Combustor and stove

A technology of burners and stoves, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as poor slag removal ability, inability to burn biomass and coal at the same time, poor combustion stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

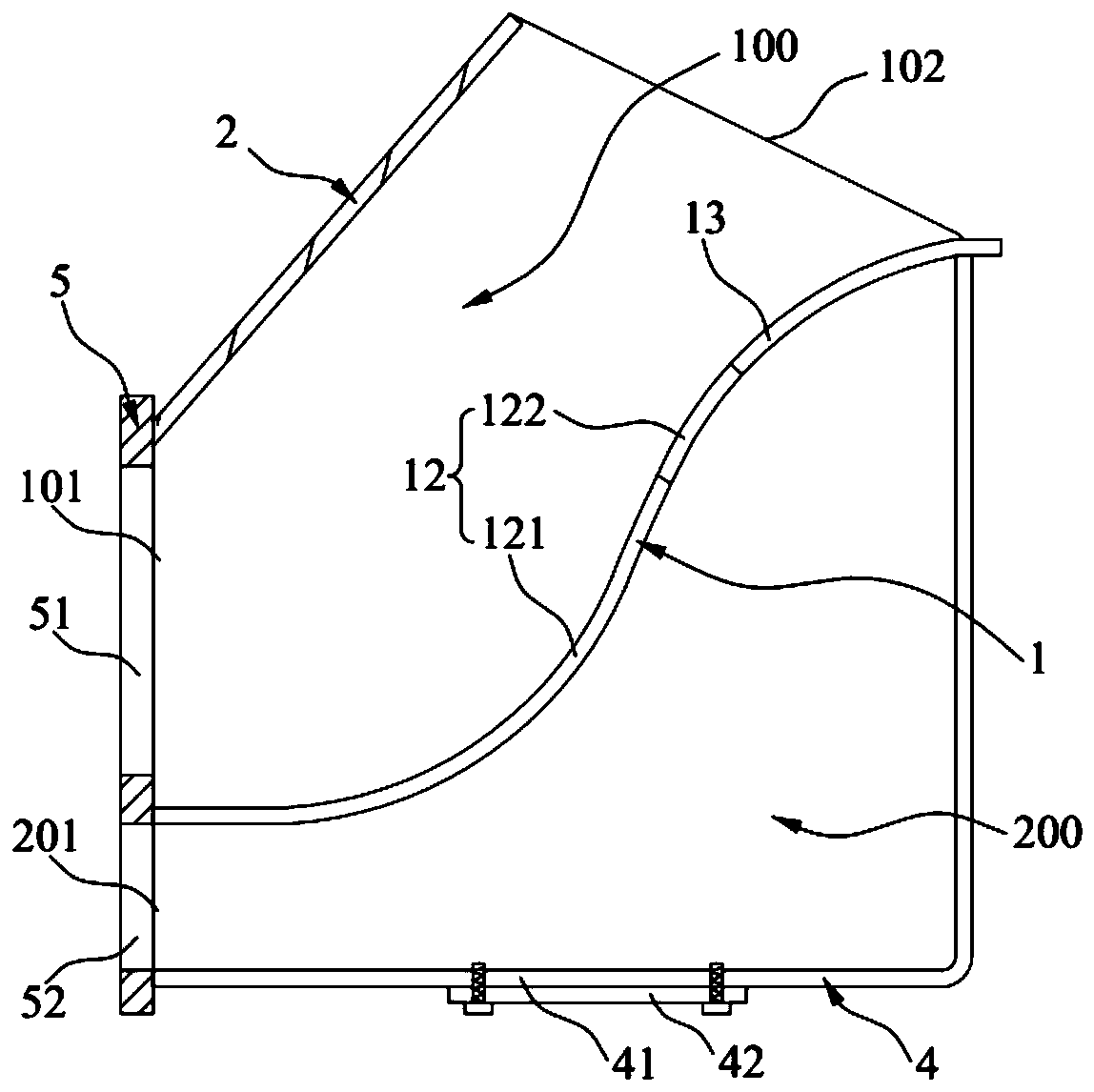

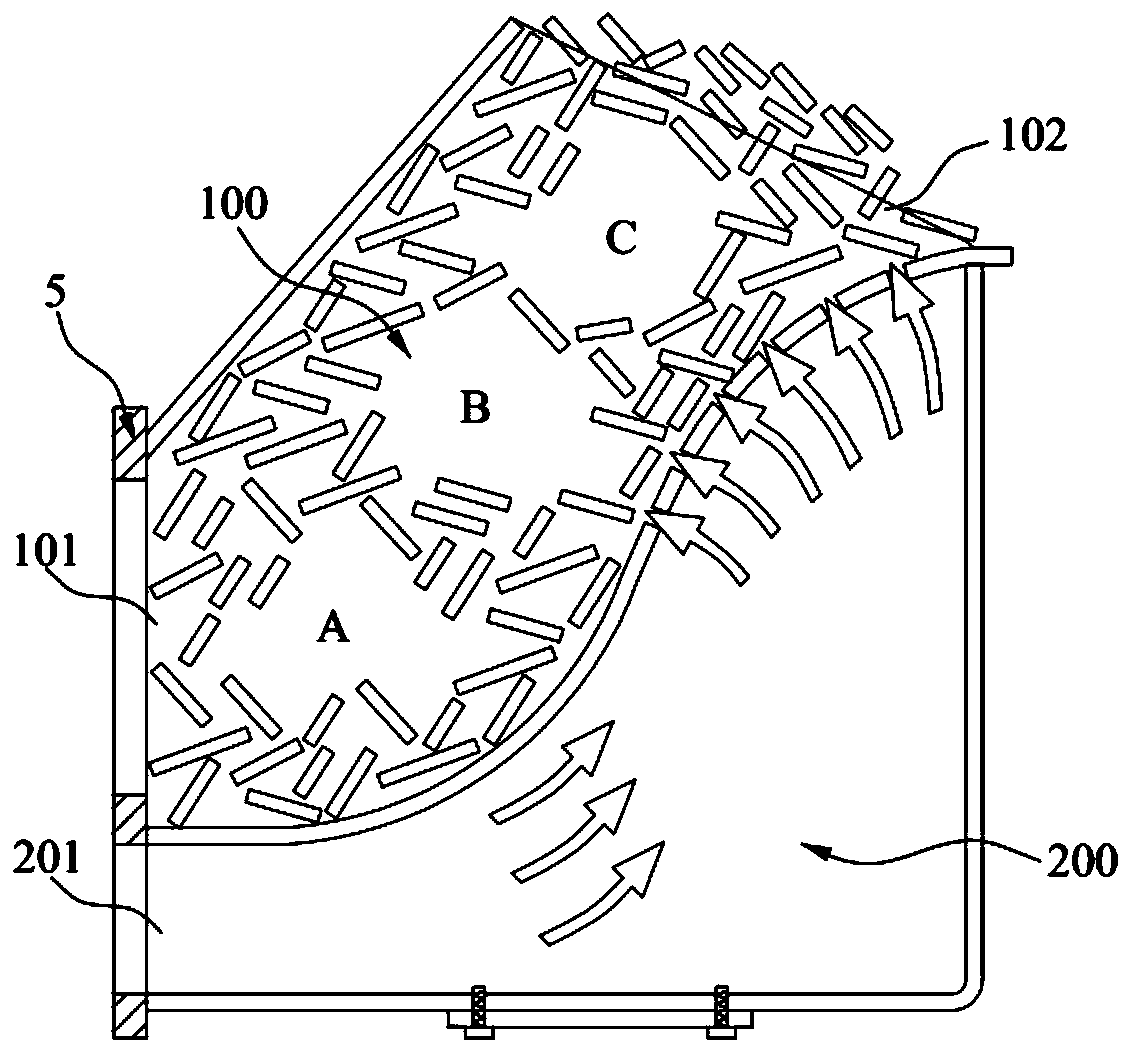

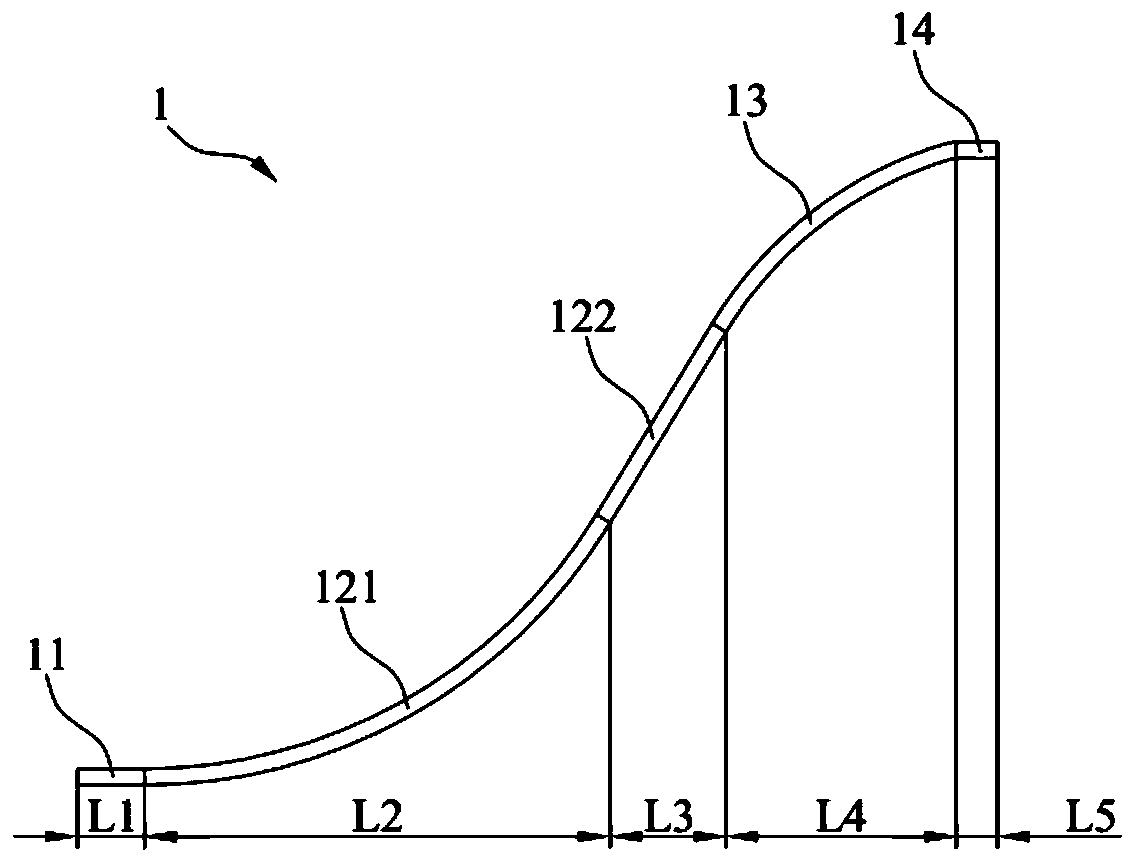

[0042] This embodiment provides a burner. Such as figure 1 As shown, the burner includes a casing and an air distribution plate 1 . The air distribution plate 1 is arranged obliquely upward in the housing, and divides the inner space of the housing to form an upper combustion chamber 100 and a lower ventilation chamber 200 . Specifically, the air distribution plate 1 includes an isolation section 12 and an upwardly convex curved section 13 which are sequentially connected from bottom to top, and a plurality of first ventilation holes are dispersedly arranged on the upwardly convex curved section 13 . Along the inclination direction of the air distribution plate 1 , the upper combustion chamber 100 has a low