Infinite-arbitrary-length bamboo chip integrated material and manufacturing method thereof

A manufacturing method and technology of laminated materials, which are applied in the fields of manufacturing tools, chemical instruments and methods, pretreatment of molding materials, etc. The effect of the joint butt joint is not obvious, avoids the bright color difference, and expands the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] In this embodiment, the surface of the bamboo unit 3 is provided with notches; the notches are point-shaped notches, the depth of the notches is 0.1-1 mm, the diameter of the notches is 0.2-2 mm, and the density of the notches is 1 ~3 dots / cm 2 .

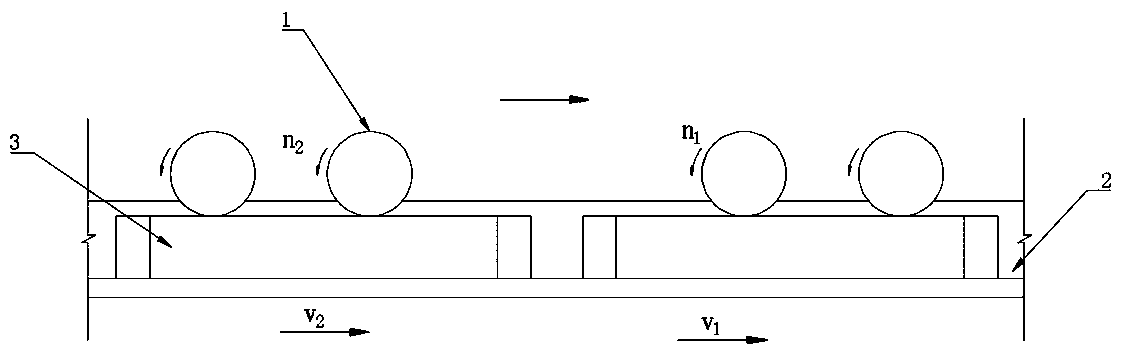

[0060] Such as figure 2 As shown, the manufacturing method of a kind of unlimited arbitrary long bamboo sheet glulam of the present embodiment comprises the following steps:

[0061] (1) Preparation of the bamboo slice unit 3: process the bamboo through processes such as sawing, splitting, preliminary milling, drying and fine milling, and process it into thin rectangular parallelepiped bamboo slices with a thickness of 8 mm and a width of 20 mm. The length is 2m, and the bamboo slices are dried to a moisture content of 10%, and the bamboo slice unit 3 is obtained.

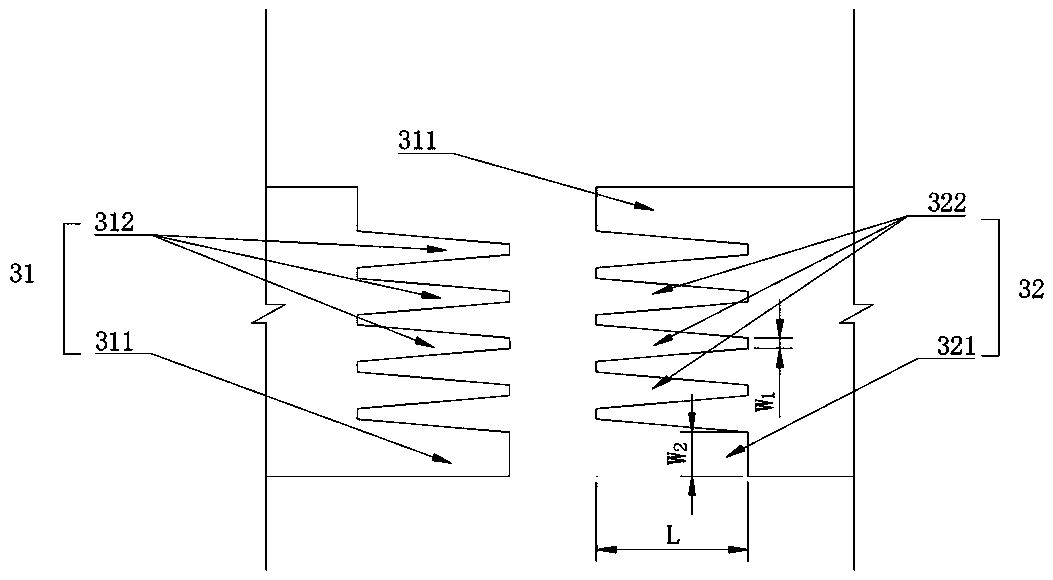

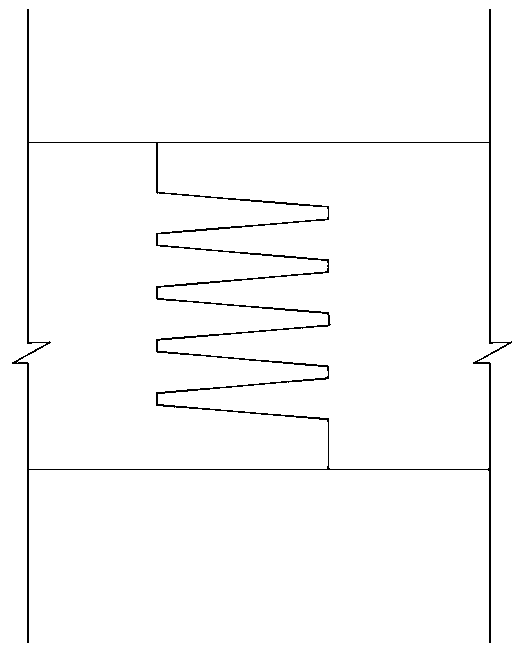

[0062] (2) Teething and docking of the bamboo unit 3: Saw the two ends of the bamboo unit 3 into triangular tines 31 and corresponding grooves 32, and apply a...

Embodiment 2

[0081] The structure of the unlimited arbitrary long bamboo sheet glulam of this embodiment is roughly the same as that of Embodiment 1, the difference is:

[0082] The surface of the bamboo unit 3 has no notches.

[0083] A kind of manufacturing method of unlimited arbitrary long bamboo sheet glulam of the present embodiment, comprises the following steps:

[0084](1) Preparation of the bamboo slice unit 3: process the bamboo through processes such as sawing, splitting, preliminary milling, drying and fine milling, and process it into a rectangular parallelepiped thin bamboo slice with a thickness of 15 mm and a width of 30 mm. The length is 2.6m, and the bamboo slices are dried to a moisture content of 12%, and the bamboo slice unit 3 is obtained.

[0085] (2) Teething and docking of the bamboo unit 3: Saw the two ends of the bamboo unit 3 into triangular tines 31 and corresponding grooves 32, and apply adhesive on the tines 31 and grooves 32 , using pressure roller tooth ...

Embodiment 3

[0093] The unlimited and arbitrary length of the laminated bamboo lumber in this embodiment is glued and connected by a plurality of glulams along the width direction, and the bamboo units 3 between the adjacent bamboo glulams are dislocated. In this example, according to the actual needs, the bamboo laminated lumber of Embodiment 1 and Embodiment 2 is taken, coated with an adhesive, and cold-pressed or hot-pressed and glued along the width direction of the bamboo laminated lumber to obtain a widened bamboo Sheet glulam.

[0094] In other embodiments, bamboo chip units 3 of different thicknesses can be prepared, and the bamboo chip units 3 with the same thickness are prepared into a plurality of bamboo chip laminated materials respectively. Therefore, the number of bamboo unit 3 in the bamboo laminated lumber is adjusted according to the actual needs during billet assembly to prepare bamboo laminated lumber with equal thickness.

[0095] A plurality of laminated bamboo sheets...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com