Bean product coagulating agent and application thereof

A technology of bean products and coagulants, which is applied in the field of making bean products and coagulants for bean products, can solve problems that need to be improved, and achieve the effects of high yield, good water holding capacity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

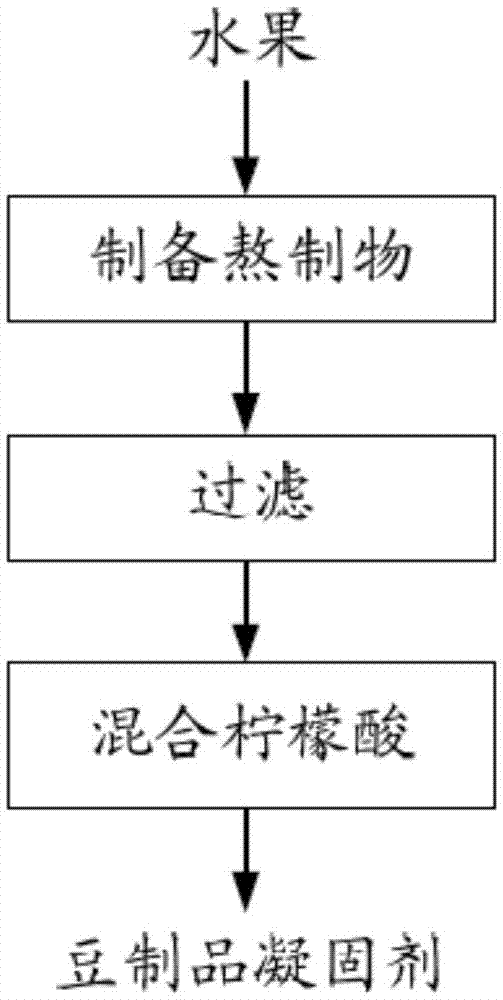

[0044] Embodiment 1: preparation of bean product coagulant

[0045] 1. Materials:

[0046] Fruits (red berries, sea buckthorn, oranges and lemons);

[0047] citric acid.

[0048] 2. Experimental steps:

[0049] 2.1 Preparation of stew

[0050] Screening insect-free, fresh fruits, wherein the fruits include 12 parts by weight of red fruit, 9 parts by weight of seabuckthorn, 8 parts by weight of orange and 15 parts by weight of lemon. Then, 44 parts by weight of the above-screened fruits were cut into pieces and mixed with 410 parts by weight of water, and boiled at a high temperature at 95° C.-100° C. to obtain a boiled product.

[0051] 2.2 Filtration

[0052] Filter the stewed product obtained above to remove the filter residue, so as to obtain a filtrate.

[0053] 2.3 Mixed citric acid

[0054] The filtrate obtained above was mixed and coagulated with 3 parts by weight of citric acid to obtain a bean product coagulant for subsequent use.

Embodiment 2

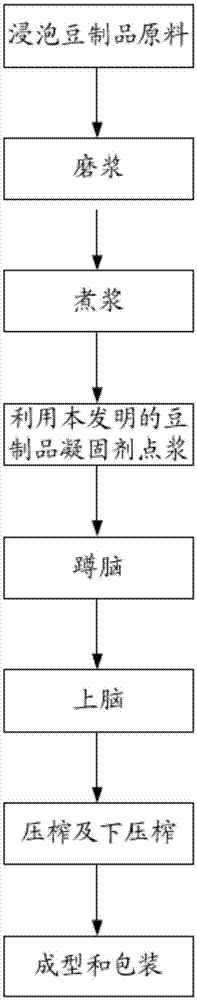

[0078] Embodiment 2: tofu preparation

[0079] Utilize respectively the soy product coagulant of the present invention prepared in Example 1 and the soy product coagulant prepared in Comparative Examples 1-5, prepare tofu according to the following steps, so as to compare the use effect of several soy product coagulants:

[0080] 1. Materials and equipment:

[0081] soy;

[0082] Water with a pH of 6.5 to 7.5;

[0083] Clear water;

[0084] The bean product coagulant prepared by embodiment 1, comparative examples 1-5;

[0085] Bean trough;

[0086] Suction machine;

[0087] drain screen;

[0088] Slurry self-separation refiner;

[0089] Centrifugal pump;

[0090] cooking pulp tank;

[0091] point slurry tank;

[0092] bean cloth;

[0093] tofu forming machine;

[0094] workbench;

[0095] Sealer.

[0096] 2. Experimental steps:

[0097] 2.1 Soak soybeans

[0098] Screen and remove impurity stones, dead beans, lint, etc. in soybeans. Then, at a room temperature...

Embodiment 3

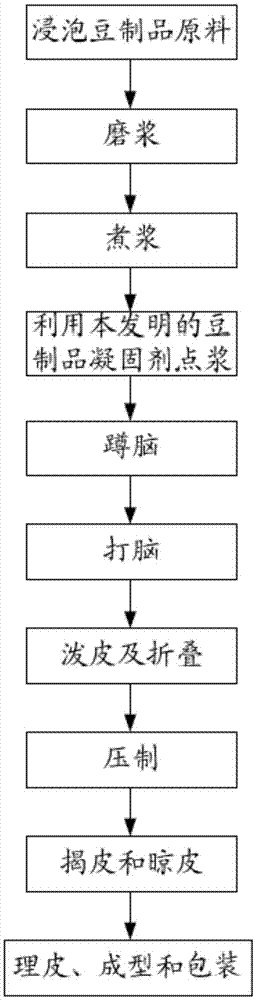

[0119] Embodiment 3: preparation of dried tofu

[0120] Utilize respectively the soy product coagulant of the present invention prepared in Example 1 and the soy product coagulant prepared in Comparative Examples 1-5, prepare dried tofu according to the following steps, so as to compare the use effect of several soy product coagulants:

[0121] 1. Materials and equipment:

[0122] soy;

[0123] Water with a pH of 6.5 to 7.5;

[0124] Clear water;

[0125] The bean product coagulant prepared by embodiment 1, comparative examples 1-5;

[0126] Bean trough;

[0127] Suction machine;

[0128] drain screen;

[0129] Slurry self-separation refiner;

[0130] Centrifugal pump;

[0131] cooking pulp tank;

[0132] point slurry tank;

[0133] bean cloth;

[0134] Dried tofu pouring plate;

[0135] Hydraulic Press;

[0136] workbench;

[0137] Sealer.

[0138] 2. Experimental steps:

[0139] 2.1 Soak soybeans

[0140] Screen and remove impurity stones, dead beans, lint, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com