Patents

Literature

34results about How to "Reduce propulsion speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

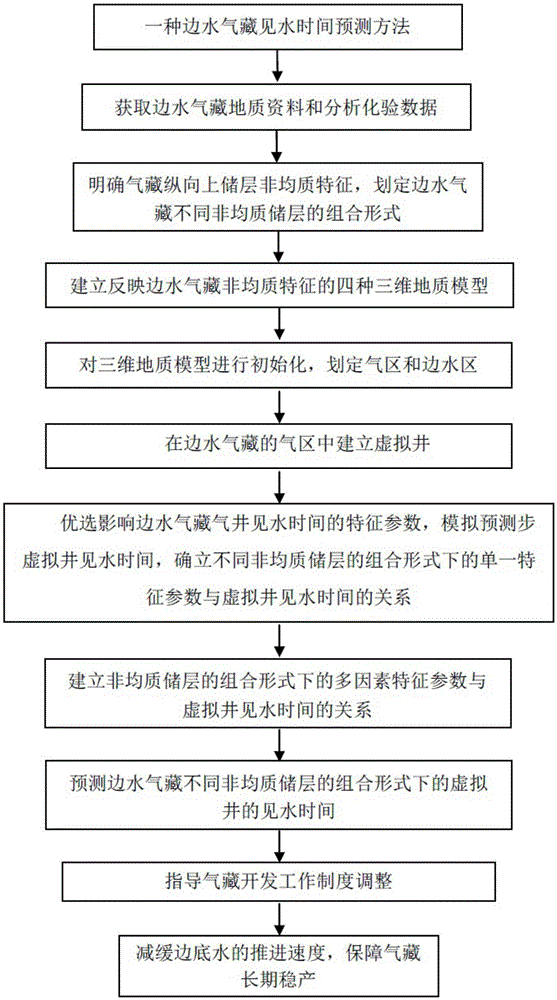

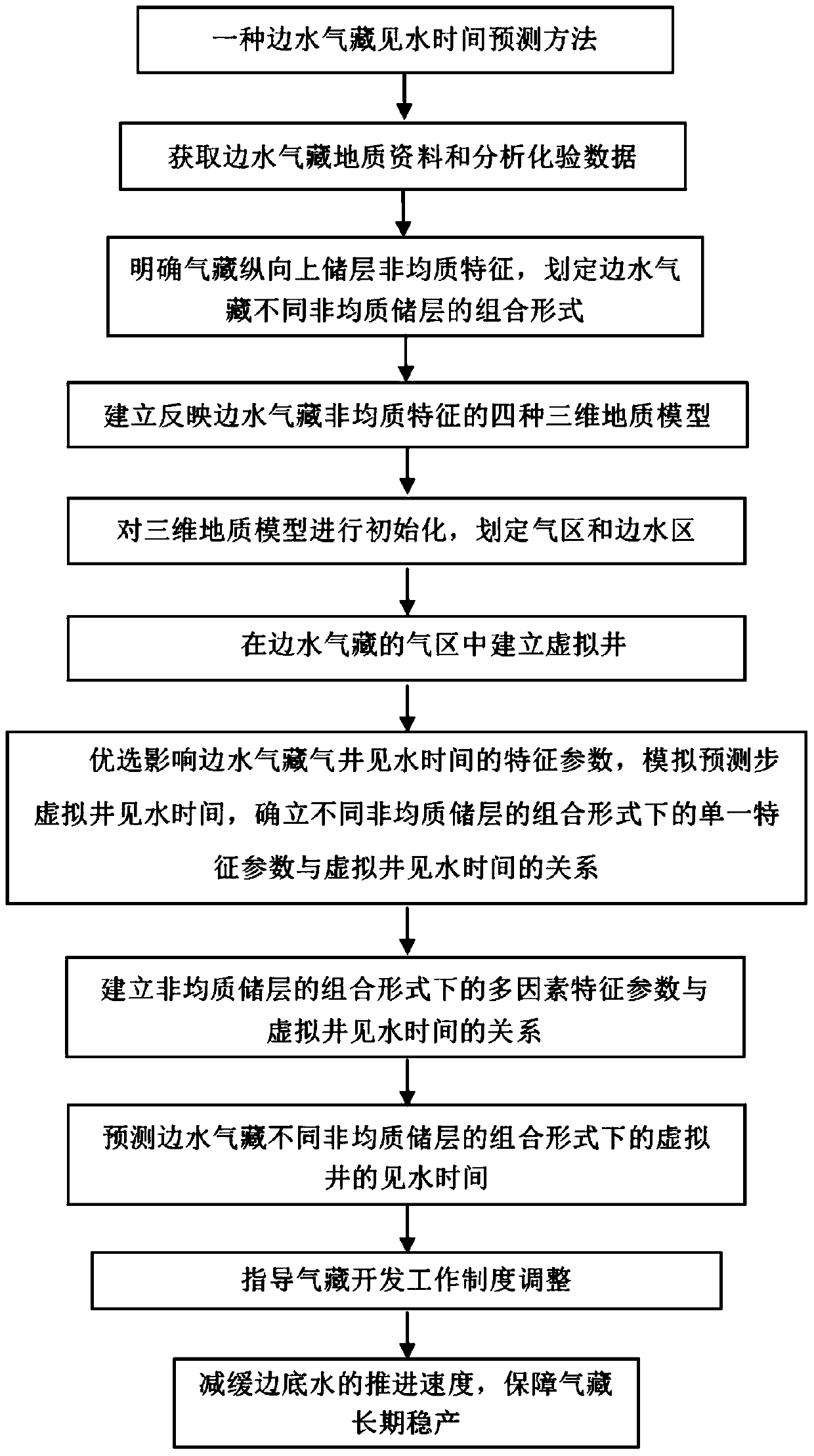

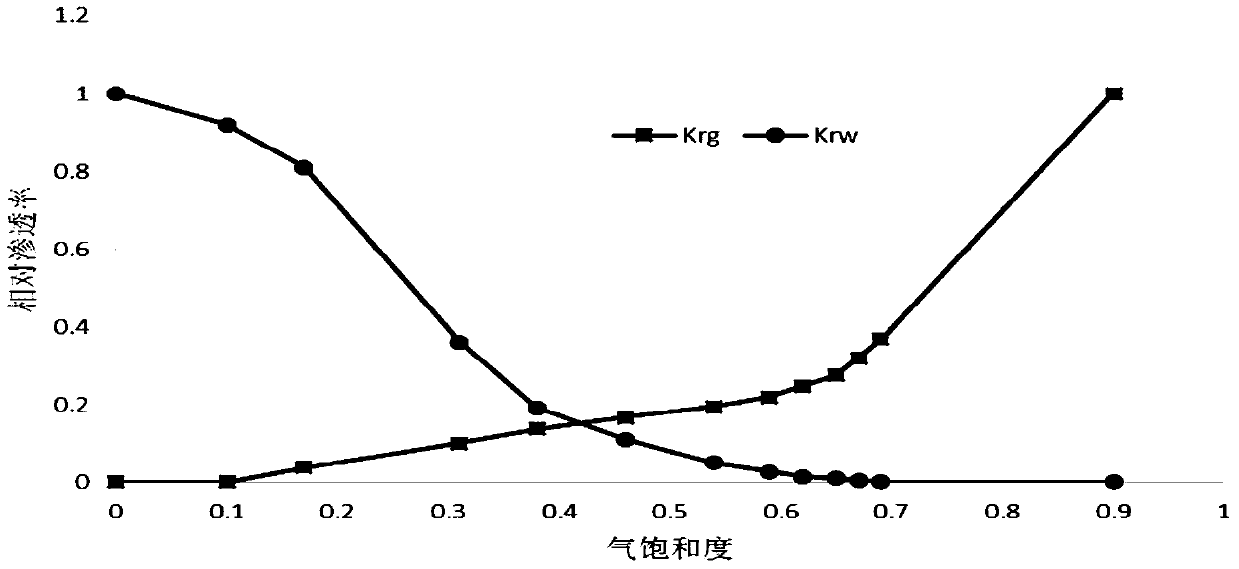

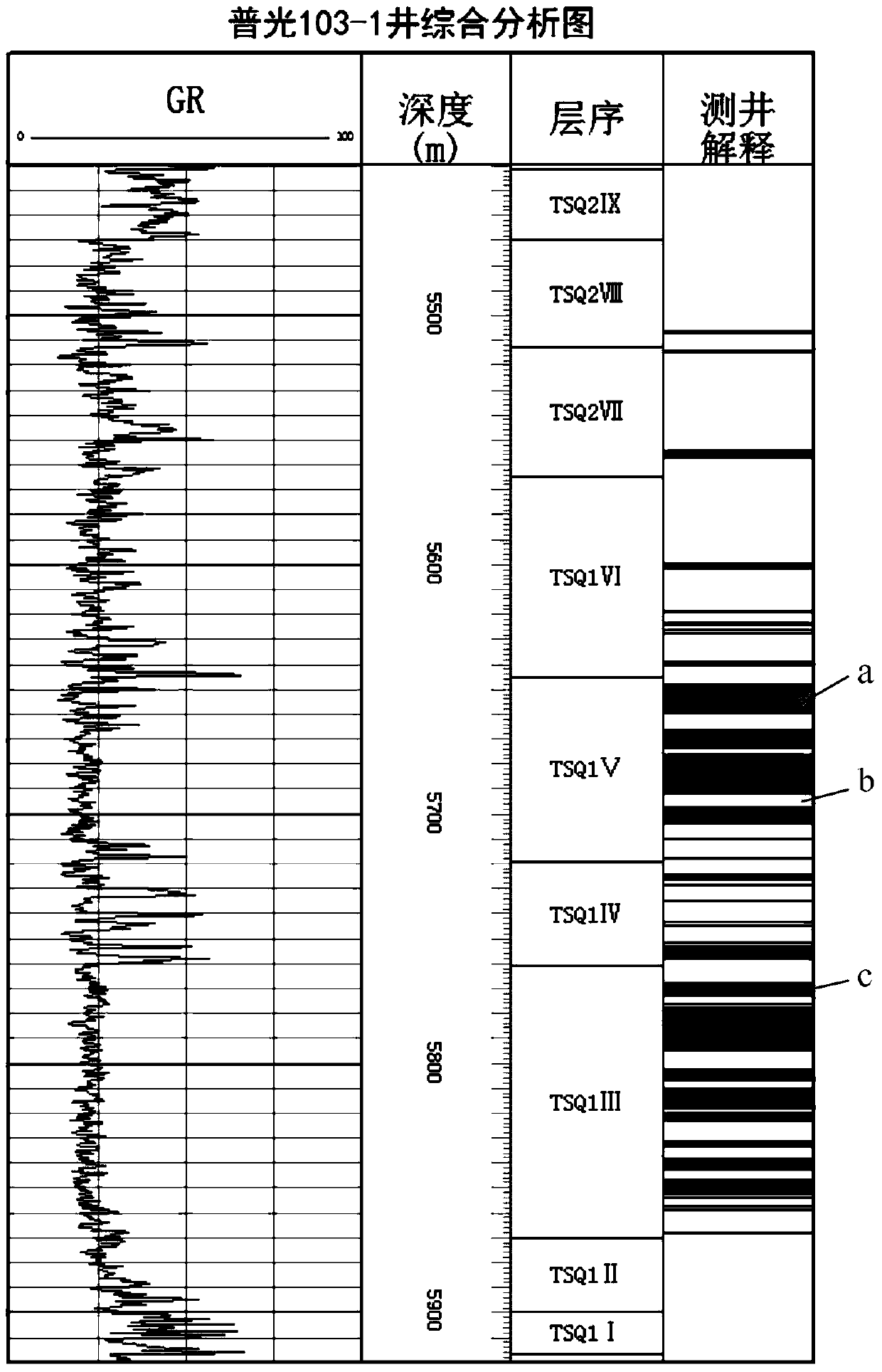

Edge water gas reservoir water breakthrough time prediction method

ActiveCN105631529AReduce propulsion speedForecasting3D modellingPredictive methodsPressure difference

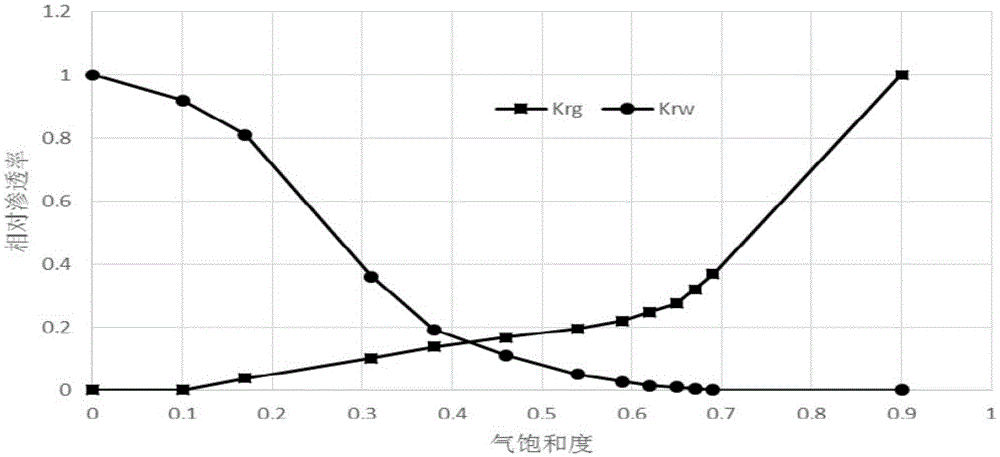

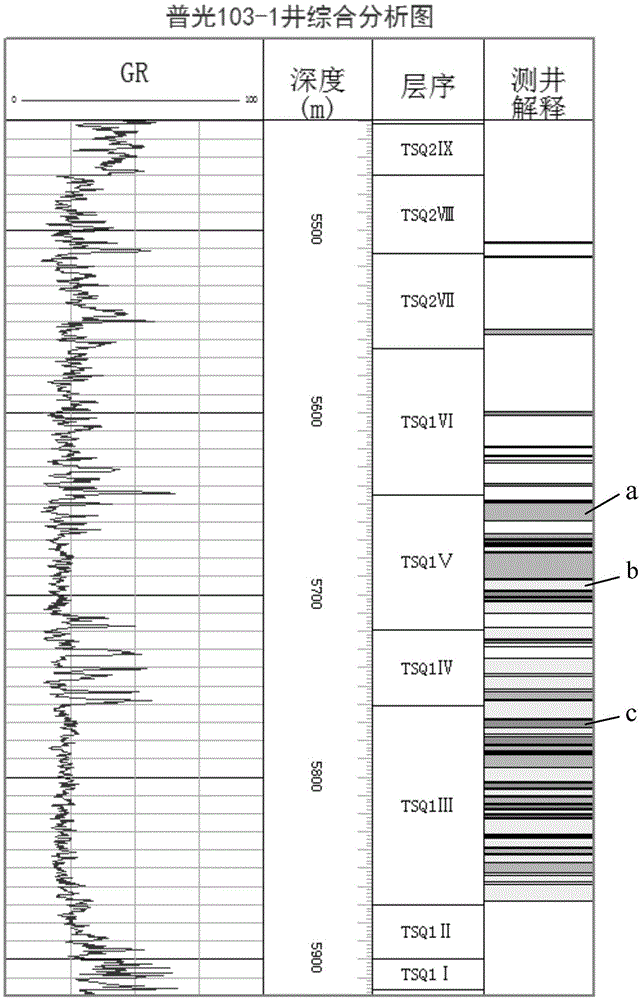

The invention belongs to the petroleum and natural gas development technical field and discloses an edge water gas reservoir water breakthrough time prediction method. The method includes the following steps that: edge water gas reservoir geological data and analysis test data are obtained; a three-dimensional geological model under combination modes of four kinds of heterogeneous reservoir stratums is established, and a gas area and an edge water area of an edge water gas reservoir are divided, and a virtual well is established in the gas area of the edge water gas reservoir; and the gas well water breakthrough time of the edge water gas reservoir under the combination modes of the different kinds of heterogeneous reservoir stratums can be accurately predicted through using response relationships between the gas well water breakthrough time and the heterogeneous feature parameters of the reservoir stratums. The method can be used for guiding the adjustment of gas reservoir development work systems. With the method adopted, the output of a well which is to be subject to water breakthrough can be decreased timely, and production pressure difference can be controlled; the advance speed of edge-bottom water can be effectively slowed down; and therefore, technical support can be provided for long-term stability of edge water gas reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

