Pre-treatment method of water supply plant iron-aluminum mud

A water supply plant and iron-aluminum slime technology, which is applied in water/sludge/sewage treatment, sludge treatment, biological water/sewage treatment, etc., can solve the problem of limiting the resource utilization of iron-aluminum mud, low wastewater treatment standards, and pollution risks Large and other problems, to achieve the effect of easy use, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

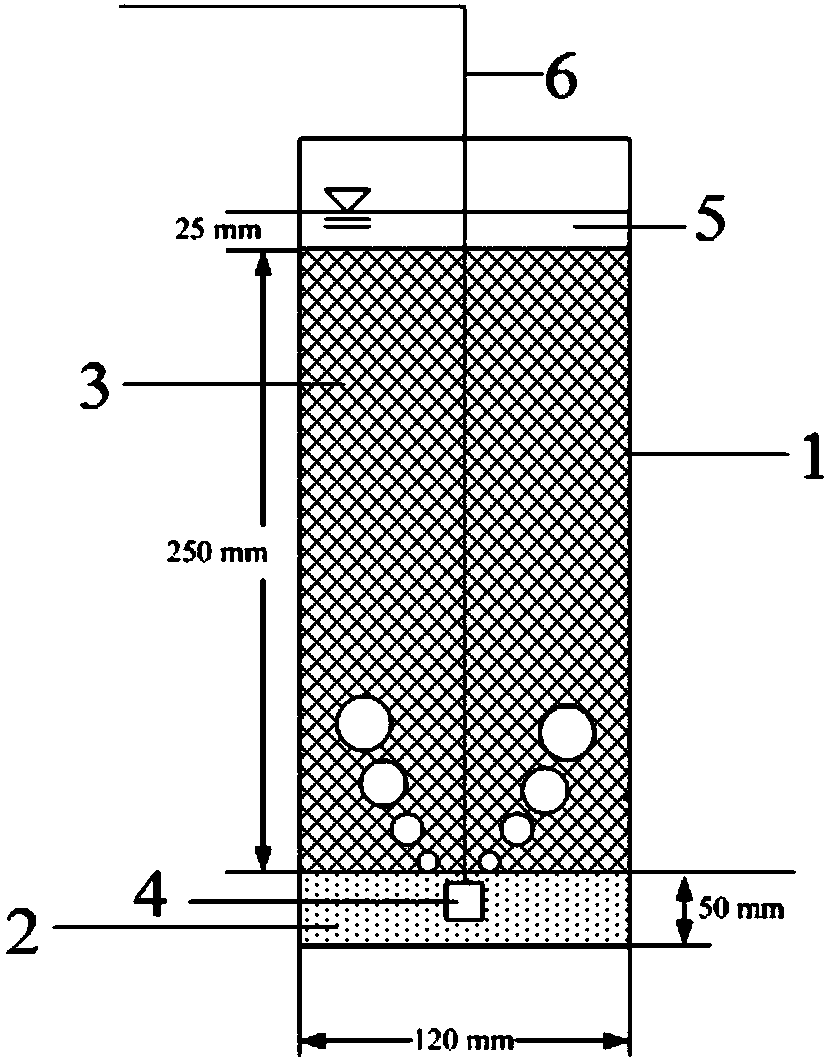

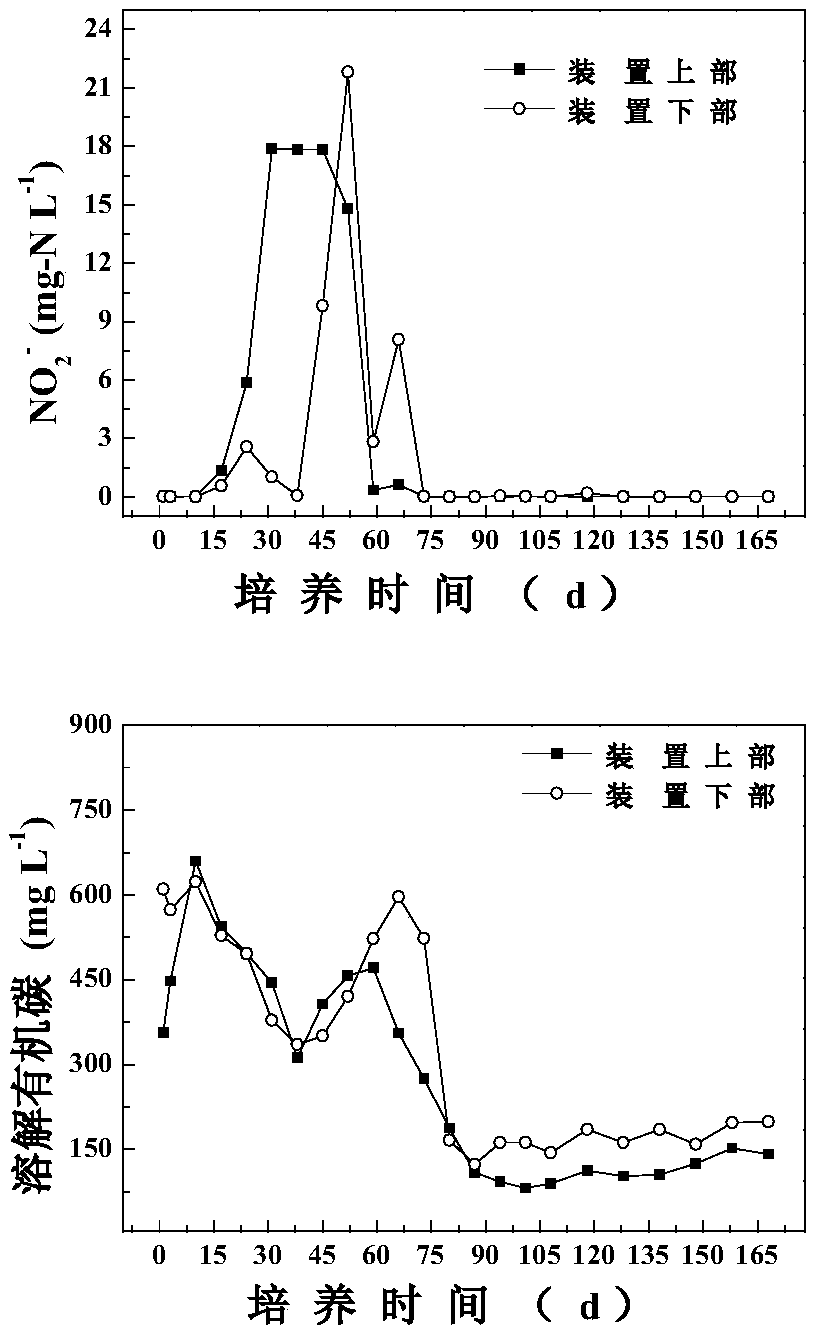

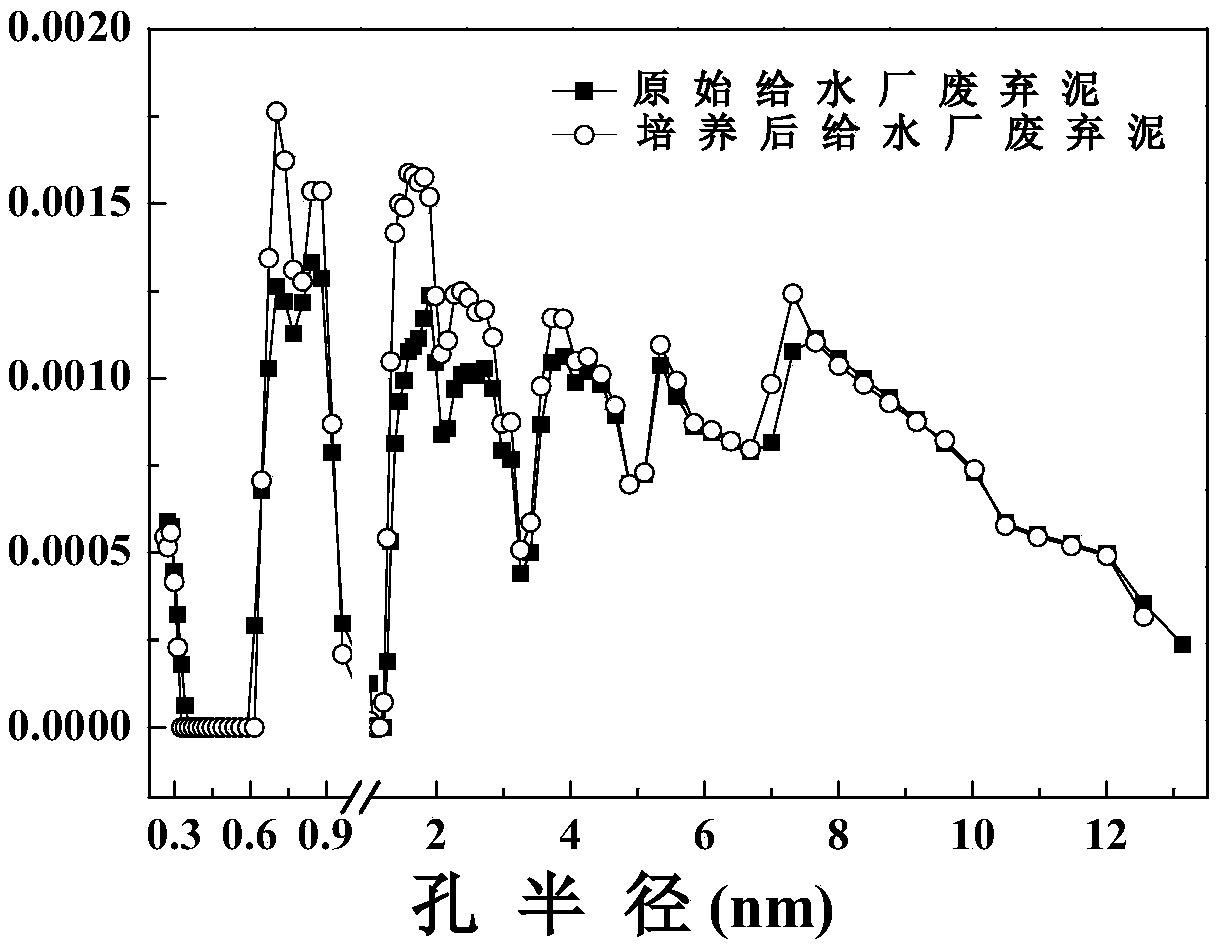

[0042] The iron-aluminum slime cultivation device of the water supply plant is used to inject tap water into the device, and the final liquid level of the tap water is 2.5 cm higher than the iron-aluminum slime of the water supply plant to construct a closed system. Interstitial aeration is implemented in the iron-aluminum slime cultivation device of the water supply plant, and the aeration time ratio is 12 h: 12 h. During the cultivation period, water was replenished according to the liquid level, and samples were taken from the upper and lower parts of the column to measure the changes of nitrogen and organic matter in the aqueous solution. The cultivation time is 6 months; after the cultivation is completed, the iron-aluminum mud of the water supply plant in the device is fully mixed, and then either air-dried or directly used for performance analysis.

[0043] The change characteristics of nitrogen and organic carbon in the water body during the cultivation period are show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com