Process for recycling and manufacturing copper granule from waste and old electric wire and cable

A technology of waste wire and process method, applied in the field of non-ferrous metal processing, can solve the problems of poor cable breaking and separation effect, unable to meet the requirements of customer products, unable to obtain high-purity copper rice grains, etc., to achieve good separation effect and cost. Low, low emission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

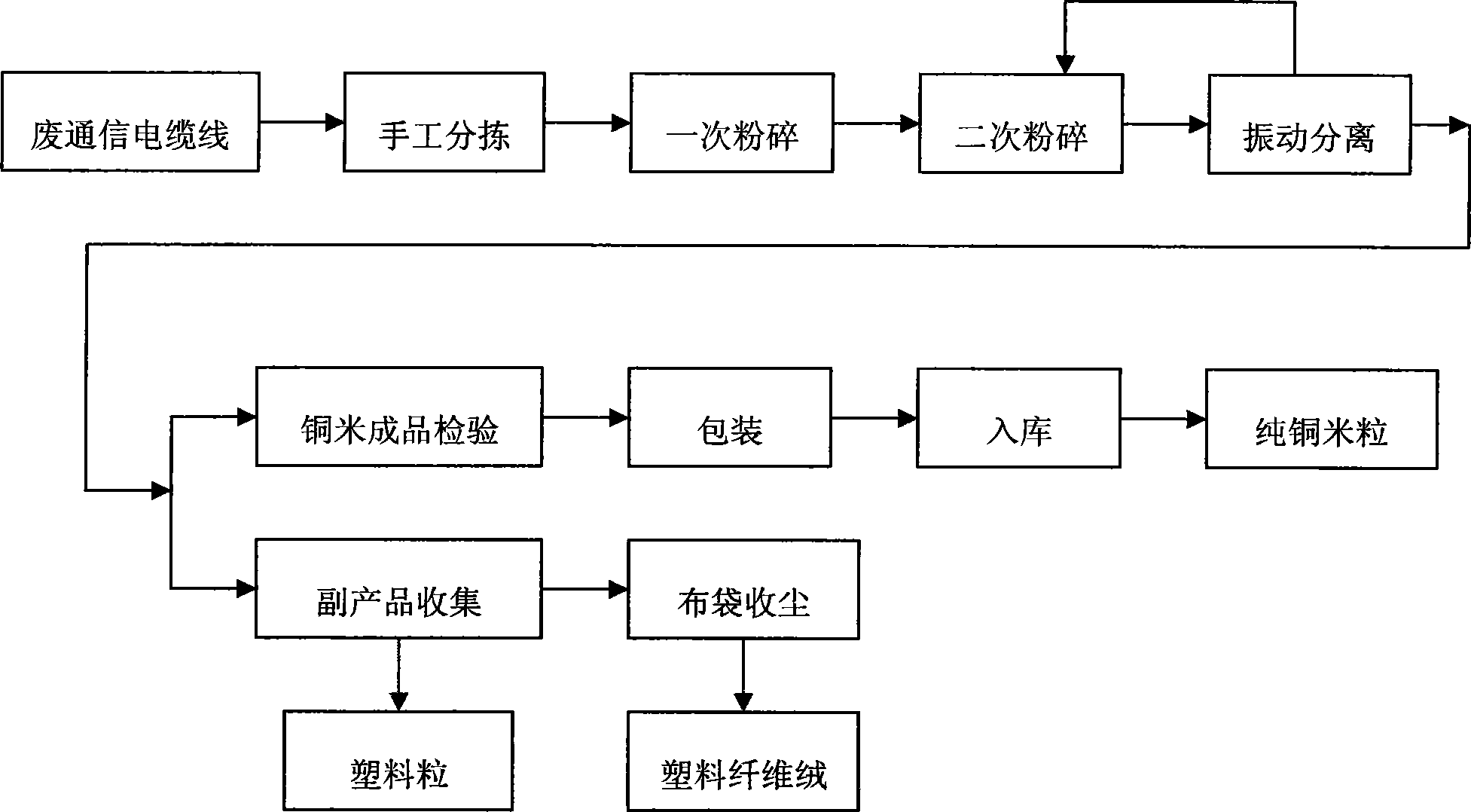

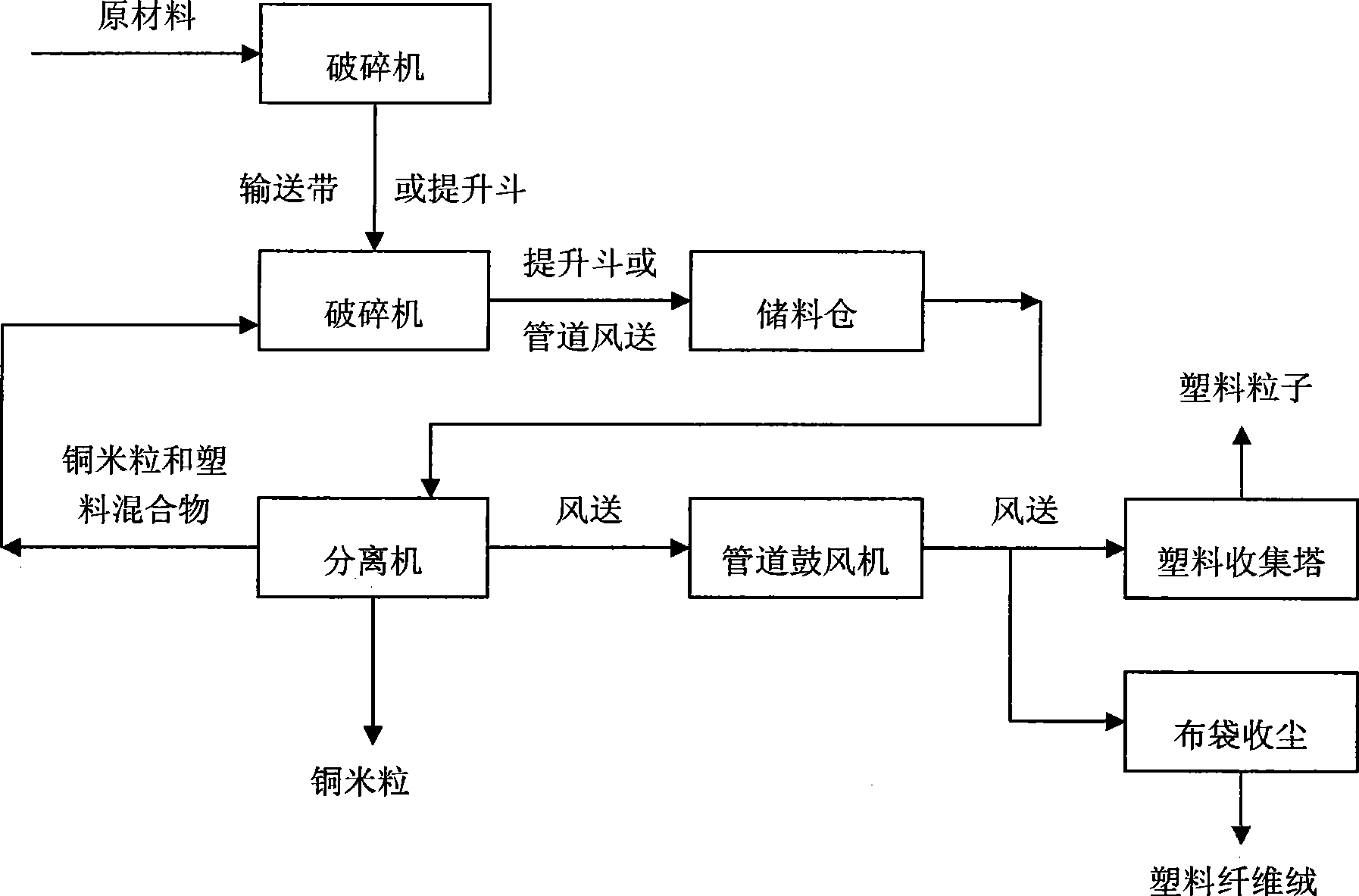

[0058] Process flow and equipment flow chart of the present invention are as figure 1 , figure 2 Shown:

[0059] 1. Prepare before operation, turn on the power to check whether the voltage and current are normal, start the equipment and observe whether the equipment is running normally.

[0060] Check the pre-sorted raw materials, there should be no obvious sundries.

[0061] Second, sorting

[0062] After carefully sorting the raw materials on the machine, the sundries such as tinned wires, brass sheets, and connectors that are easily confused must be detected one by one, or cut off with scissors, and strictly separated from the machine line.

[0063] Three, on the machine

[0064] Start the belt conveyor until it runs normally.

[0065] Evenly thread the wires and cables onto the conveyor belt.

[0066] The feeding amount shall not exceed the maximum load of the belt conveyor, and it is better to control the feeding amount at 1500Kg / hour.

[0067] The upper thread c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com