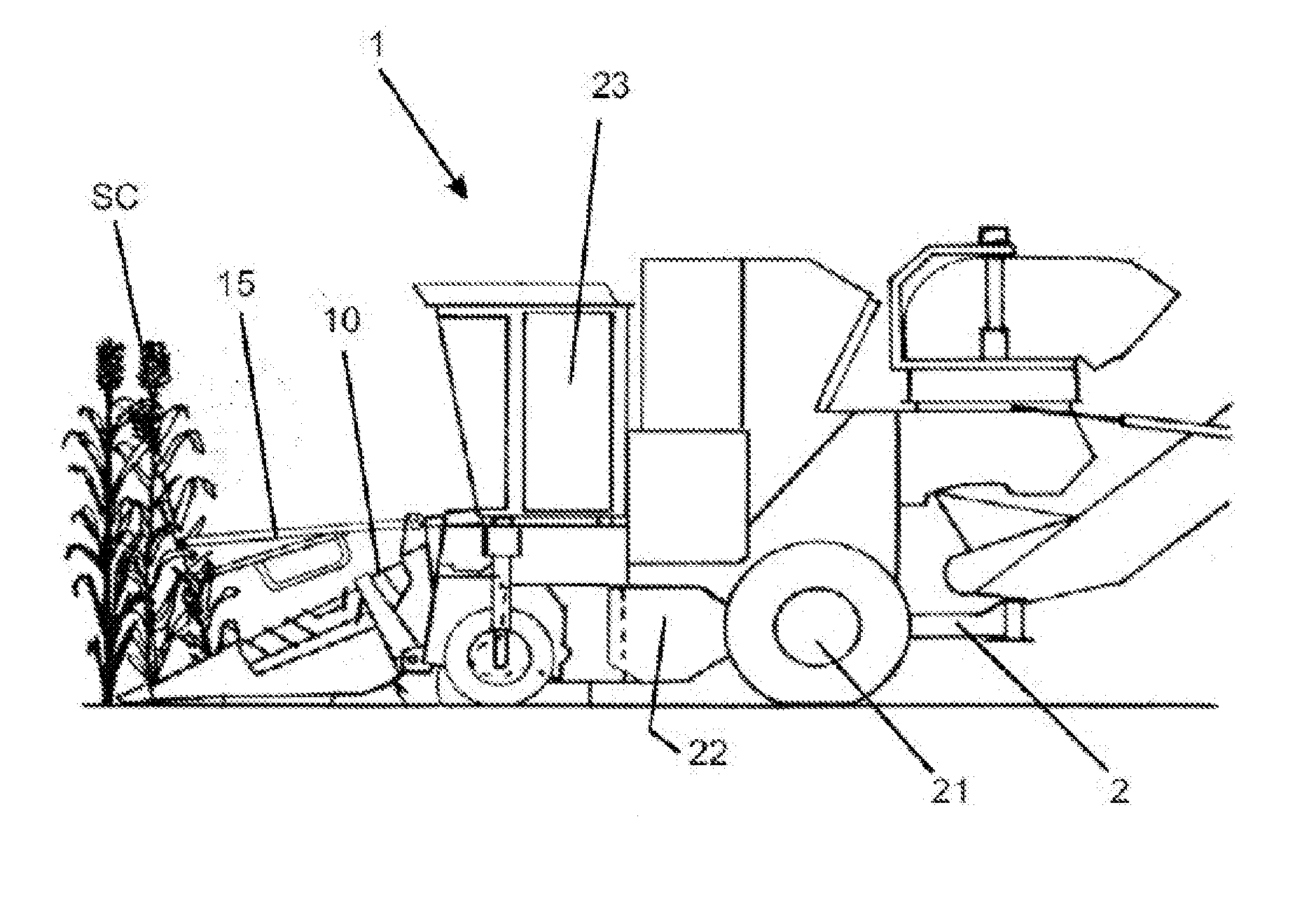

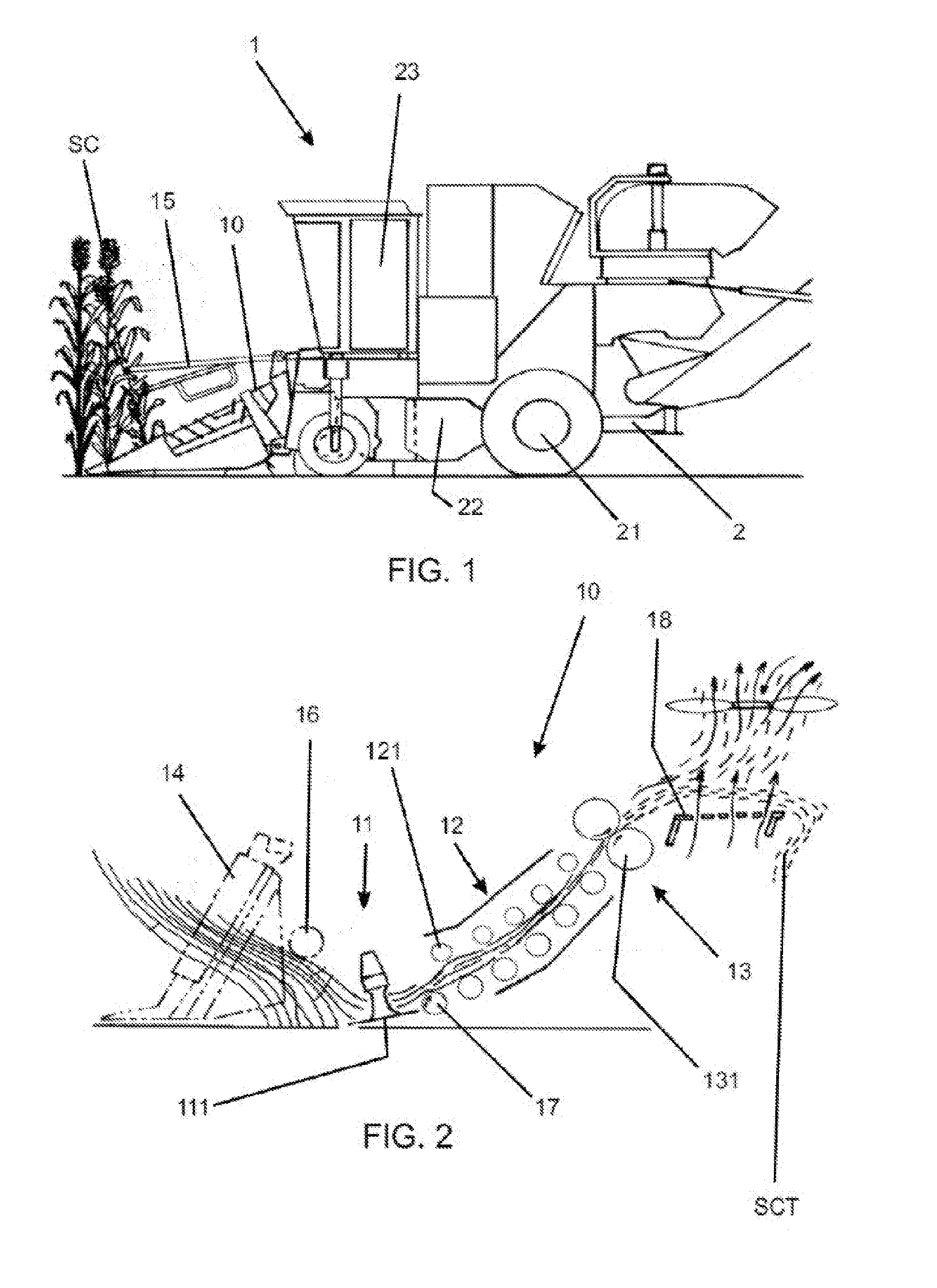

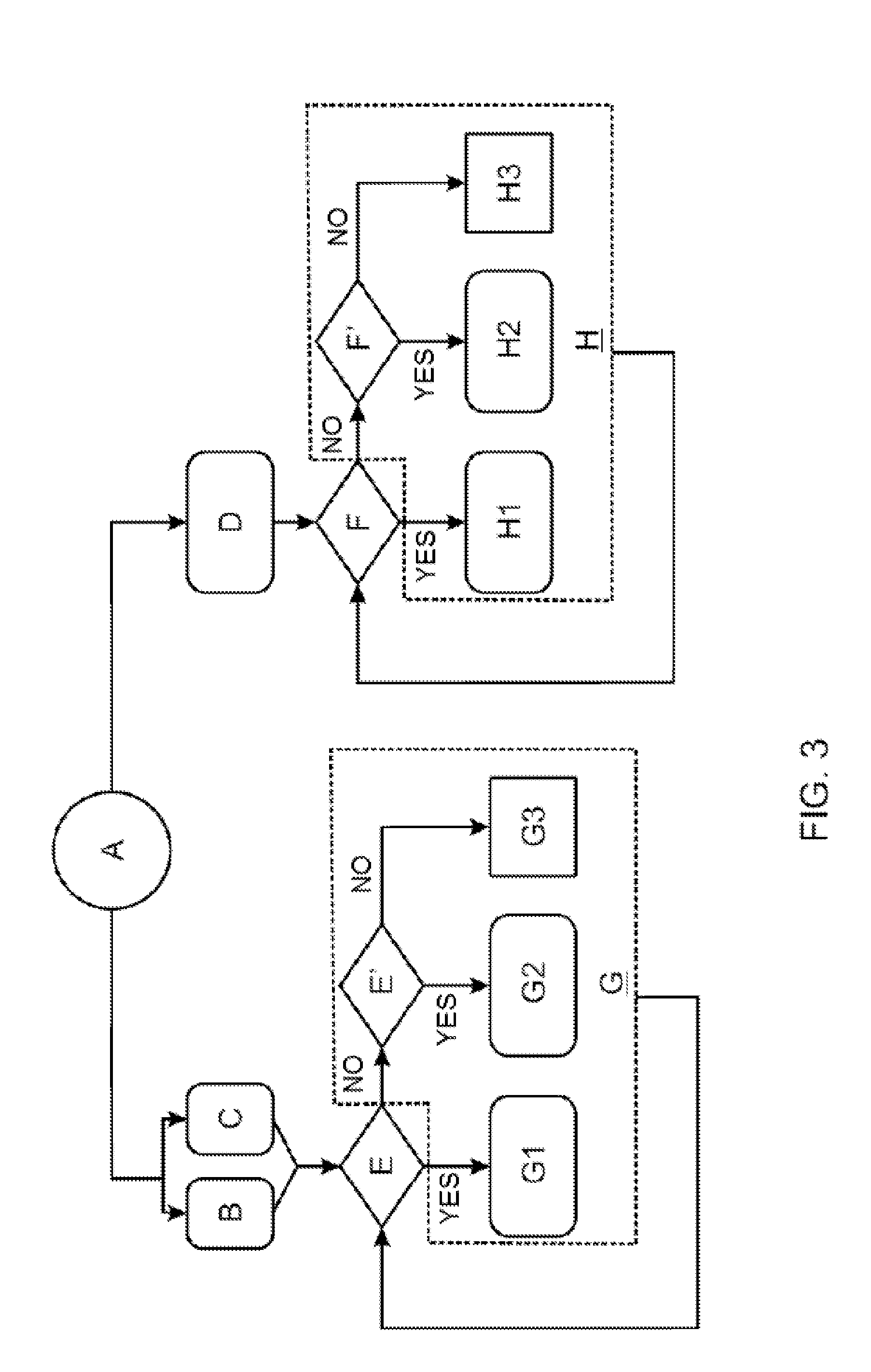

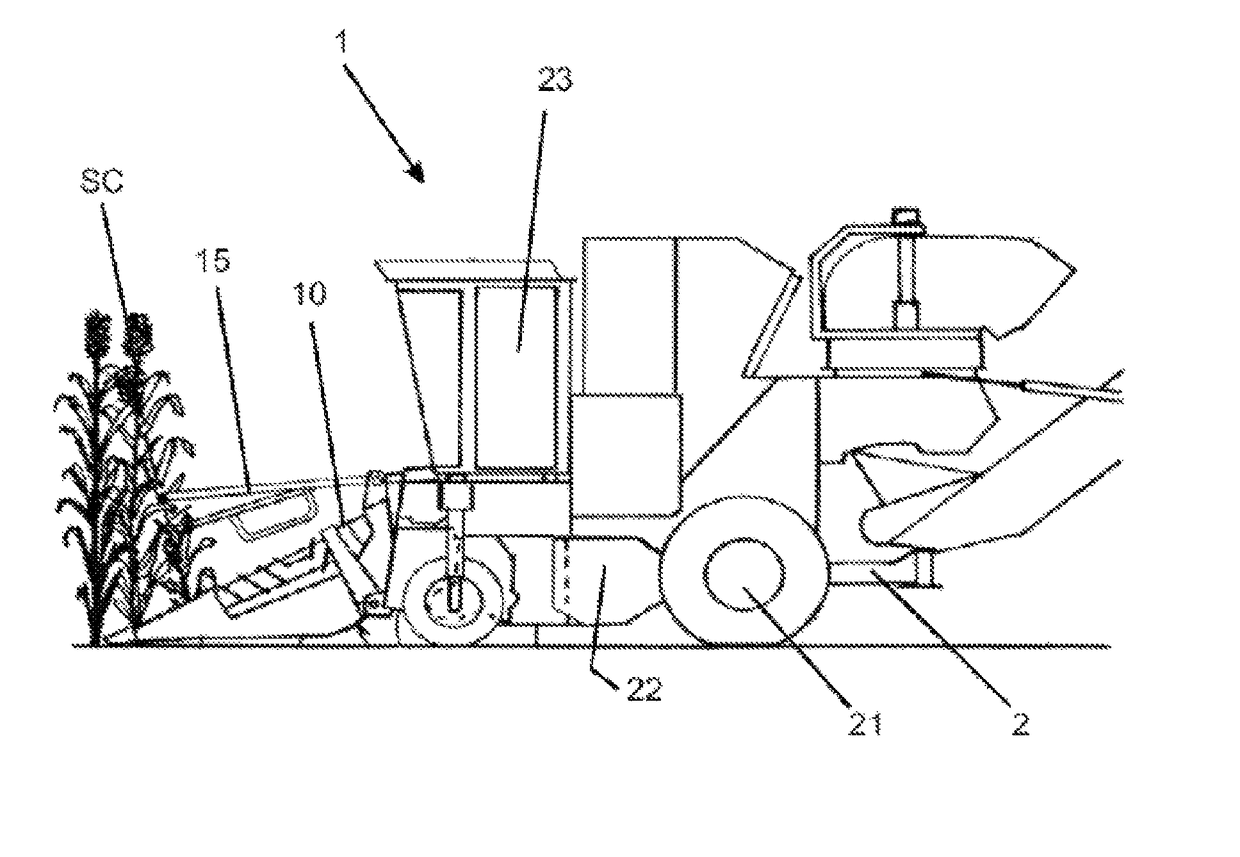

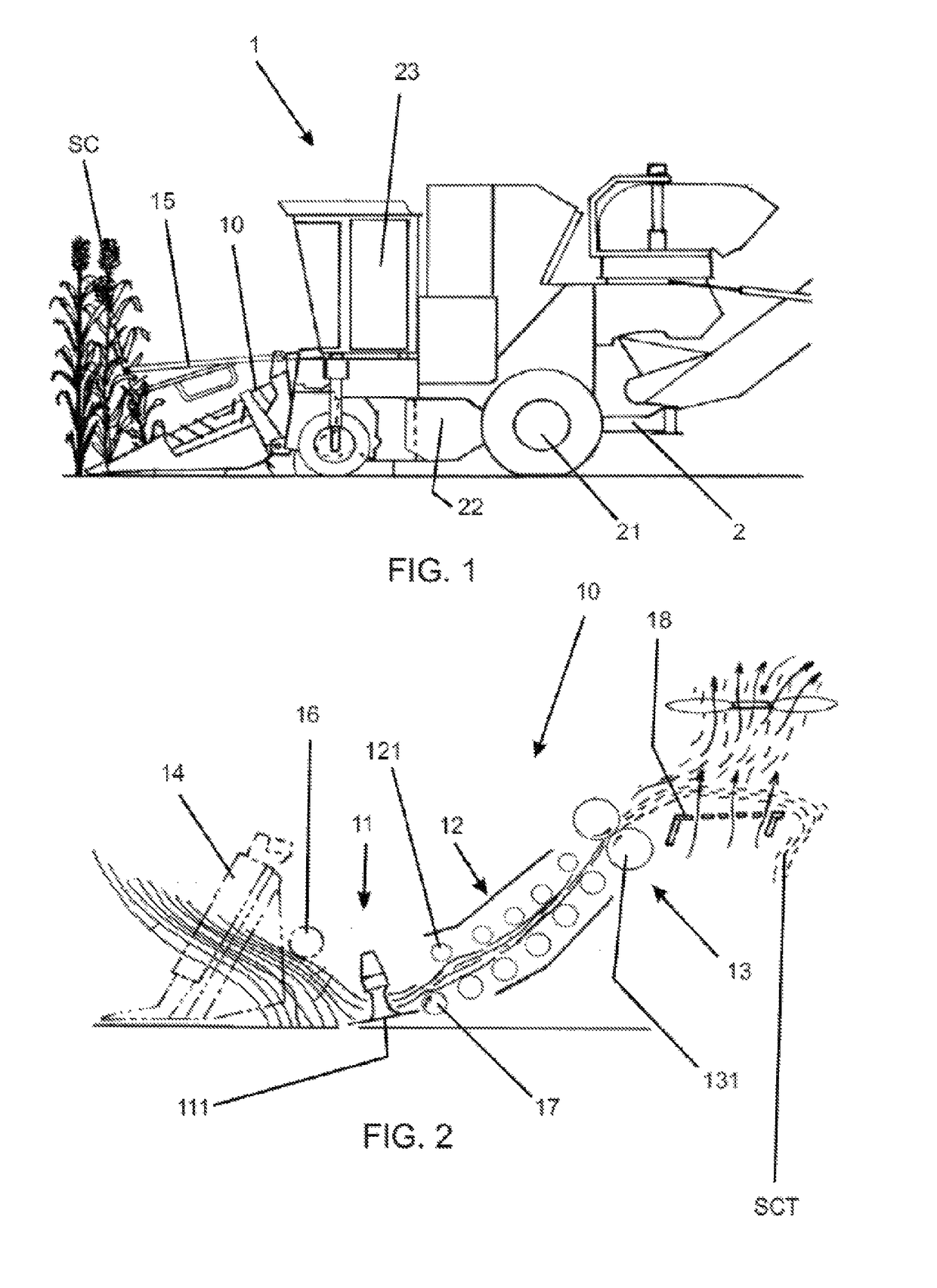

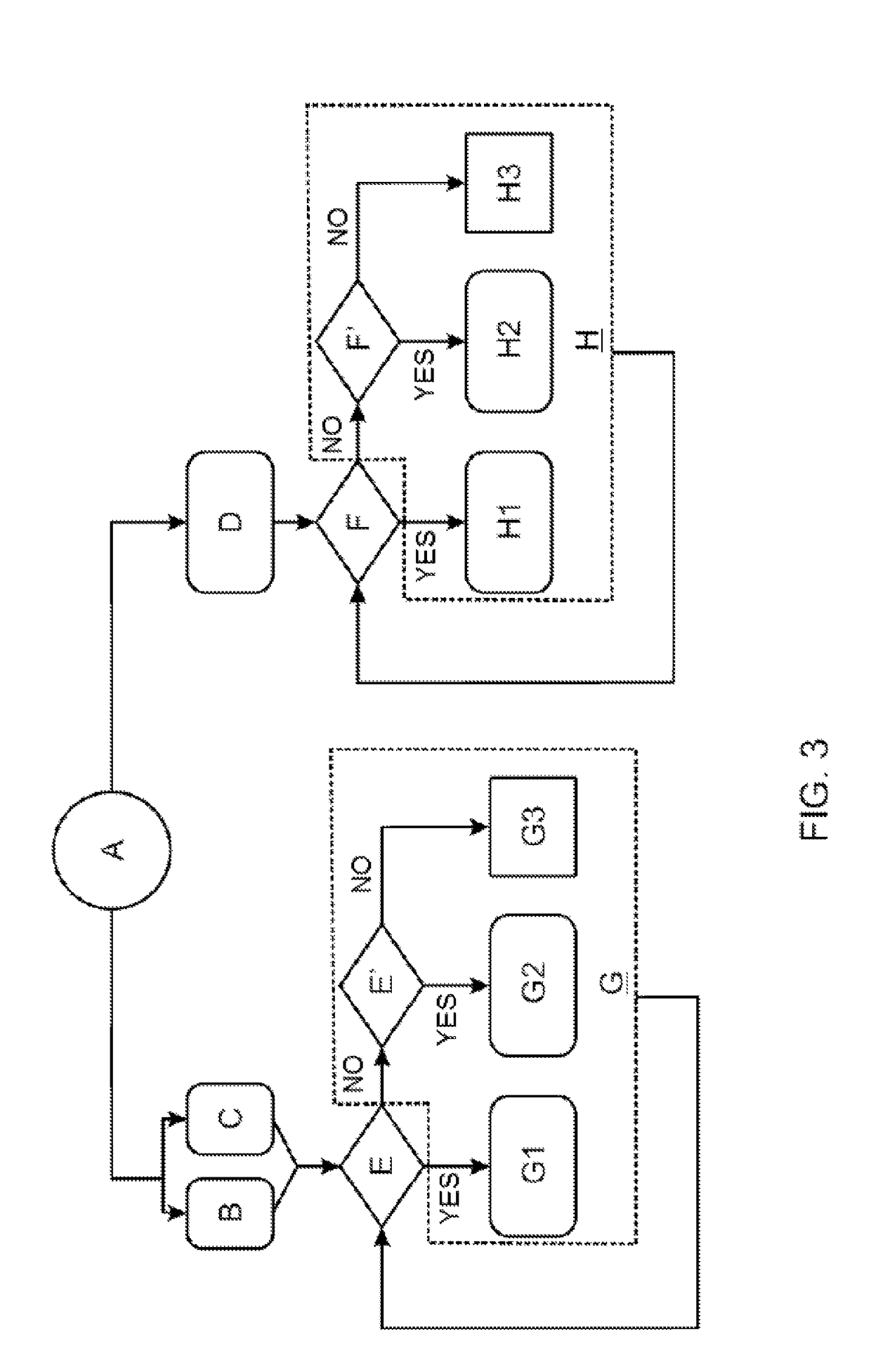

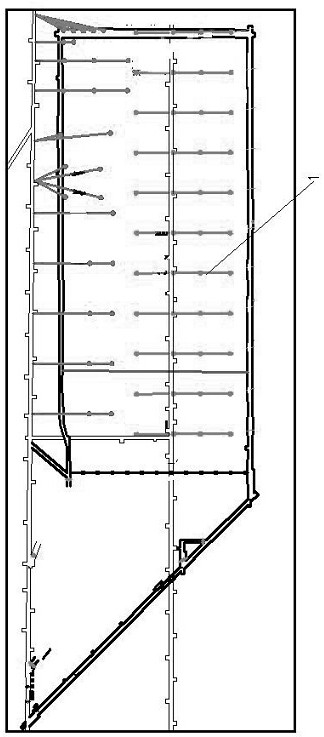

Method and System of Operating an Automotive Harvester

A method and system of operating a machine harvester that presents an improved solution for preventing clogging. There is provided simultaneous measurement of at least a parameter of a base-cutting set, of at least a parameter of a chopping assembly, and of a position of at least a floating roller of a conveyance system. Based on comparisons of the parameters measured and reference values, during a pre-defined time interval, it is possible to manage a propulsion speed of the machine harvester and to manage a rotation speed of cutting disks of the base-cutting set and of billet-cutting blades of the chopping assembly.

