Patents

Literature

36results about How to "Meet the requirements of circular economy development" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

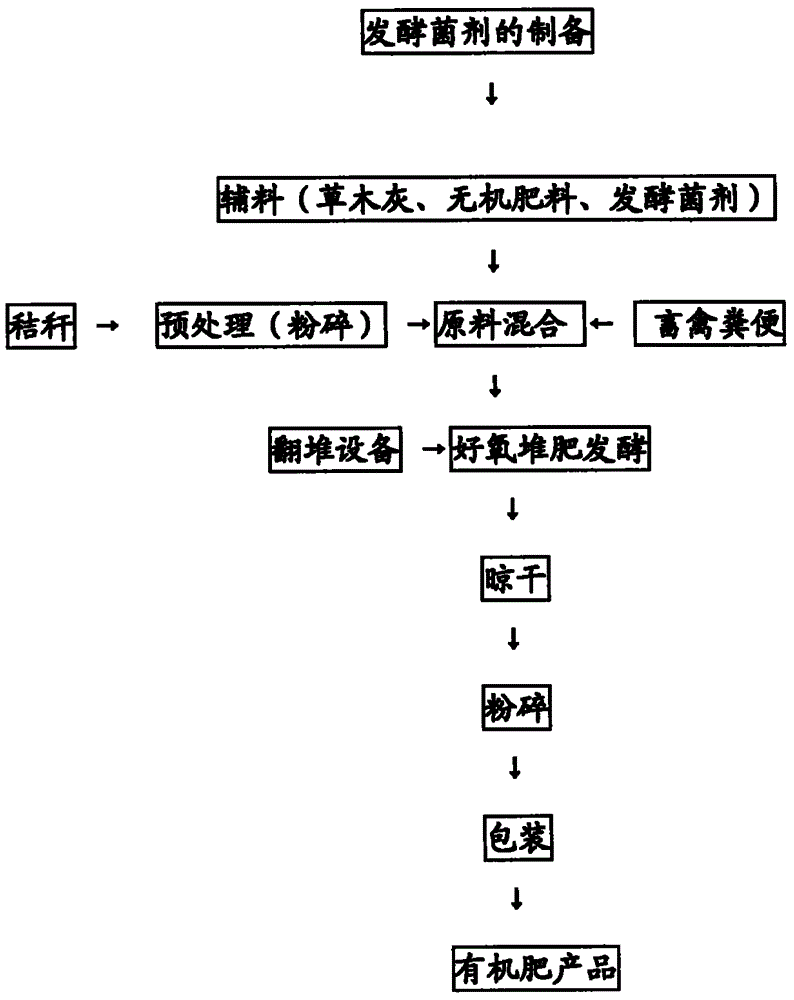

High-quality organic fertilizer prepared by straw and livestock and poultry night soil and method thereof

InactiveCN104609933ANutritional diversitySimple structureSuperphosphatesOrganic fertiliser preparationNational standardBiofertilizer

The invention provides a method for preparing a high-quality organic fertilizer by straw and livestock and poultry night soil, which belongs to the biology fertilizer field. The organic fertilizer is prepared by the following components by weight ratio,25-35% of straw, 50-60% of livestock and poultry night soil, 10-20% of plant ash, 0.5-1% of inorganic fertilizer, and 0.1-0.2% of microbial inoculum. The preparation method of the organic fertilizer comprises the following steps: preparing a microbial inoculum, drying straw, crushing, mixing with livestock and poultry night soil, plant ash, an inorganic fertilizer and the microbial inoculums according to a certain proportion, uniformly stirring, piling the mixed raw materials into a stripe, regularly measuring the temperature of piles, timely turning and stirring, and completing decomposing after 2-3 weeks to obtain the organic fertilizer. The preparation method is simple, the prepared organic fertilizer has comprehensive nutrient composition, and can reach a national standard for the organic fertilizer, processing for waste can be completed, and waste resource reutilization and environment protection can be realized.

Owner:CHANGXING JINTU BIOTECH CO LTD

Pyrolysis based resource reclaiming process of waste circuit board

InactiveCN101767104AImprove resource recoveryMeet the requirements of circular economy developmentSolid waste disposalElectronic waste recyclingPartial oxidationPrinted circuit board

The invention discloses a pyrolysis based resource reclaiming process of a waste circuit board, belonging to the technical field of waste resource reclamation and recycle. The method comprises the following steps: placing a waste circuit board with an electric element detached in a pyrolyzing furnace for thermal cracking; collecting pyrolyzed oil, pyrolyzed gas and pyrolyzed residues generated in the pyrolyzing process; directly introducing the purified pyrolyzed gas serving as gas into a pyrolysis system to provide energy for the pyrolyzing process; polymerizing the pyrolyzed oil and formaldehyde to synthesize pyrolyzed oil-phenolic aldehyde resin; selectively synthesizing carbon functional materials with different shapes and structures by using the prepared pyrolyzed oil-phenolic aldehyde resin as precursor; peeling glass fiber in the collected pyrolyzed waste circuit board residues from a metal layer, and reclaiming glass fiber cloth and metal; and removing carbon on the surface of the separated glass fiber by adopting a partial oxidization method, and preparing a veneer sheet together by the carbon and the synthesized pyrolyzed oil-phenolic aldehyde resin. The process ensures that material reclamation in the waste circuit board forms a closed circulation system, and has high resource reclamation rate.

Owner:DALIAN UNIV OF TECH

Yeast grease and preparation method and application thereof

InactiveCN102100260AAnti agingLower blood fatFatty-oils/fats refiningWaste based fuelBiotechnologyEnvironmental resistance

The invention relates to the technical field of biological engineering and the fields of food and medicaments, particularly provides a method for extracting refined yeast grease from yeast, particularly waste saccharomyces cerevisiae and oil production yeast, and further provides soft capsules prepared by compounding the yeast grease, vegetable grease rich in necessary fatty acid for a human bodyand anti-oxidation grease and a preparation method thereof. The obtained yeast grease composite soft capsules have the effects of reducing serum cholesterol and reducing blood fat; the method for producing the yeast grease by using the waste yeast has powerful results of improving the additional value of the waste yeast and generating higher economic benefit; and meanwhile, by comprehensive utilization of the waste yeast, the problem that wastes pollutes environment is solved, and the requirement of circular economy development is met.

Owner:BINZHOU UNIV +1

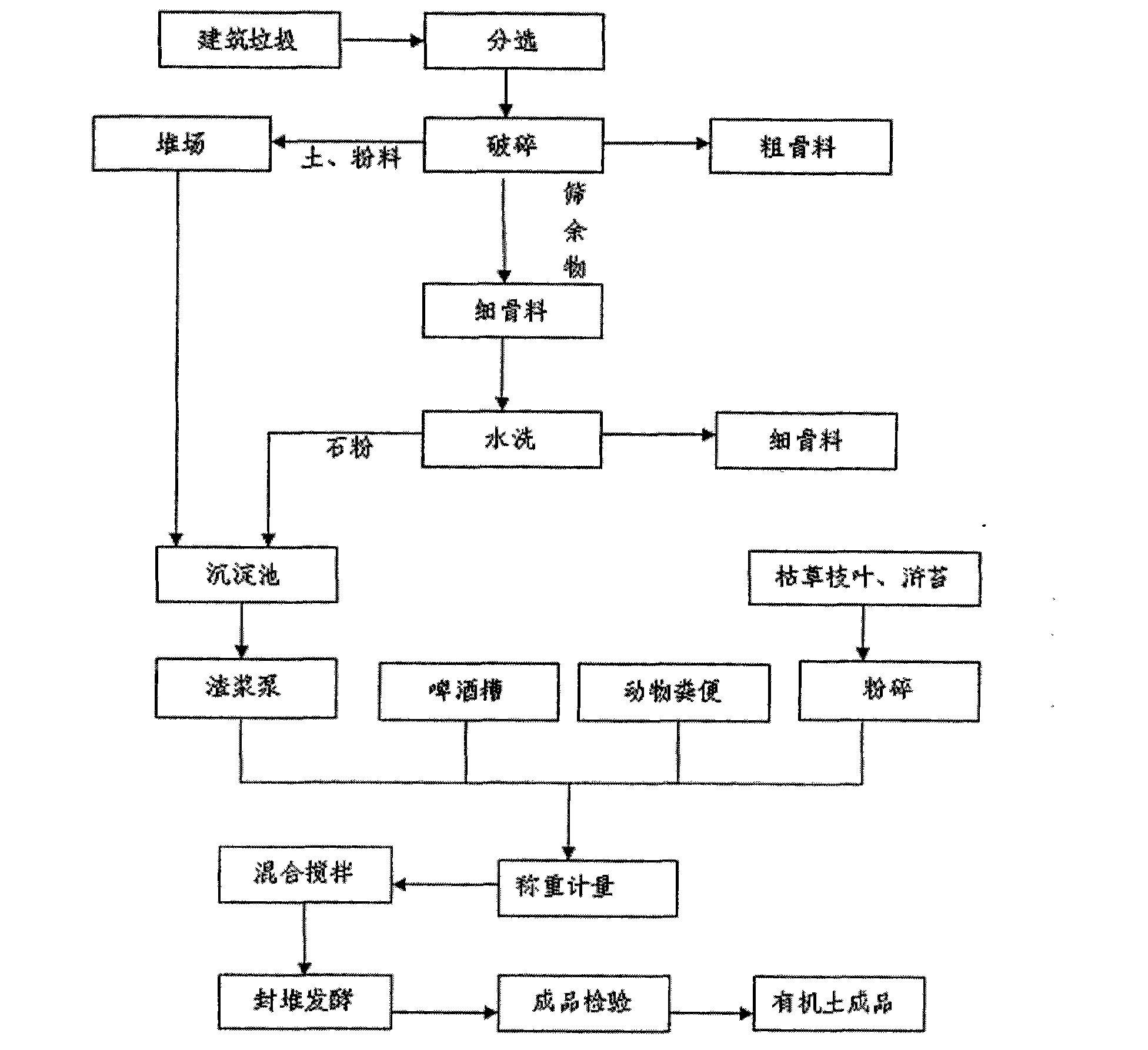

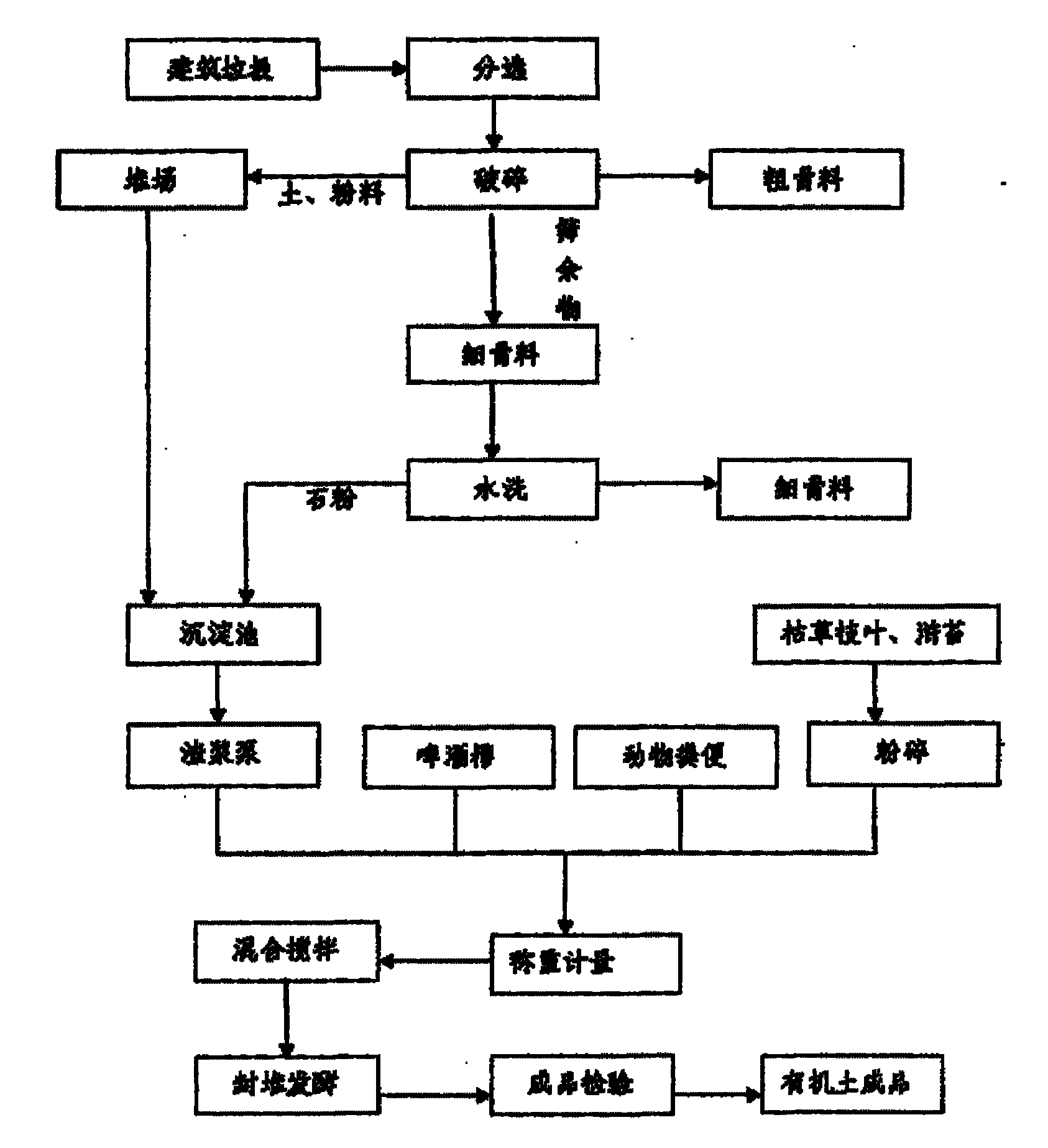

Regenerative organic planting soil and preparation method thereof

InactiveCN102643147AAddressing the threat of scarcityReduce difficultyFertilizer mixturesCircular economyPlant soil

The invention relates to regenerative organic planting soil, and meanwhile, also relates to a preparation method for the planting soil. The regenerative organic planting soil comprises the following components in mass percentage: 70-80 percent of construction waste spoil, 10-20 percent of beer lees, 1-5 percent of withered grass branches and leaves, 0-3 percent of Enteromorpha and 5 percent of animal waste. The construction waste spoil comprises clay and sandy soil, wherein the mass percentage of the clay is higher than that of the sandy soil by 5 percent. The invention also provides the preparation method for the regenerative organic planting soil. The method comprises the following flows of crushing, weighing and metering, fermenting, testing, packaging and delivering into a finished products warehouse. According to the regenerative organic planting soil, spoil generated after construction waste is recycled and processed is made into the organic planting soil, therefore, not only are building material byproducts recycled but also the social issues that the land is occupied and the environment is polluted can be solved. Moreover, the preparation method for the regenerative planting soil is advanced in process and is mature in technology. Recycling of resources is realized, and the requirement of the state circular economy development is met.

