Smoke gas inlet structure of fire tube boiler

A fire tube boiler and flue gas technology, applied in the field of fire tube boilers, can solve problems such as stable product quality affecting production, equipment safety, easy damage to the welding seam between heat exchange tubes and tube sheets, leakage of heat exchange tubes and tube sheets, etc. problems, to achieve safe and reliable operation, prevent leakage, and protect the welding seam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

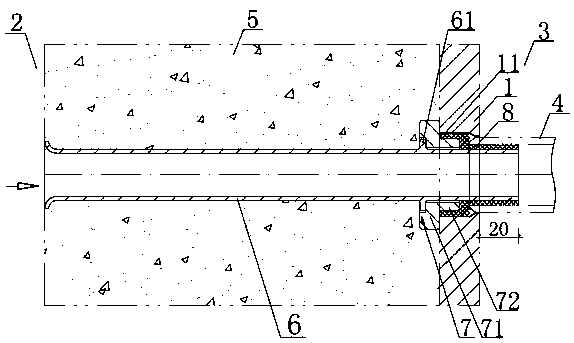

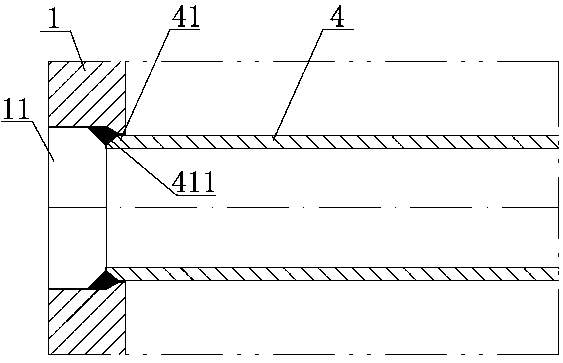

[0015] like figure 1 , figure 2 As shown, the flue gas inlet structure of the fire tube boiler includes: a tube plate 1, one side of the tube plate 1 is the smoke box side 2, and the other side of the tube plate 1 is the water side 3. The nozzle of each heat exchange tube 4 on the water side 3 extends into a tube hole 11 of the tube sheet 1 , and the nozzle of each heat exchange tube 4 is welded and sealed to the corresponding tube hole 11 . The nozzle 41 of each heat exchange tube 4 extends into the end of the tube hole 11 near the water side 3, and the nozzle 41 of each heat exchange tube 4 is welded and sealed to the inner wall of the tube hole 11 near the water side 3 . The nozzle 41 of each heat exchange tube 4 is provided with a welding groove 411 , and the welding groove 411 is fully welded to the tube sheet 1 .

[0016] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com