Strong-hydrophobic porous carbon nanofiber and preparation method thereof

A nanofiber and porous carbon technology, applied in the field of porous carbon fibers, can solve the problems of low specific surface area and low carbonization yield of PAN fibers, and achieve the effects of low surface oxygen content, reduced surface oxygen content, and improved hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of strong hydrophobicity porous carbon nanofiber utilizes electrospinning technology, comprises the following steps:

[0025] Step 1: Add thermosetting phenolic resin and polyvinyl butyral to n-propanol and N,N -in a mixed solvent of dimethylacetamide (N,N-dimethylacetamide accounts for 10wt%), and stir until completely dissolved;

[0026] Step 2, under the condition that the spinning voltage is 24kV, the feeding speed is 1mL / h, and the working distance is 22cm, the above solution is spun into nanofibers;

[0027] The third step is to heat the above fiber from room temperature to 180° C. for 1.5 hours, and then carbonize it under an argon atmosphere at 800° C. to obtain highly hydrophobic porous carbon nanofibers.

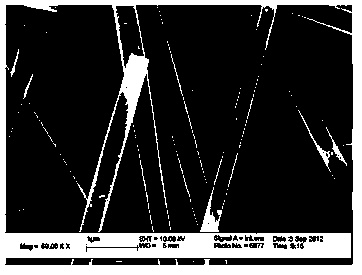

[0028] The microstructure of the obtained carbon nanofibers is as follows: figure 1 As shown, the diameter range is 310-520nm, and the specific surface area is 734m 2 / g, the micropore volume is 0.24cm 3 / g, and the water contact a...

Embodiment 2

[0030] The preparation method of strong hydrophobicity porous carbon nanofiber utilizes electrospinning technology, comprises the following steps:

[0031] Step 1, according to the mass ratio of thermosetting phenolic resin (commercially available, molecular weight 2300) and polyvinylpyrrolidone is 1:0.024, add thermosetting phenolic resin and polyvinylpyrrolidone to methanol and N,N-dimethylformaldehyde amide mixed solvent (N,N-dimethylformamide accounted for 40wt%), and stirred until completely dissolved;

[0032] Step 2, under the condition that the spinning voltage is 23kV, the feeding speed is 0.9mL / h, and the working distance is 25cm, the above solution is spun into nanofibers;

[0033] Step 3, the above-mentioned fiber is heated stepwise from room temperature to 180° C. for curing for 3 hours, and then carbonized at 950° C. under a nitrogen atmosphere to obtain highly hydrophobic porous carbon nanofibers.

[0034] Among them, in the process of stepwise heating method, ...

Embodiment 3

[0037] The preparation method of strong hydrophobicity porous carbon fiber, utilizes electrospinning technique, comprises the following steps:

[0038] Step 1, according to the mass ratio of thermosetting phenolic resin (commercially available, molecular weight 600) and polyvinyl alcohol is 1:0.020, add thermosetting phenolic resin and polyvinyl alcohol to ethanol and N,N-dimethylacetamide Mixed solvent (N,N-dimethylacetamide accounted for 30wt%), and stirred until completely dissolved;

[0039] Step 2, under the condition that the spinning voltage is 23kV, the feeding speed is 1mL / h, and the working distance is 24cm, the above solution is spun into nanofibers;

[0040] Step 3: Stepwise raising the temperature of the above fibers from room temperature to 180° C. for 2 hours to cure, and then carbonizing at 850° C. under a nitrogen atmosphere to obtain highly hydrophobic porous carbon nanofibers.

[0041] Among them, in the process of stepwise heating method, the heating rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com