Owner:QINGDAO GREEN SAIL RECYCLED BUILDING MATERIALS

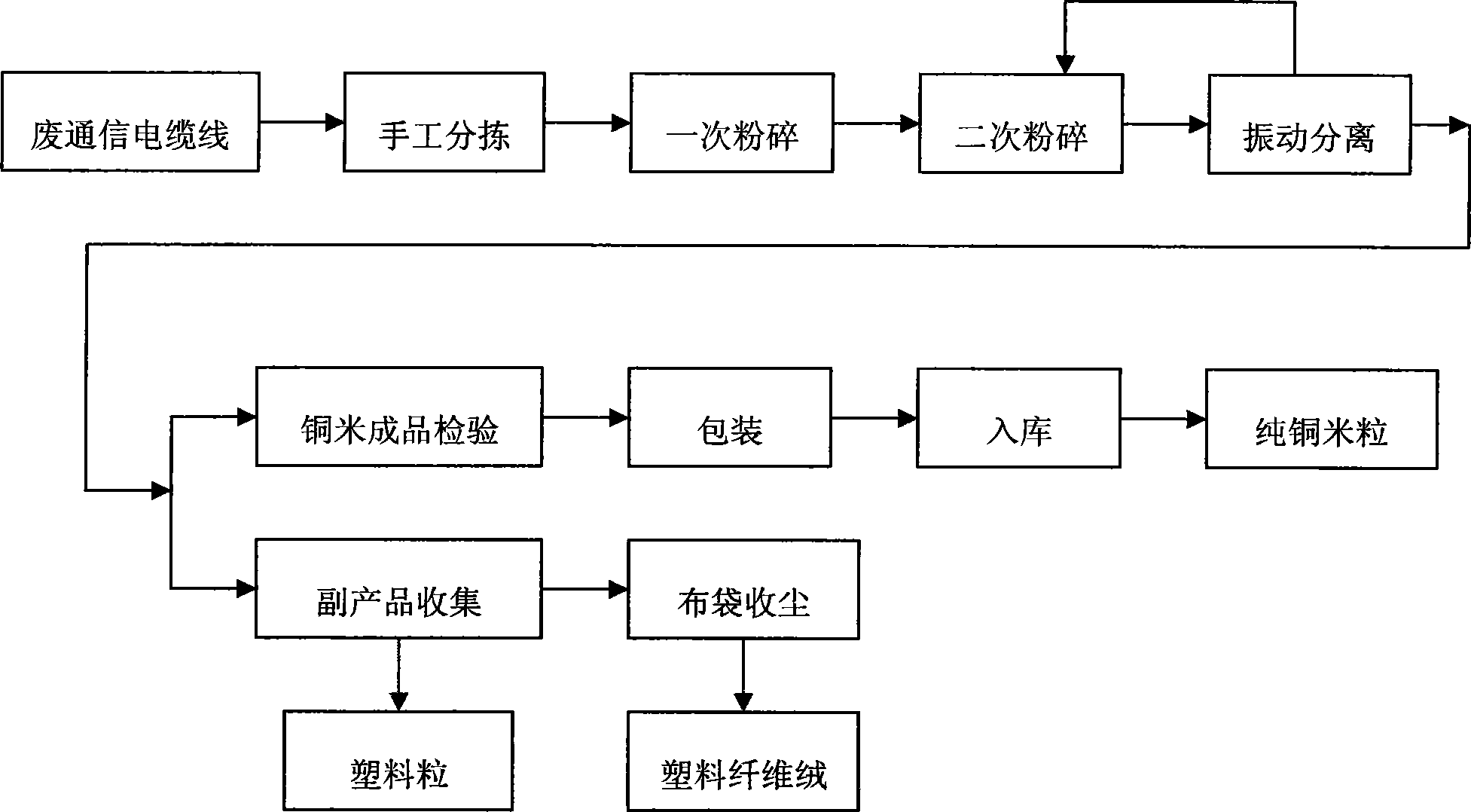

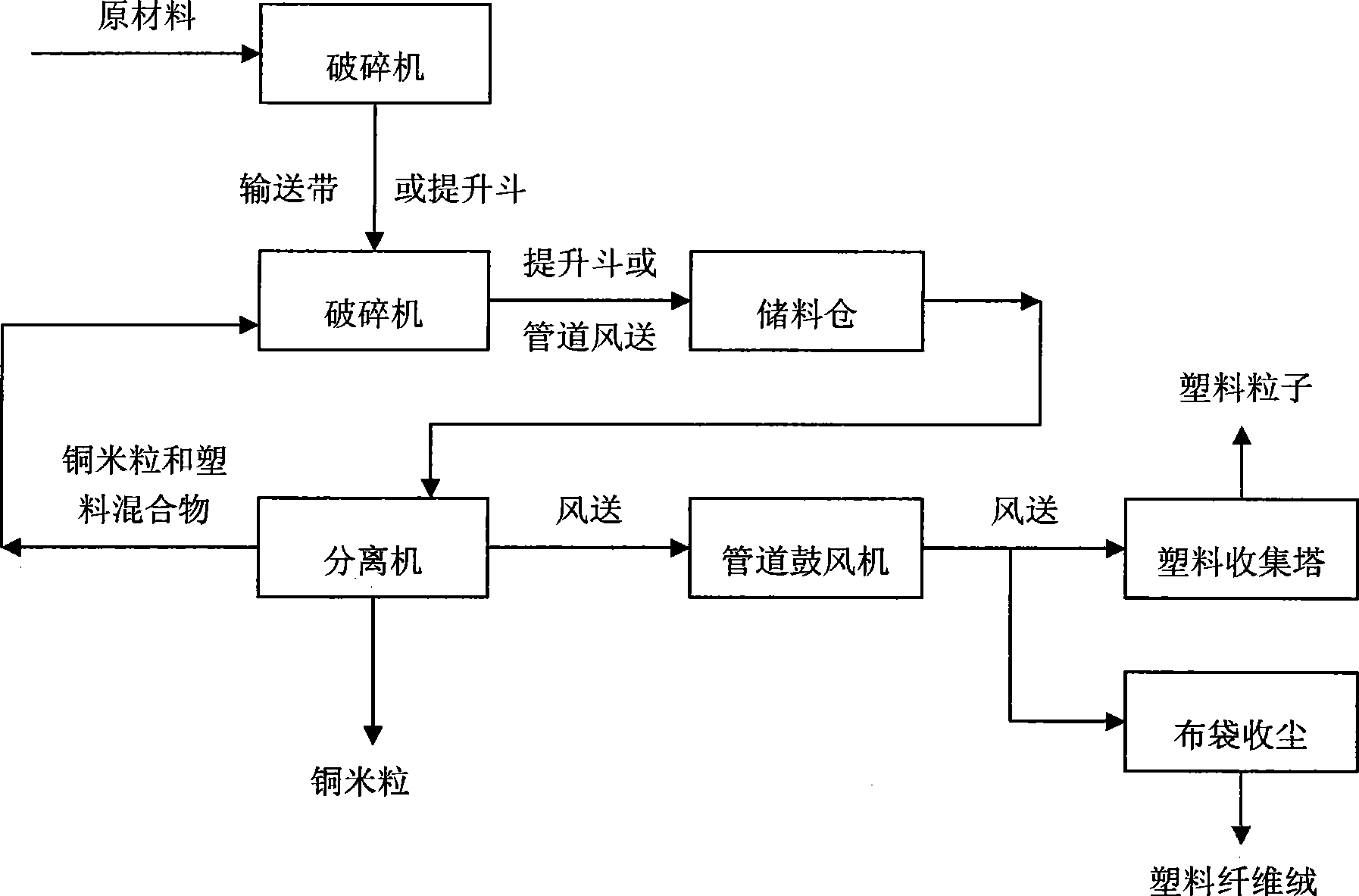

Process for recycling and manufacturing copper granule from waste and old electric wire and cable

InactiveCN101367084ALow costReduce energy consumptionSievingSolid waste disposalEngineeringMixed materials

The invention discloses a technological method for producing copper rice grains by recovering waste wires and cables based on an improvement of the prior production mode that the waste wires and cables recover copper raw materials. The technological method has low cost, small energy consumption, less discharge and no waste pollution, meets the requirement of circular economy development, and can obtain a copper rice grain product the purity of which reaches 99.9 percent. The technological process comprises the steps of classification inspection, loading, primary crushing, secondary crushing, and vibration separation; the angle of a vibration sieve is adjusted according to the content of copper and the wire diameter, and the copper rice grains and plastic are subjected to optional separation through vibration sieving; a material from a mixed material port flows into an air suction pipe, and is sent for secondary crushing through a circulating air pipe; the air suction pipe above the vibration sieve sucks plastic fibers and other dust in the space of the vibration sieve to a dust collector for treatment; the qualified copper rice grains obtained at a copper outlet flow into a packing bag; and the finished product inspection is performed, namely the obtained copper rice grains enter a warehouse through the inspection.

Owner:南京东南铜业有限公司

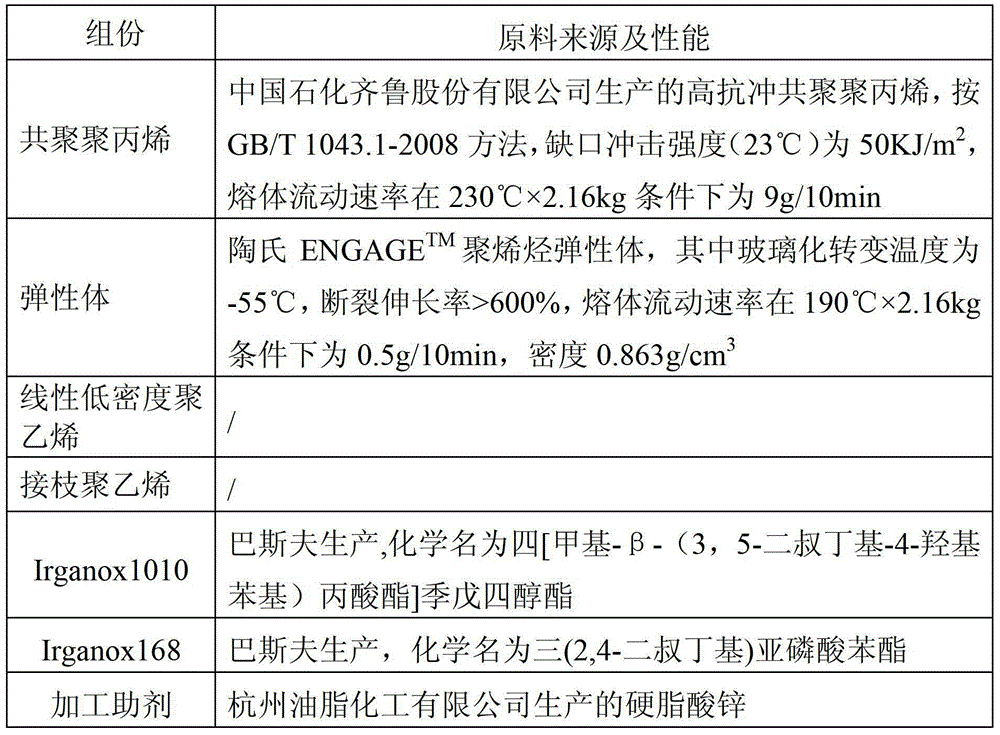

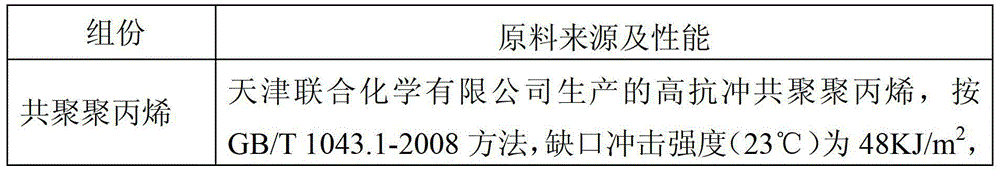

Low-temperature resisting co-polypropylene modified material as well as preparation method and application thereof

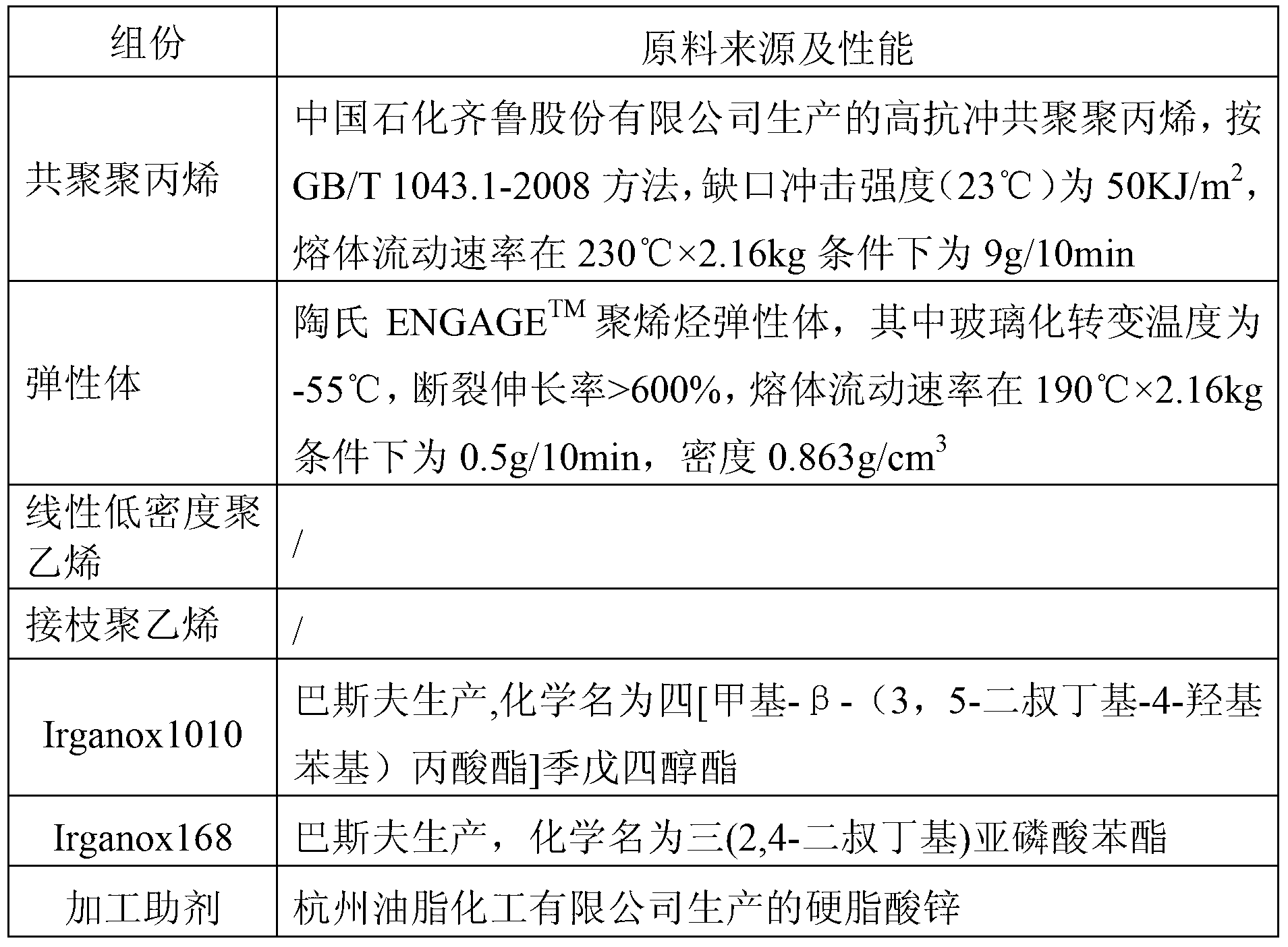

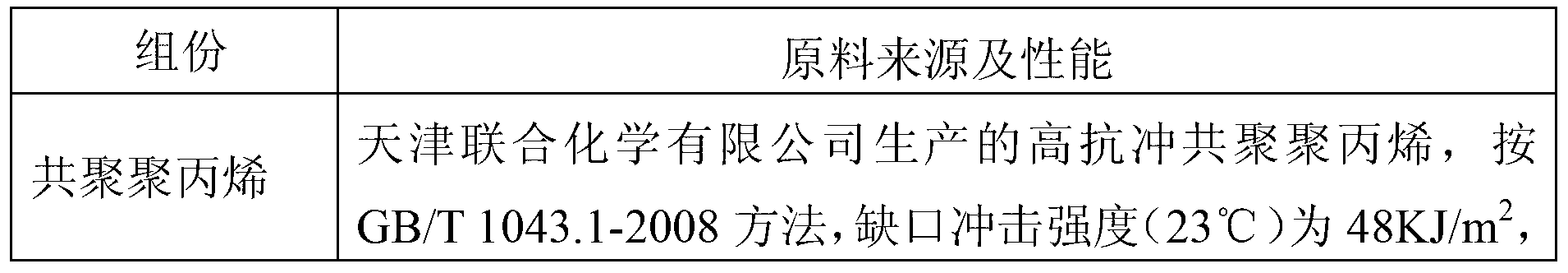

ActiveCN103254515AHigh tensile strengthImprove high temperature performanceElastomerLinear low-density polyethylene

