Method for preparing glass beads by using recovery of waste glass powder

A technology of glass microspheres and waste glass powder, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of increasing the production cost of glass microspheres, waste of resources, etc., and achieve long effective reflection distance and uniform outer shape , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

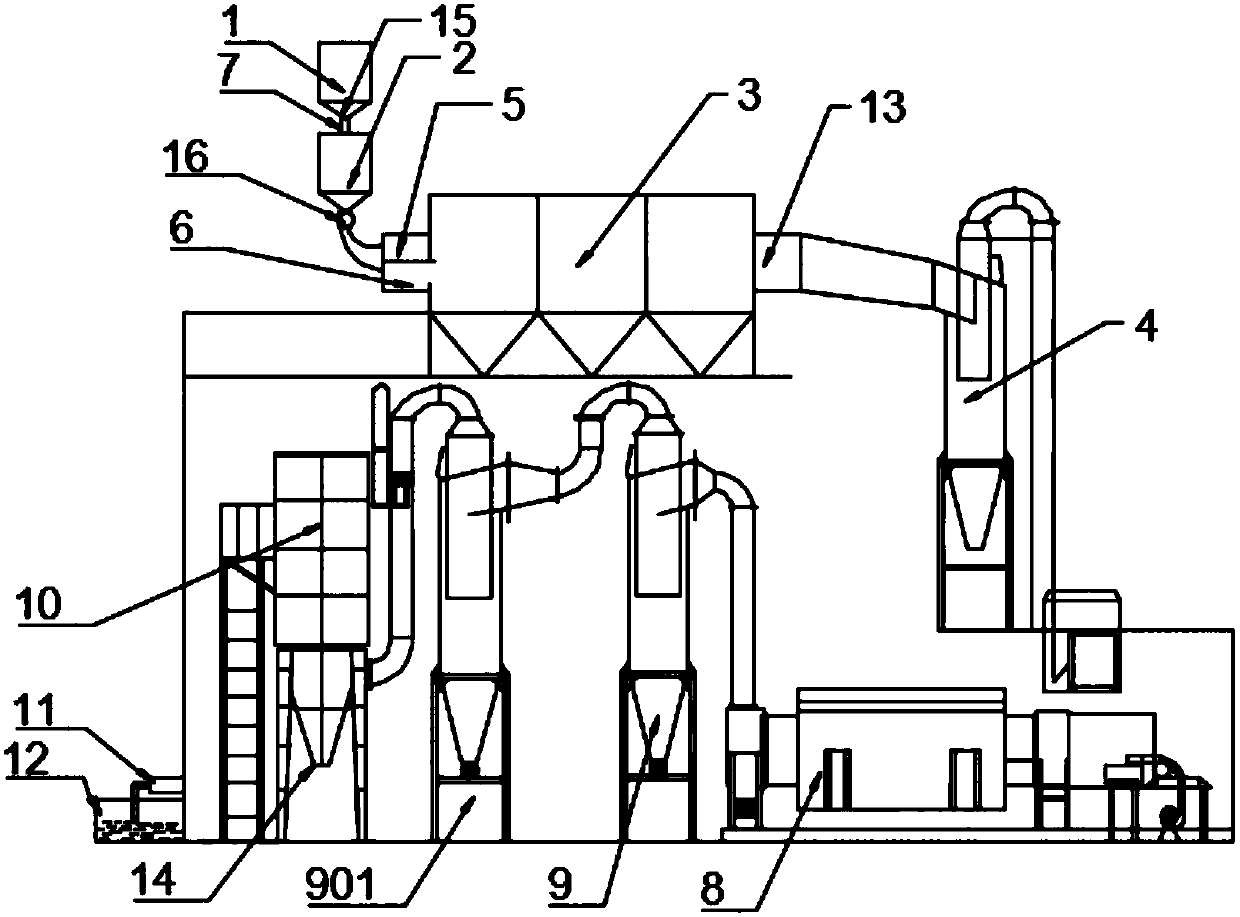

Method used

Image

Examples

specific Embodiment approach

[0019] Specific embodiments: the present invention will be further described in detail below in conjunction with specific embodiments.

[0020] The following examples will help to further understand the present invention, but do not limit the content of the present invention.

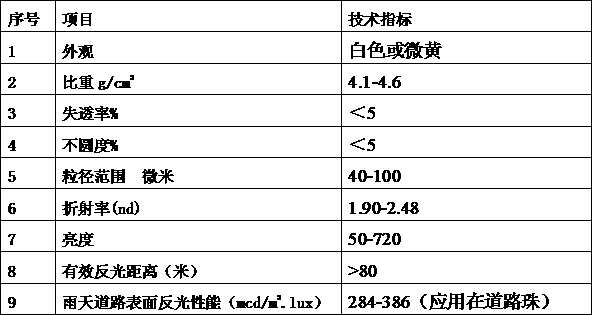

[0021] One object of the present invention is to disclose a method for preparing glass microspheres by using waste glass powder without recovery, a method for preparing glass microspheres by utilizing waste glass powder without recovery, using waste glass powder or glass microsphere powder as raw materials, including The method is as follows: 1) Mix waste glass powder or waste glass microbead powder and corresponding materials to form a powder-free mixture; 2) Make the powder mixture through the injection port and the spray gun to make the material, form beads at high temperature, and collect them in the collection device Then it is separated into glass microbead water-quenching powder by cyclone separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com