Novel feed for cattle and sheep and preparation method of novel feed

A cattle and sheep, feed technology, applied in animal feed, animal feed, applications, etc., can solve the problems of not being well utilized, not being able to realize value, and being thrown away in vain, so as to achieve low cost of raw materials, strong social value, and prevention of diarrhea Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

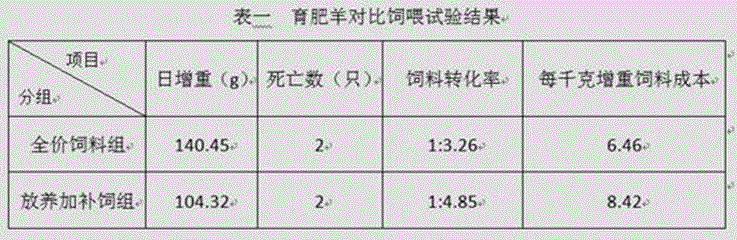

Examples

Embodiment 1

[0020] Preparation method of fattening sheep feed:

[0021] Feed formula for fattening sheep:

[0022] 51 parts of corn straw powder; 4 parts of corn flour; 2 parts of soybean meal, 15 parts of sprayed corn husks; 13 parts of corn gluten powder; 8 parts of saccharification liquid filter residue;

[0023] The specific preparation method is as follows:

[0024] (1) Use a hammer mill to crush corn stalks with a moisture content of no more than 15% in the natural air to form corn stalk powder with a length of 15 mm and a width of 1.5 mm;

[0025] (2) Spray the by-product corn syrup on the corn husks, and dry them to obtain the sprayed corn husks;

[0026] (3) Put 51 parts of corn stalk powder, 15 parts of sprayed corn husk, 13 parts of corn gluten powder, 8 parts of saccharification liquid filter residue; 5 parts of yeast cells; 2 parts of compound premix for cattle and sheep into the feed mixer to fully Mix evenly, take samples, and calculate the nutrient content of the mixtur...

Embodiment 2

[0031] Pre-pregnancy ewe feed preparation method:

[0032] Pre-pregnancy ewe feed formula:

[0033] 75 parts of corn straw powder; 1.5 parts of corn flour; 1 part of soybean meal, 9 parts of sprayed corn husks; 6 parts of corn gluten powder; 3 parts of saccharification liquid filter residue;

[0034] The specific preparation method is as follows:

[0035] (1) Use a hammer mill to pulverize corn stalks with a moisture content of no more than 15% in the natural air to form corn stalk powder with a length of 18 mm and a width of 2 mm;

[0036] (2) Spray the by-product corn syrup on the corn husks, and dry them to obtain the sprayed corn husks;

[0037] (3) Put 75 parts of corn stalk powder, 9 parts of sprayed corn husks, 6 parts of corn gluten powder, 3 parts of saccharification liquid filter residue; 3 parts of yeast cells; 1.5 parts of compound premix for cattle and sheep into the feed mixer to fully Mix evenly, take samples, and calculate the nutrient content of the mixture...

Embodiment 3

[0042] Feed preparation method for late pregnancy ewes:

[0043] Feed formula for late pregnancy ewes:

[0044] 58.5 parts of corn straw powder; 2 parts of corn flour; 1.5 parts of soybean meal, 14 parts of sprayed corn husks; 10 parts of corn gluten powder; 7 parts of saccharification liquid filter residue;

[0045] The specific preparation method is as follows:

[0046] (1) Use a hammer mill to pulverize corn stalks with a moisture content of no more than 15% and use a hammer mill to make corn stalk powder with a length of 17 mm and a width of 2.5 mm. The corn stalk powder should not be too fine, otherwise it is not conducive to the rumination of cattle and sheep;

[0047] (2) Spray the by-product corn syrup on the corn husks, and dry them to obtain the sprayed corn husks;

[0048] (3) Put 58.5 parts of corn stalk powder, 14 parts of sprayed corn husks, 10 parts of corn gluten powder, 7 parts of saccharification liquid filter residue; 5 parts of yeast cells; 2 parts of com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com