The invention discloses a low-temperature resisting co-polypropylene modified material as well as a preparation method and an application thereof. The low-temperature resisting co-polypropylene modified material comprises the following raw materials in percentage by weight: 60-98% of co-polypropylene, 1-20% of an elastomer, 0-10% of linear low-density polyethylene, 0-8% of stem grafting polyethylene, 0.1-1% of a stabilizer and 0.1-1% of a processing agent. The modified material has both good tension strength and high-temperature property and good low-temperature property, the performances of a conventional polypropylene plastic sealing stripe are improved, the requirements on use of the plastic sealing stripe at high and low temperatures are met, and the modified material can be used for preparing various plastic sealing stripes, such as air container sealing stripes, cultivation sealing stripes, self-locking type sealing stripes and anti-theft sealing stripes.

Owner:CGN JUNER NEW MATERIALS +1

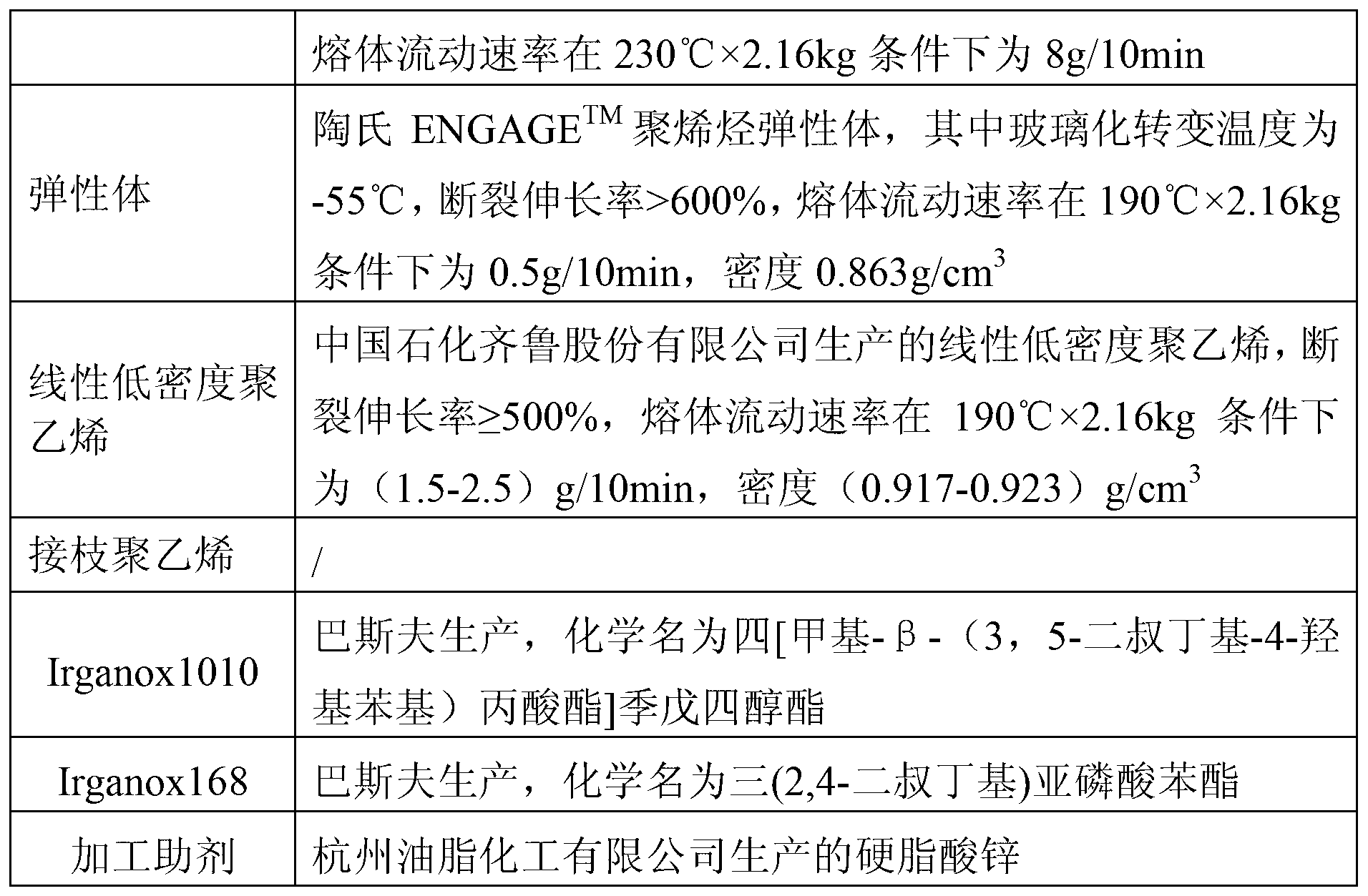

Straw fiber silicon plastic composite building form board and method for making same

InactiveCN101307641AReduce land occupationSolve the problem that the price is too high and difficult to promoteFlat articlesDomestic articlesFiberPlastic waste

The invention discloses a straw fiber silicon-plastic composite building formwork and a method for preparing the same. The proportion of the formulation of per 100 kilogram of straw fiber silicon-plastic composite building formworks is as follows: 28 to 39 kilograms of plastic waste, 35 to 55 kilograms of plant straw short fibers, 15 to 25 kilograms of fly ash and 1 to 2 kilograms of auxiliary agent. The preparation method comprises the following steps of: fiber treatment of straws; mixing; high-speed fusing and extruding; mould pressing; cooling; and product package and storage. The straw fiber silicon-plastic composite building formwork and the method have the advantages of low production cost, high cost performance, good product quality, waste recycling, energy conservation and environmental protection, accordance with the development requirements of recycling economy and so on.

Owner:绍兴一普塑业有限公司

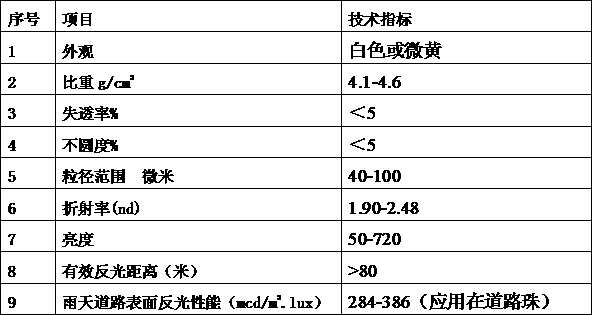

Method for preparing glass beads by using recovery of waste glass powder

InactiveCN107673606AReduce manufacturing costUniform shapeGlass shaping apparatusVisibilityPowder mixture

The invention discloses a method for preparing glass beads by using recovery of waste glass powder. The method takes waste glass powder or glass beads powder as a raw material, and comprises the following steps: 1) mixing waste glass powder or / and waste glass beads and a corresponding material to obtain a powder mixture; 2) passing the powder mixture through a material spraying port and performingspray gun combustion flame material production, forming beads at high temperature, collecting the beads by a collection device, and separating the beads by a cyclone separator to the glass beads water-quenching powder; and 3) drying the glass beads water-quenching powder, separating the material by the separator for several times, and introducing the material in a dedusting collection device forcollection to obtain the glass beads. The glass beads prepared by using waste glass powder or waste and old glass beads powder as the raw materials have high reflection performance, provides high visibility as a road sign, greatly reduces the production cost of the glass beads, and realizes energy saving and environmental protection.

Owner:JIANGXI SHENGHUI OPTICAL TECH

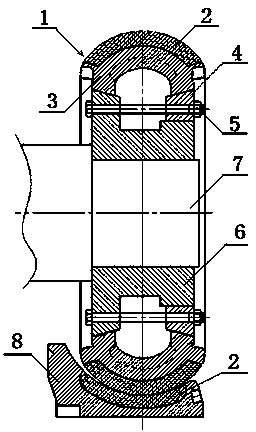

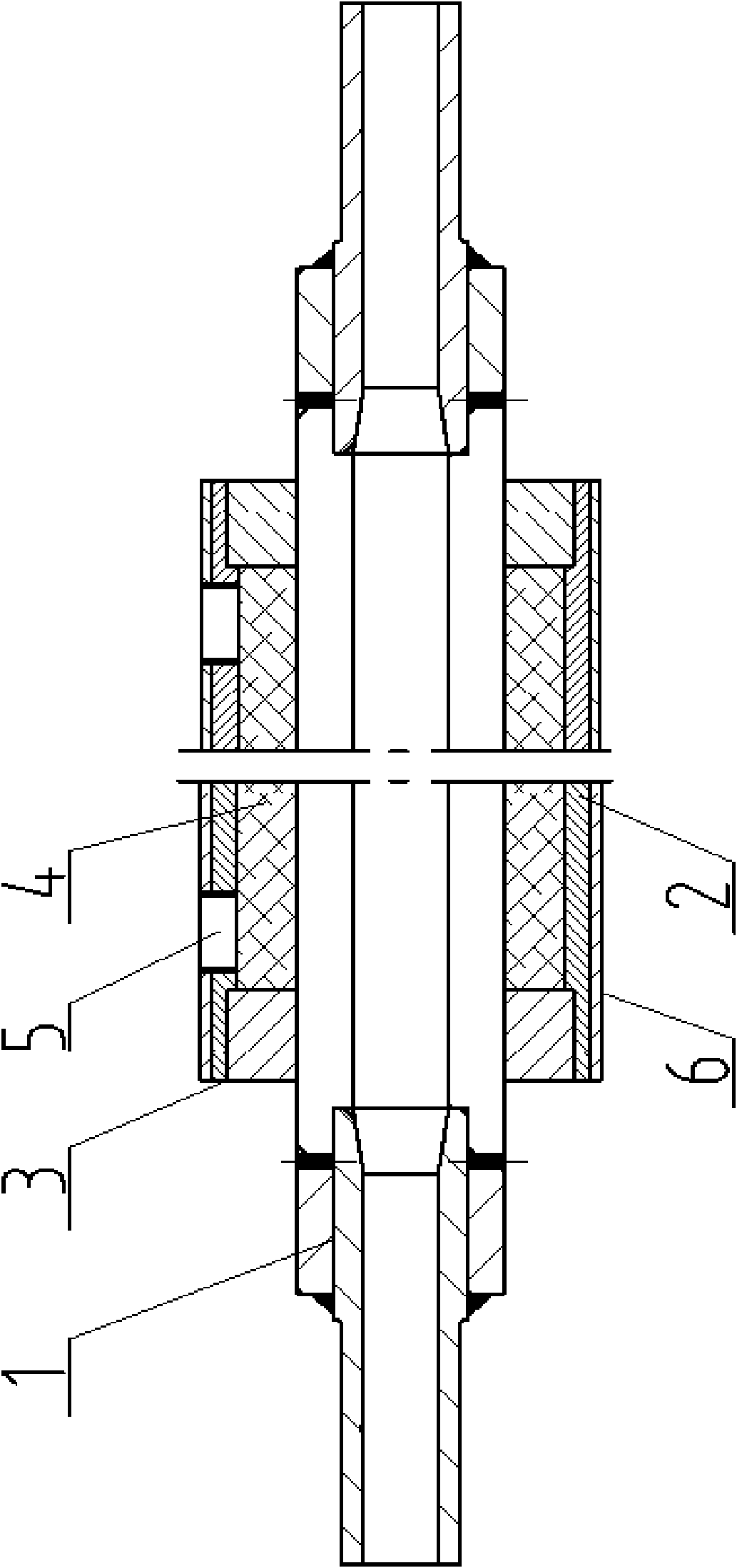

Surfacing composite grinding roller

InactiveCN103406172AExtended service lifeReduce manufacturing costGrain treatmentsHeat resistanceWear resistant

The invention discloses a surfacing composite grinding roller applied to pulverized coal grinding equipment in the fields of electric power, metallurgy, coal, iron and steel and coal chemical industry. The surfacing composite grinding roller comprises a grinding roller sleeve, a shaft sleeve and a grinding shaft. The shaft sleeve is sheathed on the grinding shaft; the grinding roller sleeve is fixed on the shaft sleeve; and the outer surface of a base layer of the grinding roller is provided with a surfacing layer. The base layer is prepared from material with high toughness and good thermal stability through one-step casting forming; the surfacing layer made of high wear-resistant and heat-resistant material is deposited on the base layer, so as to solve a series of problems of an existing grinding roller sleeve. The surfacing composite grinding roller has the advantages of long service life, safety, reliability and low manufacturing cost; and at the same time, the surfacing layer can be reused in surfacing compound, so as to meet the requirements of the development of circular economy.

Owner:朱华平

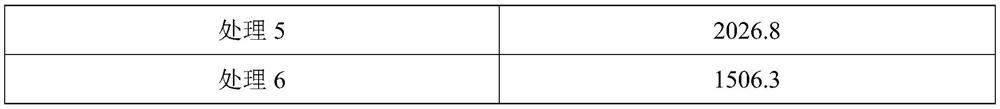

Ceramic-based water-permeable brick using total tailings as raw material and preparation method

The invention relates to a ceramic-based water-permeable brick using total tailings as raw material and a preparation method, and belongs to the technical field of inorganic non-metallic materials. Asintered water-permeable brick is prepared from the following chemical components in percentage by weight: 64 to 72% of SiO2 (silicon dioxide), 8 to 12% of Al2O3 (aluminum oxide), 8 to 10% of Fe2O3 (iron oxide), 3 to 7% of CaO (calcium oxide), 1.5 to 3.5% of MgO (magnesium oxide), and 3 to 5% of K2O (potassium oxide) and Na2O (sodium oxide). The main crystal phase of the prepared sintered water-permeable brick is quartz; the secondary phases are feldspar, diopside and mica minerals; the sintered water-permeable brick also contains a small amount of serpentine, amphibole and tremolite minerals.The sintered water-permeable brick has the advantages that the properties of the sintered water-permeable brick prepared by the whole raw material sintering method are better than the properties of the cement-based water-permeable brick, so that the range of the raw materials of the sintered water-permeable brick is expanded, and a novel path is opened for the high-value utilization of the tailings; while the tailings are recycled at high efficiency, the sintered water-permeable brick with high strength, durability and anti-freezing and thawing property is obtained; the positive function is realized on the reutilization of resources and the protection of ecological environment.