Owner:BLUE LEAF I P

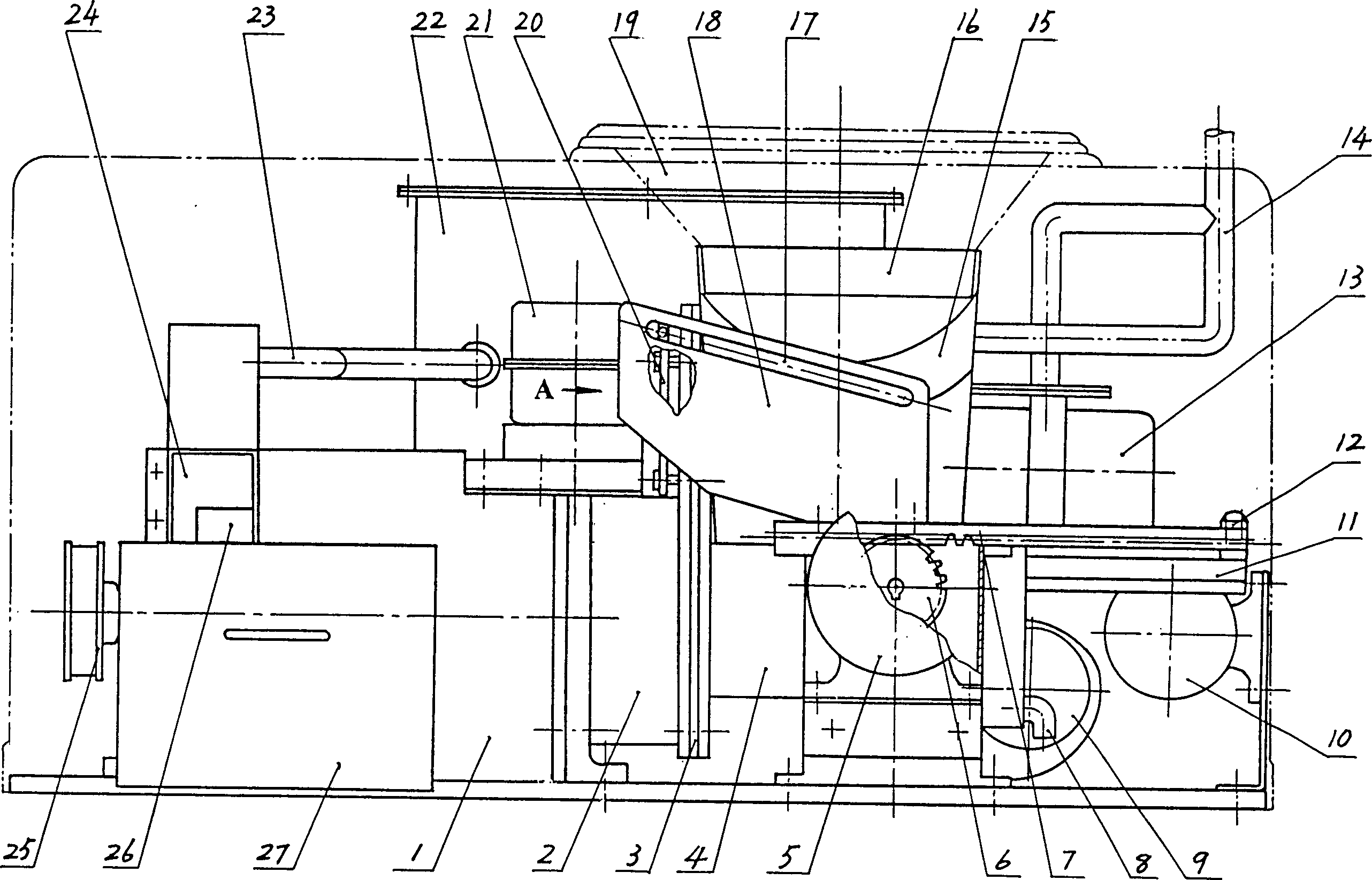

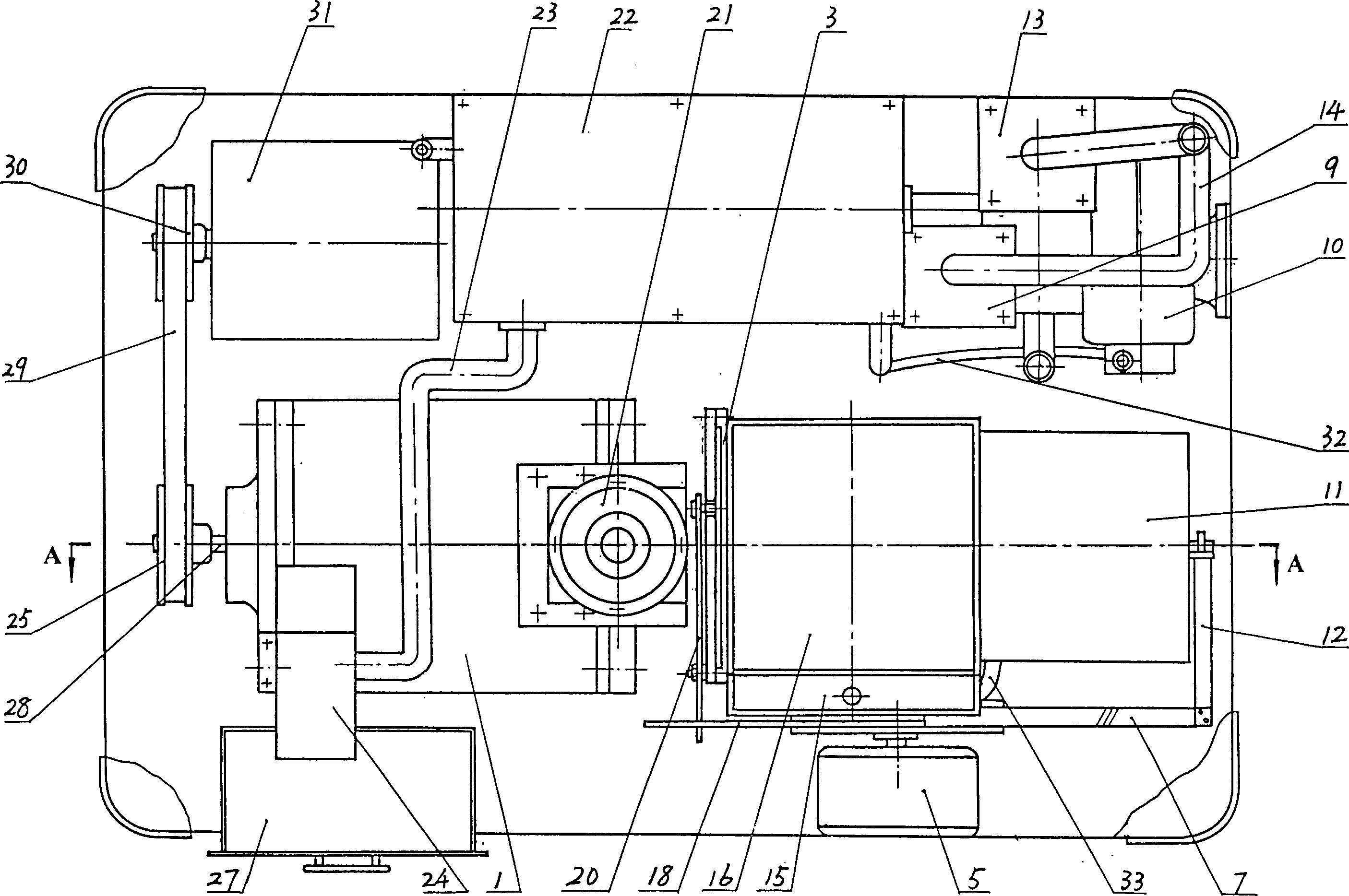

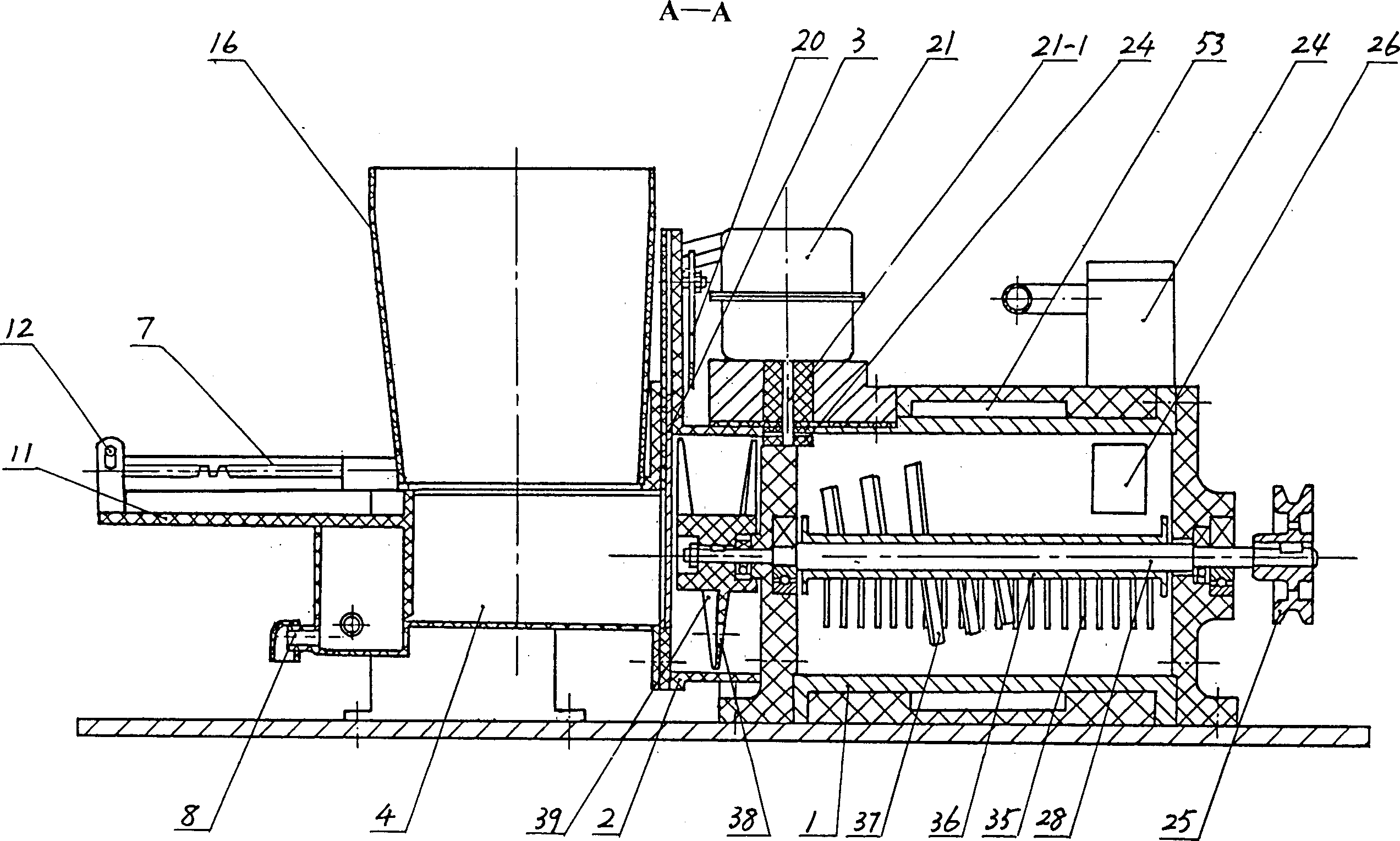

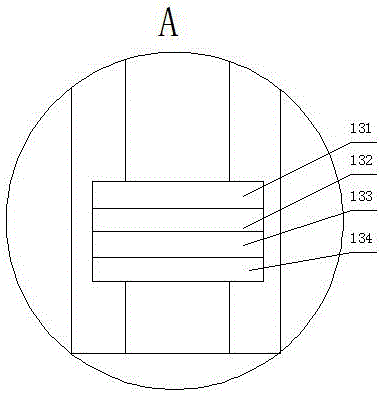

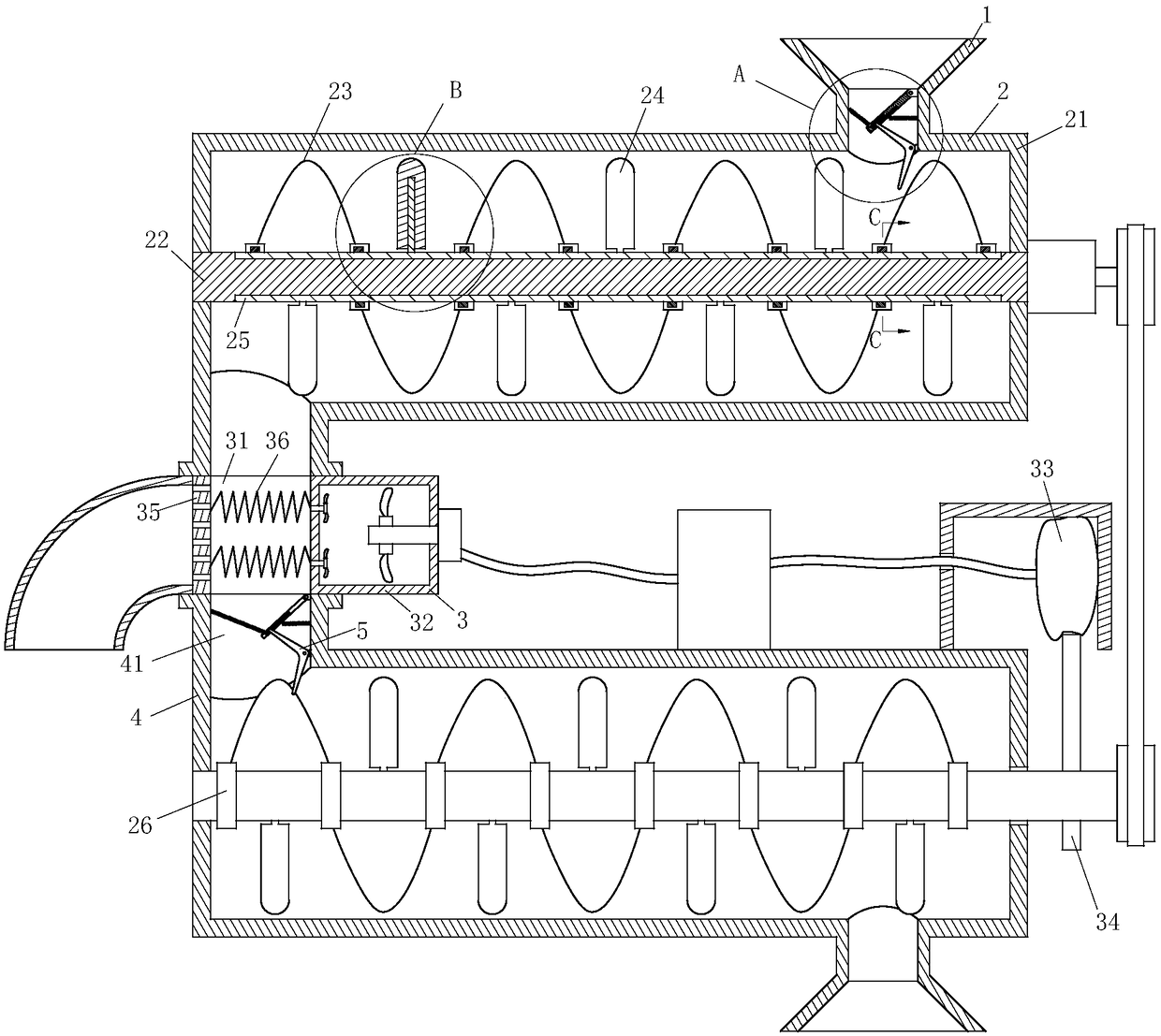

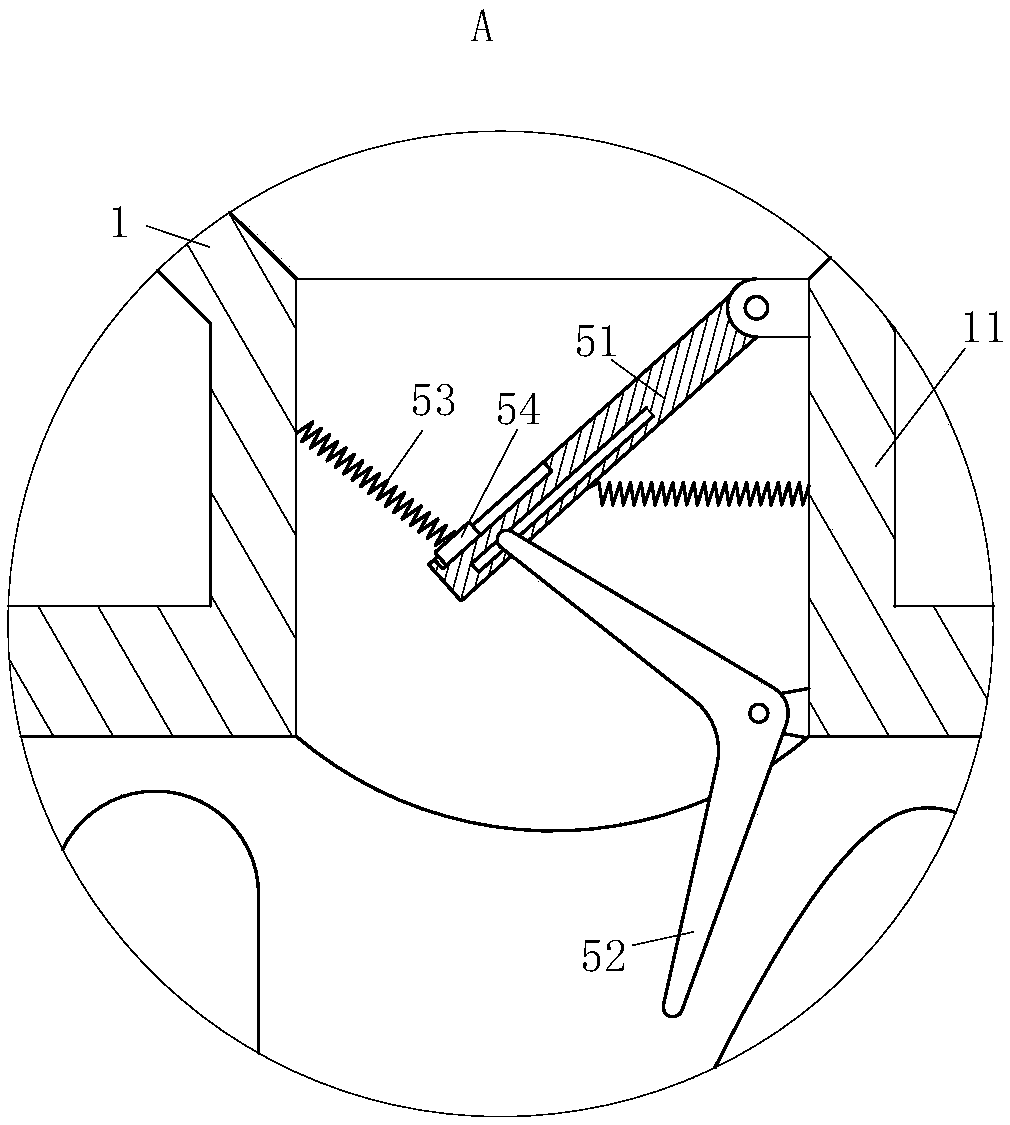

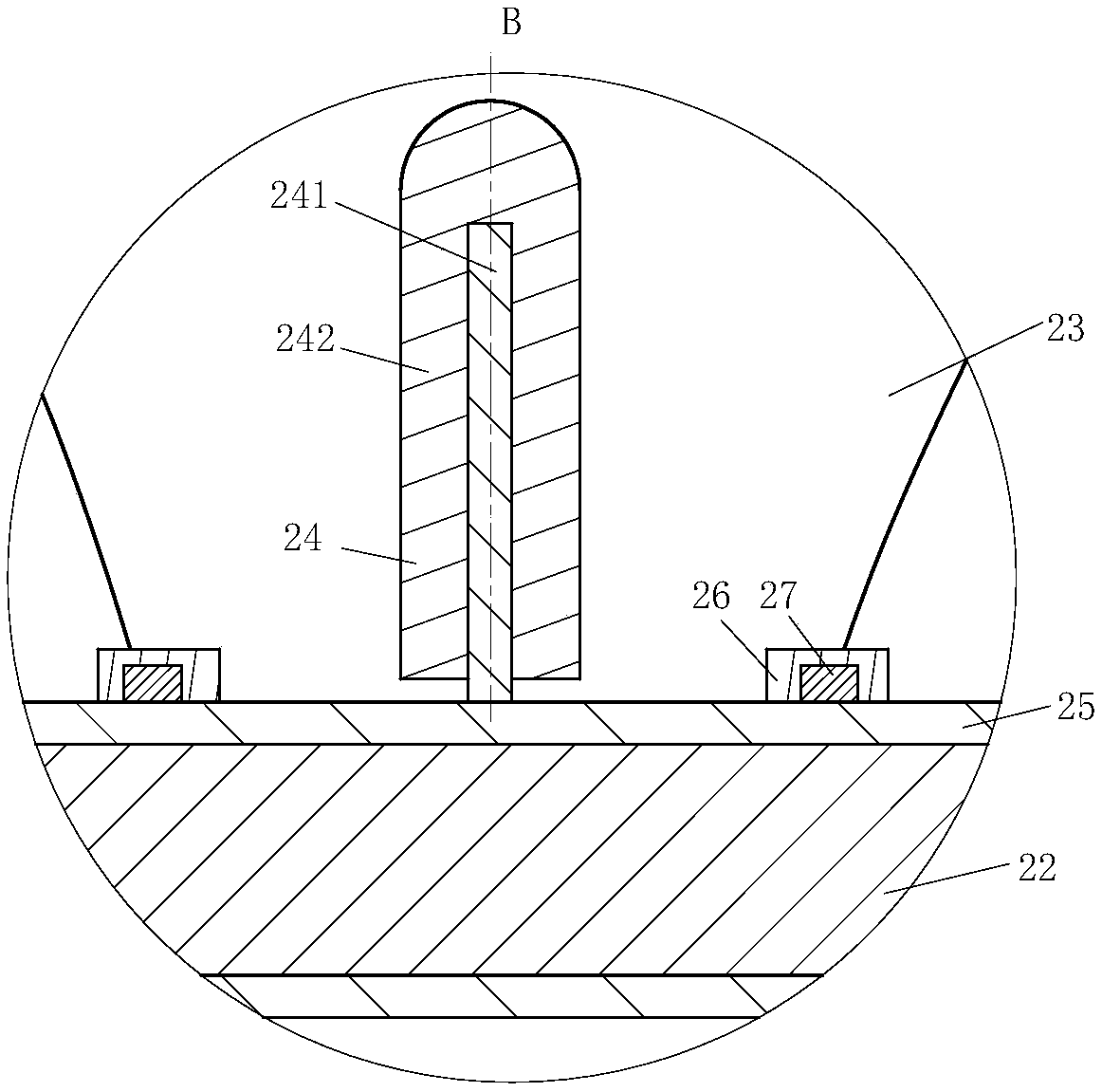

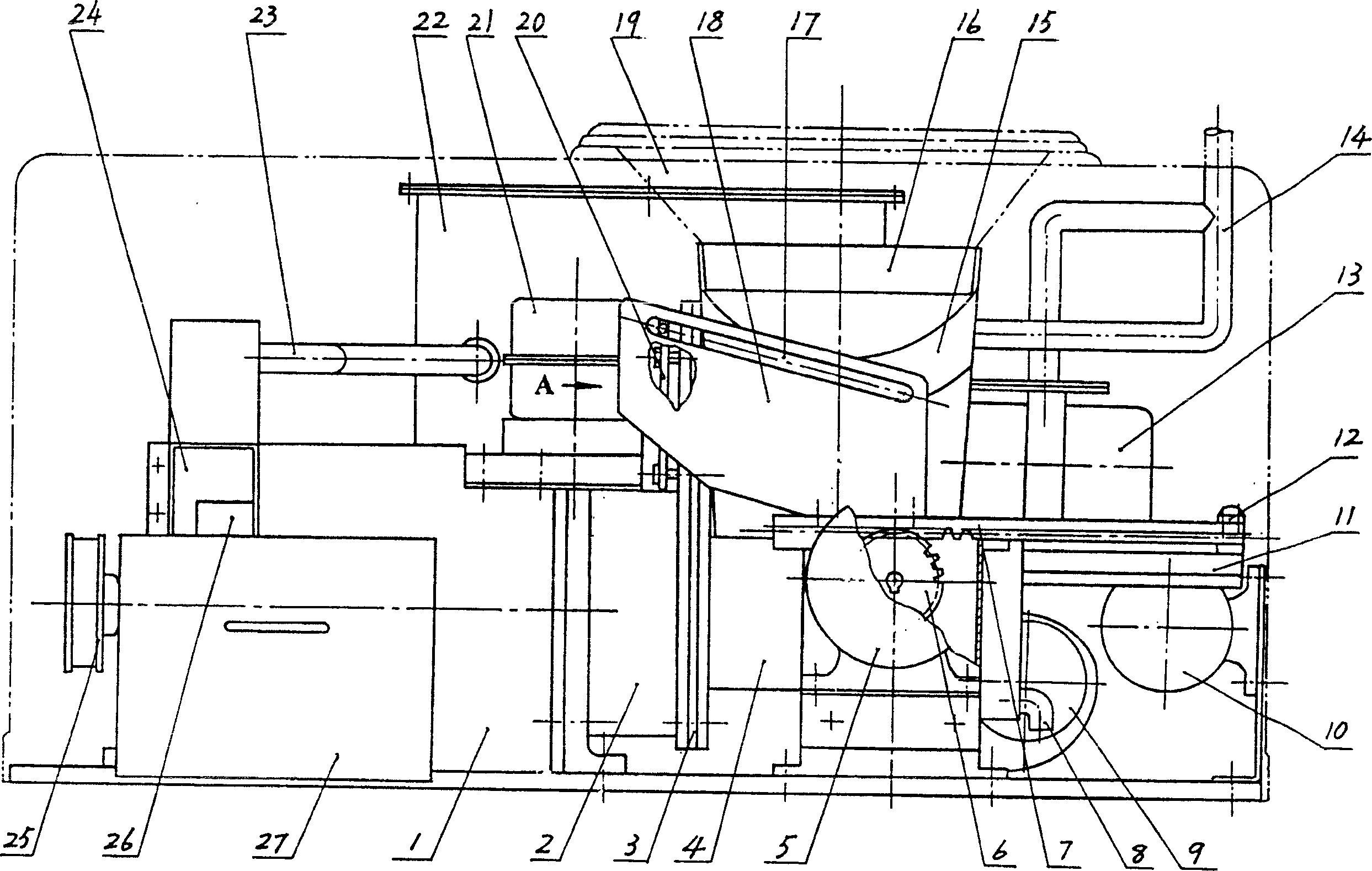

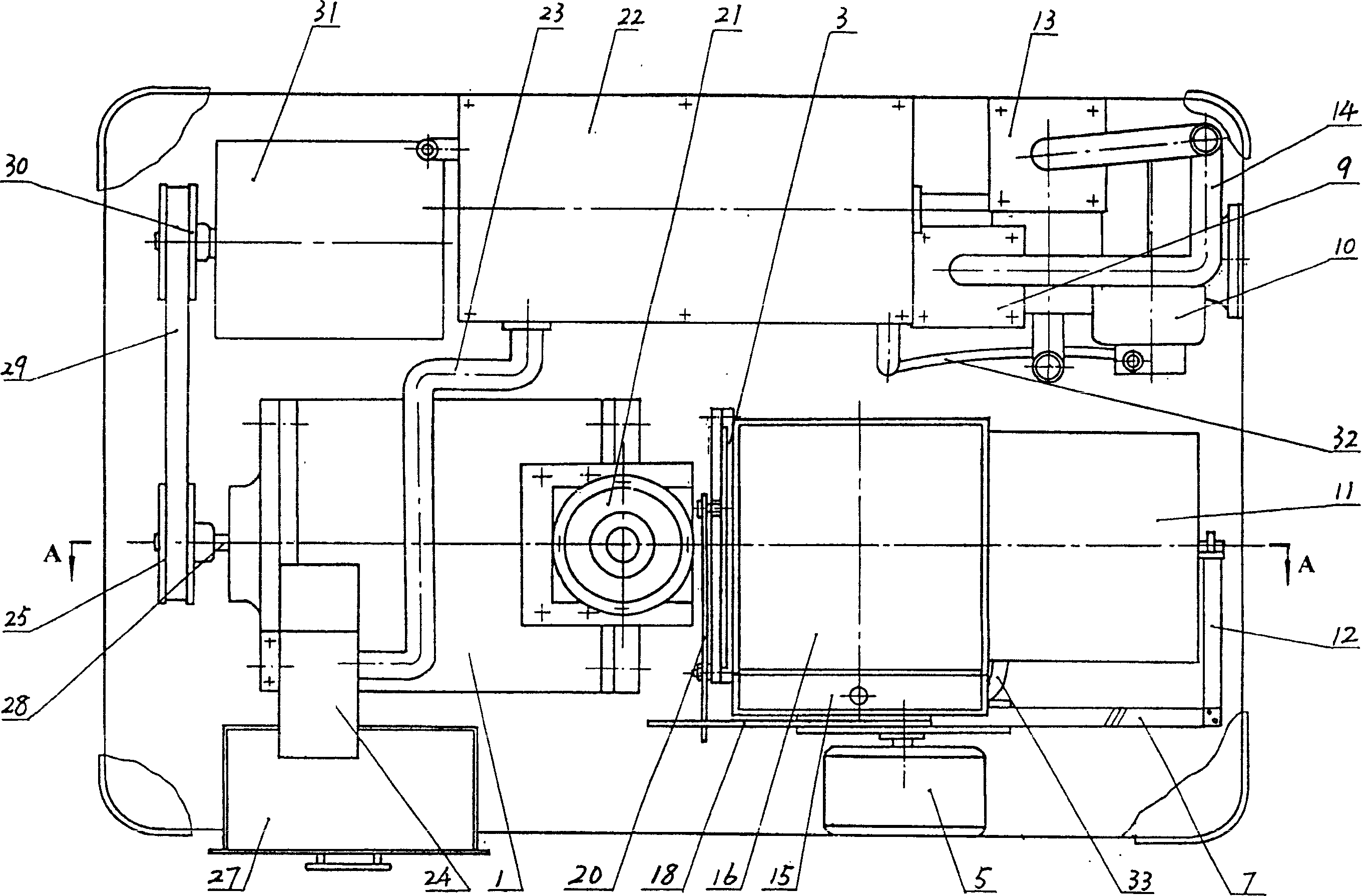

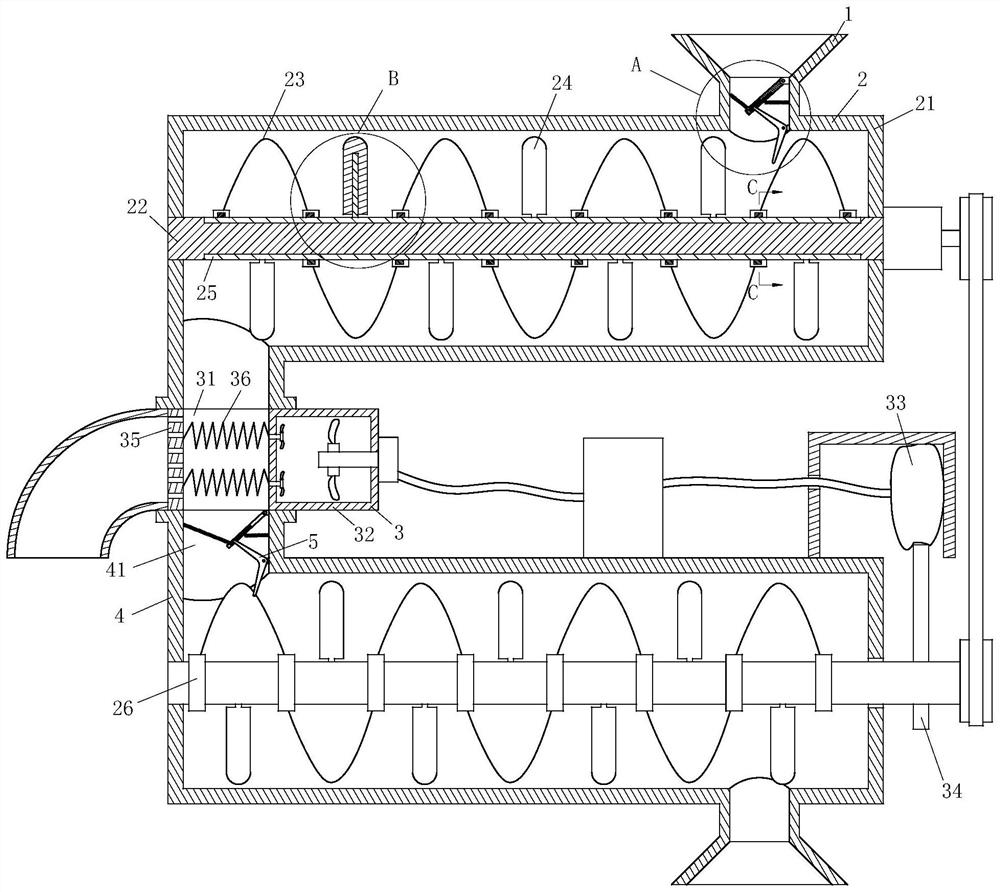

Environment protection type excrement and urine treatment machine

InactiveCN1433979ARelieve pressureReduce propulsion speedSludge treatment by de-watering/drying/thickeningSolid waste disposalImpellerTreatment effect

The environment-protecting fecal treatment machine includes closet pan, falling feces connecting barrel, feces channel, material cylinder and drying cylinder, in the feces channel a push plate is inserted and mounted, said push plate is connected with power device by means of driving mechanism, the interior of drying cylinder is equipped with main shaft connected with power device, the interior of material cylinder is equipped with feeding blade wheel on which the pressure-reducing hole is set, a centrifugal cutter frame is mounted in the interior of the drying cylinder, and the periphery of the drying cylinder is equipped with heater. Besides, it also includes the components of motor, main shaft and gate plate, etc. and its treatment effect is good and its treatment efficiency is high.

