Comprehensive recovery and utilization method of manganese tetraoxide production wastewater

A technology for manganese tetroxide and waste water production, which is applied in chemical instruments and methods, improvement of process efficiency, multi-stage water/sewage treatment, etc. secondary pollution and other problems, to achieve the effects of low equipment investment and wastewater treatment costs, good economic benefits, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

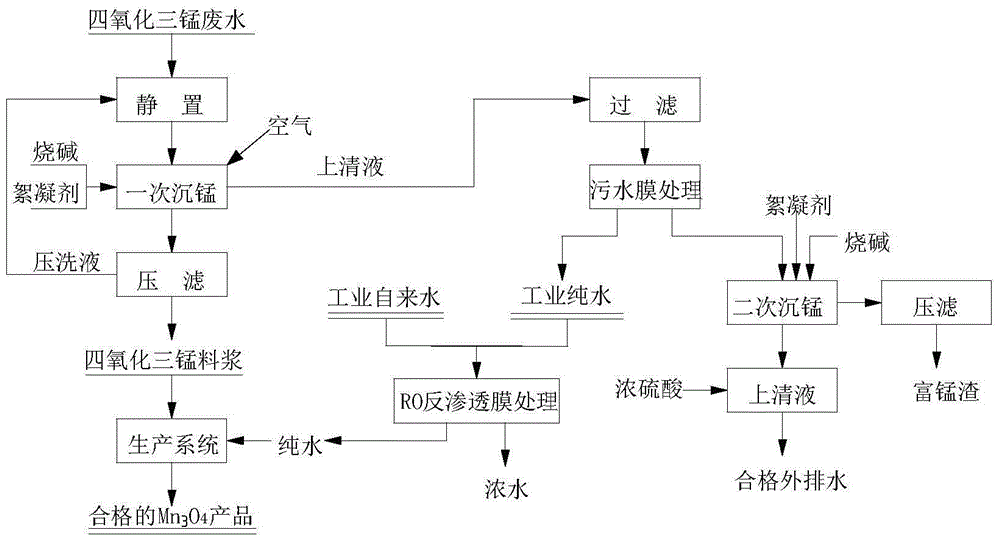

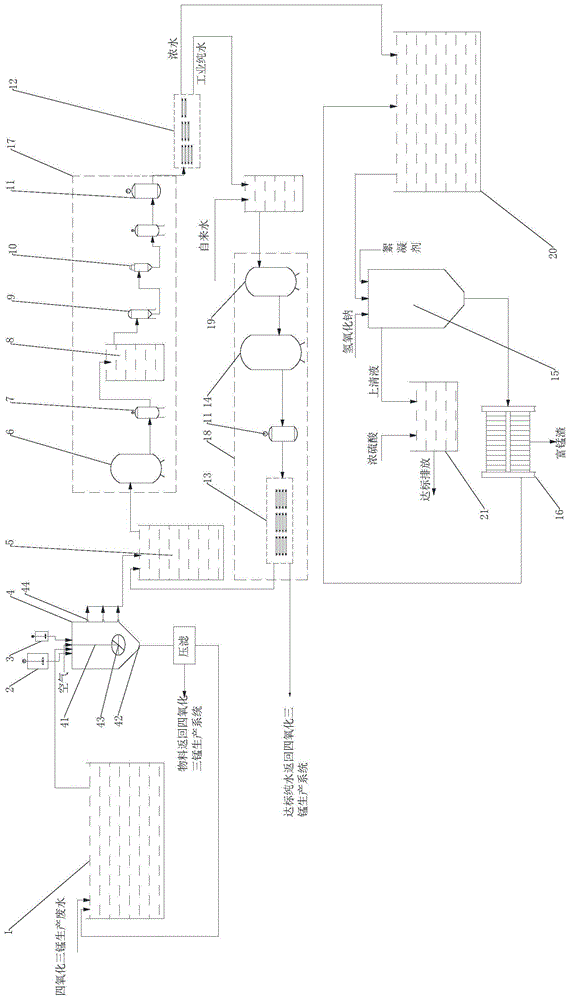

[0038] a kind of like figure 1 , figure 2 The comprehensive recycling method of the manganese tetraoxide production wastewater of the present invention shown, the manganese tetraoxide production wastewater in the present embodiment comprises the washing overflow water and the trimanganese tetraoxide production workshop in the production process of a certain manganese tetraoxide plant Cleaning equipment water, after testing its Mn 2+ The content reaches 0.7g / L, and the pH value is 6-7; the comprehensive recycling method specifically includes the following steps:

[0039] 1. the manganese manganese tetraoxide production waste water in the present embodiment is pumped into 30m after static pond 1 is collected and left standstill 3 In the sedimentation treatment tank 4, sodium hydroxide solution (ammonia can also be added) and flocculant (control flocculant polyacrylamide The consumption is about 0.001% of the waste water treatment capacity), by monitoring the pH value of the ...

Embodiment 2

[0042] a kind of like figure 1 , figure 2 The comprehensive recycling method of manganese tetraoxide production waste water of the present invention shown, the manganese manganese tetraoxide production waste water in the present embodiment comprises the effluent mother liquor in the production process of a certain manganese tetraoxide plant production process and waste water such as running, emitting, dripping and leaking, After testing its Mn 2+ The content reaches 2.68g / L, and the pH value is 5.5-7; the comprehensive recycling method specifically includes the following steps:

[0043] 1. the manganese manganese tetraoxide production waste water in the present embodiment is pumped into 30m after static pond 1 is collected and left standstill 3 In the sedimentation treatment tank 4, sodium hydroxide solution (ammonia can also be added) and flocculant (control flocculant polyacrylamide The consumption is about 0.001% of the waste water treatment capacity), by monitoring the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com