Owner:河北睿索固废工程技术研究院有限公司 +1

A preparation method of construction waste recycled artificial landscape stone

ActiveCN102924011BReduce construction costsGood environmental benefitsSolid waste managementSpecial ornamental structuresKeelArchitectural engineering

The invention provides a method for preparing an artificial landscape stone from regenerative construction wastes. The method is characterized by comprising the following steps of: 1) manufacturing a support of the landscape stone by channel steel or steel angles; 2) brushing a layer of releasing agent on a mould box and putting a processed landscape stone keel into the mould box to be fixed; 3) adding water into a stirring machine, adding construction waste based regenerative fine aggregates, construction waste based regenerative coarse aggregates, construction waste powder, silicate cements, artificial sand and crushed granite into the stirring machine to stir for 3-5 minutes, and pouring the mixture into the mould box; 4) putting the poured mould box into a curing chamber to carry out initial curing at constant temperature for 10-20 days; 5) demoulding the artificial landscape stone which is initially cured; 6) evenly stirring unsaturated resins, accelerants and hardening agents to prepare a binding agent; 7) uniformly smearing the binding agent to a semi-finished product; 8) performing quality inspection; and 9) putting a finished product into a warehouse. The method has the advantages that the construction wastes are comprehensively utilized, so that construction resources are saved, construction cost is reduced, and environment pollution is reduced.

Owner:QINGDAO GREEN SAIL RECYCLED BUILDING MATERIALS

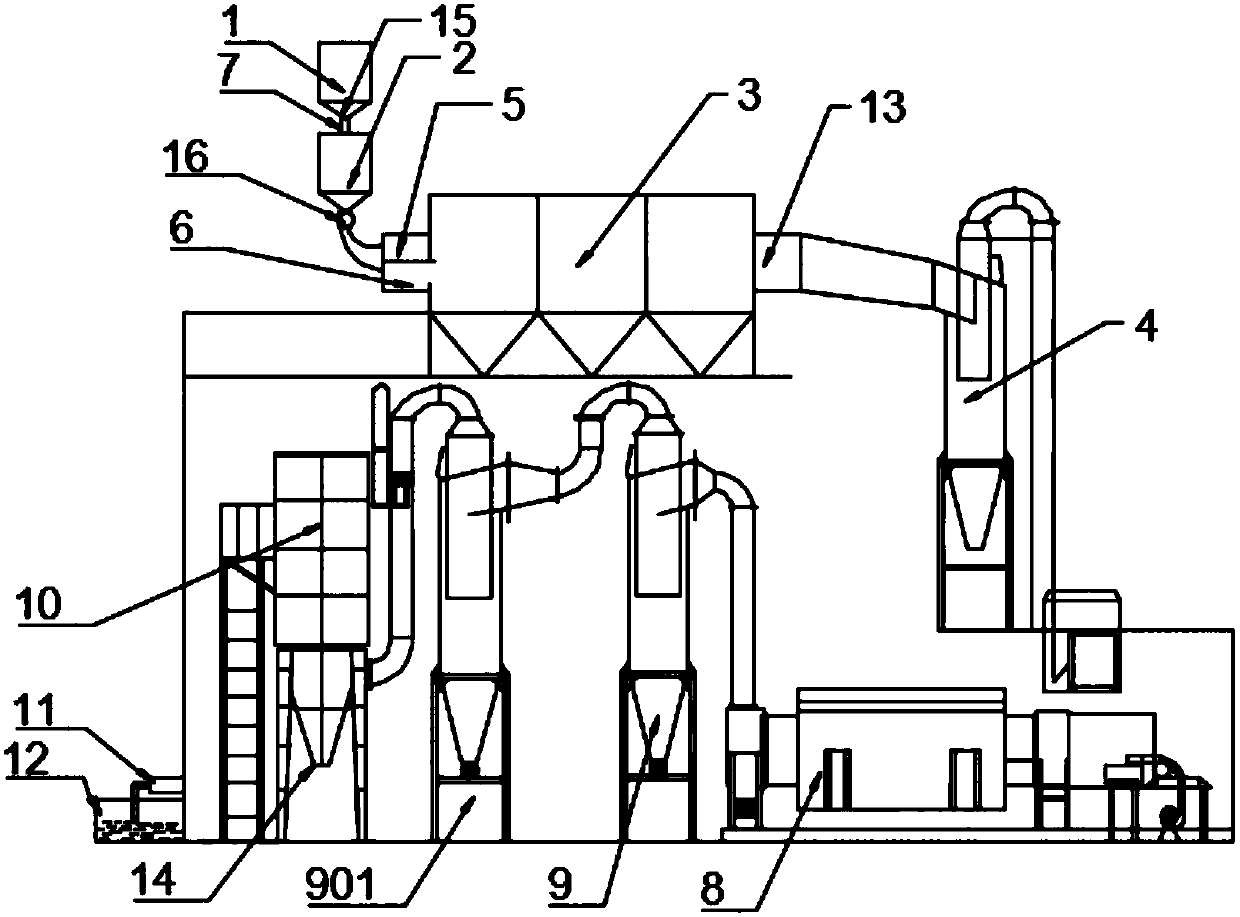

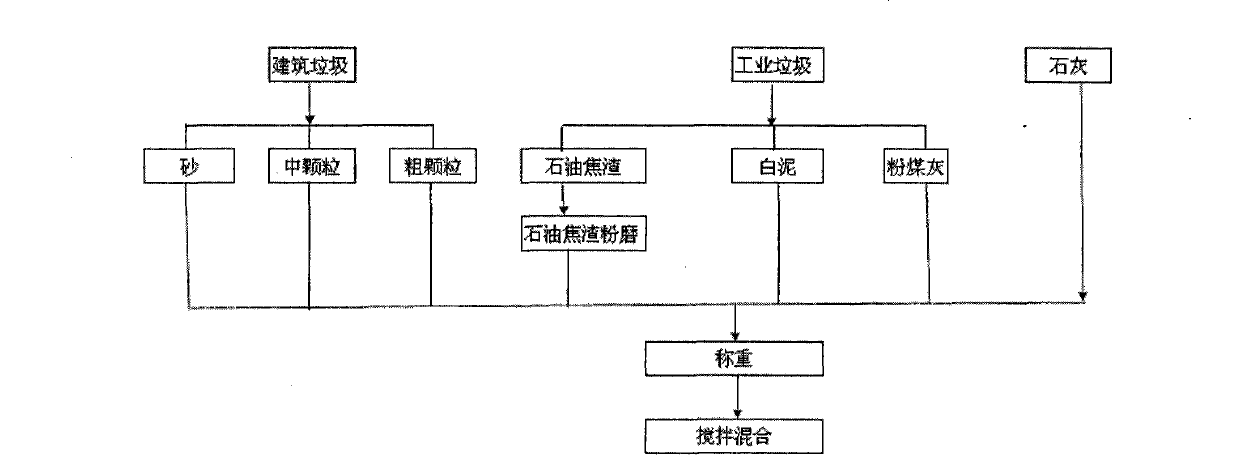

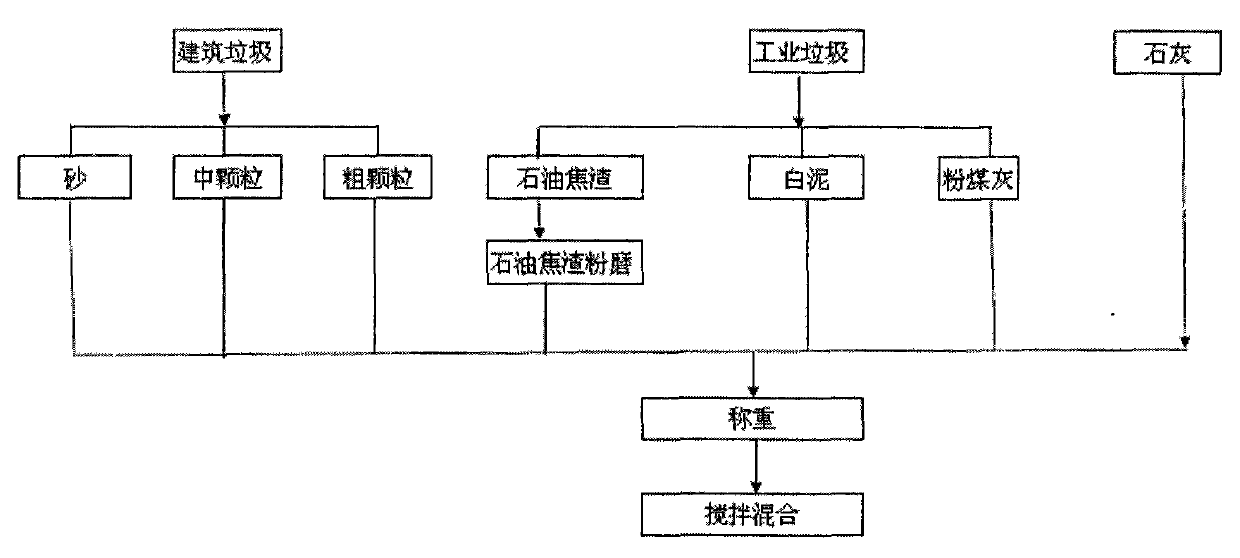

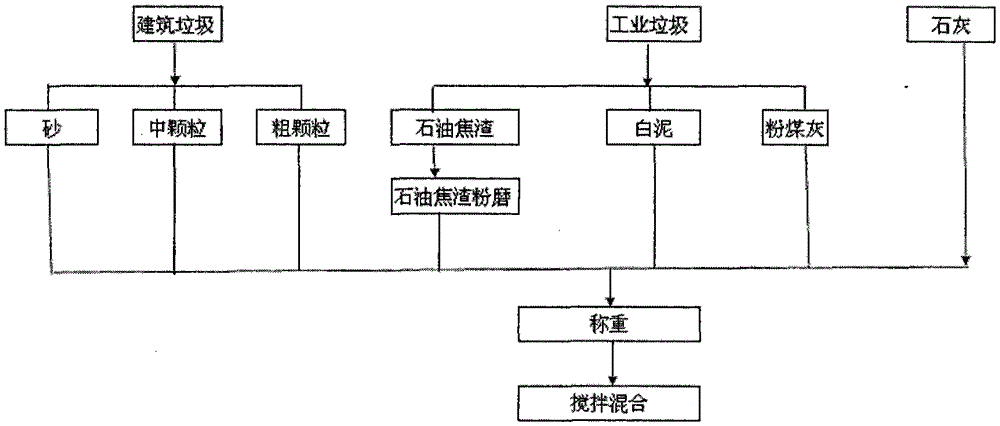

Highway roadbase stabilized soil and production method thereof

The invention relates to highway roadbase stabilized soil and particularly relates to highway roadbase stabilized soil produced by use of a product of building rubbish disposal and an industrially produced byproduct. The invention also relates to a production method of the stabilized soil. The highway roadbase stabilized soil comprises the following components by mass: 60-80% of graded gravel produced during crushing process of building rubbish, 2-5% of petroleum coke residue, 0.5-1% of white mud, 10-16% of fly ash and 2-5% of lime. The production method of the highway roadbase stabilized soil comprises the following steps: smashing, grading and adjusting, grinding, weighing, measuring, stirring and the like. Each detection index of the highway roadbase stabilized soil conforms to the stipulation of base materials in Technical Specifications for Construction of Highway Roadbases. The production method is simple in process flow, easy in operation and low in cost and is economic and environment-friendly; and special equipment is not needed.