Owner:李国民

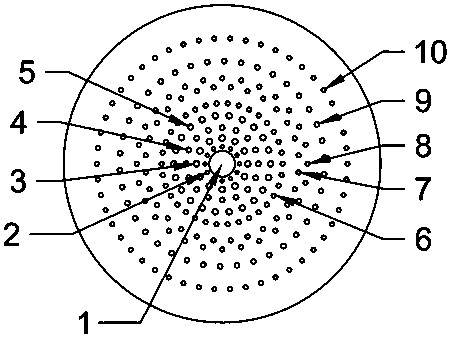

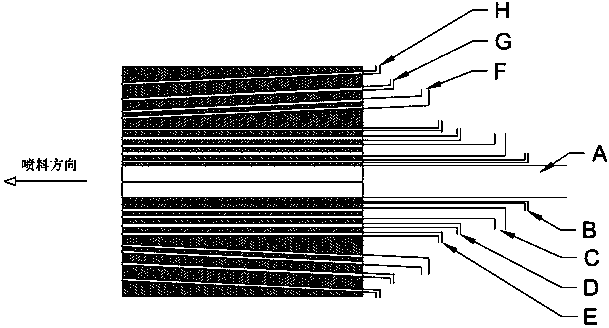

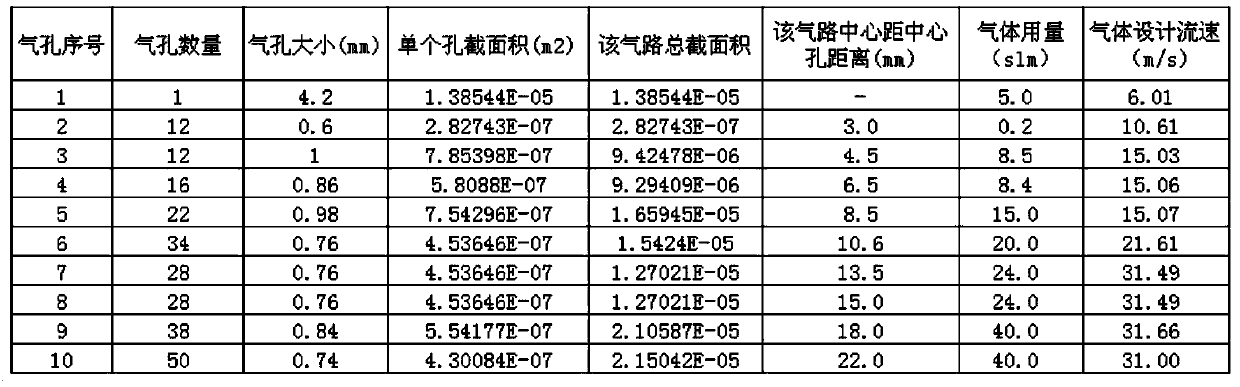

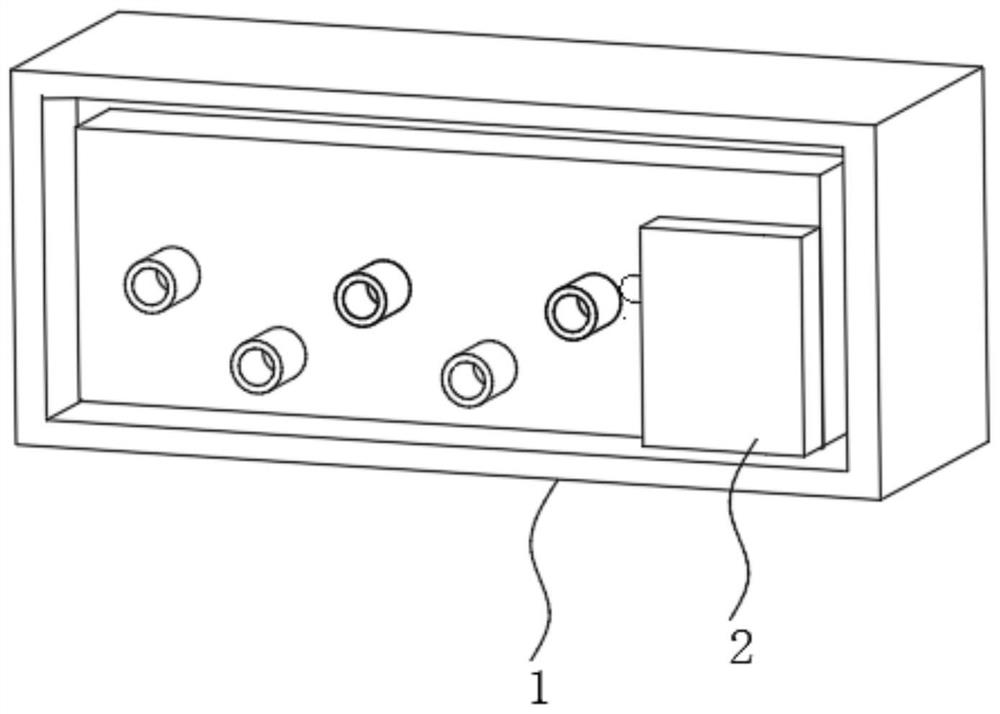

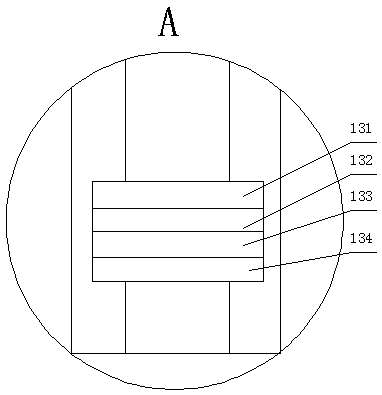

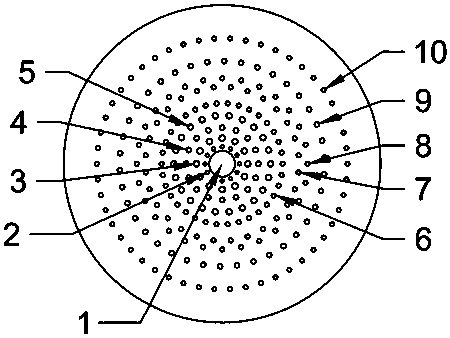

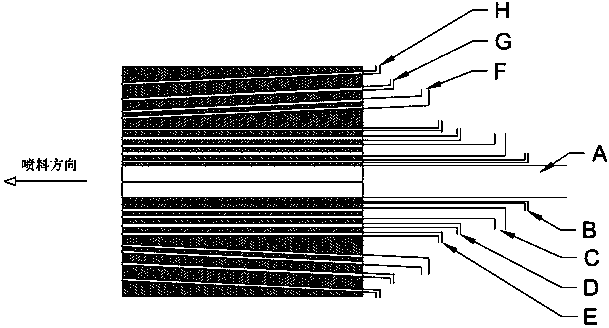

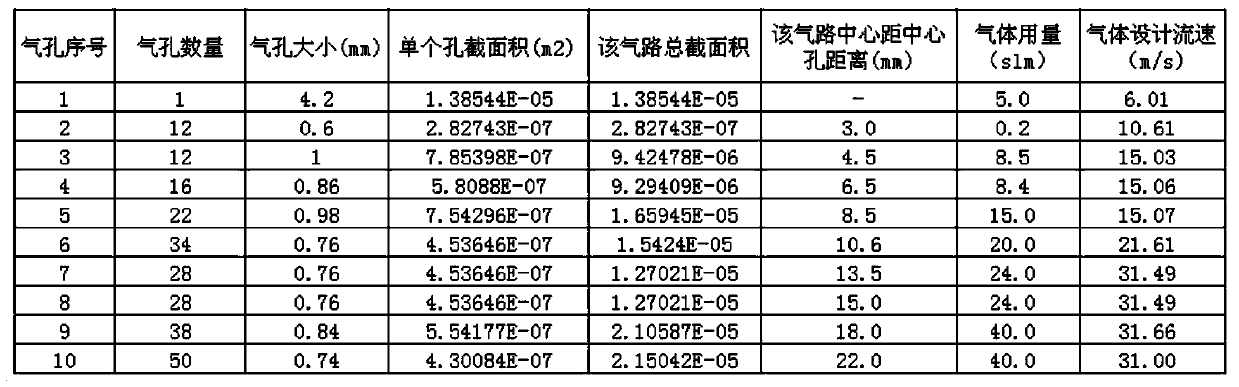

VAD prepared large-core optical fiber parent metal blast burner

ActiveCN107857470AAvoid getting lostImprove efficiencyGlass making apparatusGlass productionGas pipelineProduct gas

The invention relates to a VAD prepared large-core optical fiber parent metal blast burner which comprises a cylindrical blast burner body, wherein a central feeding hole and a plurality of layers ofannularly-distributed air holes around the central feeding holes are formed in the peripheral direction of the blast burner body. The blast burner is characterized in that the plurality of layers of the annularly-distributed air holes sequentially include inner-layer separation air holes, inner-layer flame air holes, outer-layer separation air holes and outer-layer frame air holes from inside to outside; the inner-layer flame air holes include inner-layer flame oxygen holes and inner-layer flame hydrogen holes; the outer-layer flame air holes include outer-layer flame oxygen holes and outer-layer frame hydrogen holes. When the blast burner disclosed by the invention is utilized, a contact area between the raw materials and inner-layer gas can be enlarged through distribution of relative positions of all the gas pipelines and flow velocity matching among gas of all the pipelines; thus, combustion can be fuller, the purpose of manufacturing large-core optical fiber parent metal is achieved, and a production efficiency is improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Method for acid stimulation after carbon dioxide huffing-puffing

InactiveCN104453812AReduce propulsion speedEasy accessFluid removalDrilling compositionOil productionWellbore

The invention provides a method for acid stimulation after carbon dioxide huffing-puffing. The method for acid stimulation after carbon dioxide huffing-puffing comprises the following steps that (1), after a ground device is connected safely, pressure testing of 30 MPa is carried out, it is required that pressure is kept down for 25 min, stabbing and leakage are avoided, pressure testing is carried out three times continuously, evacuation is needed every time pressure testing is finished, and pressure is required to be zero; (2), composite foam acid of 30-50 m<3> is injected; (3), large-displacement injection testing is carried out, the displacement gradual rising method is adopted, and displacement fluid is injected after the foam acid is injected. The method prevents the gar block-up effect from being generated at the immediate vicinity of a wellbore, improves the success rate of measures and increases the oil production of a single well.

