High-quality organic fertilizer prepared by straw and livestock and poultry night soil and method thereof

A technology of livestock and poultry manure and organic fertilizer, applied in the direction of organic fertilizer, organic fertilizer preparation, phosphate fertilizer, etc., can solve the problems of damage to the roots of crops, slow natural decomposition, slow decomposition, etc. Effects of soil structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

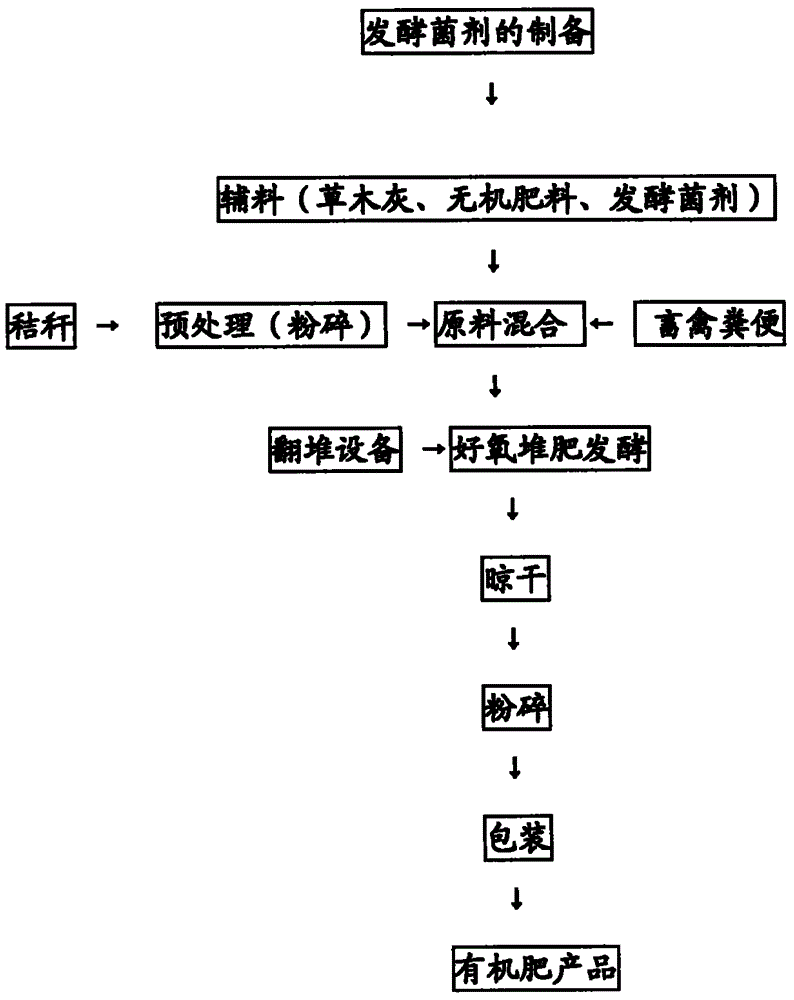

Method used

Image

Examples

Embodiment 1

[0021] Take 250kg of sun-dried plant straw, crush it to a particle size of 10mm, mix it with 550kg of livestock and poultry manure, 200kg of plant ash, 5kg of inorganic fertilizer (urea and half of superphosphate), and 1kg of fermentation agent, and pile it up to a bottom width of 160cm. Pile a semicircular pile with a height of 80 cm, measure the temperature of the pile regularly, turn the pile and stir when the temperature reaches 50-60°C, and complete the decomposition in 2-3 weeks to obtain high-quality organic fertilizer prepared from straw and manure.

Embodiment 2

[0023] Take 350kg of sun-dried plant straw, crush it to a particle size of 5mm, mix it with 550kg of livestock and poultry manure, 100kg of plant ash, 10kg of inorganic fertilizer (urea and half of superphosphate), and 2kg of fermentation agent, and pile it up to a bottom width of 170cm. Pile a semi-circular pile with a height of 85 cm, measure the temperature of the pile regularly, turn the pile and stir when the temperature reaches 50-60°C, and complete the decomposing in 2-3 weeks, that is, high-quality organic fertilizer prepared from straw and manure.

Embodiment 3

[0025] Take 300kg of sun-dried plant straw, crush it to a particle size of 7.5mm, mix it with 550kg of livestock and poultry manure, 150kg of plant ash, 7.5kg of inorganic fertilizer (urea and half of superphosphate), and 1.5kg of fermentation agent, and pile it into the bottom A semi-circular pile with a width of 180cm and a height of 90cm is used to regularly measure the temperature of the pile. When the temperature reaches 50-60°C, the pile is turned and stirred. After 2-3 weeks, the compost is completed and the high-quality organic fertilizer prepared from straw and manure is obtained.

[0026] Test items unit of measurement Embodiment 1 detection result Embodiment 2 detection result Embodiment 3 detection result Organic content % 48.2 46.7 47.5 Total nutrient (nitrogen, phosphorus, potassium) content % 6.7 7.6 7.3 moisture % 28.7 26.3 27.5 Acidity (PH value) 6.8 7.5 7.2

[0027] National standard for organic ferti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com