Owner:QINGDAO GREEN SAIL RECYCLED BUILDING MATERIALS

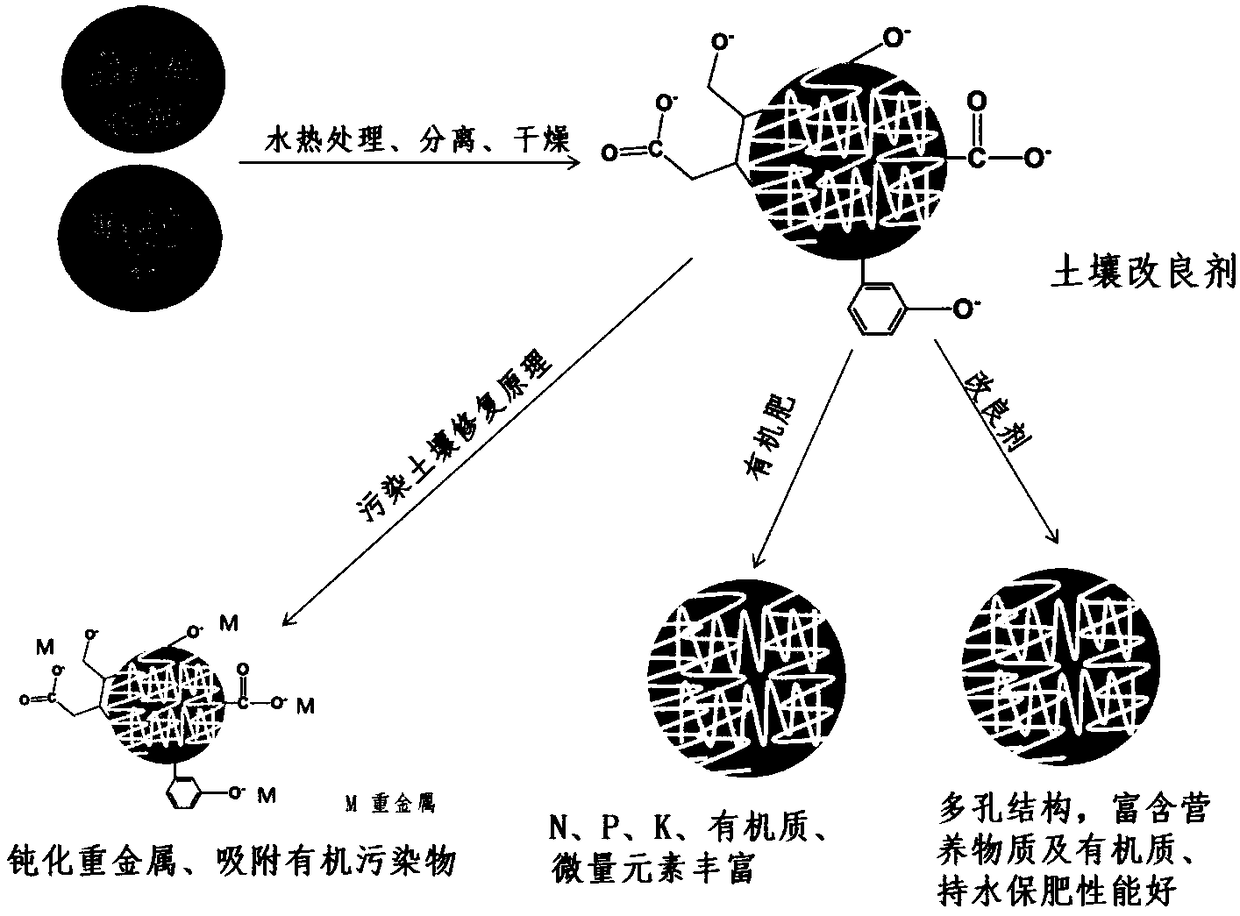

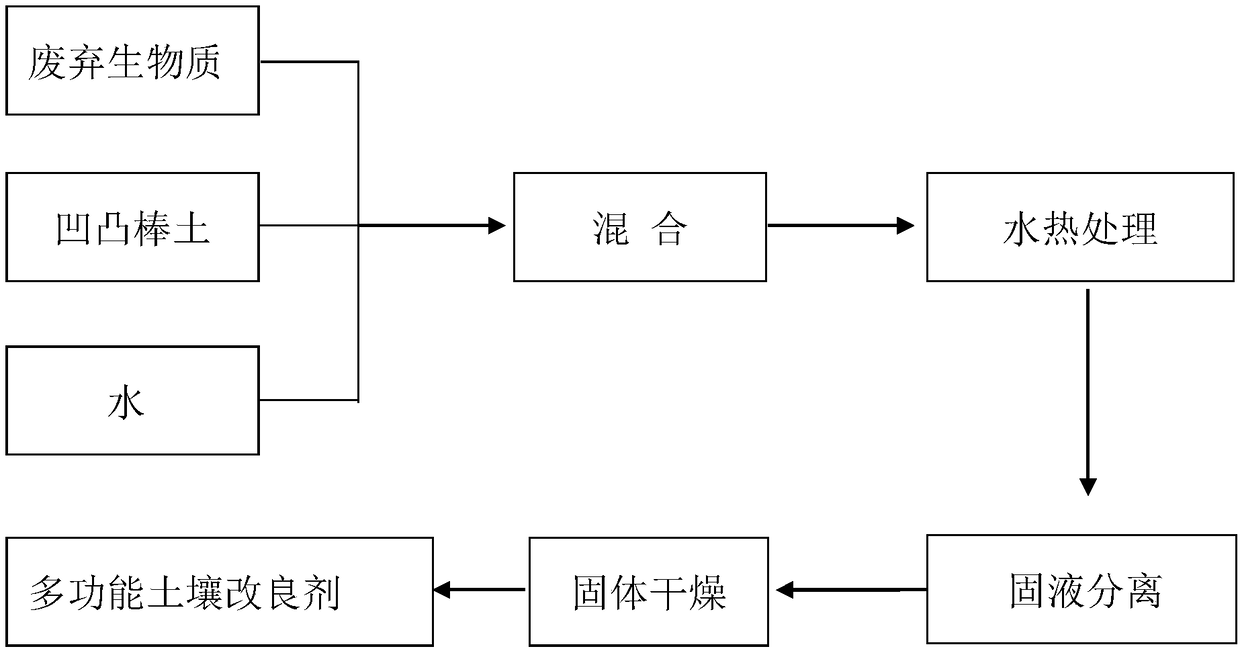

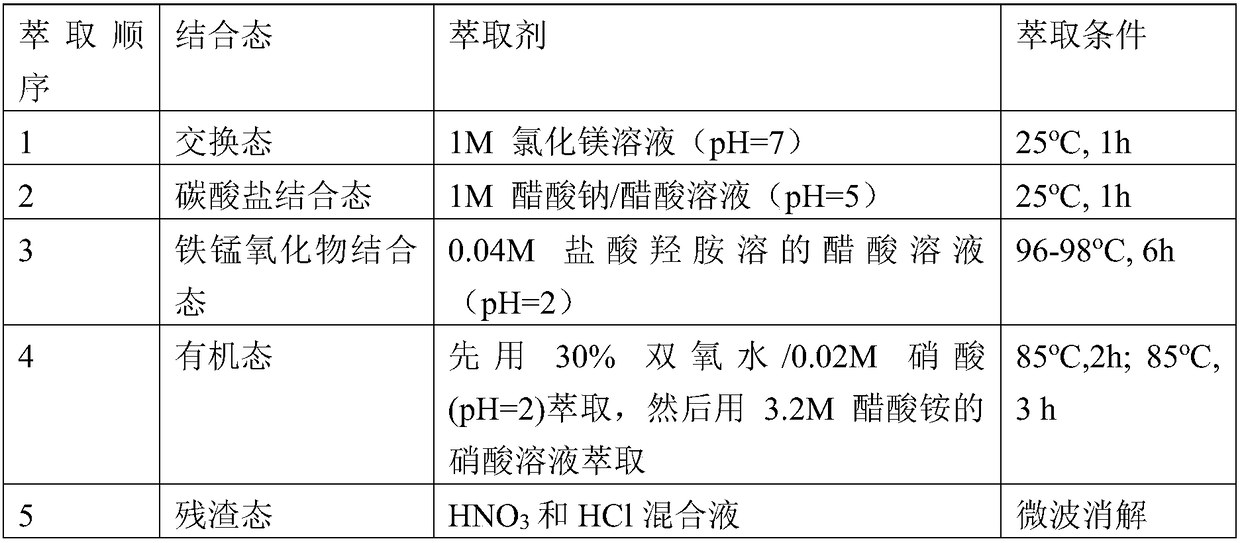

Preparation method and use of multifunctional soil improving agent

InactiveCN108752133AImprove water and fertilizer retention capacityImprove passivation effectExcrement fertilisersAgriculture gas emission reductionBiologyPollution

The high-strength utilization mode of the land in China accelerates the deterioration of a soil function, and soil pollution is very serious due to excessive application of chemical fertilizer and agricultural products. The crop yield declining and food safety incidents caused by soil degradation and soil pollution take place frequently and cause serious threats to people's health. The developmentof an eco-friendly, cheap and high-efficiency soil conditioner for improving soil fertility and reducing soil pollution is extremely urgent. The invention discloses a preparation method of a multifunctional soil improving agent. The preparation method comprises mixing waste biomass and a certain amount of attapulgite and modifying the mixture under specific conditions to obtain the multifunctional soil improving agent. The preparation method has simple processes. The multifunctional soil improving agent is renewable and eco-friendly, realizes a low cost, is rich in nutrients such as trace elements necessary for crop growth and can be used as organic fertilizer and a contaminated soil repairing agent.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

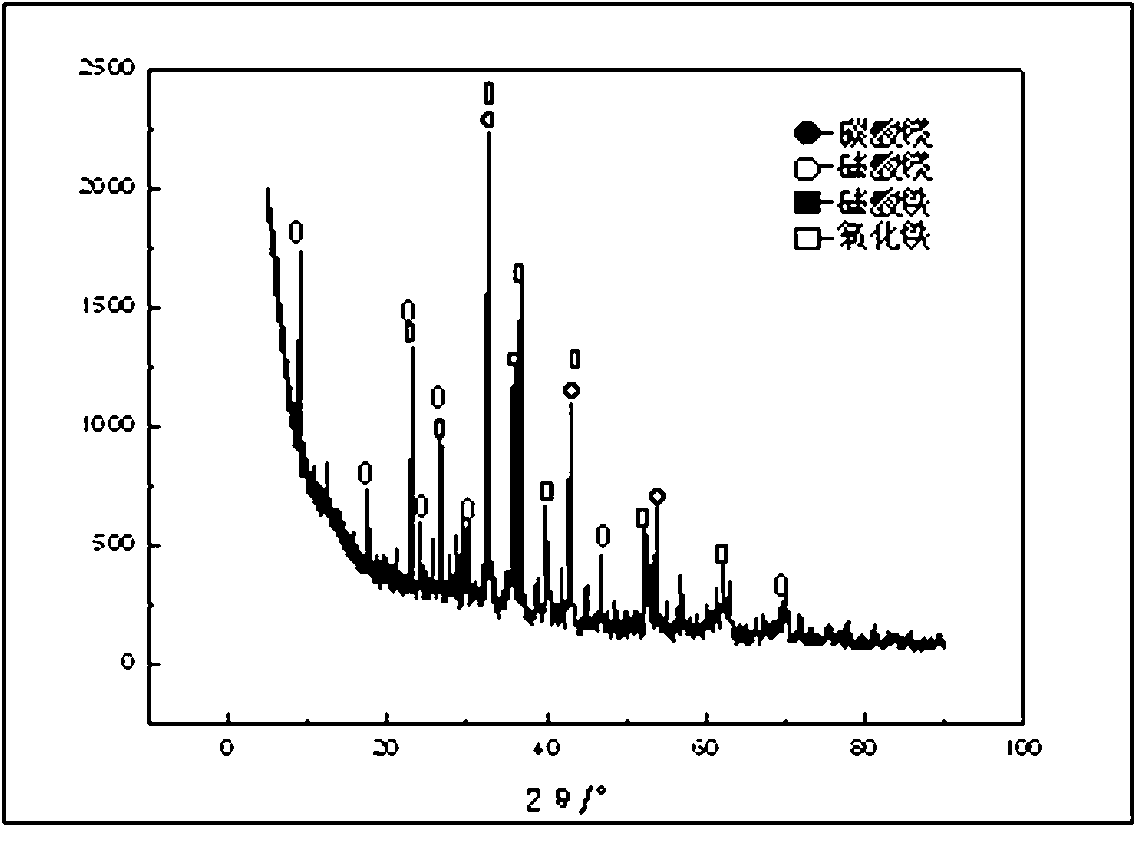

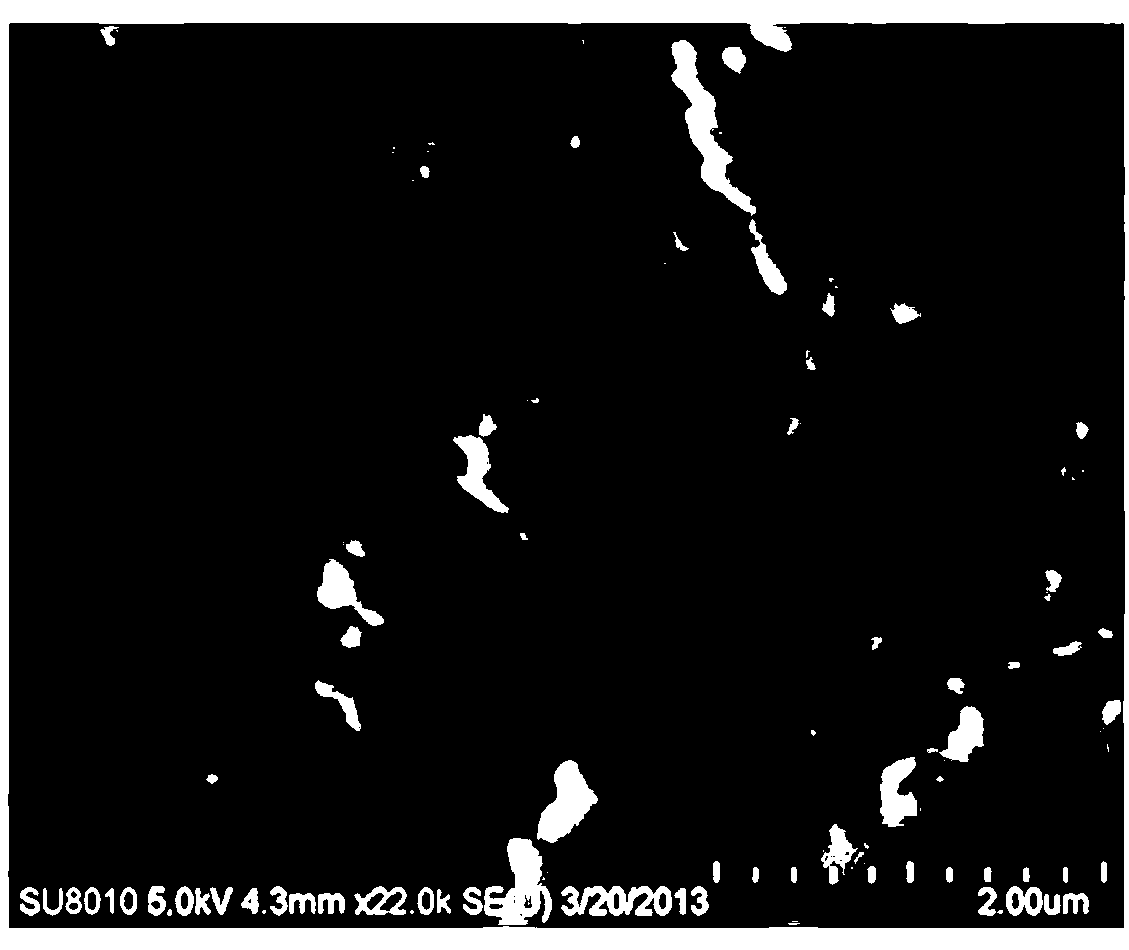

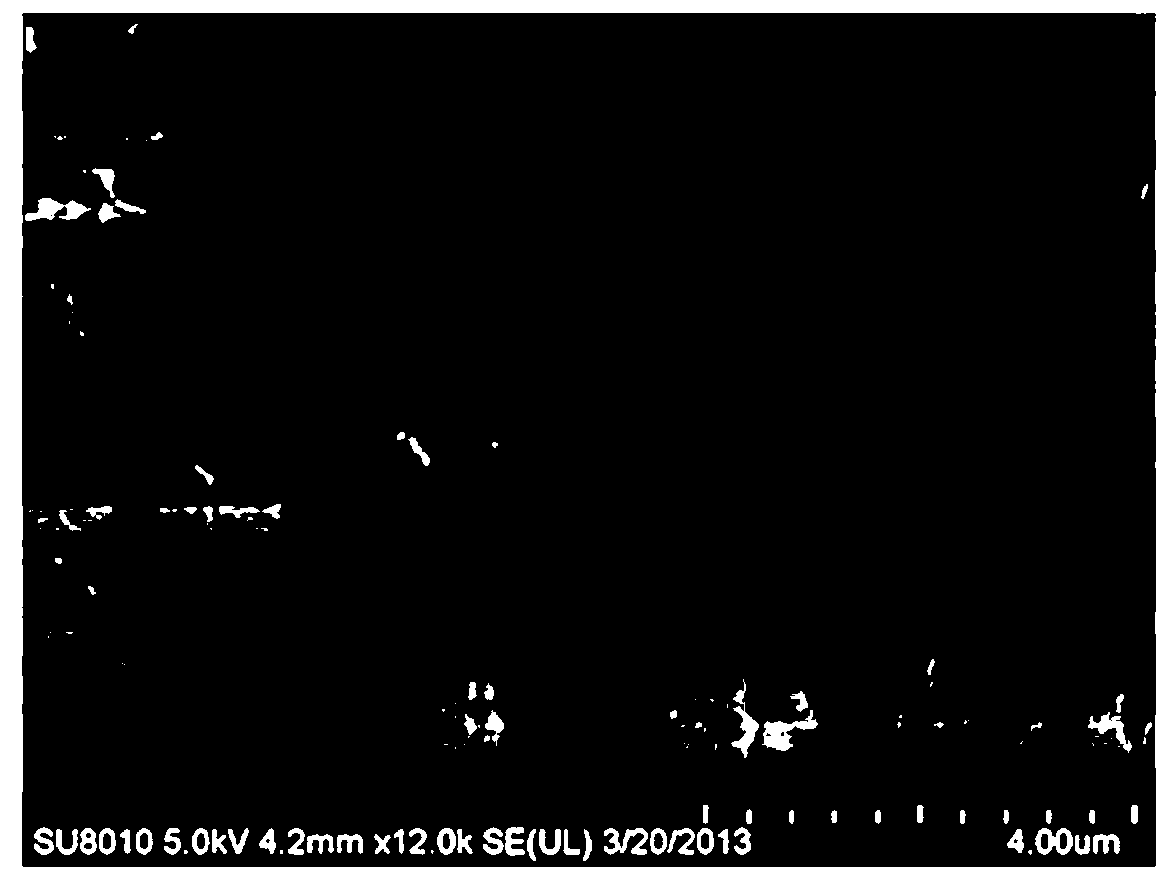

Boric sludge comprehensive utilization method for preparing nanometer magnesia and nanocrystalline iron oxide