Owner:DAQING JINJUN PETROLEUM TECH DEV CO LTD

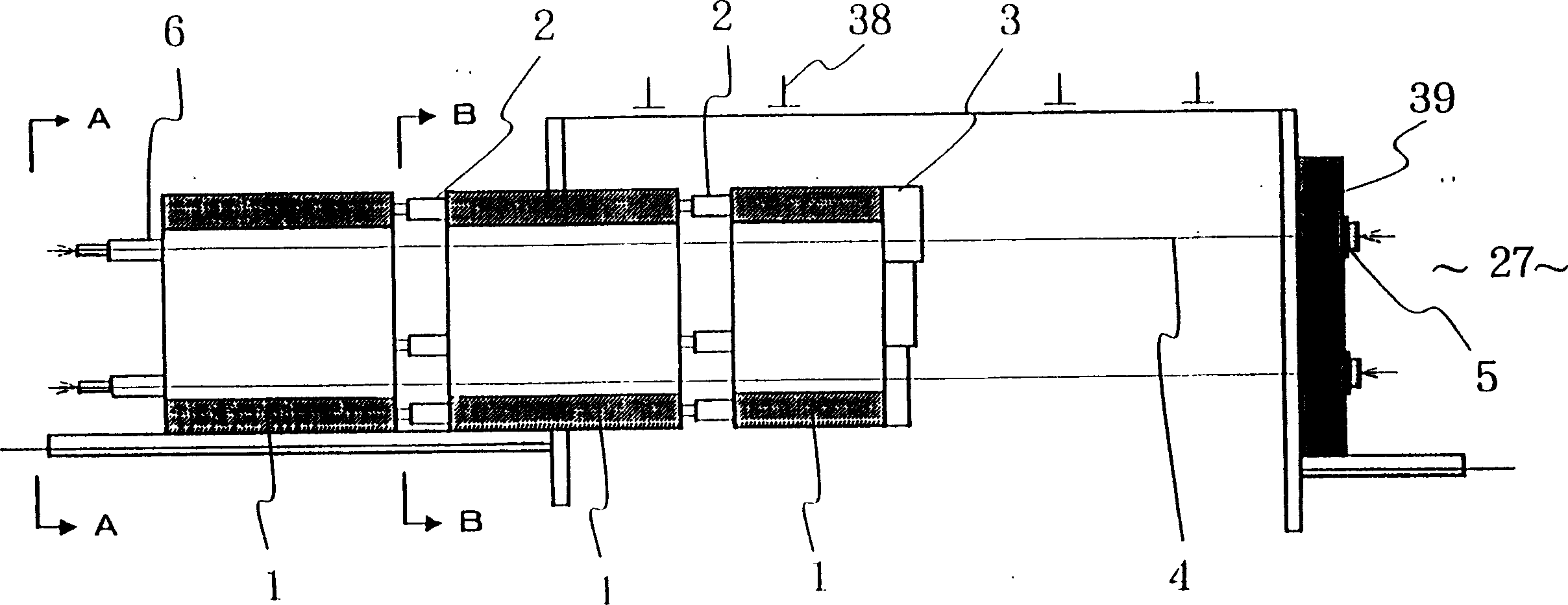

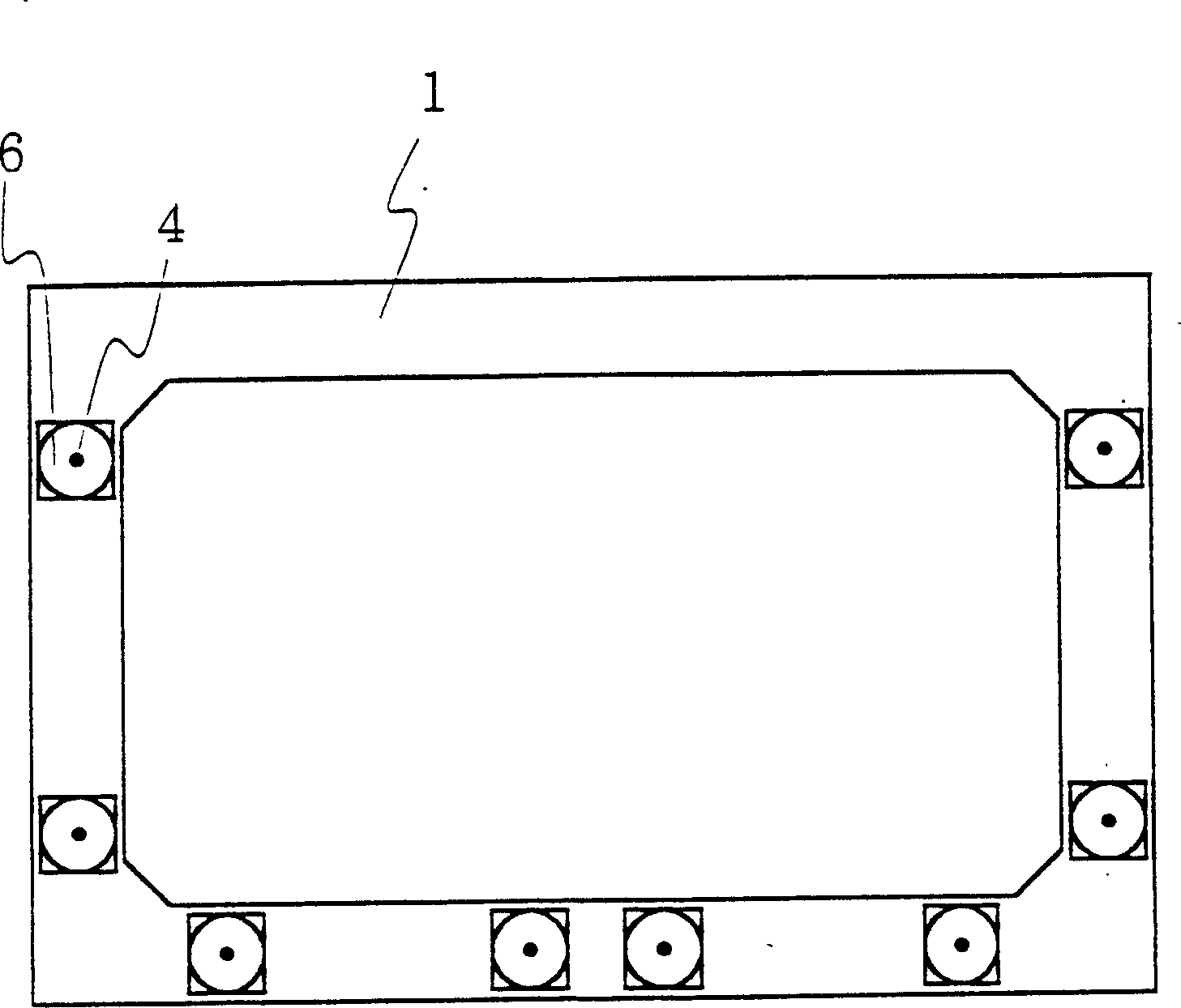

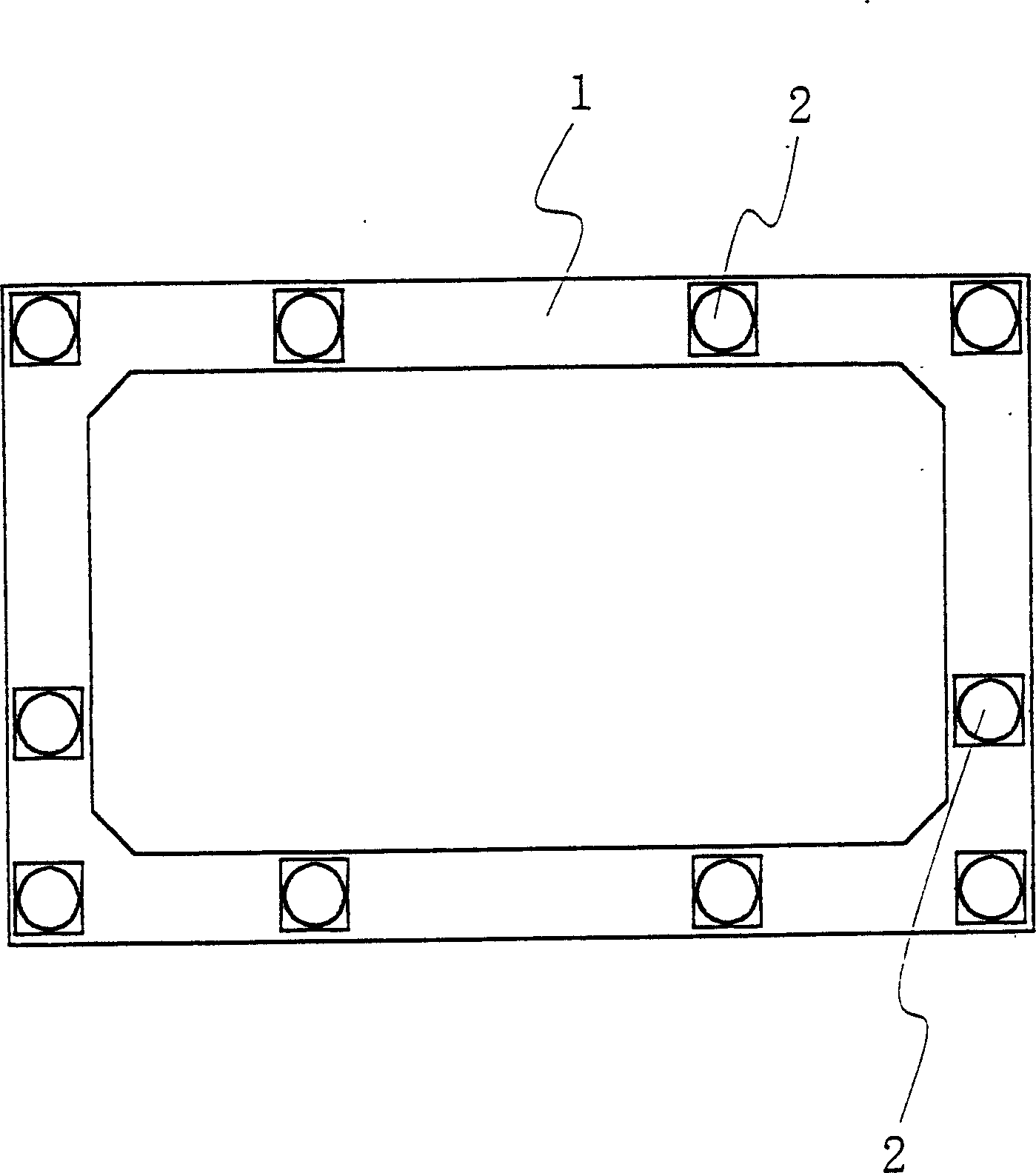

Method and device for structuring tunnel by propulsion of underground box

A method for constructing tunnel by driving underground case body to advance includes installing cutting tools to front end of said case body, passing the drawing member (such as PC-steel cable) through the case body, arranging the fixing part or driving jack to the back end of case body, arranging the driving jack or fixing part at another end, and digging segment by segment.

Owner:UEMURA ENG

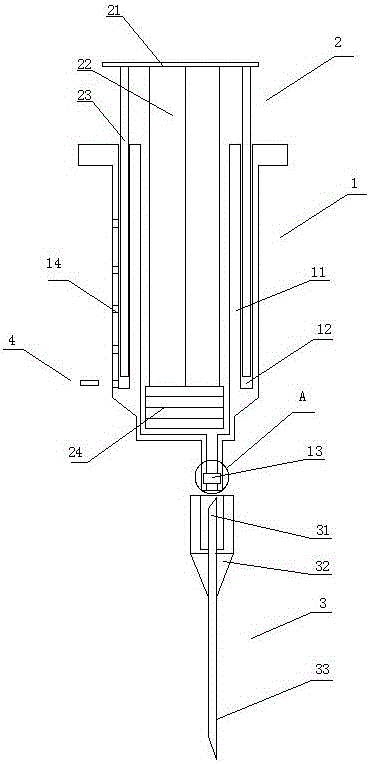

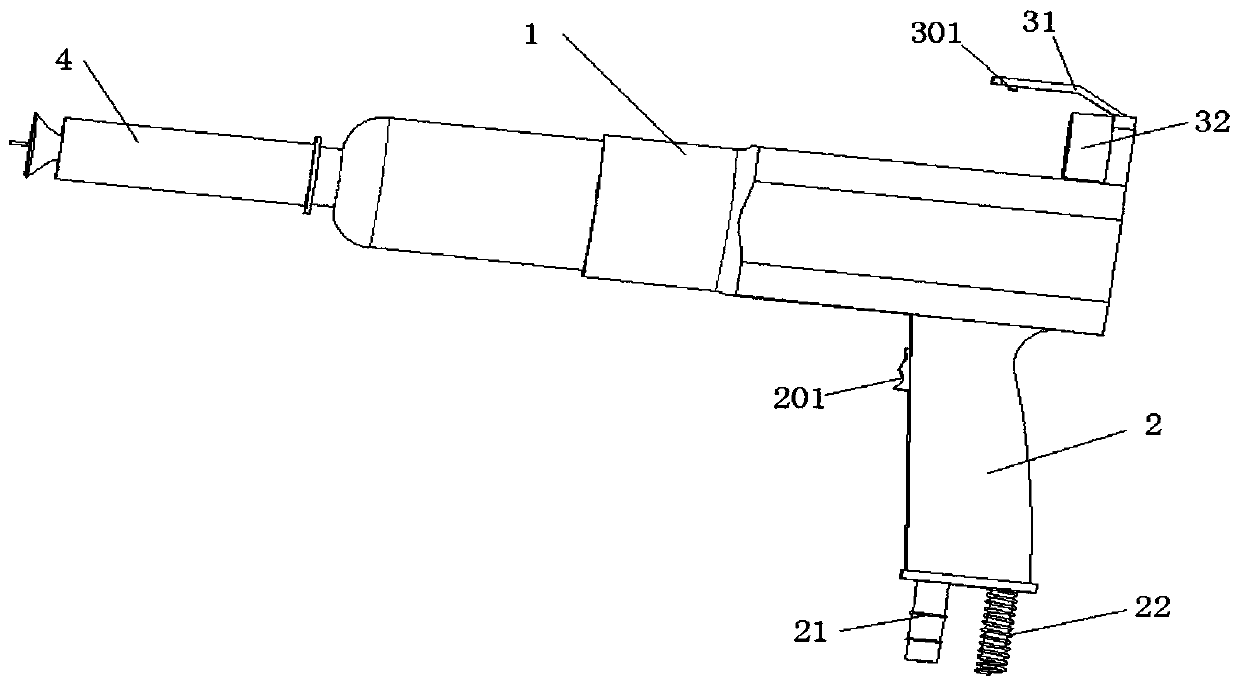

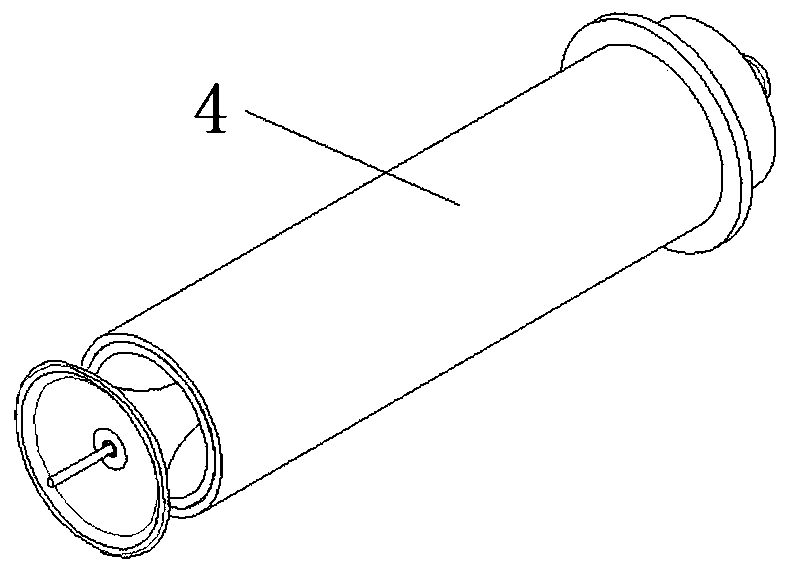

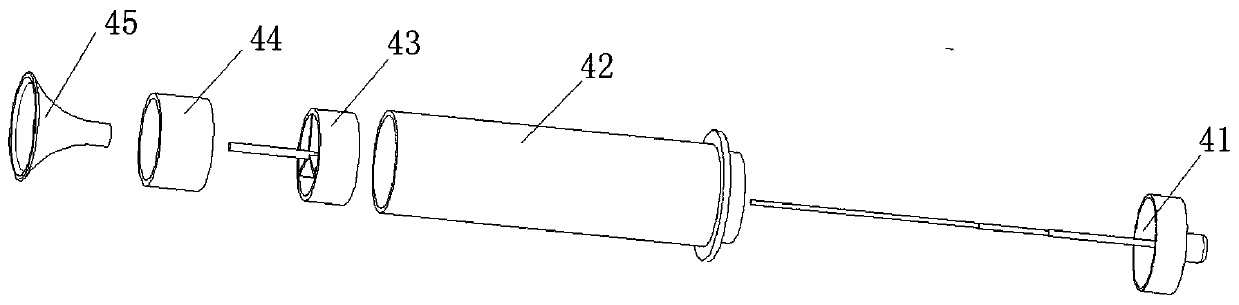

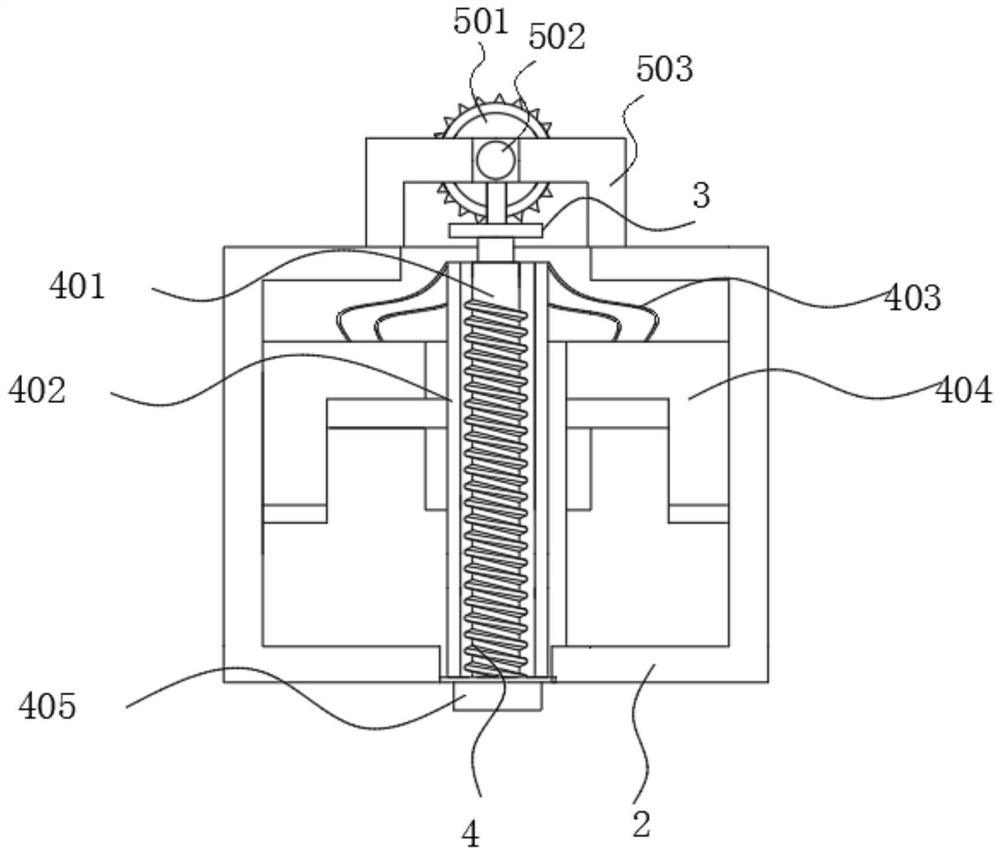

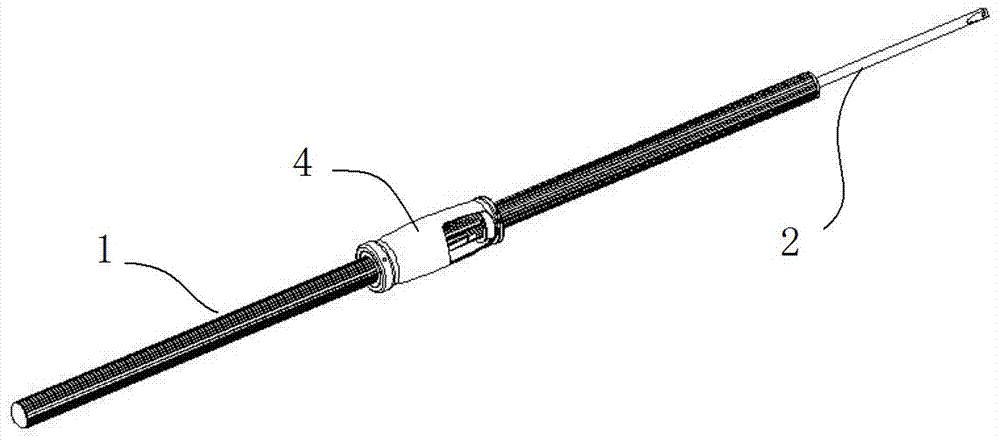

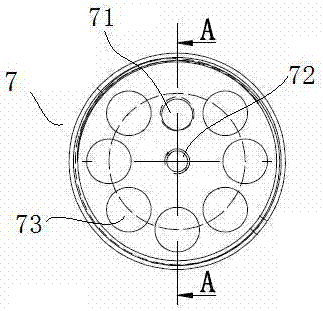

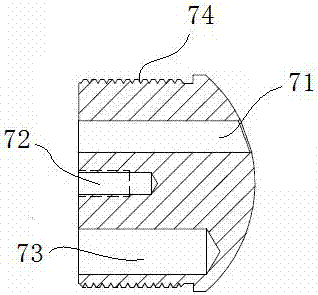

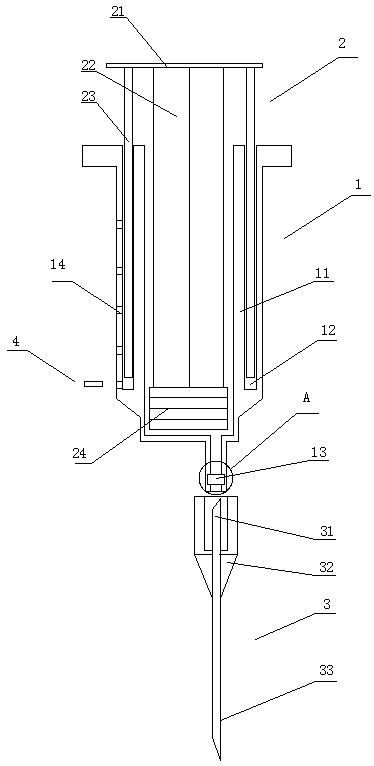

Syringe

ActiveCN106823068AControl injection speedReduce propulsion speedEngine sealsInfusion syringesInjection portInjection equipment

The invention relates to the field of injection equipment, in particular to a syringe. The syringe comprises a syringe canister, a syringe piston and an entry needle; the injection port of the syringe canister is provided with a sealing part, and the connecting end of the entry needle is provided with an acicular part used for piercing the sealing part. The arrangement of the sealing part and the entry needle corresponding to the sealing part can prevent the syringe from being polluted at the mouth portion of the syringe by bacteria and improve the anti-bacteria and sterilization effect. The structure can make it convenient to produce the syringe and the entry needle separately, and accordingly the production difficulty is reduced. The sealing part is thin film integrally shaped with the syringe canister. The thin film is integrally shaped, better in leakproofness and lower in cost, and can prevent the bacteria completely with the characteristic of being disposable. Through control over resistance of push of a limiting rod, the push speed of the piston is effectively reduced, the precise control over added quantity of the syringe is improved, and the lower the push speed is, the preciser the added quantity control is.

