Printing and dyeing wastewater processing system

A treatment system, printing and dyeing wastewater technology, applied in textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as ammonia nitrogen exceeding the standard, water resource pollution, etc., achieve stable operation and treatment High efficiency and great environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

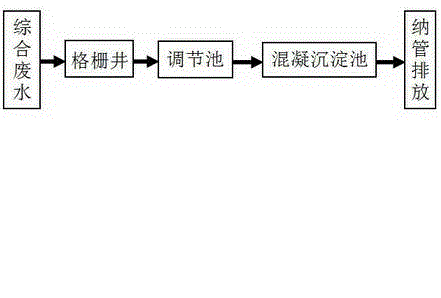

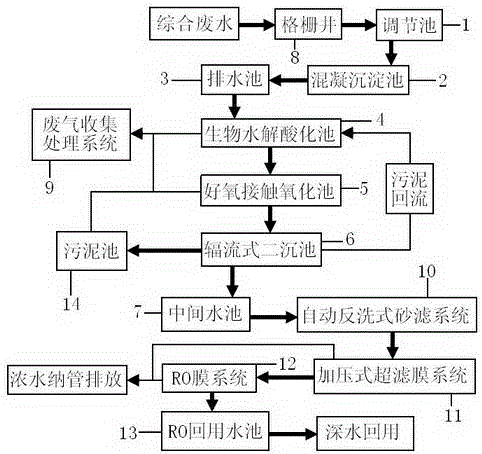

[0019] Such as figure 2 As shown, a printing and dyeing wastewater treatment system is divided into three parts, including a comprehensive wastewater pretreatment system, an advanced reuse treatment system and a sludge treatment system.

[0020] 1. Comprehensive wastewater pre-treatment system

[0021] The comprehensive wastewater pre-treatment system first pre-treats through pH adjustment and coagulation sedimentation, and then adopts the secondary biochemical combined treatment process of "hydrolytic acidification and biological contact oxidation" to treat the wastewater to the primary standard (COD≦100mg / L), Finally, the effluent from the secondary sedimentation tank enters the advanced treatment system.

[0022] The comprehensive wastewater pretreatment system includes a regulating tank 1, a coagulation sedimentation tank 2, a drainage tank 3, a biological hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com