ActiveCN103214011AImprove leaching efficiencyShorten the leaching timeSolid waste disposalFerric oxidesExhaust fumesFerrous

The invention belongs to the field of nanometer technology, and particularly relates to a boric sludge comprehensive utilization method for preparing nanometer magnesia and nanocrystalline iron oxide. The boric sludge comprehensive utilization method is carried out according to the following steps of: pressing and leaching boric sludge in a hydrochloric acid system at a low temperature; filtering and separating to obtain magnesium chloride and ferric chloride leachate and borosilicate-rich residue; adding MgO or Fe2O3 to the magnesium chloride and ferric chloride leachate to adjust the pH (Potential Of Hydrogen) of the leachate; adding H2O2 to oxidize bivalent ferrous ions in the leachate into ferric ions during precipitating, in order to precipitate and separate the iron ions in the leachate in a form of ferric hydroxide; filtering and separating to obtain an Fe(OH)3 precipitate and a magnesium chloride solution; roasting the obtained Fe(OH3) precipitate to obtain Fe2O3 powder; and directly pyrolyzing the obtained magnesium chloride solution, thus obtaining the nanometer MgO powder and a hydrochloric acid solution, wherein the hydrochloric acid solution can be returned to be recycled. The boric sludge comprehensive utilization method has high leaching efficiency, enables the leaching time to be reduced, saves the energy, reduces the exhaust emission, realizes non-waste clean production in the whole process, and is a novel typical green and clean production process.

Owner:NORTHEASTERN UNIV

Surfacing compound furnace roller

InactiveCN101571354AThe structure of the material is stableImprove wear resistanceArc welding apparatusCharge manipulationCircular economyEngineering

The invention discloses a surfacing compound furnace roller transporting billets to a heating furnace. The surfacing compound furnace roller comprises a roller shaft and a roller body, wherein, the roller body is fixed on the roller shaft by roller shoulders at the two ends; the roller body is provided with an air hole; a surfacing layer is arranged on the roller body. The invention changes the originally single casting body into a complex of casting, forging and surfacing. During the process of surfacing and compounding, fusion bonding is carried out on the welding materials and the roller body to form the surfacing layer which has a stable material structure and fine crystal grains. In use, the surfacing compound furnace roller eliminates worldwide problems such as roller surface accretion, dead burning and the like in steel industry; simultaneously, surfacing can be continued after the surfacing layer is worn, thus corresponding with the development requirement of recycling economy and improving the service life of the furnace roller.

Owner:杨祥生

Method for preparing fattening feed for river crab in Taihu Lake

The invention discloses a method for preparing fattening feed for river crab in Taihu Lake, the feed comprises the following components by weight percentage: 3-5% of peanut meal, 15-20% of domestic fish meal, 35-40% of soybean meal, 18-20% of wheat, 4-5% of rice bran, 10-15% of rapeseed meal, 2% of soya-bean oil and 4% of premix. The method comprises the following steps: 1)performing superfine grinding on peanut meal, domestic fish meal, soybean meal, wheat, rice bran and rapeseed meal, sending to a mixing warehouse of a mixer in order; 2)directly adding soya-bean oil and the premix in the mixing warehouse of the mixer; 3)turning on a mixer for stirring for 8-10 minutes to prepare a mixture, sending the mixture into a pelleting bin; 4)preparing the slaking particles by the mixture in the pelleting bin through a granulator under high temperature steam effect, sending the slaking particles to a stabilizer and cooling to normal temperature in a stable mode; and 5)grading for processing the cooled particles by a grading sieve, then sealing and packaging according to required weight. According to the invention, the preparation cost is low, the feed nutrition is comprehensive and safe, anaphase growth of the crab is fast, and crab cream can be greatly grown.

Owner:长兴大洋生物饲料有限公司

Processing method of organic fertilizer based on Chinese herbal residues

InactiveCN107986827AImprove fertilitySave resourcesBio-organic fraction processingExcrement fertilisersLivestock manureDisease damage

The invention discloses a processing method of organic fertilizer based on Chinese herbal residues. The method comprises the following steps: (1) the Chinese herbal residues, crop residues and livestock manure are added to a fermentation tank, water is added, and the materials are stirred uniformly; (2) JT strains are dissolved in water and uniformly mixed, the mixed solution is sprayed to the materials in the fermentation tank, overturning and stirring are performed, and the strain solution and the materials are mixed uniformly; (3) the mixture of the strain solution and the materials is placed in a closed environment and fermented for 8-12 days. According to the processing method of the organic fertilizer based on the Chinese herbal residues, the Chinese herbal residues are used effectively, and waste use and energy saving are realized; by means of the organic fertilizer based on the Chinese herbal residues, soil fertility can be improved effectively, and soil is improved; the organic fertilizer further has the effects of killing bacteria and controlling pest and disease damage and meets development requirement of circular economy.

Owner:贵州龙富洪生态投资有限公司

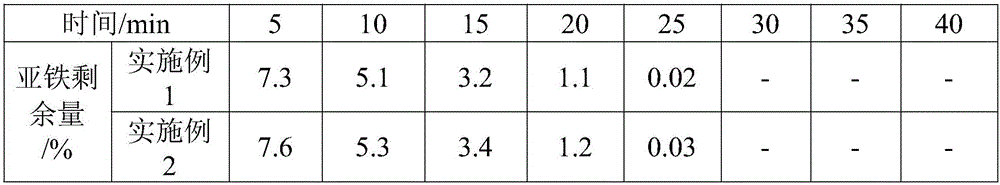

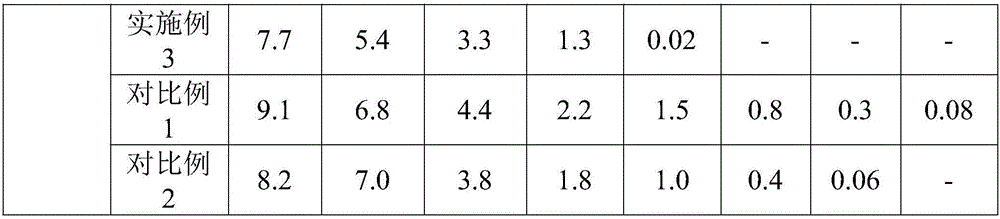

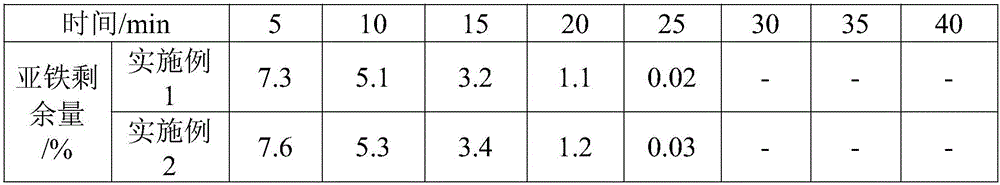

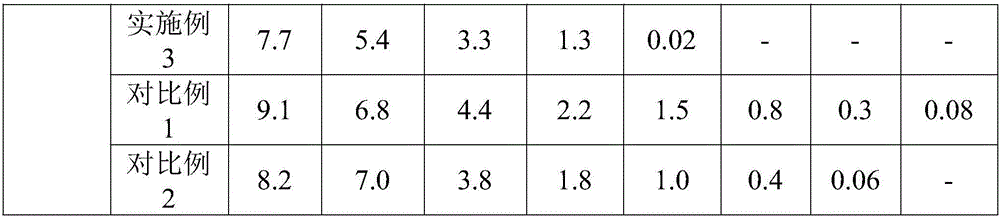

Method for preparing polymeric ferric sulfate

ActiveCN105836813ARealize resource utilizationNo emissionsIron sulfatesWater/sewage treatment by flocculation/precipitationLiquid wasteIron sulfate

The invention belongs to the field of preparation of water treatment agents, and relates to a method for preparing polymeric ferric sulfate. An acidic ferrous solution is produced to obtain polymeric ferric sulfate under the action of an oxidant in the presence of a catalyst and an auxiliary catalyst, wherein the auxiliary catalyst is urea. The method has the beneficial effects that an acid-washed waste liquid is used as a raw material, the waste resource utilization is realized, the urea is oxidized to produce carbon dioxide and nitrogen to achieve the purposes of non-residue and non-emission, the environmental protection requirement and recycling economy development requirement are met, and the production efficiency is greatly improved by using the urea as the auxiliary catalyst.

Owner:CHANGZHOU QINGLIU WATER TREATMENT AGENT

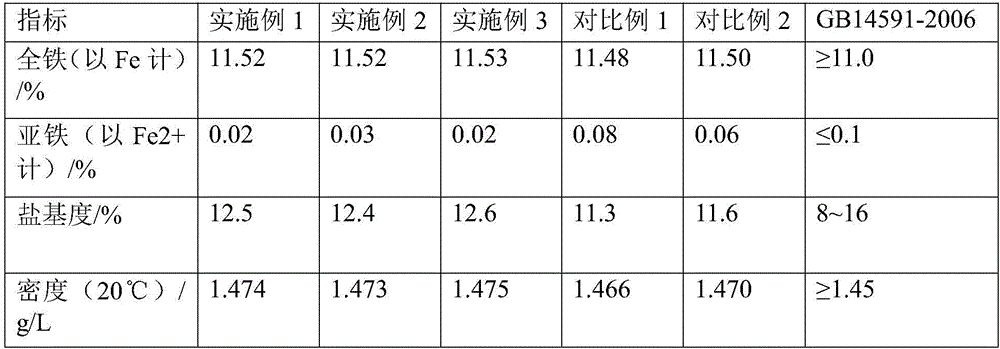

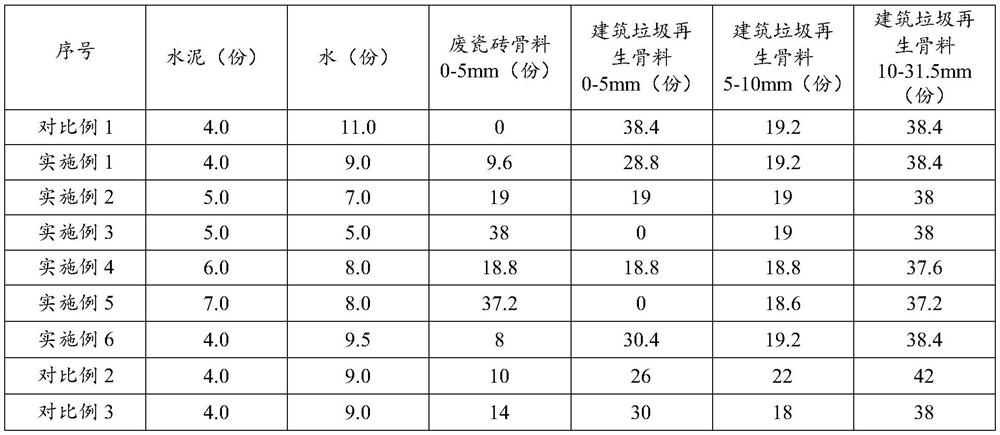

Inorganic mixture and preparation method thereof

InactiveCN112299779AImprove mechanical propertiesImprove frost resistanceSolid waste managementConstruction wasteCeramic tiles

The invention discloses an inorganic mixture and a preparation method thereof. The inorganic mixture comprises the following components in parts by weight: 10-38 parts of waste ceramic tile fine aggregate, 55-86 parts of construction waste recycled aggregate, 4-7 parts of cement and 5-9 parts of water, wherein the particle size d of the waste ceramic tile fine aggregate is larger than 0 and smaller than or equal to 5 mm; the construction waste recycled aggregate comprises first-particle-grade aggregate with a particle size d larger than 0 and smaller than or equal to 5 mm, second-particle-grade aggregate with a particle size d larger than 5 and smaller than or equal to 10 mm and third-particle-grade aggregate with a particle size d larger than 10 and smaller than or equal to 31.5 mm; and aweight ratio of the total weight of the waste ceramic tile fine aggregate and the first-particle-grade aggregate to the weight of the second-particle-grade aggregate to the weight of the third-particle-grade aggregate is (3.8-4.2): (1.8-2.2): (3.8-4.2). The inorganic mixture prepared from waste ceramic tile construction waste is excellent in mechanical property and remarkably enhanced in durability, and is a green and environment-friendly novel building material.

