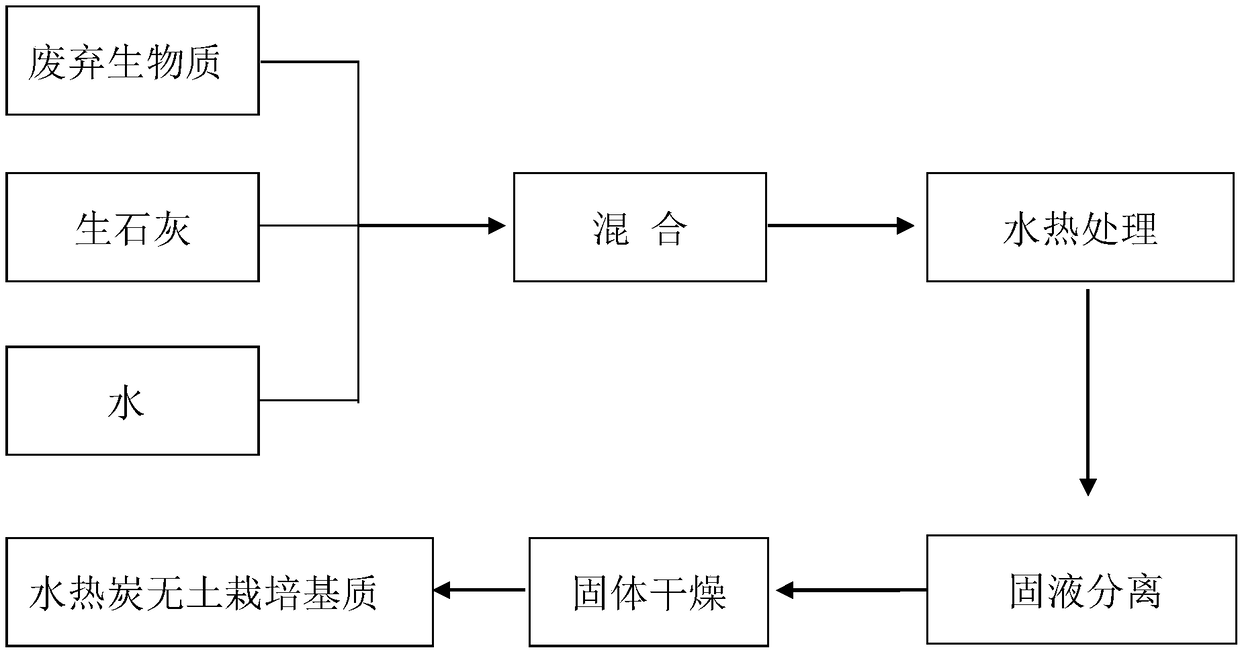

Method used

Image

Examples

Embodiment 1

[0022] 1. Material preparation

[0023] Crush the waste biomass such as tomato stalks, branches and leaves to less than 5mm, and set aside. The test tray is a 32-hole tray, of which the hole depth is 59mm, the upper diameter is 54x54mm, and the lower diameter is 26x26mm. The laboratory cuts the tray from the middle and uses it as two trays. The nutrient solution adopts the universal formula of Hoagland Amon. Vermiculite, a common soilless cultivation substrate, was purchased from the market as a research comparison.

[0024] 2. Preparation of Soilless Culture Substrate

[0025] 1) Mix waste biomass such as tomato stalks, branches and leaves (the tomato variety is improved wool powder 802, on a dry basis), quicklime, and water in a ratio of 4:1:20, then mechanically stir for 30 minutes;

[0026] 2) After the mixture is transferred to the hydrothermal reaction kettle, seal it;

[0027] 3) Heat the reactor to 220°C for hydrothermal treatment, stop heating after 40 minutes of ...

Embodiment 2

[0039] Except that pig manure and corn stover (10:1 dry weight ratio of corn stover and pig manure) were used instead of tomato plantation waste biomass.

[0040] 3) In the preparation of soilless culture medium, the reaction kettle was heated to 240° C. for hydrothermal treatment, and the hydrothermal treatment time was the same as in Example 1 except that the hydrothermal treatment time was 60 minutes.

[0041] Rapeseed (variety April slow) was used instead of tomato in the study of the influence of substrate on crop growth.

[0042] The results are shown in Tables 1 and 3.

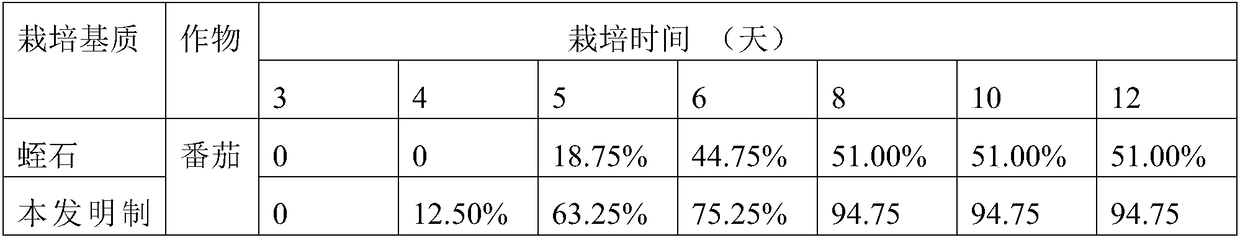

[0043] Table 1. Effects of different soilless culture substrates on tomato and rape seedling emergence.

[0044]

[0045]

[0046] Table 2. Effects of different soilless culture substrates on tomato growth.

[0047]

[0048] Table 3. Effects of different soilless culture substrates on the growth of rapeseed.

[0049]

[0050] As can be seen from Table 1, the soilless culture substrate prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com