Inorganic mixture and preparation method thereof

A mixed material and inorganic technology, applied in the field of construction waste recycling, can solve the problems of natural environment damage, consumption of large natural sand and gravel, and expensive raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

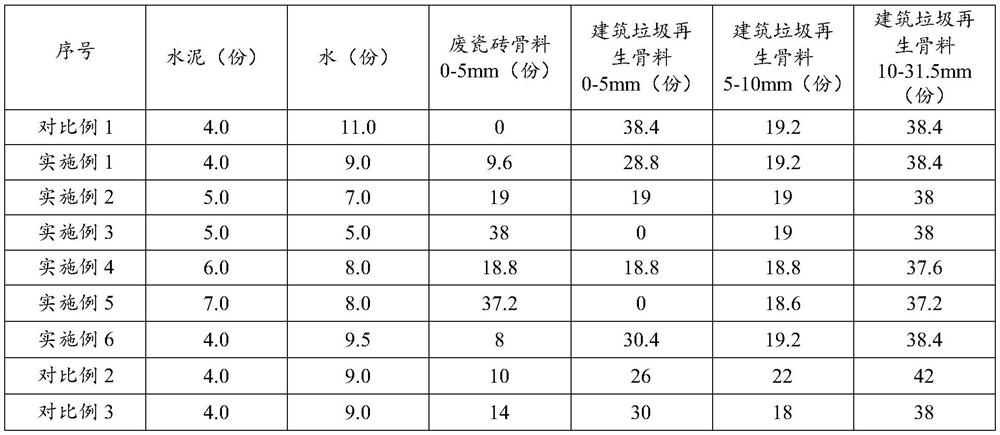

Examples

preparation example Construction

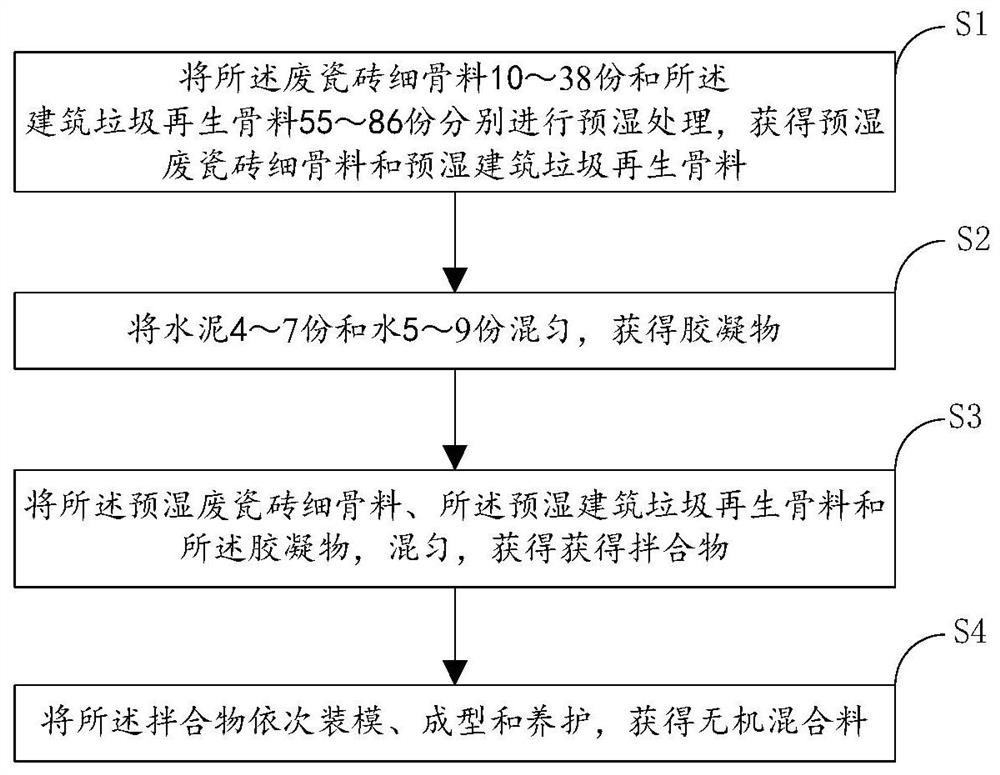

[0040] According to another typical embodiment of the present invention, the preparation method of inorganic compound is provided, such as figure 1 shown, including:

[0041] S1. Perform pre-wet treatment on 10-38 parts of waste tile fine aggregate and 55-86 parts of construction waste recycled aggregate, respectively, to obtain pre-wet waste tile fine aggregate and pre-wet construction waste recycled aggregate;

[0042] S2, mixing 4-7 parts of cement and 5-9 parts of water to obtain a gel;

[0043] S3. Mix the pre-wetted waste ceramic tile fine aggregate, the pre-wetted construction waste regenerated aggregate and the gel to obtain a mixture;

[0044] S4. Molding, forming and curing the mixture in sequence to obtain an inorganic mixture.

[0045] The pre-wet treatment in step S1 is a necessary step, the purpose of which is that the regenerated aggregate of construction waste has strong water absorption, and the water-cement ratio of inorganic materials can be kept stable by...

Embodiment 6

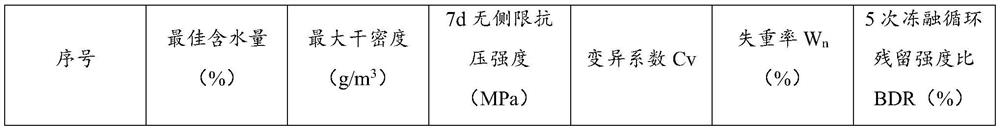

[0060] In Example 6, the total weight of the waste ceramic tile fine aggregate and the first grade aggregate, the weight ratio of the second grade aggregate and the third grade aggregate is 4:2: 4. Within the scope of the present invention, the ratio of the weight of the waste tile fine aggregate to the total weight of the waste tile fine aggregate and the first grade aggregate is less than 25%, and the prepared inorganic mixture The optimal water content is as high as 9.4%, and the residual strength of waste ceramic tile inorganic mixture after 5 freeze-thaw cycles reaches 87.5%; the water-binder ratio of the inorganic binder is high, and the structural density is low, and the frost resistance is worse than that of Example 1- 5.

[0061] Through the analysis of comparative examples and Examples 1-6, it can be seen that the residual strength ratio of the waste ceramic tile inorganic mixture after 5 freeze-thaw cycles increases significantly with the increase of the waste ceram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com