Owner:SHOUGANG ENVIRONMENTAL IND

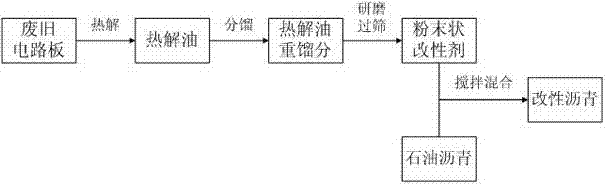

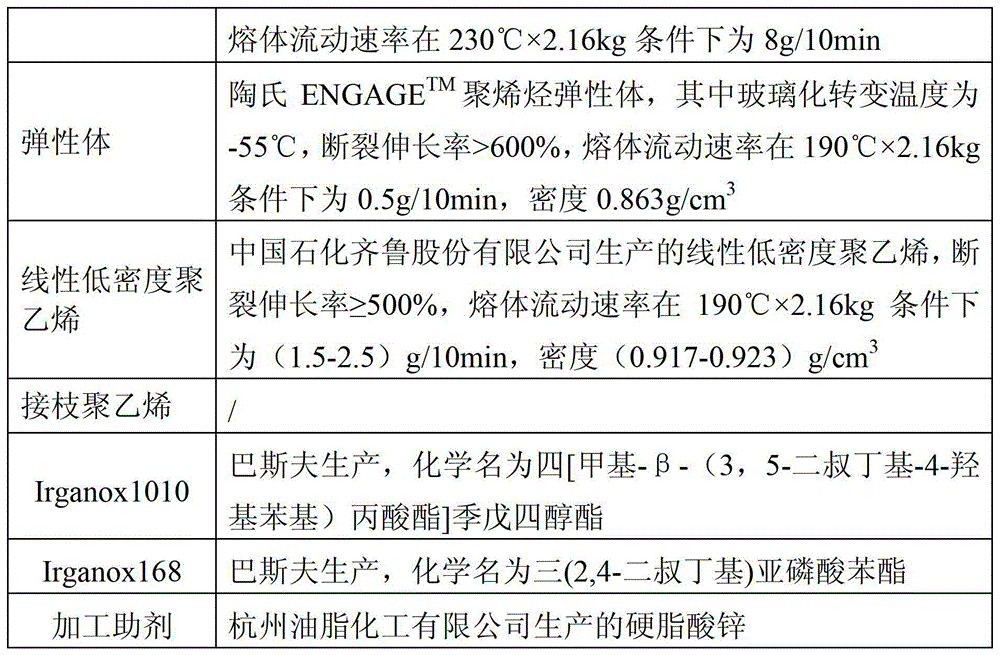

Method for modifying asphalt by using pyrolytic oil heavy fraction of waste printed circuit board

InactiveCN102391657AImprove resource recovery efficiencyMeet the requirements of circular economy developmentHydrocarbon distillationLiquid hydrocarbon mixture productionLiquid productRolling resistance

The invention discloses a method for modifying asphalt by using pyrolytic oil heavy fraction of a waste printed circuit board. The crushed pyrolytic oil high-temperature heavy fraction powder of the waste printed board, which is used as a modifier is added into the asphalt so as to improve the high temperature performance of road asphalt, and greatly improve rolling resistance and stability of the road asphalt; the high-temperature fraction in the pyrolytic oil of the waste printed circuit board is extracted by fractionation, and is crushed and sieved at high temperature, heavy fraction powder of which the grain size is greater than 200 meshes is used as the asphalt modifier, and 2 to 10 weight parts of pyrolytic oil heavy fraction of the waste printed circuit board, which is used as the modifier is added into 90 to 98 weight parts of petroleum asphalt at the temperature of between 130 and 160 DEG C to form a mixture and the mixture is stirred under the condition of heat preservation for 0.5 and 1 hour to form the modified asphalt; and in the method, all components of a liquid product which is obtained after a circuit board is treated by a pyrolysis method are utilized, the performance of asphalt is improved and the cost of the modified asphalt is reduced.

Owner:GUANGDONG UNIV OF TECH

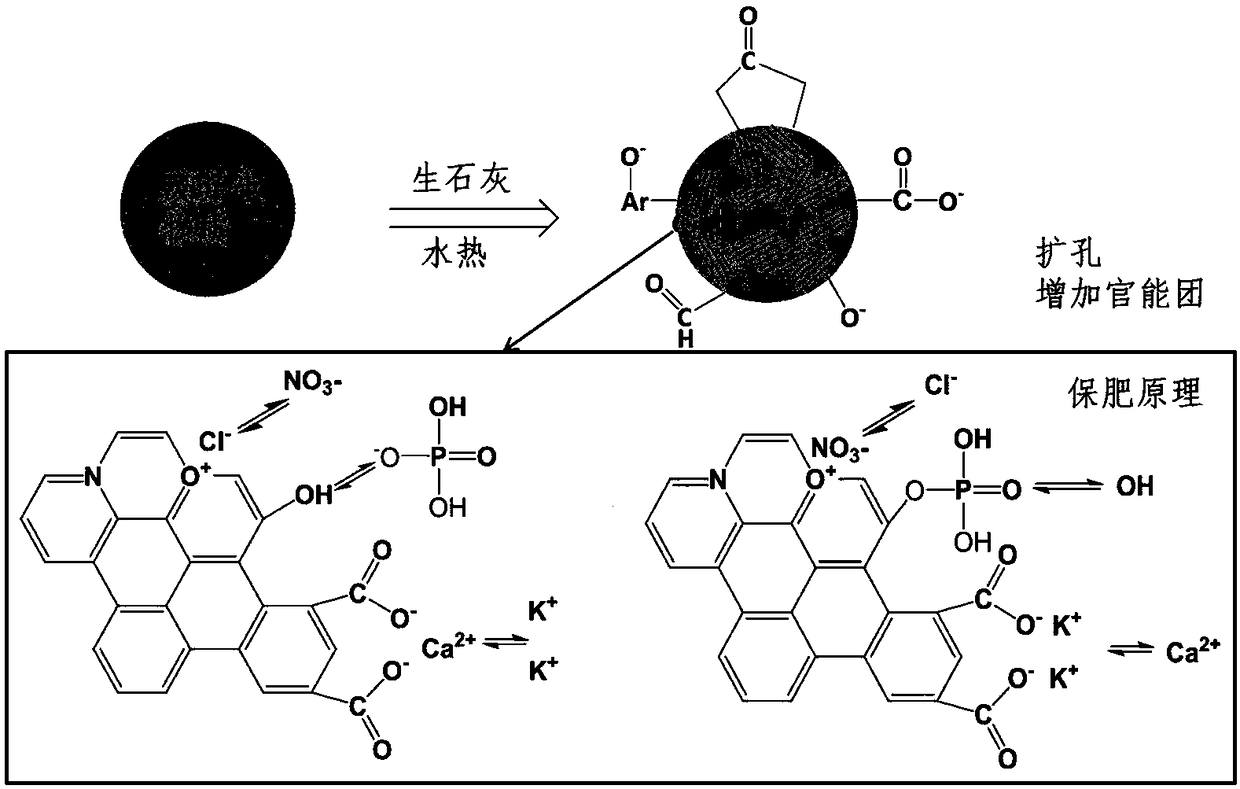

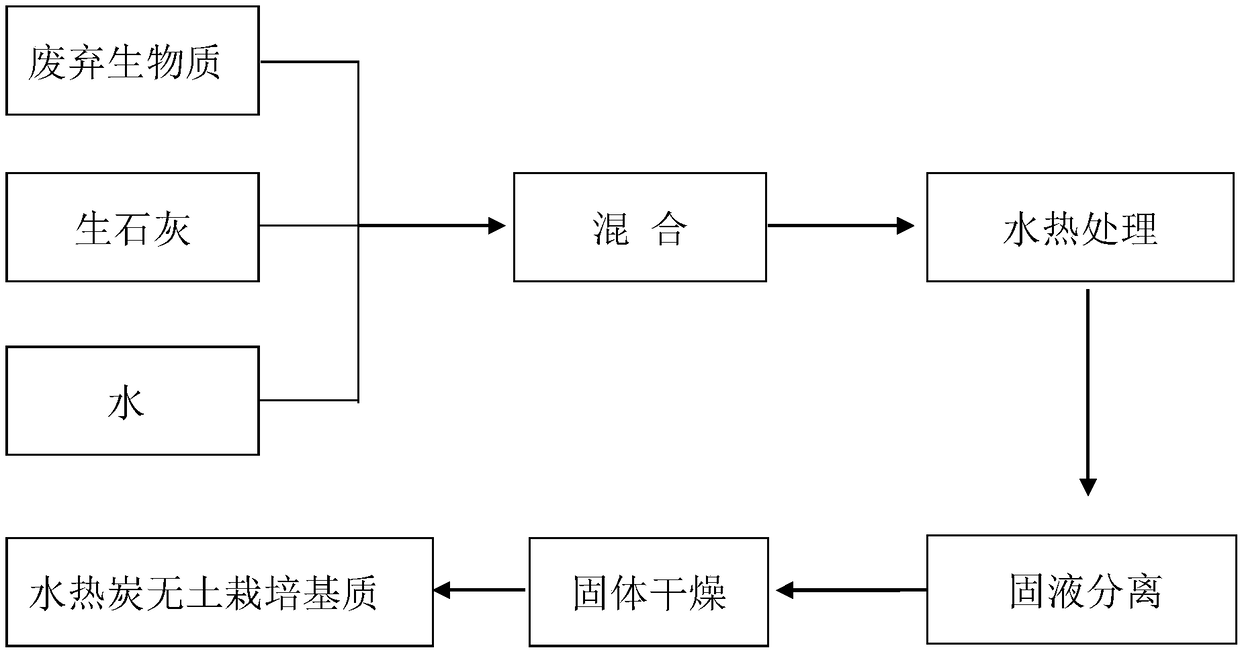

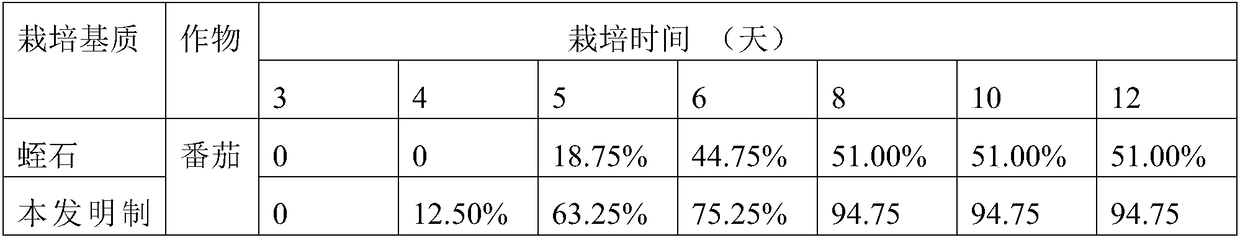

Method for preparing soilless culture substrate from waste biomass

As economy grows and food safety incidents caused by soil contamination occur frequently, demand for culture substrates required by production of pollution-free green vegetables is increased day by day. At present, a soilless culture substrate mainly uses non-renewable resources such as vermiculite and perlite, so that development of a potential renewable culture substrate is particularly important; and untimely or improper processing of a large amount of waste biomass (livestock and poultry manure, straw and the like) in China causes serious environmental pollution. The process obtains the soilless culture substrate by mixing the waste biomass and a certain amount of quicklime, performing hydrothermal treatment under specific conditions, and performing solid-liquid centrifugation. The process provided by the invention adopts the waste biomass to prepare the soilless culture substrate, the preparation process is simple, and the costs are low; and the substrate is not only rich in nutrients such as microelements necessary for crop growth, but also can improve utilization efficiency of fertilizers by crops.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

A kind of preparation method of polyferric sulfate

ActiveCN105836813BRealize resource utilizationNo emissionsIron sulfatesWater/sewage treatment by flocculation/precipitationResource utilizationSulfate

The invention belongs to the field of preparation of water treatment agents, and relates to a method for preparing polymeric ferric sulfate. An acidic ferrous solution is produced to obtain polymeric ferric sulfate under the action of an oxidant in the presence of a catalyst and an auxiliary catalyst, wherein the auxiliary catalyst is urea. The method has the beneficial effects that an acid-washed waste liquid is used as a raw material, the waste resource utilization is realized, the urea is oxidized to produce carbon dioxide and nitrogen to achieve the purposes of non-residue and non-emission, the environmental protection requirement and recycling economy development requirement are met, and the production efficiency is greatly improved by using the urea as the auxiliary catalyst.

Owner:CHANGZHOU QINGLIU WATER TREATMENT AGENT

Yeast grease and preparation method and application thereof

InactiveCN102100260BAnti agingLower blood fatFatty-oils/fats refiningWaste based fuelBiotechnologyEnvironmental resistance

