A low temperature resistant copolymerized polypropylene modified material and its preparation method and application

A technology of copolymerized polypropylene and modified materials, which is applied in the field of low temperature resistant copolymerized polypropylene modified materials and its preparation, can solve the problem of not checking the patent of modified polypropylene materials, etc., and achieve good low temperature resistance and alkali resistance. The effect of excellent, good tensile strength and high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Add polypropylene copolymer, elastomer, linear low-density polyethylene, grafted polyethylene, stabilizers (including Irganox1010 and Irganox168) and processing aids into the high-speed mixing pot according to the amount shown in Table 6, stir and mix evenly, Obtain mixed material, wherein raw material source and performance are shown in Table 1. The mixed material is sent into the twin-screw extruder from the feeder, and the residence time of the material in the screw is 50 seconds to 120 seconds. The temperature of the twin-screw extruder from the feeding section to the head is: 180 ° C, 215 ° C , 215°C, 215°C, 215°C, 215°C, 215°C, the temperature of the die head is: 220°C. After high-speed twin-screw (screw speed: 600r / min) shearing and mixing, extruding from the machine head, drawing, air cooling, drying, pelletizing and packaging, the low-temperature resistant copolymerized polypropylene modified material is obtained.

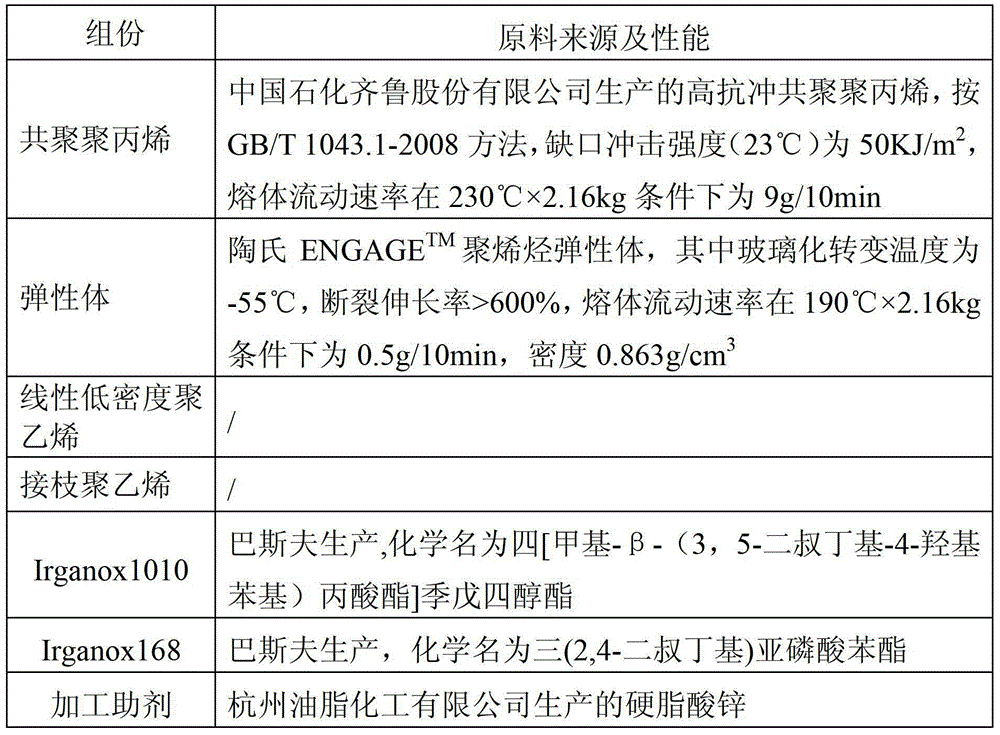

[0057] Table 1 Raw material source and perfo...

Embodiment 2

[0060] The preparation method is as in Example 1, the sources and properties of raw materials are shown in Table 2, and the amount of raw materials is shown in Table 6.

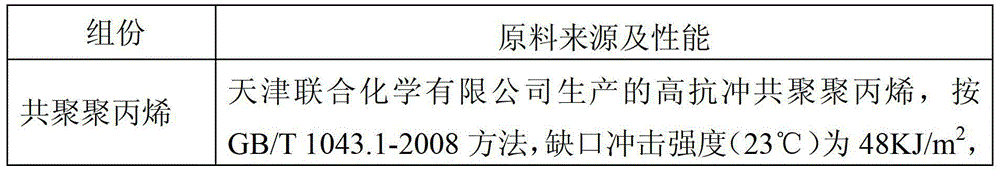

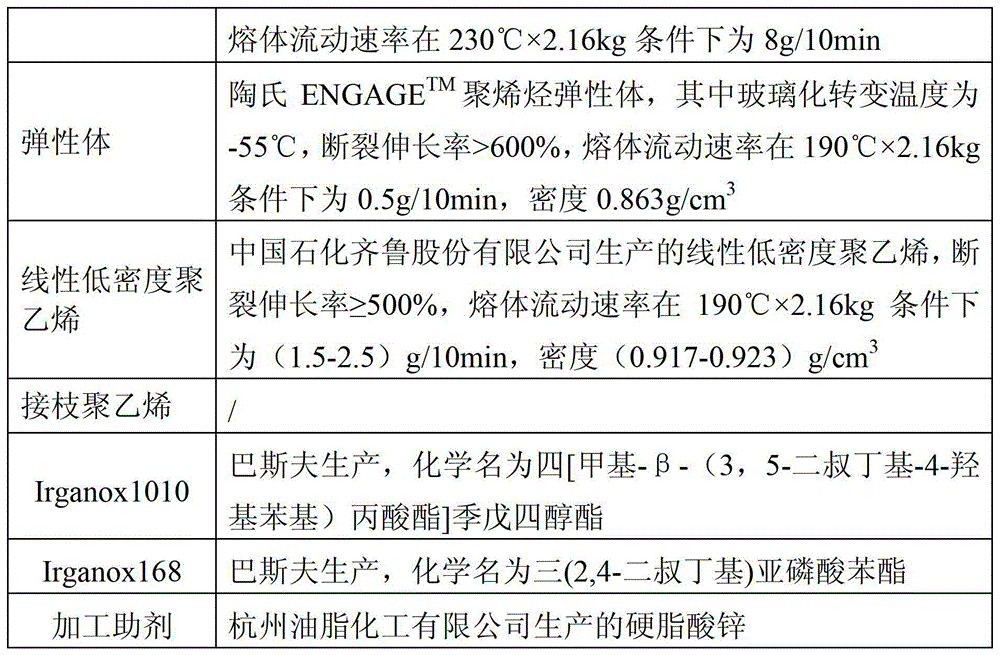

[0061] Table 2 raw material source and performance

[0062]

[0063]

Embodiment 3

[0065] The preparation method is as in Example 1, the sources and properties of raw materials are shown in Table 3, and the amount of raw materials is shown in Table 6.

[0066] Table 3 raw material source and performance

[0067]

[0068]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com