Preparation method of iron and cyclodextrin co-modified biochar composite material

A composite material and cyclodextrin technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, water pollutants, etc., can solve the problem of hindering the adsorption and treatment effect of biochar/cyclodextrin Catalytic degradation of organic matter, affecting the effect of repeated use, etc., to achieve the effect of improving the performance of repeated use, good physical adsorption performance, and not easy to deintercalate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation method of iron, β-cyclodextrin co-modified biochar composite material, the steps are as follows:

[0045] (1) Weigh 0.5-15 grams of ferric chloride hexahydrate, 0.1-10 grams of sodium citrate, 0.1-30 grams of β-cyclodextrin and 0.1-30 grams of bamboo charcoal in a conical flask, pour 200mL of water, adjust the pH to 10 with ammonia water, dissolve at room temperature, stir, and react for 1.5h.

[0046] (2) Transfer to an autoclave again, react at a temperature of 100° C. and a pressure of 1.0 MPa for 24 hours, wash the prepared black solid with absolute ethanol and deionized water, and dry to obtain iron, β-cyclodextrin co- Modified biochar composites.

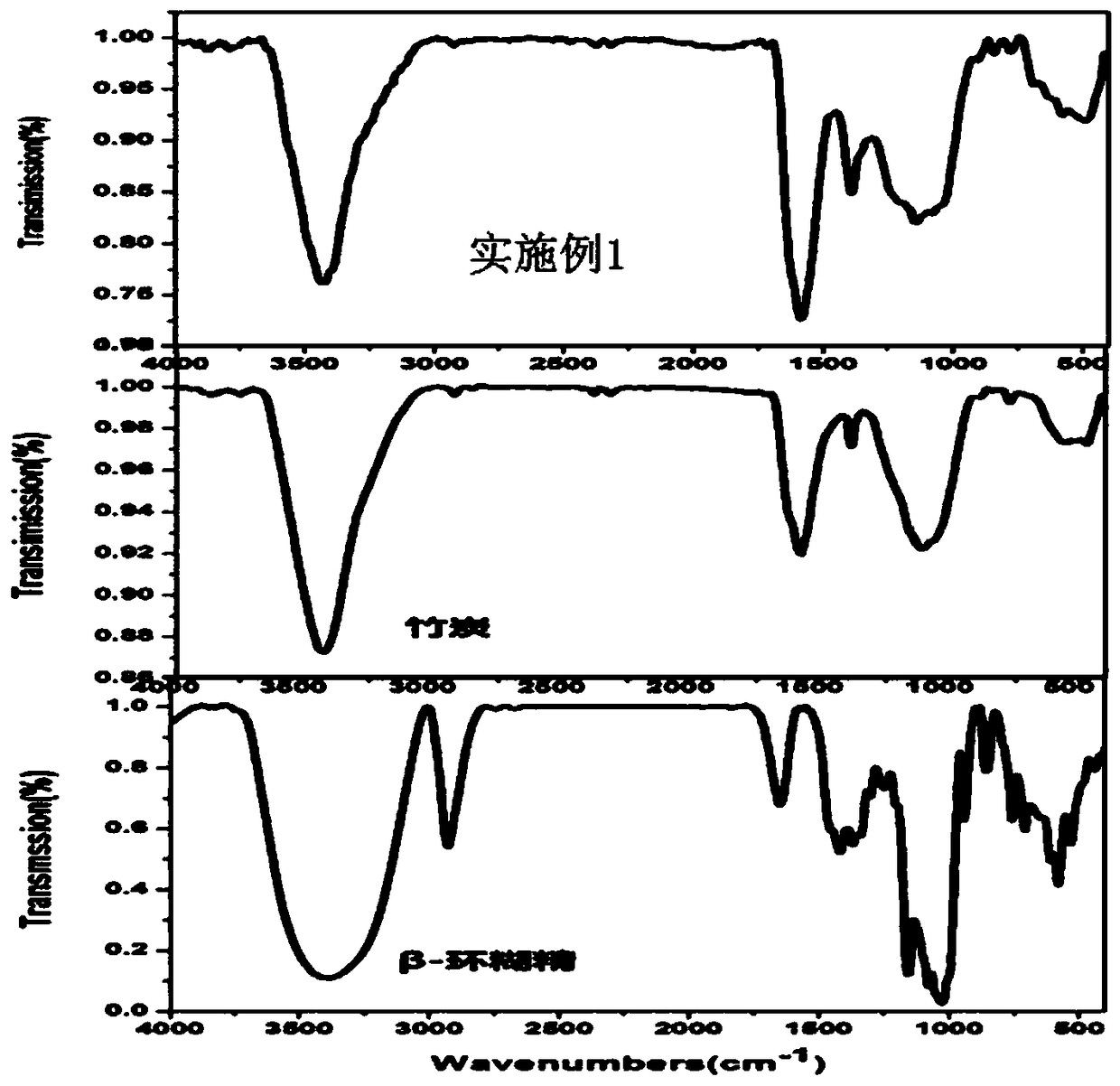

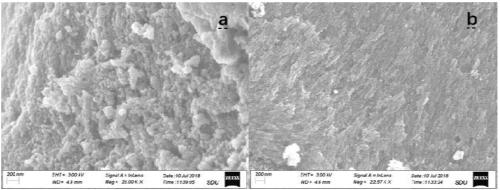

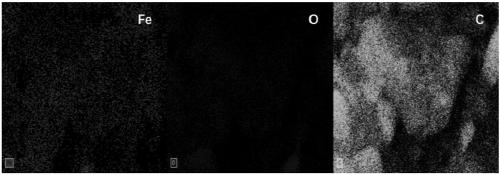

[0047] The Fourier transform infrared spectrum (FTIR) of the obtained iron and β-cyclodextrin co-modified biochar composites is as follows: figure 1 As shown, scanning electron microscopy (SEM) and elemental analysis are shown in Figure 2, by figure 1 , Figure 2, it can be seen that the method of the ...

Embodiment 2

[0050] Preparation method as described in Example 1, the difference is: step (1) replaces ferric chloride hexahydrate with ferric sulfate.

Embodiment 3

[0052] Preparation method as described in Example 1, the difference is: step (1) replaces ferric chloride hexahydrate with ferric nitrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com