Owner:BINZHOU UNIV +1

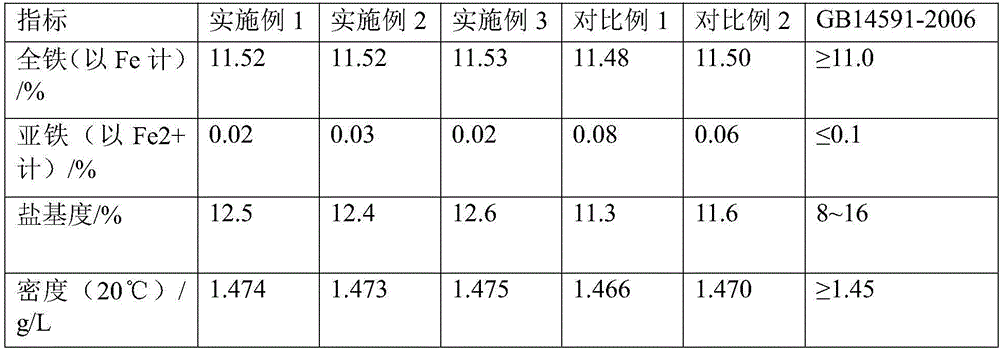

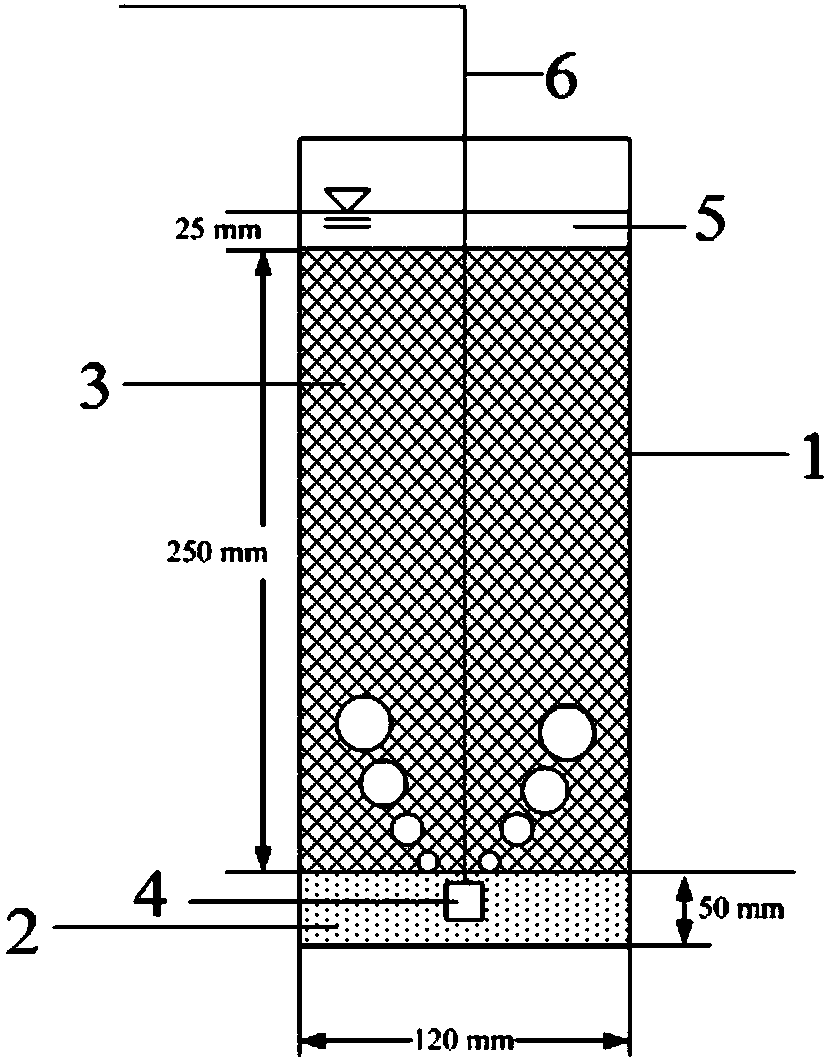

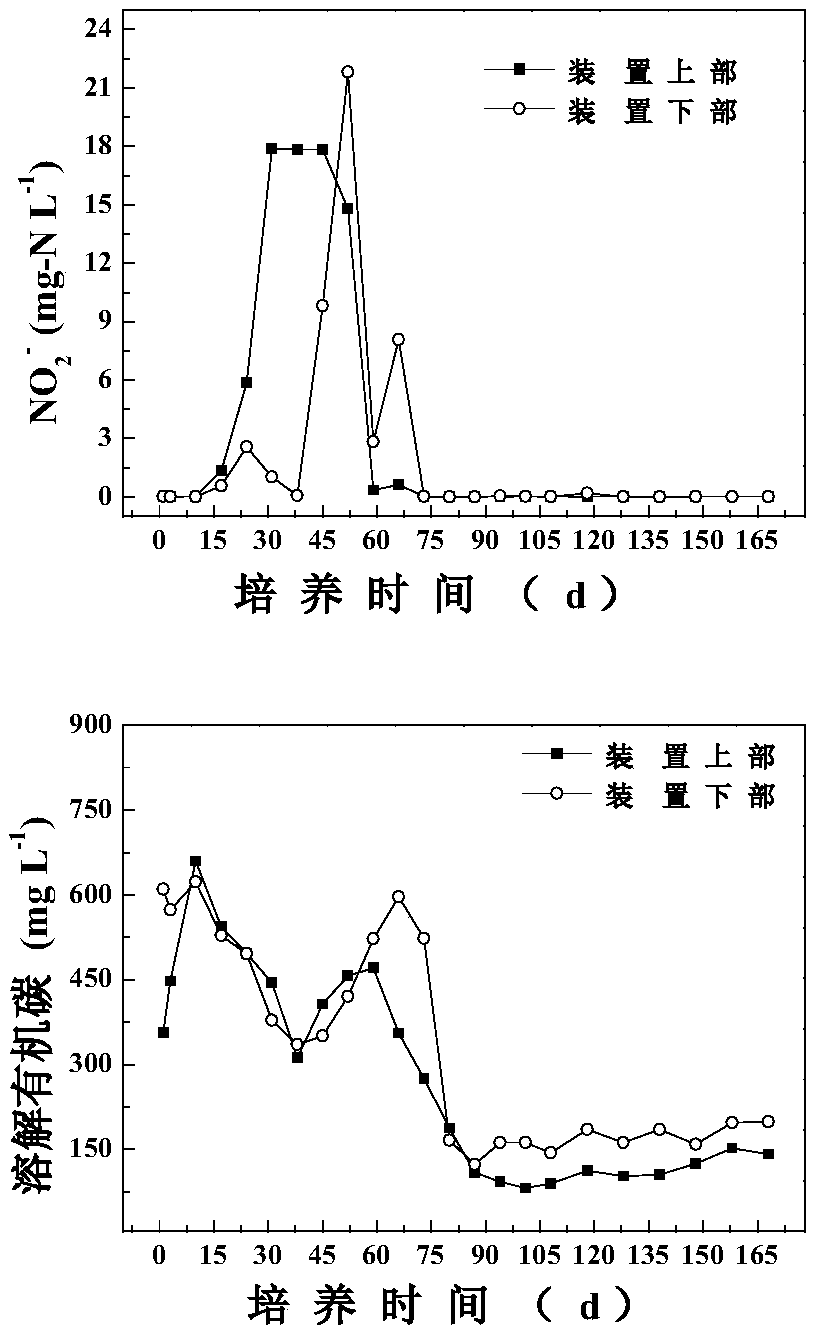

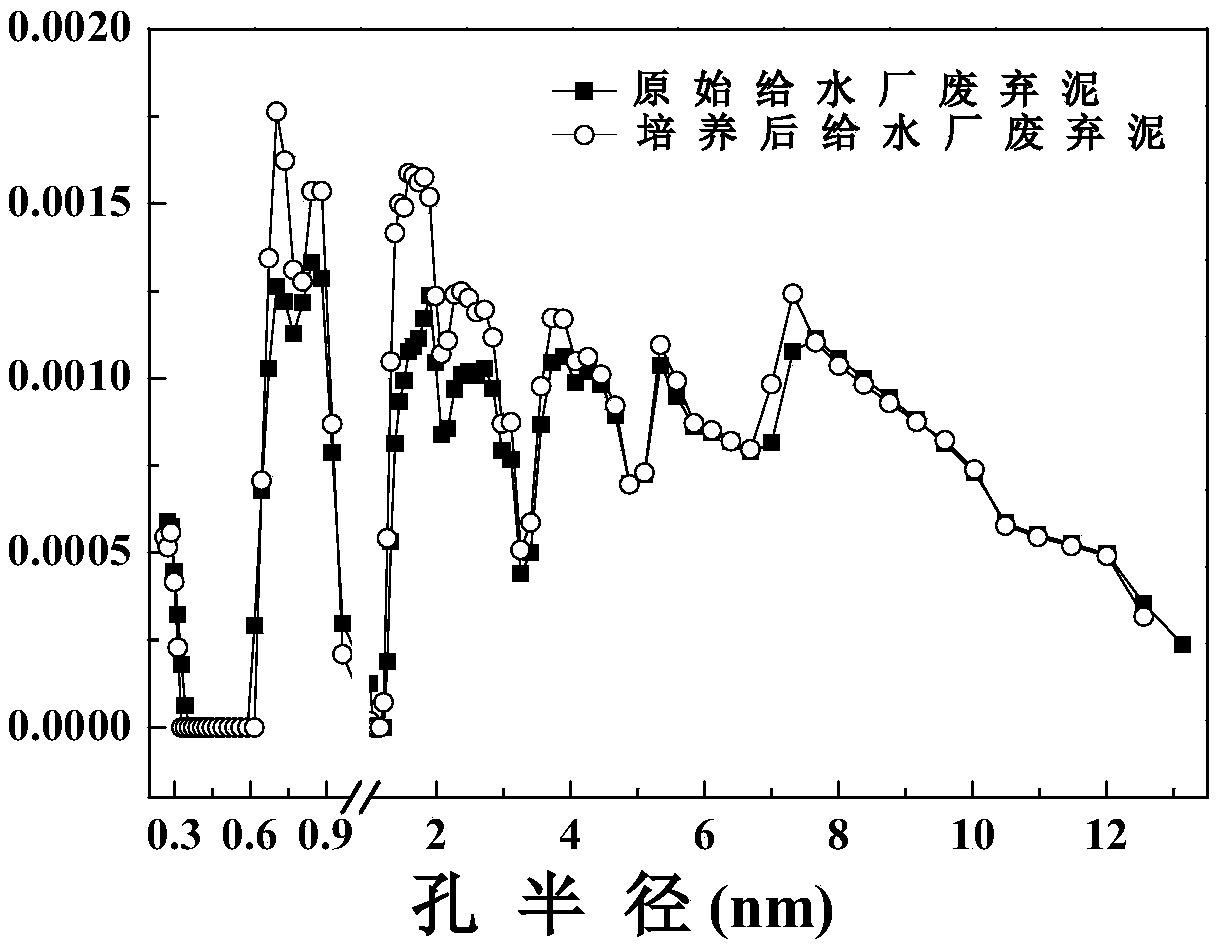

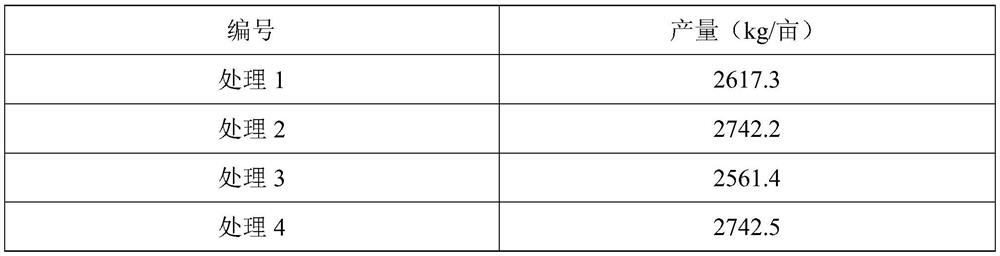

Pre-treatment method of water supply plant iron-aluminum mud

InactiveCN108503159AEasy accessEfficient use ofSludge treatmentWater contaminantsResource utilizationClosed system

The invention belongs to the field of remediation of water environment, and specifically relates to a pre-treatment method of water supply plant iron-aluminum mud. The pre-treatment method comprises the following steps: injecting water into a water supply plant iron-aluminum mud culture device, enabling the final liquid level to be slightly higher than the water supply plant iron-aluminum mud, constructing a closed system, carrying out intermittent aeration culture on the closed system for at least four months, and then uniformly mixing, wherein the water supply plant iron-aluminum mud culturedevice comprises a container, a gravel layer, the water supply plant iron-aluminum mud and an aeration head, the gravel layer is arranged at the bottom part of the container, the water supply plant iron-aluminum mud is arranged above the gravel layer in the container, and the aeration head is arranged in the gravel layer and is communicated with the outer part of the container through an air pipe. According to the pre-treatment method disclosed by the invention, the water supply plant iron-aluminum mud can be deeply purified, most of active nitrogen and organic matters of the water supply plant iron-aluminum mud can be removed, a potential risk caused by recycling of the water supply plant iron-aluminum mud during a natural surface water environment remediation process can be further reduced, the adsorption capacity of the water supply plant iron-aluminum mud is tend to be improved, and enrichment of functional bacteria related to carbon-nitrogen cycling can be promoted; the process is simple, the cost is low, the operation is convenient, and resource utilization of waste is promoted.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

Amino acid trace element type water-soluble fertilizer as well as preparation method and application thereof

PendingCN114085106AIncrease resistancePromote the formation of aggregate structureAmmonium salt fertilisersOrganic fertilisersPotassium nitratePlant growth

The invention relates to the technical field of agricultural fertilizer manufacturing, in particular to an amino acid trace element type water-soluble fertilizer as well as a preparation method and an application thereof. The amino acid trace element type water-soluble fertilizer is prepared from the following raw material components in parts by weight: 600 to 800 parts of citrus processing waste fermentation liquor, 400 to 500 parts of 40 percent amino acid powder, 150 to 200 parts of biochemical potassium fulvate, 175 to 205 parts of calcium nitrate, 100 to 125 parts of magnesium nitrate, 50 to 70 parts of potassium nitrate, 140 to 160 parts of liquid efficient agent, 6 to 10 parts of emulsifier, 6 to 10 parts of scale remover and 2 to 4 parts of auxiliary agent. The amino acid trace element type water-soluble fertilizer is rich in trace elements, and can promote the growth and development of plants, improve the resistance, increase the yield and quality and improve the soil structure by topdressing in the middle and later periods of crop growth.

Owner:HUNAN AGRICULTURAL UNIV +1

Boric sludge comprehensive utilization method for preparing nanometer magnesia and nanocrystalline iron oxide

ActiveCN103214011BEmission reductionImprove leaching efficiencySolid waste disposalFerric oxidesFerric hydroxidePhysical chemistry

The invention belongs to the field of nanometer technology, and particularly relates to a boric sludge comprehensive utilization method for preparing nanometer magnesia and nanocrystalline iron oxide. The boric sludge comprehensive utilization method is carried out according to the following steps of: pressing and leaching boric sludge in a hydrochloric acid system at a low temperature; filtering and separating to obtain magnesium chloride and ferric chloride leachate and borosilicate-rich residue; adding MgO or Fe2O3 to the magnesium chloride and ferric chloride leachate to adjust the pH (Potential Of Hydrogen) of the leachate; adding H2O2 to oxidize bivalent ferrous ions in the leachate into ferric ions during precipitating, in order to precipitate and separate the iron ions in the leachate in a form of ferric hydroxide; filtering and separating to obtain an Fe(OH)3 precipitate and a magnesium chloride solution; roasting the obtained Fe(OH3) precipitate to obtain Fe2O3 powder; and directly pyrolyzing the obtained magnesium chloride solution, thus obtaining the nanometer MgO powder and a hydrochloric acid solution, wherein the hydrochloric acid solution can be returned to be recycled. The boric sludge comprehensive utilization method has high leaching efficiency, enables the leaching time to be reduced, saves the energy, reduces the exhaust emission, realizes non-waste clean production in the whole process, and is a novel typical green and clean production process.

Owner:NORTHEASTERN UNIV LIAONING

A kind of base stabilized soil for highway and its production method

The invention relates to a stabilized soil for road bases, in particular to a kind of stabilized soil for bases used in roads produced by utilizing the processed construction waste and by-products of industrial production, and also relates to a production method of the stabilized soil. A stabilized soil for a road base, comprising the following components in mass percentage: 60-80% of graded gravel produced in the crushing process of construction waste, 2-5% of petroleum coke residue, 0.5-1% of white mud, and 10% of fly ash ~16%, lime 2~5%. The production method of the road base stabilized soil provided by the invention comprises the steps of crushing and gradation adjustment, grinding, weighing and measuring, stirring and the like. The various detection indicators of the stabilized soil for road bases provided by the invention conform to the provisions of the "Technical Specifications for Construction of Highway Pavement Bases" on base materials; equipment, low cost, economic and environmental protection.

Owner:QINGDAO GREEN SAIL RECYCLED BUILDING MATERIALS

A low temperature resistant copolymerized polypropylene modified material and its preparation method and application

ActiveCN103254515BHigh tensile strengthImprove high temperature performanceElastomerLinear low-density polyethylene

The invention discloses a low-temperature resisting co-polypropylene modified material as well as a preparation method and an application thereof. The low-temperature resisting co-polypropylene modified material comprises the following raw materials in percentage by weight: 60-98% of co-polypropylene, 1-20% of an elastomer, 0-10% of linear low-density polyethylene, 0-8% of stem grafting polyethylene, 0.1-1% of a stabilizer and 0.1-1% of a processing agent. The modified material has both good tension strength and high-temperature property and good low-temperature property, the performances of a conventional polypropylene plastic sealing stripe are improved, the requirements on use of the plastic sealing stripe at high and low temperatures are met, and the modified material can be used for preparing various plastic sealing stripes, such as air container sealing stripes, cultivation sealing stripes, self-locking type sealing stripes and anti-theft sealing stripes.

Owner:CGN JUNER NEW MATERIALS +1

Method for modifying asphalt by using pyrolytic oil heavy fraction of waste printed circuit board

InactiveCN102391657BImprove resource recovery efficiencyMeet the requirements of circular economy developmentHydrocarbon distillationLiquid hydrocarbon mixture productionLiquid productRolling resistance

Owner:GUANGDONG UNIV OF TECH

Organic fertilizer based on Chinese herbal residues

InactiveCN107986891ARealize comprehensive utilizationImprove fertilityExcrement fertilisersBioloigcal waste fertilisersLivestock manureFeces

The invention discloses organic fertilizer based on Chinese herbal residues. The organic fertilizer is prepared from 50-60 parts by weight of the Chinese herbal residues, 20-30 parts by weight of cropresidues, 15-25 parts by weight of livestock manure and 1-2 parts by weight of JT strains. The Chinese herbal residues are combined with the crop residues, the livestock manure and the JT strains, sothat waste utilization of the Chinese herbal residues is realized, and resources are saved; soil fertility is improved, and soil is improved; the organic fertilizer further has the effects of killingbacteria and controlling pest and disease damage and meets development requirement of circular economy.

Owner:贵州龙富洪生态投资有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com