Grinding gear, grinding device and grinder

A crushing device and gear technology, applied in the field of crushing gears, crushing or crushing devices, crushing devices and pulverizers, can solve the problems of unfavorable crushing materials and low crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

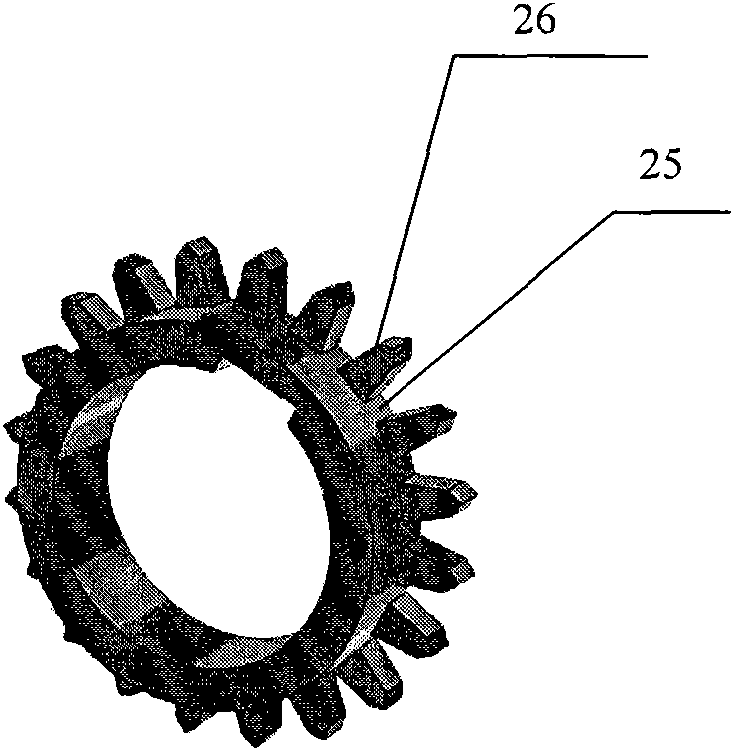

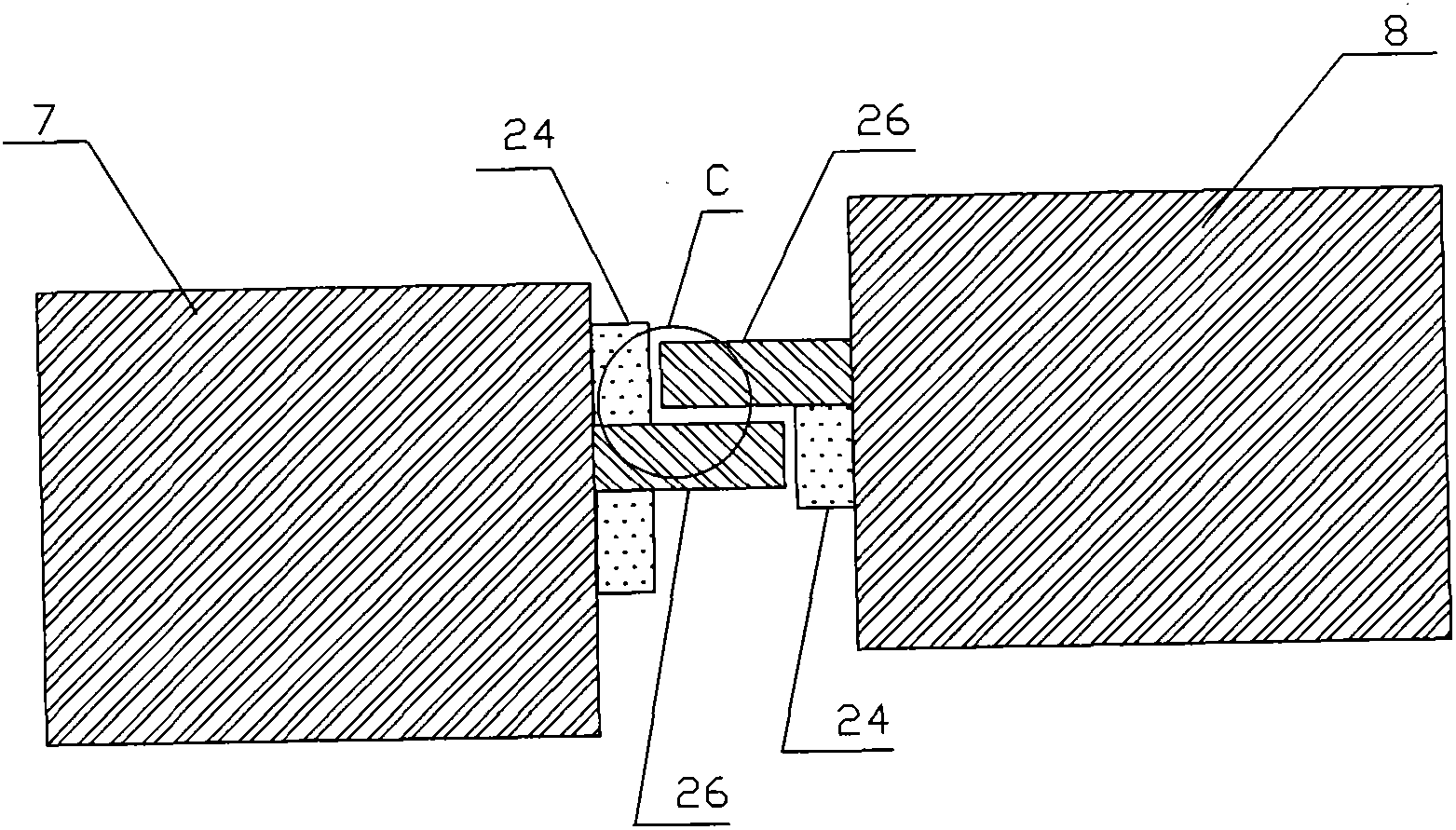

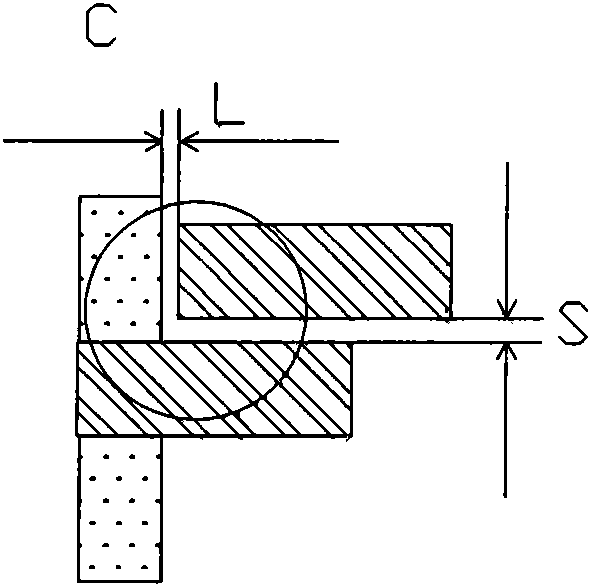

[0036] Such as figure 1 , Figure 4 , Figure 5 and Figure 6 As shown, the present invention provides a crushing gear 11, which includes a gear ring 25, on which gear teeth 26 are arranged, and the tips of the teeth are in the shape of sharp blades. The inner diameter of the gear ring is provided with key grooves.

Embodiment 2

[0038] Such as figure 1 and Figure 6 As shown, the present invention provides a kind of pulverizing gear, comprises gear ring 25, and described gear ring is provided with gear tooth 26, and the tip of described gear tooth is sharp blade shape; Described sharp blade shape top end 28 is made up of two slopes, The angle between the two slopes can be 50°. The inner diameter of the gear ring is provided with key grooves.

Embodiment 3

[0040] Such as figure 1 and Figure 6 As shown, the present invention provides a kind of pulverizing gear, comprises gear ring 25, and described gear ring is provided with gear tooth 26, and the tip of described gear tooth is sharp blade shape; Described sharp blade shape top end 28 is made up of two slopes, The angle between the two slopes can be 140°. The inner diameter of the gear ring is provided with key grooves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com