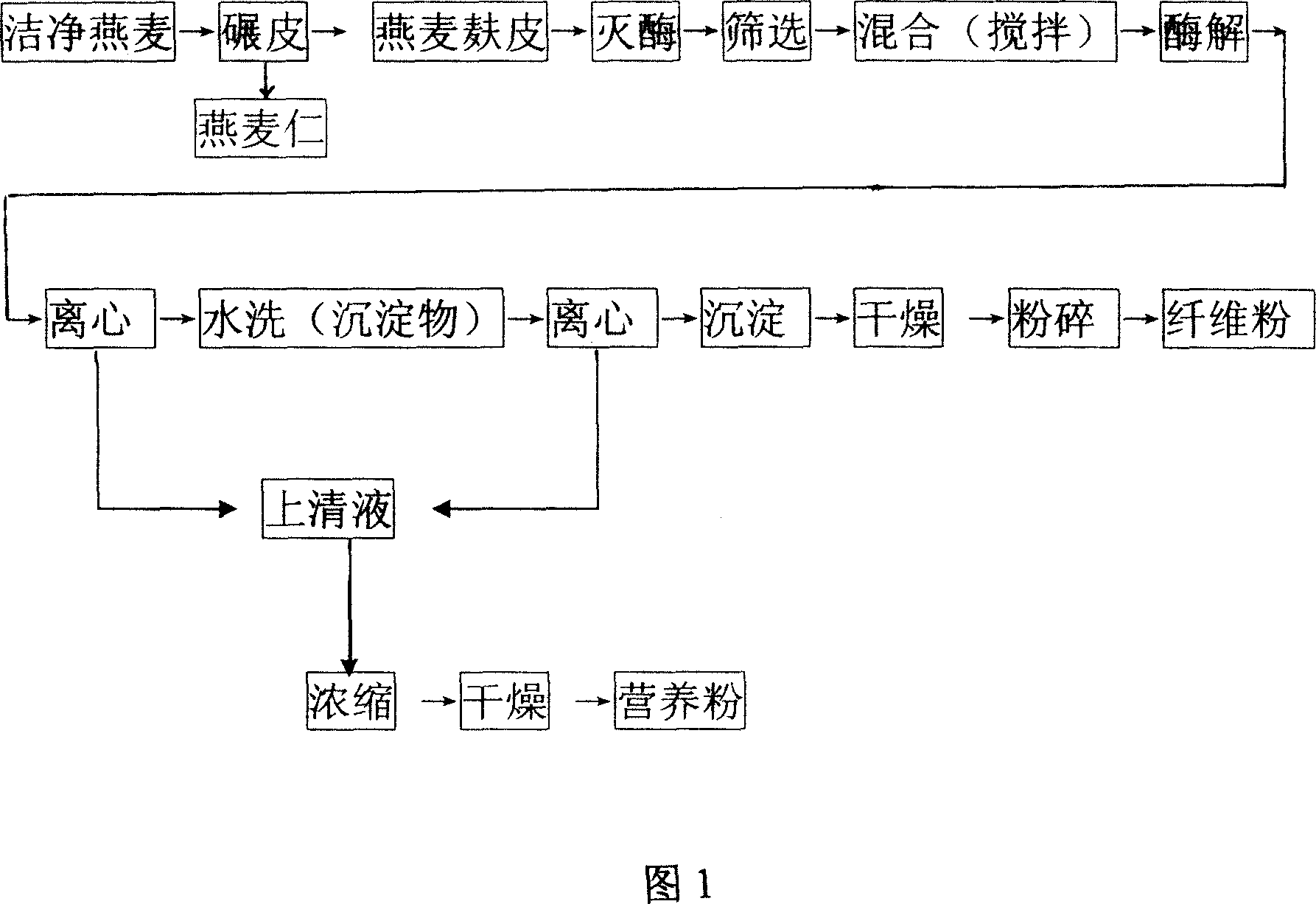

Technological process of producing oat diet fiber and nutritious powder with oat bran

A technology of oat dietary fiber and oat bran, which is applied in the field of oat dietary fiber produced from nutrient powder and oat bran, can solve the problems that oats cannot be effectively comprehensively developed and utilized, and achieve the reduction of water consumption and sewage treatment, reduction of crushing, The effect of improving yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Oat bran is obtained by grinding oats, and the rate of grinding oats is controlled at 13%. In the present invention, an emery roller rice mill is used to grind down the oat bran.

[0027] 2) Oat bran adopts microwave to kill enzyme; Oat bran among the present invention adopts microwave to kill enzyme, inactivates the activity of enzyme, to prevent the rancidity of oat bran, prolong the shelf-life of oat bran, the power of microwave equipment is 60KW, and the rotating speed It is 2.0-2.5m / min, and the thickness of the material layer is 10-20mm. Sieve the oat bran after deactivating the enzyme (the diameter of the sieve hole is 1.2mm).

[0028] 3) enzymatic hydrolysis of the oat bran after deactivating the enzyme, adding water and mixing in a weight ratio of 1:6, adjusting the pH value to 6.0 with hydrochloric acid and sodium hydroxide, adding α-amylase and glucoamylase for treatment, the total The added amount is 1.5% of the raw material oat bran, and the ratio of α...

Embodiment 2

[0034] 1) Oat bran is obtained by grinding oats, and the rate of grinding oats is controlled within the range of 18%. In the present invention, an emery roller rice mill is used to grind down the oat bran.

[0035] 2) Oat bran adopts microwave to kill enzyme; Oat bran among the present invention adopts microwave to kill enzyme, inactivates the activity of enzyme, to prevent the rancidity of oat bran, prolong the shelf-life of oat bran, the power of microwave equipment is 60KW, and the rotating speed It is 2.0-2.5m / min, and the thickness of the material layer is 10-20mm. Sieve the oat bran after deactivating the enzyme (the diameter of the sieve hole is 1.2 mm).

[0036] 3) enzymatic hydrolysis of the oat bran after deactivation, adding water and mixing in a weight ratio of 1:8, adjusting the pH value to 6.5 with hydrochloric acid and sodium hydroxide, adding α-amylase and glucoamylase for treatment, the total The added amount is 2.5% of the raw material oat bran, and the rat...

Embodiment 3

[0042] 1) Oat bran is obtained by milling oats, and the rate of oat milling is controlled within the range of 15-16%. In the present invention, an emery roller rice mill is used to grind down the oat bran.

[0043] 2) the oat bran adopts microwave to inactivate enzyme; oat bran in the present invention adopts microwave to inactivate enzyme, the activity of deactivation enzyme, to prevent the rancidity of oat bran, prolong the shelf-life of oat bran, the power of microwave equipment is 60KW, and the rotating speed It is 2.0-2.5m / min, and the thickness of the material layer is 10-20mm. Sieve the oat bran after deactivating the enzyme (the diameter of the sieve hole is 1.2mm).

[0044] 3) enzymatic hydrolysis of oat bran after deactivation, adding water and mixing in a weight ratio of 1:7, adjusting the pH value to 6.3 with hydrochloric acid and sodium hydroxide, adding α-amylase and glucoamylase for treatment, the total The added amount is 2% of the raw material oat bran, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com