Owner:PANZHIHUA JIUDINGZHIYUAN INTPROP OPERATION CO LTD

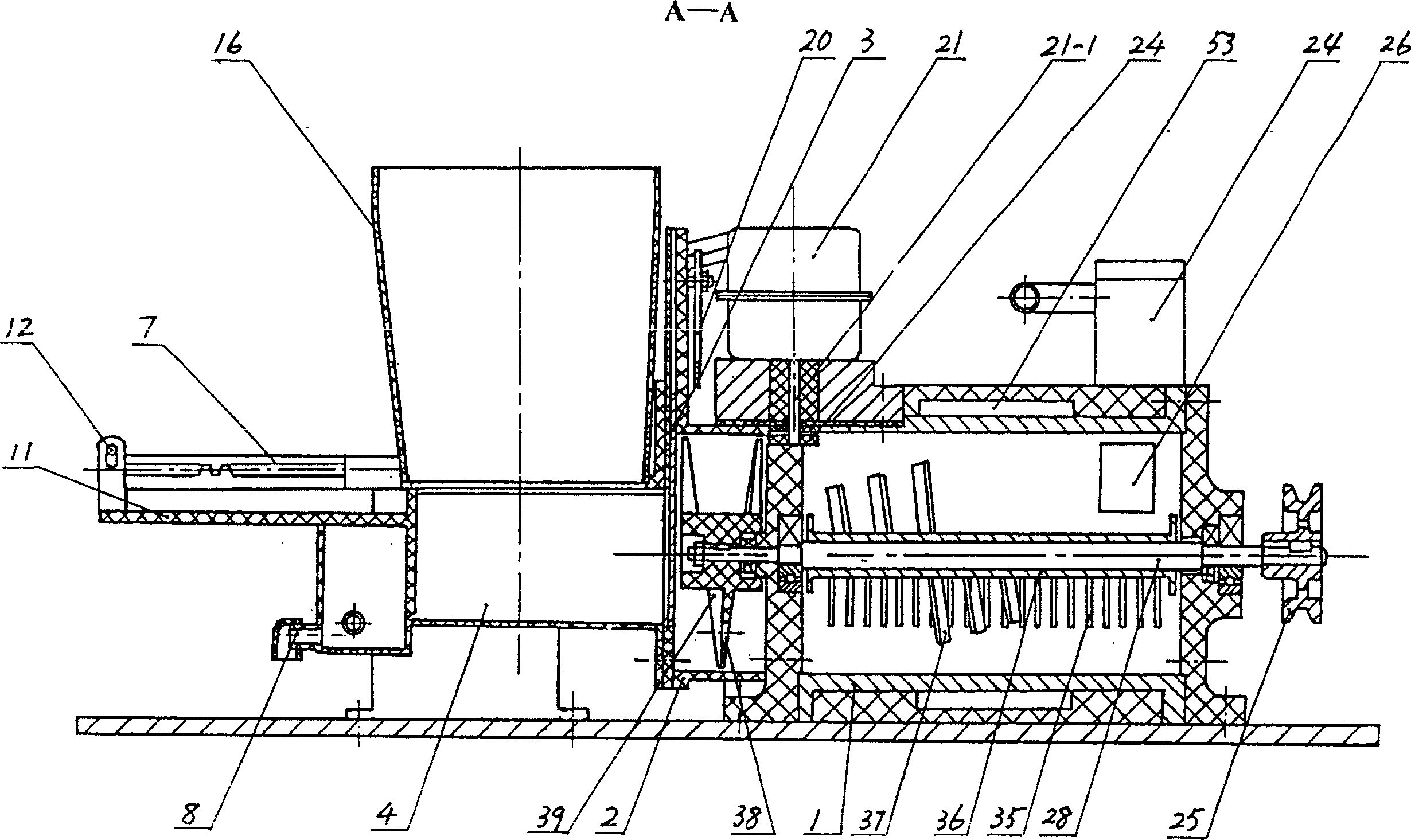

Activated carbon grinding equipment

ActiveCN109499721AReduce propulsion speedImprove adsorption capacityGrain treatmentsActivated carbonEngineering

The invention belongs to the technical field of grinding equipment and particularly relates to activated carbon grinding equipment. The activated carbon grinding equipment comprises a hoper, a first-stage grinding device, a screening module and a second-stage grinding device. The first-stage grinding device and the second-stage grinding device conduct driving synchronously. The first-stage grinding device comprises a grinding box, a grinding rotary shaft, a grinding spiral lamina and grinding rods. The grinding rotary shaft is connected to the interior of the grinding box. The grinding rotaryshaft is provided with grooves in the length direction. Magnets I are inlaid in the grooves. The grinding rotary shaft is sleeved with a plurality of grinding rings distributed uniformly. The grindingrings are provided with magnets II. The grinding spiral lamina is fixed to the grinding rings. The screening module is used for screening out activated carbon meeting the standards and guiding activated carbon not meeting the standards into the second-stage grinding device for continuous grinding. According to the activated carbon grinding equipment, differential rotation is formed between the grinding rotary shaft and the grinding spiral lamina, the grinding time of the activated carbon is prolonged, the activated carbon is ground more sufficiently, and the grinding quality is improved.

Owner:金寨智行知识产权运营有限公司

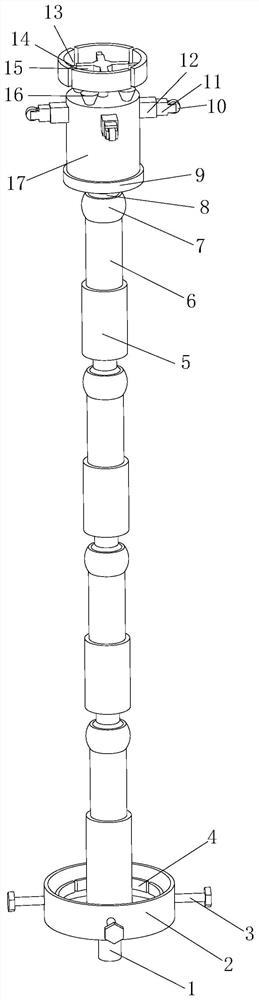

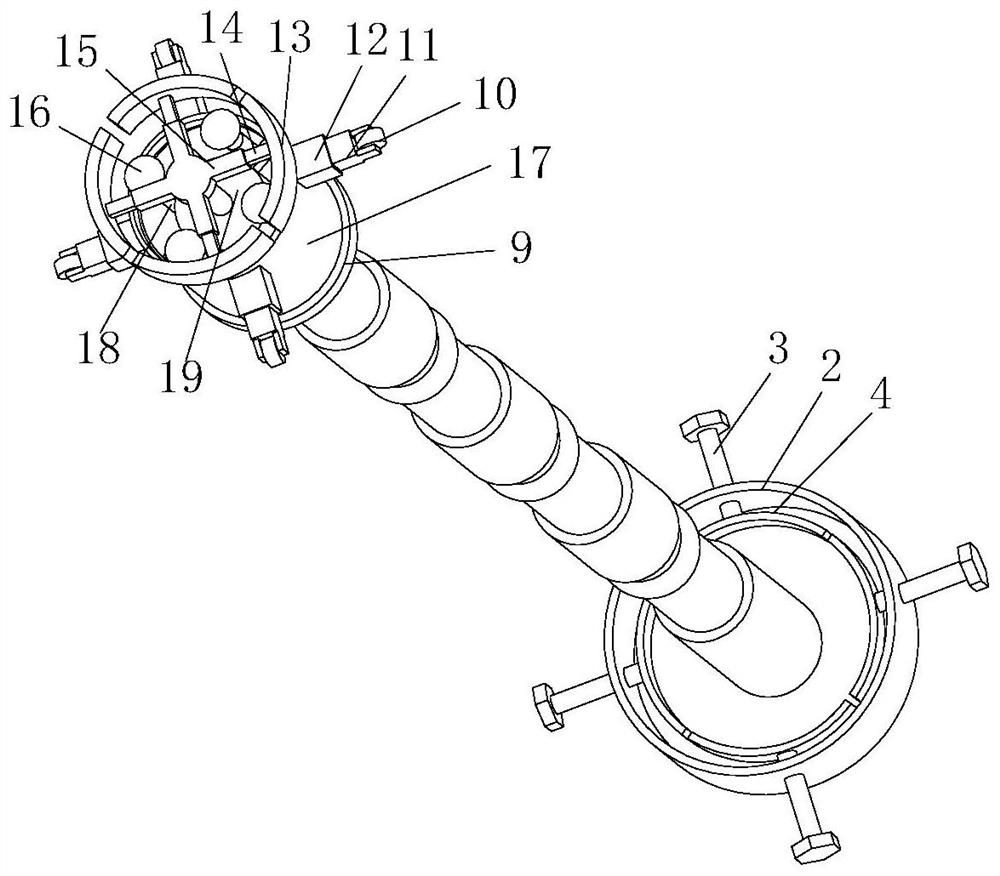

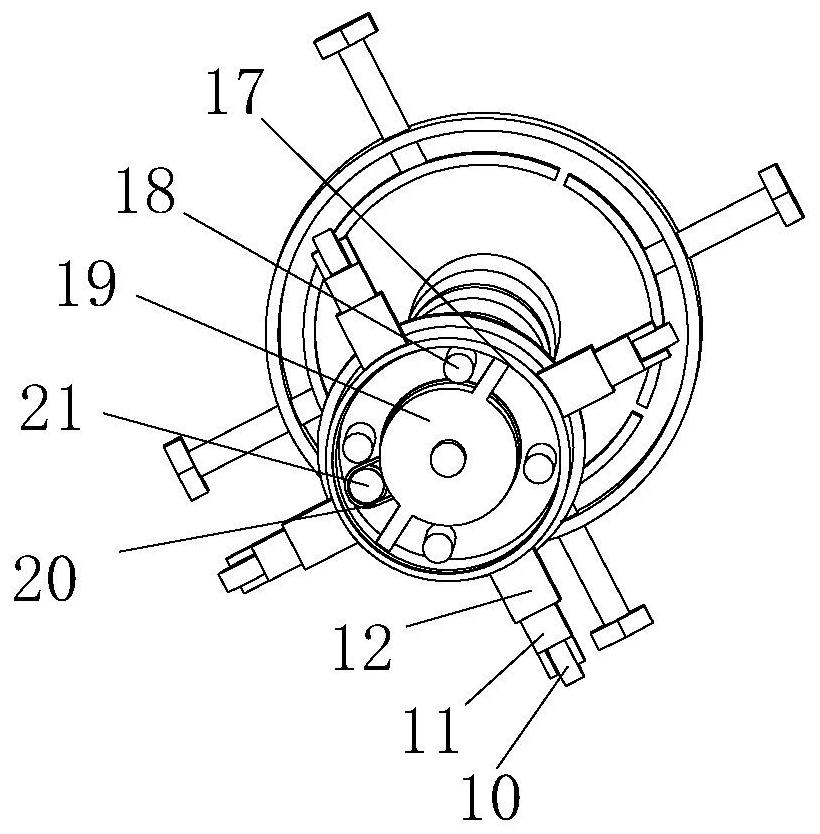

Rod type automatic moving bent pipe inner wall cleaning device

ActiveCN112643418AEasy to cleanArc automatically adaptsRevolution surface grinding machinesGrinding drivesPipeMechanics

The invention relates to the technical field of steel pipe machining, and discloses a rod type automatic moving bent pipe inner wall cleaning device. The device comprises a base and four outer rods, a fixing device is arranged in the base, a water inlet pipe is fixedly connected to the bottom of the base, and extendable rods are arranged in the outer rods. According to the rod type automatic moving bent pipe inner wall cleaning device, when a bent pipe is cleaned and the cleaning device enters the bent pipe, an inner ball can rotate in an outer ball, the interior of the bent pipe can be cleaned conveniently, bending can be conducted according to the radian of the bent pipe, then the inner wall of a steel pipe can be cleaned, the situation that the interior of the bent pipe is inconvenient to clean is avoided, it is guaranteed that the device can automatically adapt to the radian of the bent pipe, then steel pipes with different bent radians can be cleaned conveniently, and when the steel pipes with the excessively-large bent radians are cleaned, the length of the extendable rod with the proper length should be changed.

Owner:杭州新元素医疗科技有限公司

Electrostatic spraying gun with illuminating function

PendingCN110038744AHigh precisionGood for spray powder coverageLiquid spraying plantsLighting elementsLight beamLight head

The invention discloses an electrostatic spraying gun with an illuminating function. The electrostatic spraying gun comprises an electrostatic gun main body, a handle seat and a gun head arranged at the front end of the electrostatic gun main body. The bottom of the electrostatic gun main body is connected to the handle seat, a powder introducing pipe and an electrifying line are separately arranged at the bottom of the handle seat, an LED lamp holder is arranged on the top of the electrostatic gun main body through a connecting seat, and the emitting direction of the LED lamp holder is aligned to the gun head direction at the front end of the electrostatic gun main body. By aligning the LED lamp holder to the gun head, the LED lamp holder will project strong light beams for spraying powerto cover included angles of a section bar, a deep groove and the like. A manual holding operation is cancelled, and meanwhile, the precision of gun head spraying is also improved and the work efficiency is improved.

Owner:李战峰

Automatic pushing device for stencil of printing machine

InactiveCN107984899AConvenient and smoothAdvance speed adjustmentPrinting platesPrinting press partsPrinting pressElectric wire

The invention discloses an automatic pushing device for a stencil of a printing machine. The automatic pushing device structurally comprises a stencil case, a control panel, a stencil outlet, a conveying table, a pressure sensor, a retractable pushing mechanism, lifting frames, lifting gears, a supporting hollow rod, a lifting toothed rail, a sliding seat, sliding rollers, a base, a sliding grooveand a stencil pushing opening. The control panel is inlaid in the upper portion of the surface of the left side of the stencil case and connected with the conveying table, the pressure sensor, the retractable pushing mechanism, the lifting gears and the sliding rollers in an electrical mode through electric wires. The automatic pushing device has the beneficial effects that the retractable pushing mechanism is arranged, by controlling the angle of the pushing mechanism, the pushing speed of the stencil is adjusted, and by controlling the extension and retraction state of the pushing mechanism, dust accumulation inside a pushing table and the automatic pushing device is prevented, so that smooth pushing of the stencil is guaranteed, meanwhile, the automatic pushing device is protected, andthe service life of the automatic pushing device is prolonged.

