Energy-saving emission-reducing vertical fire-tube boiler capable of using water as oxidant

A technology of energy saving and emission reduction, fire tube boiler, applied in water heaters, lighting and heating equipment, fluid heaters, etc., can solve problems such as environmental pollution, smoke and dust cannot be effectively treated, and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

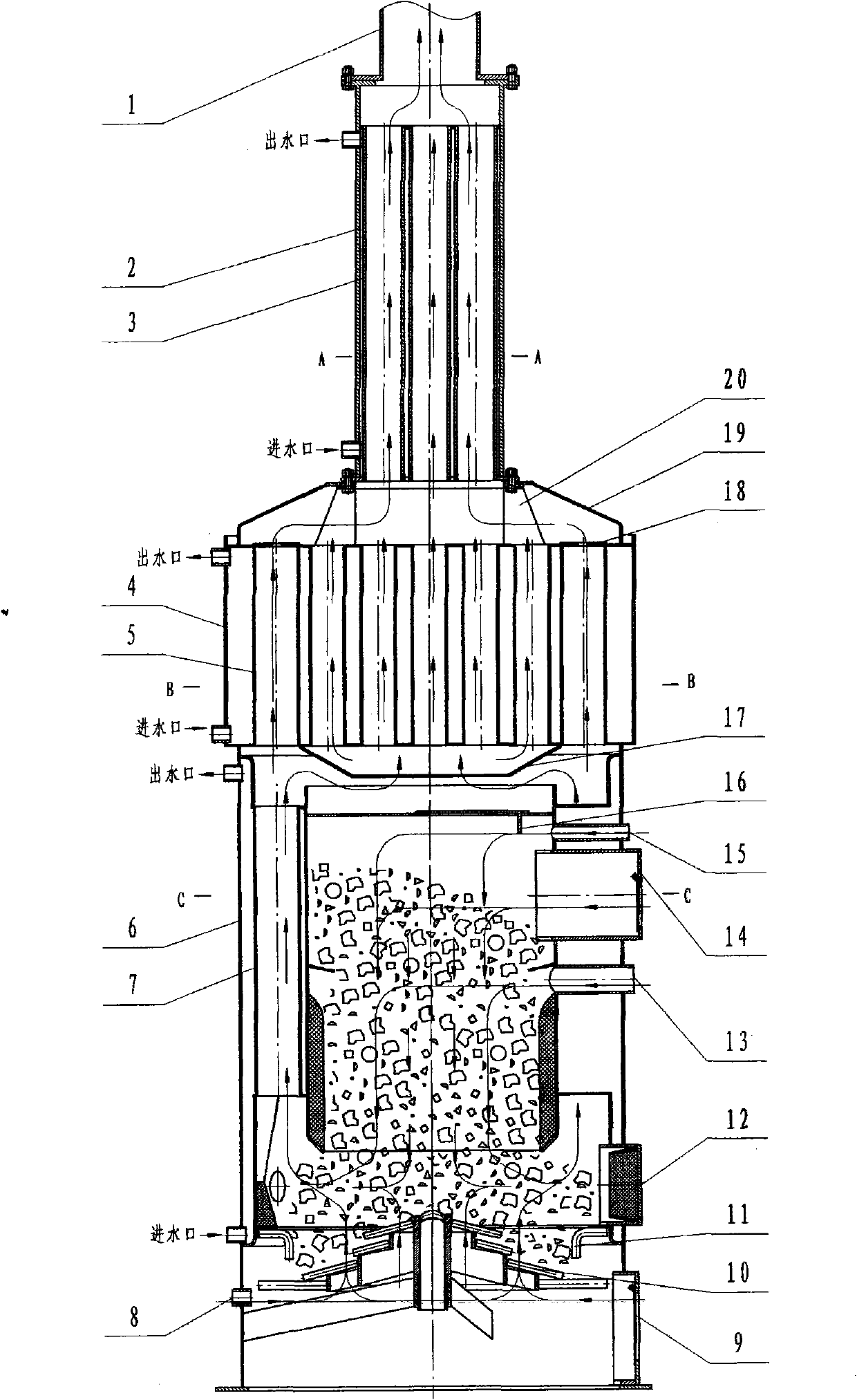

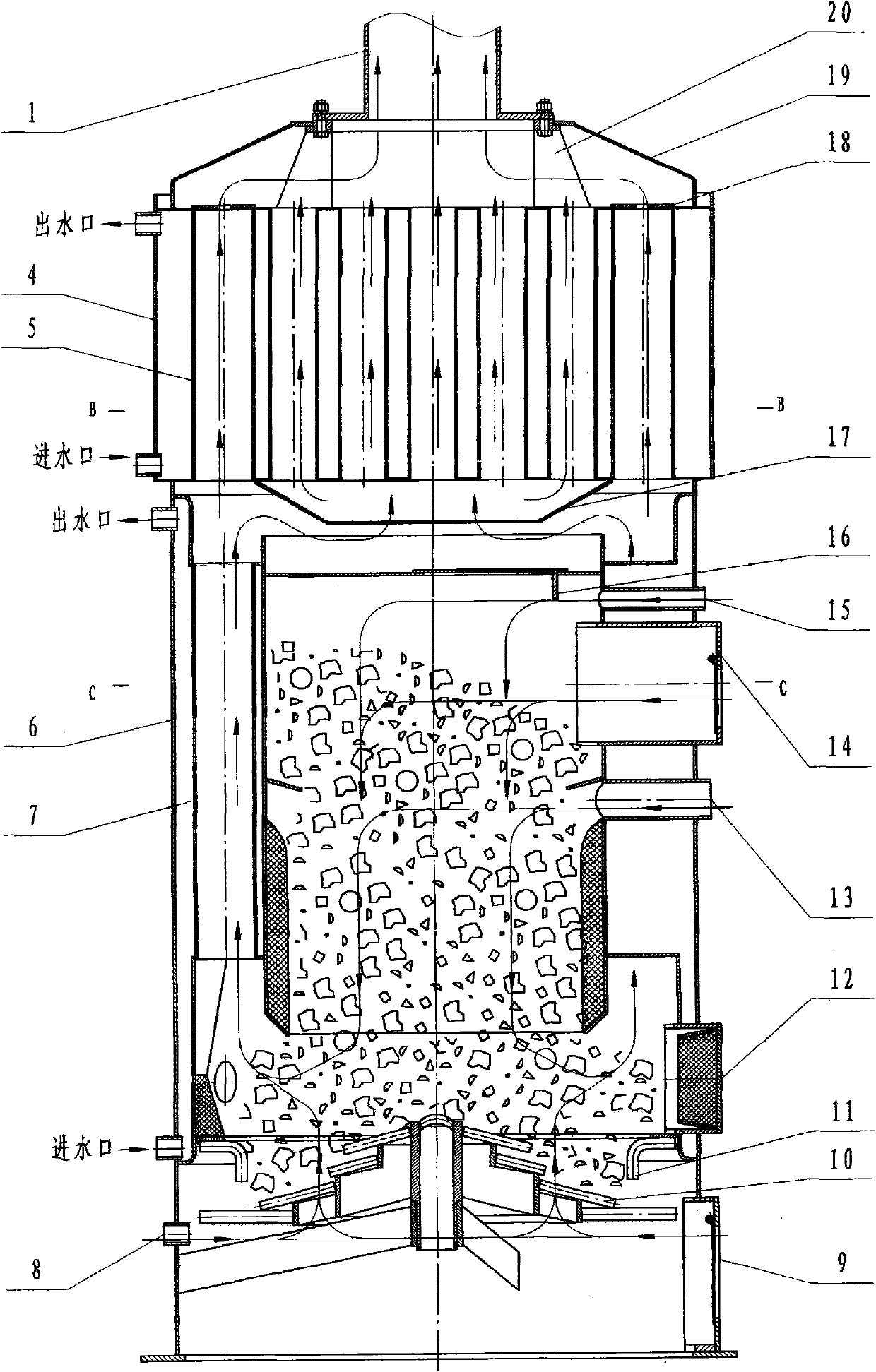

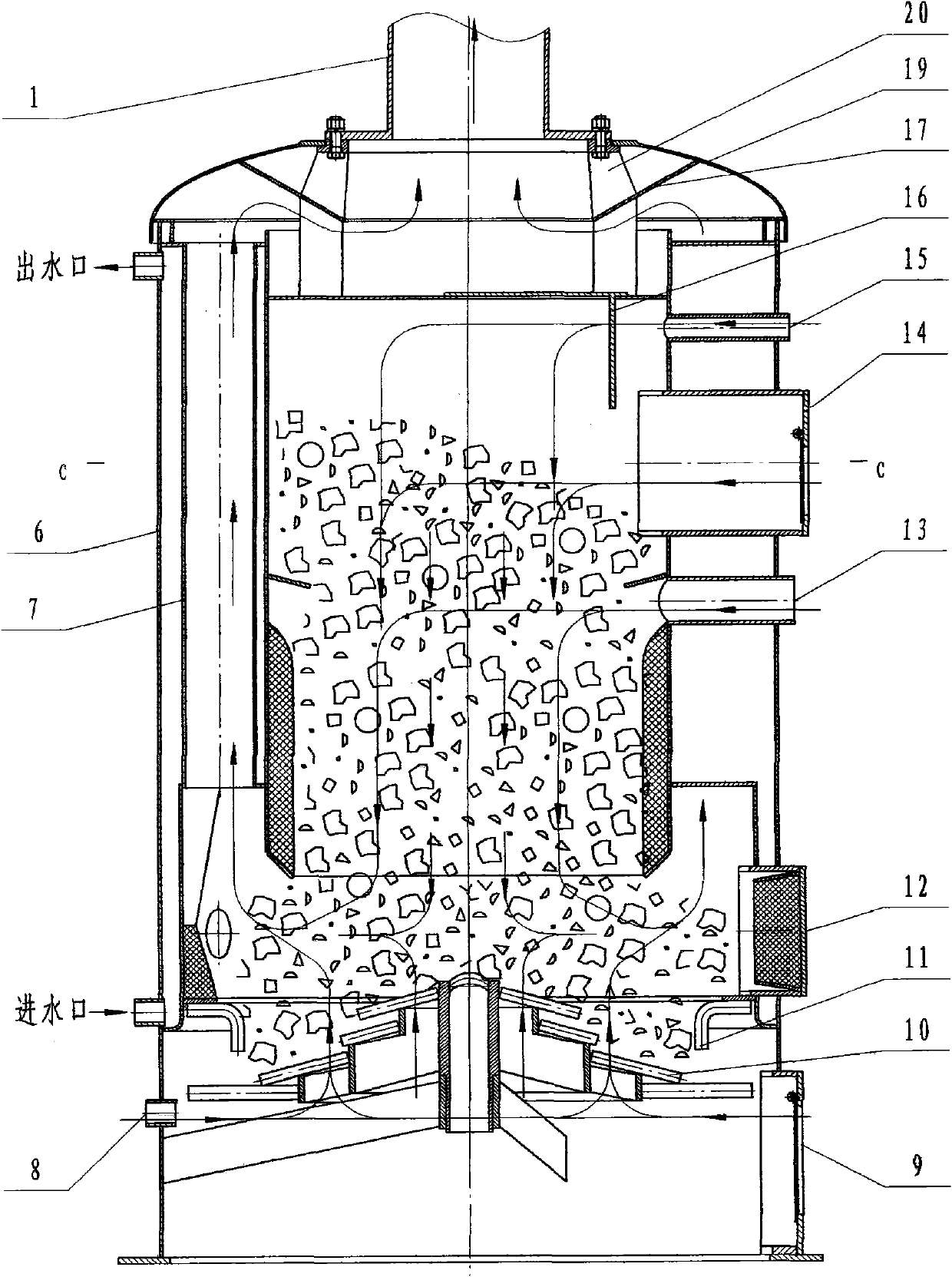

[0042] figure 1 It is a structural schematic diagram of the first embodiment of the present invention. Open push-pull ash door 6, light a fire, its method is identical with general vertical boiler.

[0043] After igniting the fire, fill up the fuel once, and close the push-pull ash door 6.

[0044] According to the use requirements of large fire and small fire, adjust the one-way valves of the lower tuyere 8, the middle tuyere 13, the upper tuyere 15, the ash removal furnace door 9 and the feeding furnace door 14 respectively, and adjust the mist according to the water content of the fuel. Reduce the amount of dripping water, so that the combustion in the furnace is in a normal smokeless combustion state. The fuel starts to dry and dehydrate from top to bottom, volatile matter is precipitated, fixed carbon is formed, tar is cracked, water is heated up to high-temperature steam as an oxidant, and a thermochemical reaction occurs with carbon or hydrocarbons to produce hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com