Highway roadbase stabilized soil and production method thereof

A production method and soil stabilization technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., to achieve the effect of advanced technology, sustainable economic development, and recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 A kind of stabilized soil for road base, comprising the following components in mass percentage: 75% of graded gravel produced in the construction waste crushing process, 2.5% of petroleum coke residue, 0.5% of white mud, 16% of fly ash, lime 2%, water 4%.

Embodiment 2

[0017] Embodiment 2 A kind of stabilized soil for road base, comprising the following components in mass percentage: 78% of graded gravel produced in the construction waste crushing process, 2.5% of petroleum coke residue, 0.5% of white mud, 12% of fly ash, lime 3%, water 4%.

[0018] Embodiment 1 A kind of stabilized soil for road base, comprising the following components in mass percentage: 72% of graded gravel produced in the construction waste crushing process, 5% of petroleum coke residue, 1% of white mud, 13% of fly ash, lime 4%, water 5%.

Embodiment 4

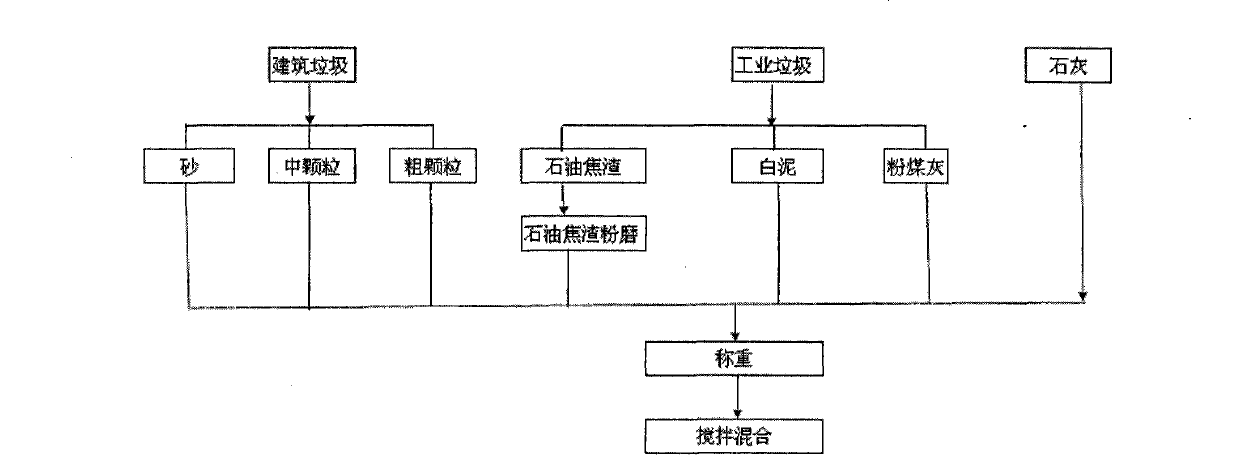

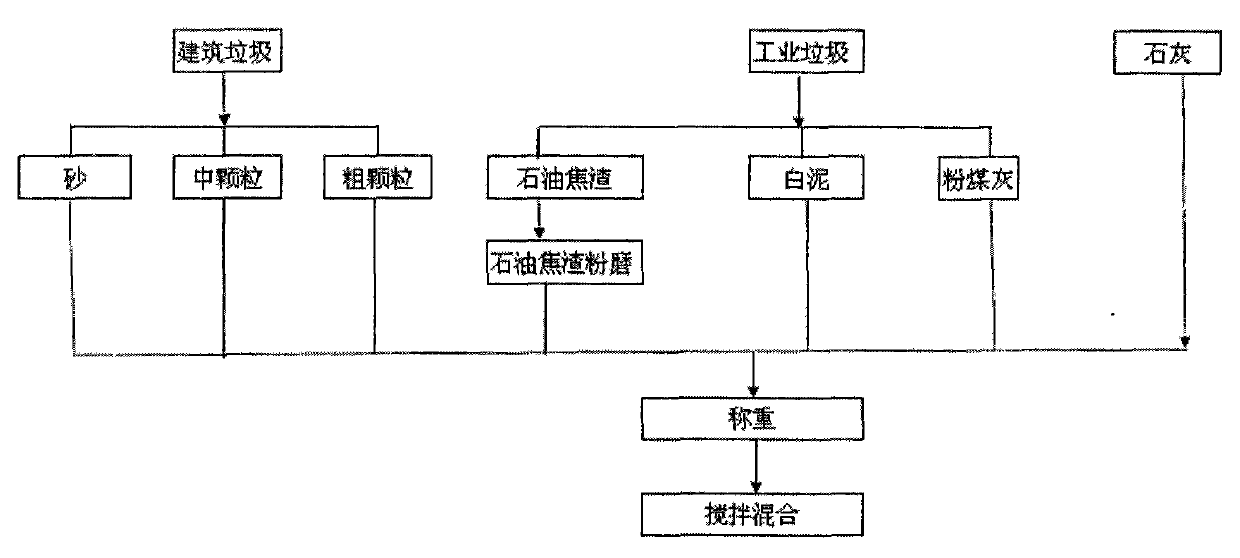

[0019] Embodiment 4 A kind of production method of stabilizing soil for road base, adopts the distribution ratio of each component of stabilizing soil for road base in Example 1, according to figure 1 Shown technological process, concrete steps are as follows:

[0020] 1. Crushing and grading adjustment: After sorting, crushing, and screening construction waste, gravel, sand, and sandy soil of different sizes are obtained and stored separately; through the grading adjustment machine, the amount of particles of various sizes is adjusted, so that The maximum particle size of construction waste recycled stone particles should not exceed 31.5mm, and the particle content of particles with a particle size less than 0.075mm should be close to 0;

[0021] 2. Grinding: Put the petroleum coke residue in the Raymond machine for grinding, so that its specific surface area reaches 380m 2 / kg.

[0022] 3. Weighing, measuring and mixing: Place the processed construction waste graded gravel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com