Method for preparing polymeric ferric sulfate

A technology for polymerizing ferric sulfate and sulfuric acid, which is applied in the fields of ferric sulfate, chemical instruments and methods, water/sewage treatment, etc., can solve the problem of low production efficiency of polymerized ferric sulfate, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

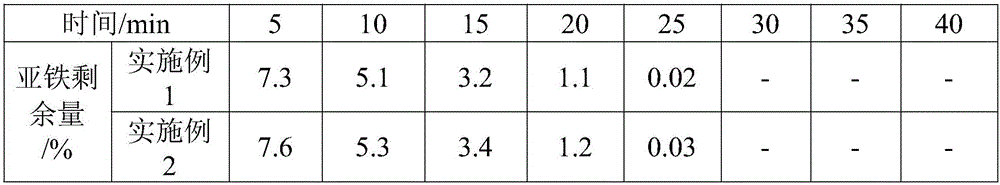

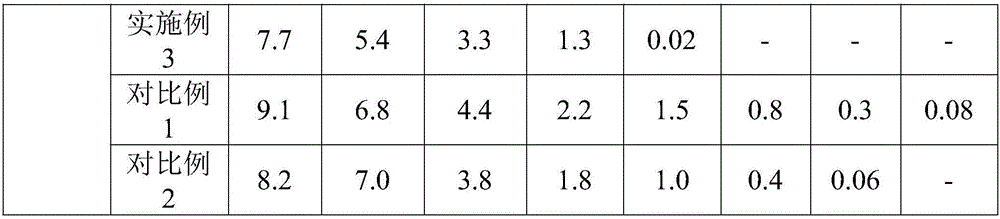

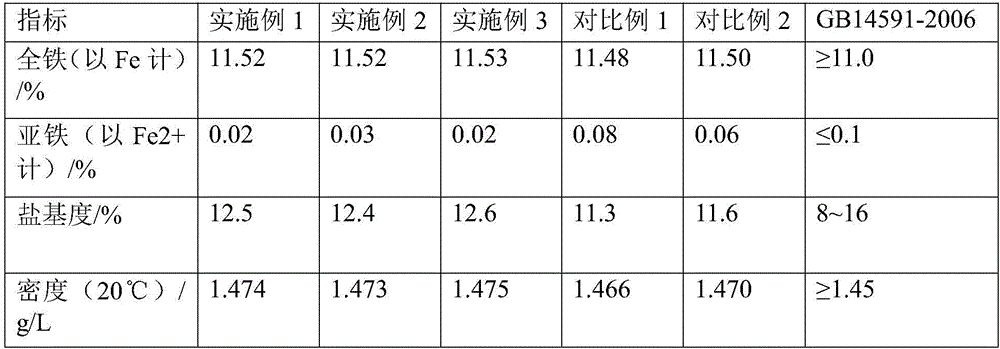

Embodiment 1

[0015] In the experimental kettle of 5L, add 2.4kg pickling waste liquid (wherein ferrous iron is with Fe 2+ The mass fraction is 5%, the acid is H 2 SO 4 The mass fraction is 5%), then add 0.12kg98% sulfuric acid, 1.48kg of titanium dioxide factory by-product ferrous sulfate (ferrous sulfate heptahydrate), add catalyst sodium nitrite working solution and auxiliary catalyst urea, then start stirring or Circulation pump, take a sample PFS-1# every five minutes, and measure the remaining ferrous content. Wherein the catalyst sodium nitrite is configured as a working solution with a mass fraction of 5‰, 3 kg of the working solution is used per ton of finished product, and the amount of the auxiliary catalyst is 2 g per ton of finished product.

Embodiment 2

[0017] In the experimental kettle of 5L, add 2.4kg pickling waste liquid (wherein ferrous iron is with Fe 2+ The mass fraction is 3%, the acid is H 2 SO 4 The mass fraction is 6%), then add 0.12kg98% sulfuric acid, 1.48kg of titanium dioxide factory by-product ferrous sulfate (ferrous sulfate heptahydrate), add catalyst sodium nitrite working solution and auxiliary catalyst urea, then start stirring or Circulation pump, take a sample PFS-1# every five minutes, and measure the remaining ferrous content. Wherein the catalyst sodium nitrite is configured as a working solution with a mass fraction of 2‰, 6 kg of the working solution is used per ton of finished product, and the amount of the auxiliary catalyst is 3 g per ton of finished product.

Embodiment 3

[0019] In the experimental kettle of 5L, add 2.4kg pickling waste liquid (wherein ferrous iron is with Fe 2+ The mass fraction is 8%, the acid is H 2 SO 4 The mass fraction is 2%), then add 0.15kg98% sulfuric acid, 0.6kg of titanium dioxide factory by-product ferrous sulfate (ferrous sulfate heptahydrate), add catalyst sodium nitrite working solution and auxiliary catalyst urea, then start stirring or Circulation pump, take a sample PFS-1# every five minutes, and measure the remaining ferrous content. Wherein the catalyst sodium nitrite is configured as a working solution with a mass fraction of 6‰, 2 kg of the working solution is used per ton of finished product, and the amount of the auxiliary catalyst is 5 g per ton of finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com