Method for modifying asphalt by using pyrolytic oil heavy fraction of waste printed circuit board

A technology of waste circuit boards and printed circuit boards, which is applied in the field of resource utilization of electronic waste, can solve problems such as high price, increased cost of asphalt usage, and increased usage of various road materials, so as to improve performance and feasibility The effect of increasing and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

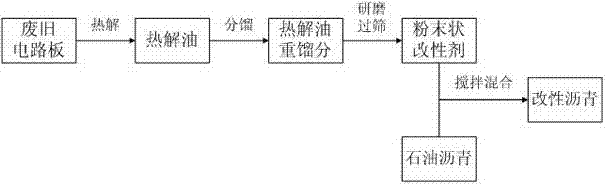

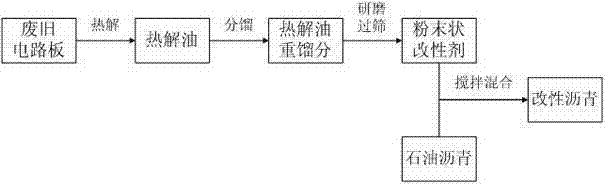

Method used

Image

Examples

Embodiment 1

[0023] (1) Put the circuit board with electronic components removed into a pyrolysis furnace, heat it to 450°C, keep it for 1 hour until it is completely pyrolyzed, and collect the pyrolysis oil produced after pyrolysis;

[0024] (2) Fractionate the circuit board pyrolysis oil at atmospheric pressure, and retain the high-temperature heavy fraction of the pyrolysis oil above 340°C. If the equipment conditions permit, the fractionation temperature of the heavy fraction can be increased to 360°C to reduce the volatile components in the heavy fraction;

[0025] (3) Grind and sieve the high-temperature heavy fraction of circuit board pyrolysis oil that is solid at room temperature, and select the heavy fraction powder greater than 200 meshes as an asphalt admixture;

[0026] (4) Add 2 parts by weight of the heavy fraction of circuit board pyrolysis oil as a modifier to 98 parts by weight of hot petroleum asphalt at 130-160°C, heat and stir for 0.5 hours to obtain modified asphalt ....

Embodiment 2

[0029] With embodiment 1, difference is that in the step (1), the heating temperature of the pyrolysis furnace is 500 DEG C, and the holding time is 1.5 hours; in the step (4), the circuit board pyrolysis oil heavy fraction of 5 parts by weight is used as The modifying agent is added to 95 parts by weight of the hot petroleum asphalt at 130-160 DEG C, and the modified asphalt is obtained by stirring for 0.75 hours while maintaining the temperature.

[0030] The softening point of the modified asphalt is 53.1°C, the penetration is 7.24mm, the ductility at 15°C is 42.7cm, the Marshall stability is 19.4kN when the asphalt ratio is 4.5, and the dynamic stability of the rutting test is 10161.29.

Embodiment 3

[0032] With embodiment 1, difference is that in the step (1), the heating temperature of the pyrolysis furnace is 550 ℃, and the holding time is 2 hours; in the step (4), the circuit board pyrolysis oil heavy fraction that is 10 parts by weight is used as The modifying agent is added to 90 parts by weight of the hot petroleum asphalt at 130-160 DEG C, and the modified asphalt is obtained by stirring for 1 hour at heat preservation.

[0033] The softening point of the modified asphalt is 54.7°C, the penetration is 4.48mm, the ductility at 15°C is 37.5cm, the Marshall stability is 18.7kN when the asphalt ratio is 4.5, and the dynamic stability of the rutting test is 12504.72.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com