end and a high end. A fuel supply port 101 and an ash discharge port 102 are respectively provided at the lower end and the upper end of the upper combustion chamber 100 . Fuel can enter the upper combustion chamber 100 through the fuel supply port 101 for combustion, an...

Embodiment 2

[0064] This embodiment provides a burner and a stove. The structure of this burner is substantially the same as that of the burner provided in Embodiment 1, the only difference is that the shape of the bottom cover plate 4 is different.

[0065] Specifically, as Figure 6 As shown, the bottom cover plate 4 can have multiple folded edges to adjust the structure of the lower ventilation chamber 200 and facilitate the installation of the burner in the stove. Further, the inspection opening 41 can also be arranged on the side of the bottom cover 4 , so that the operator can enter and exit the inspection opening 41 conveniently. However, it should be noted that when adjusting the shape of the bottom cover plate 4 , the ventilation area of any position in the lower ventilation chamber 200 should not be smaller than the ventilation area of the primary air inlet 201 .

Embodiment 3

[0067]This embodiment provides a burner and a stove. The structure of this burner is substantially the same as that of the burner provided in Embodiment 1, the only difference is that a cooling wind jacket 6 is provided along the circumferential direction of the upper combustion chamber 100 .

[0068] Specifically, such as Figure 7 As shown, the cooling air jacket 6 is provided with a cooling air inlet 61 and a cooling air outlet 62 , and the cooling air outlet 62 communicates with the ash discharge port 102 of the upper combustion chamber 100 . After the cooling air is introduced into the cooling air jacket 6, the upper combustion chamber 100 can be cooled, and the temperature of the combustion zone C can be lowered, so that the efficiency of sulfur fixation can be effectively improved when burning briquettes containing a sulfur fixation agent. At the same time, since the cooling air outlet 62 communicates with the ash discharge port 102 of the upper combustion chamber 100,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com