Owner:蔡政伟

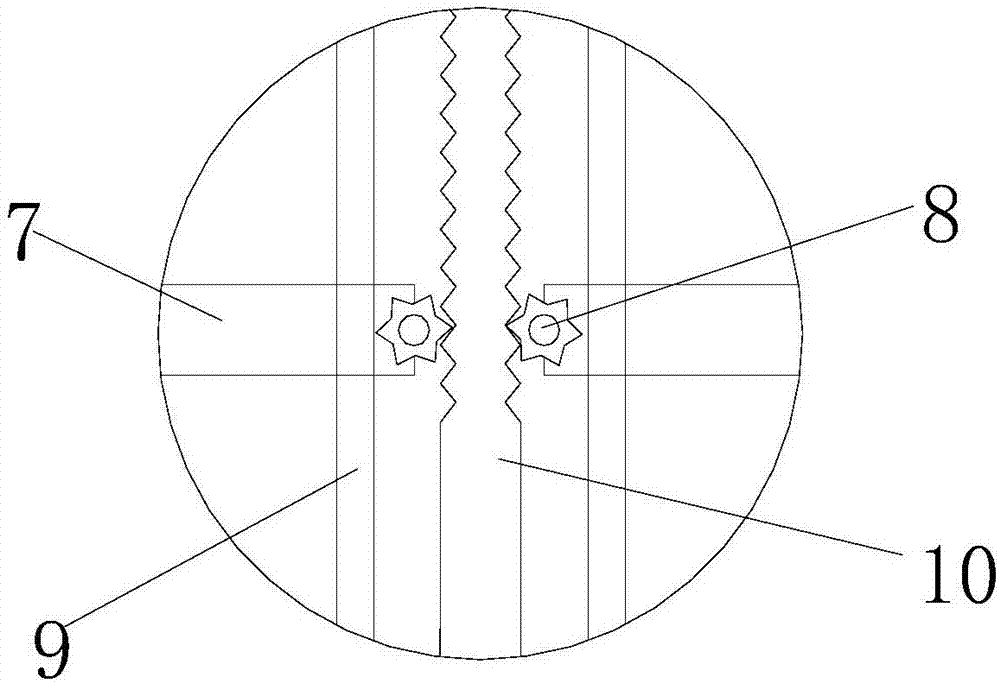

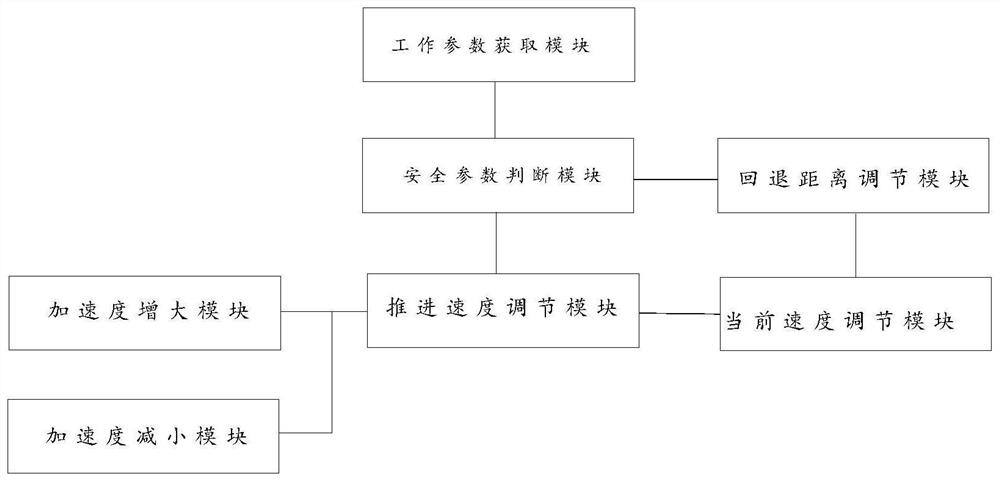

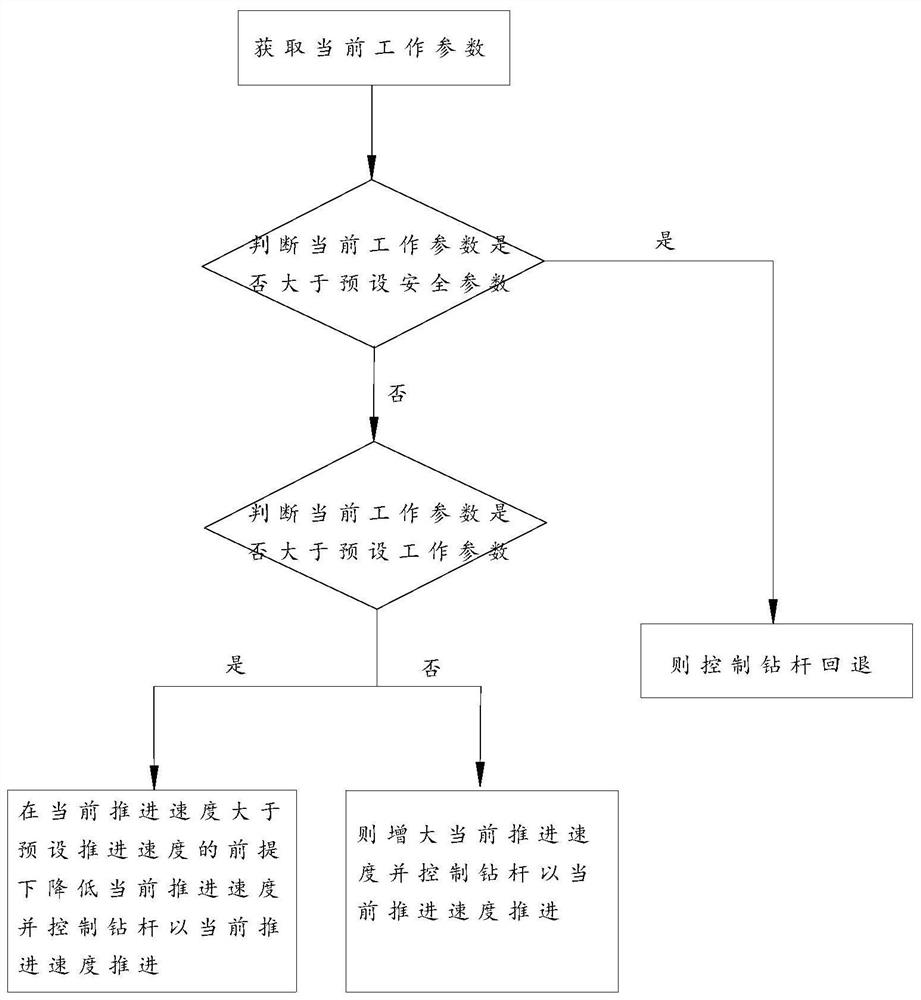

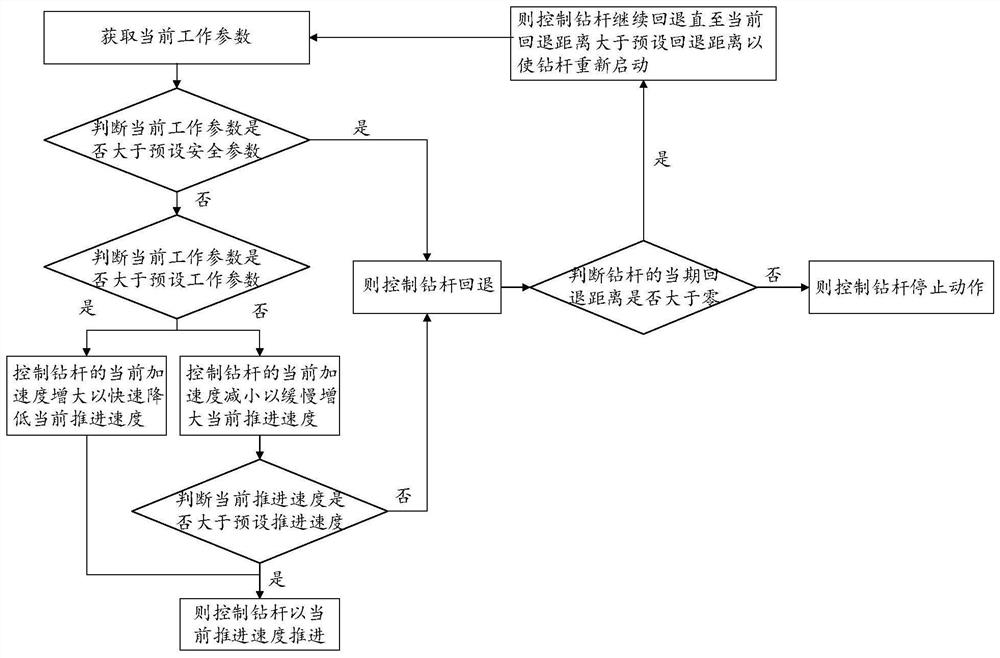

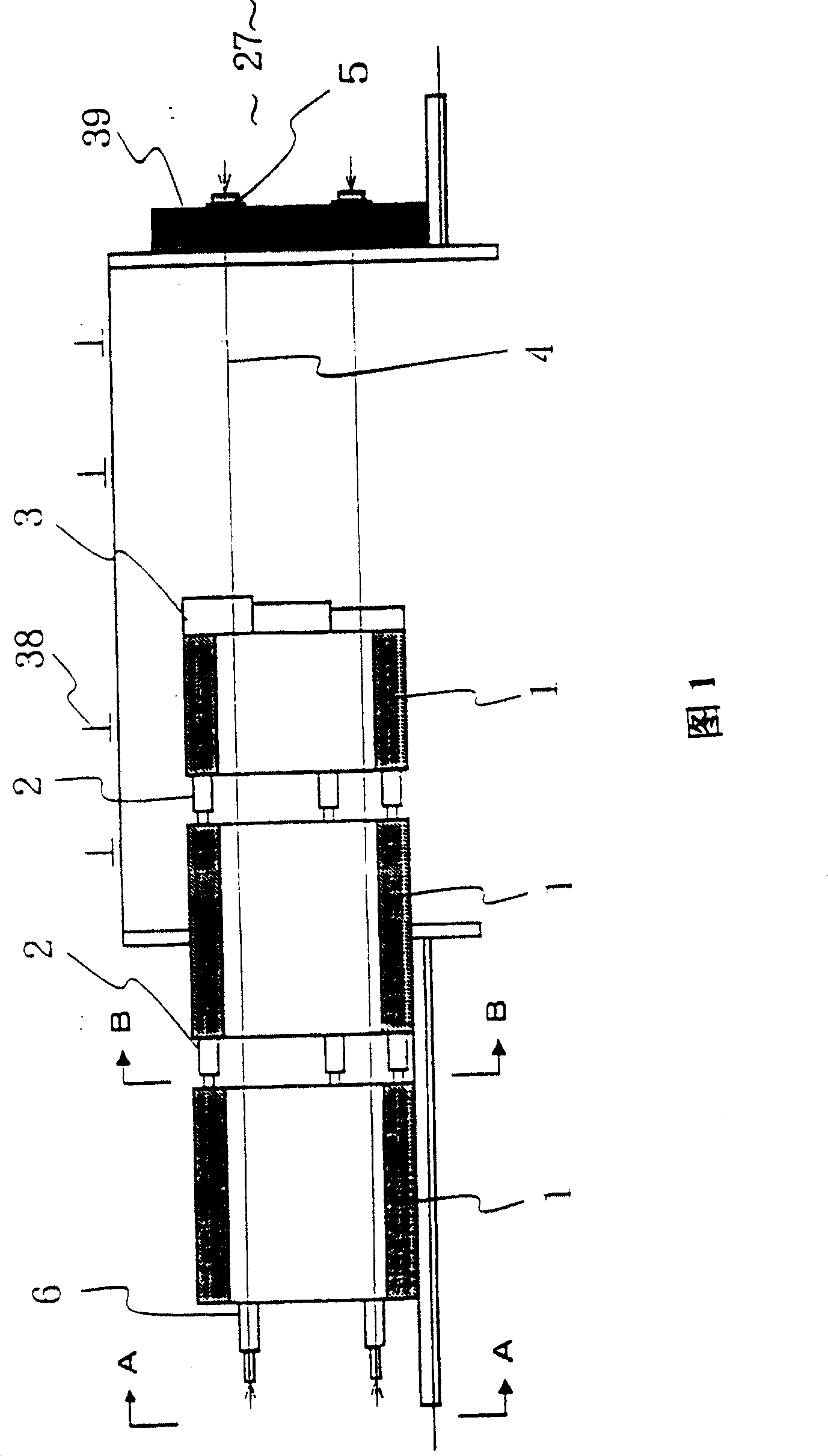

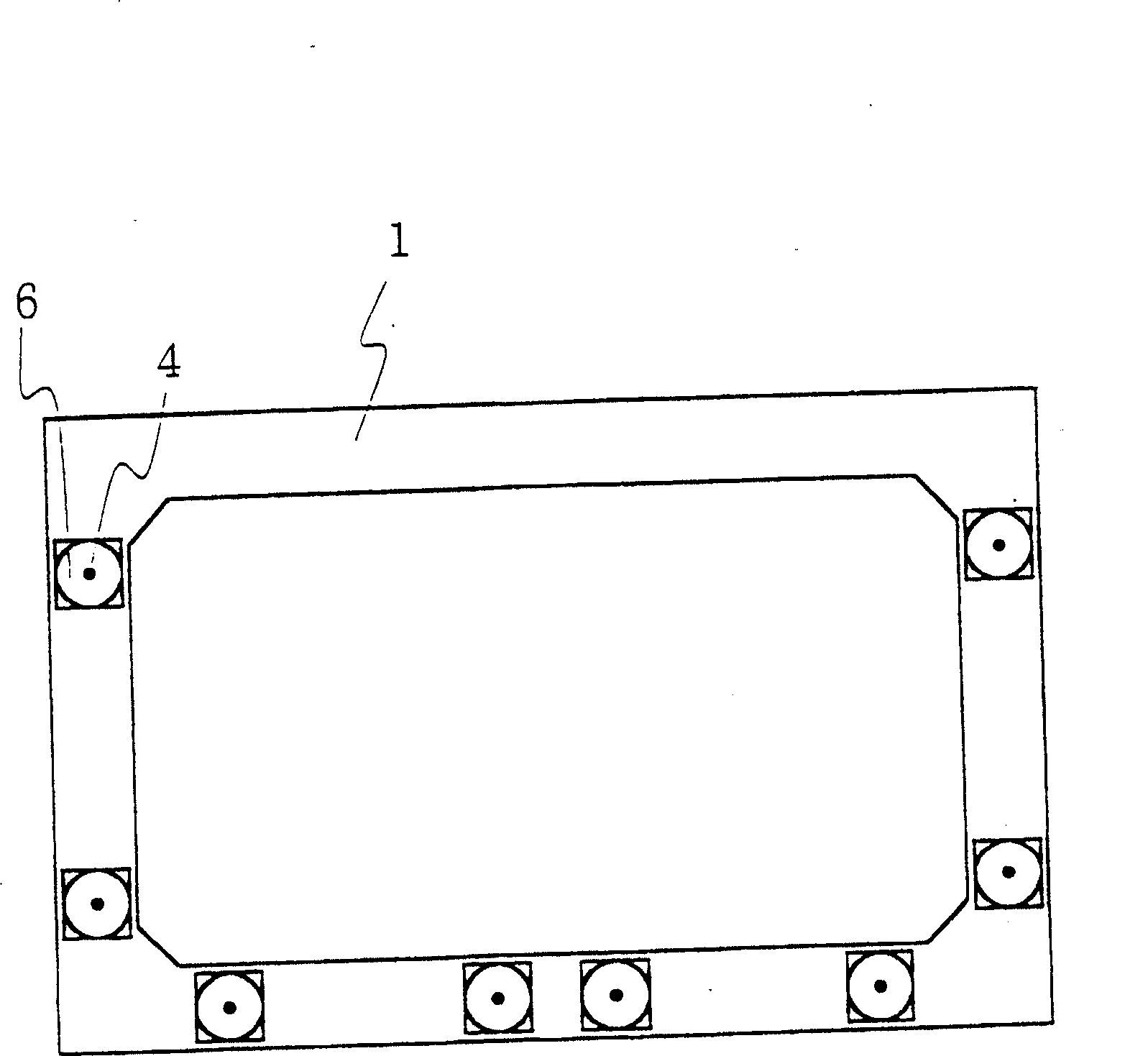

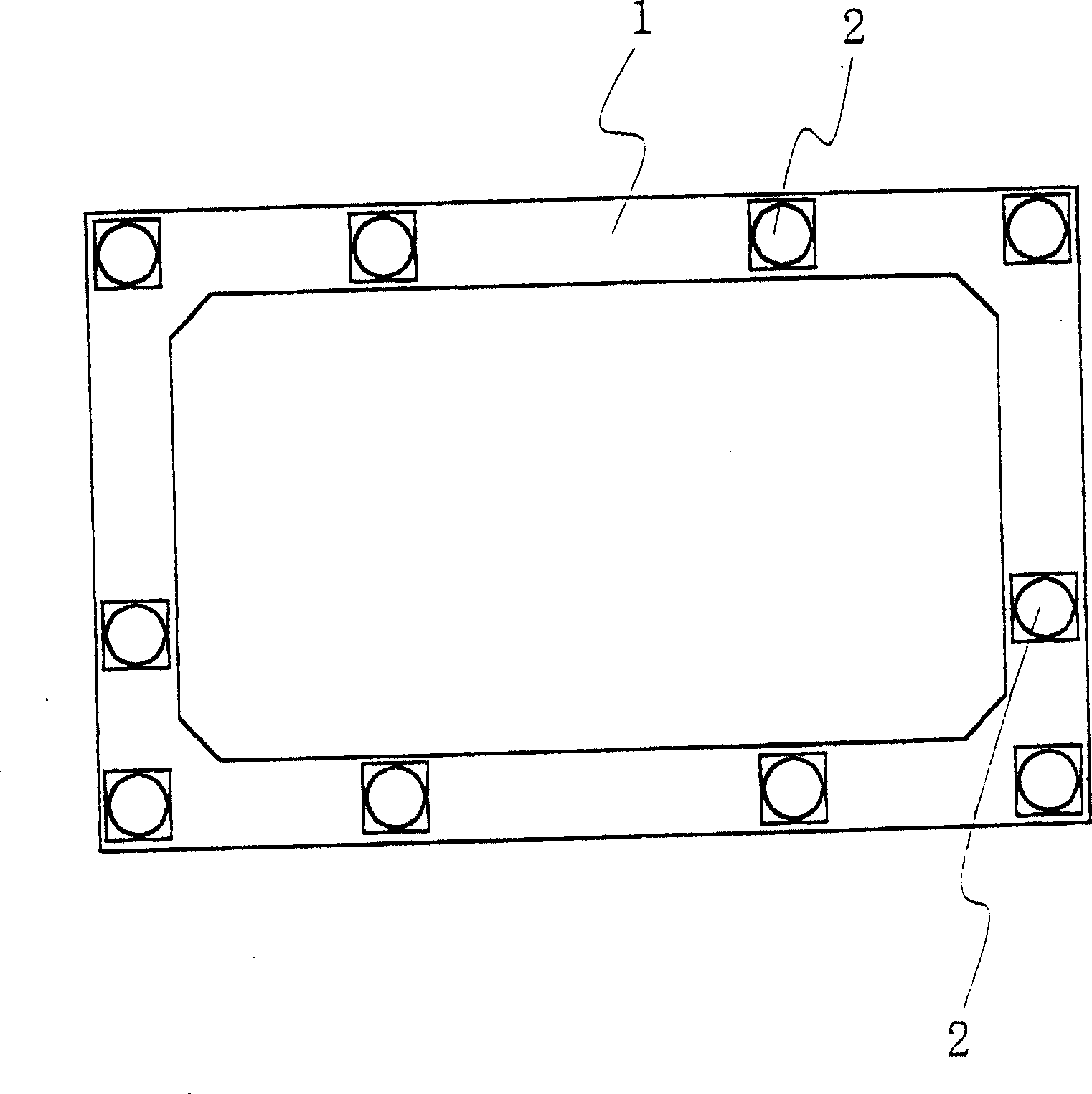

Drilling machine propulsion control system and method and drill rod

ActiveCN111720107AAvoid control delayImprove control efficiencyAutomatic control for drillingControl systemControl engineering

The invention discloses a drilling machine propulsion control system. The system comprises a working parameter module, a safety parameter judgment module and a propelling speed adjusting module; current working parameters are acquired by the working parameter module; whether the current working parameters are greater than preset safety parameters or not is judged by the safety parameter judgment module, and if so, a drill rod is controlled to return; if not, the current working parameters and the preset working parameters are compared; finally, whether the current working parameters are greater than preset working parameters or not is judged by the propelling speed adjusting module, and if yes, on the premise that the current propelling speed is greater than the preset propelling speed, the current propelling speed is reduced, and the drill rod is controlled to propel at the current propelling speed; and if not, the current propelling speed is increased, and the drill rod is controlledto propel at the current propelling speed. Therefore, an existing hydraulic control system or an existing manual control system is replaced by an electric control mode, the problem of control delay is avoided, the number of related parts is small, the control efficiency is high, and the production cost is low. The invention further discloses a drilling machine comprising the drilling machine propulsion control system and a drilling machine propulsion control method.

Owner:CHINA RAILWAY CONSTR HEAVY IND

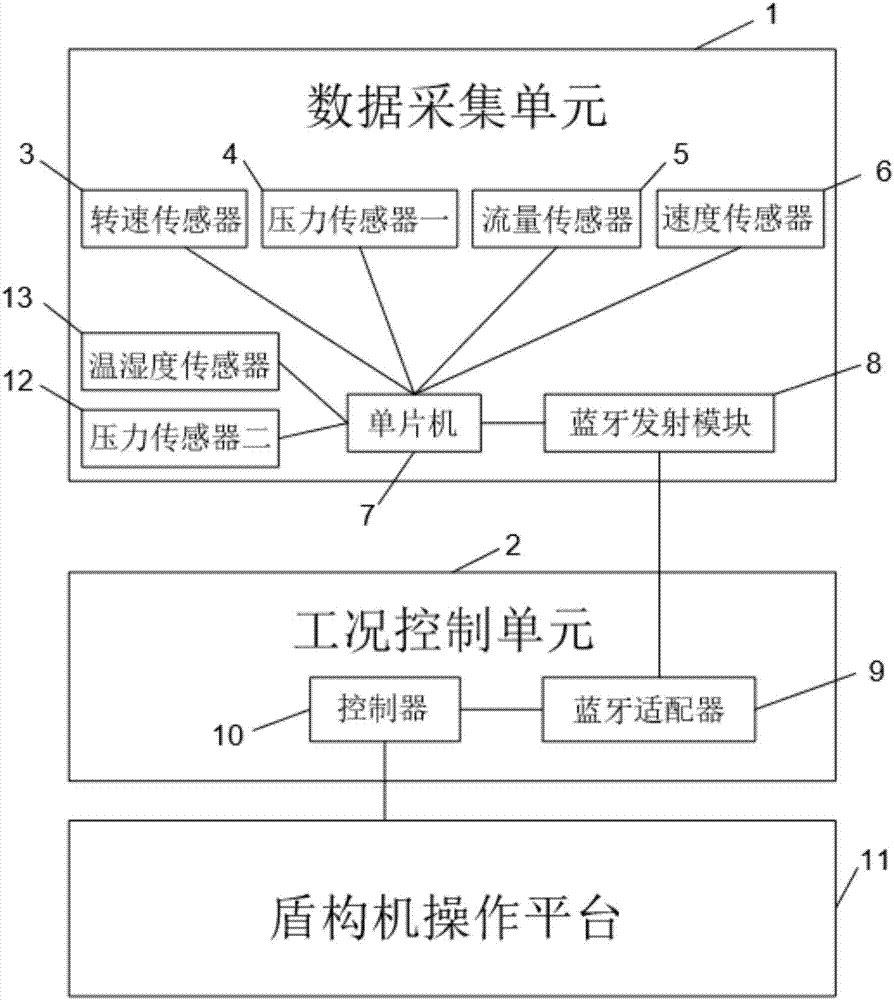

Multi-sensor-based shield condition acquisition system

InactiveCN107329453ANo delay in construction progressReal-time collection of dataProgramme control in sequence/logic controllersMicrocontrollerData acquisition

The invention discloses a multi-sensor-based shield condition acquisition system comprising a data acquisition unit and a condition control unit. The data acquisition unit comprises a rotating speed sensor, a first pressure sensor, a flow sensor, a speed sensor, a single-chip microcomputer and a bluetooth transmitting module. The rotating speed sensor, the first pressure sensor, the flow sensor and the speed sensor are electrically connected with the I / O pin of the single-chip microcomputer, and the bluetooth transmitting module is also electrically connected with the single-chip microcomputer. The condition control unit comprises a bluetooth adapter and a controller. The bluetooth adapter is electrically connected with the controller, and the controller is electrically connected with a shield machine operation platform. According to the system, data acquisition is performed on multiple sensors through the single-chip microcomputer, data acquisition is real-time and more accurate, intelligent adjustment of the single-chip microcomputer for the rotating speed of the cutterhead, the flow of the mud pipe and the propulsion speed of the shield machine does not delay the construction progress of the shield machine, and the shield machine can be protected so as to be quite effective.

Owner:合肥引力波数据科技有限公司

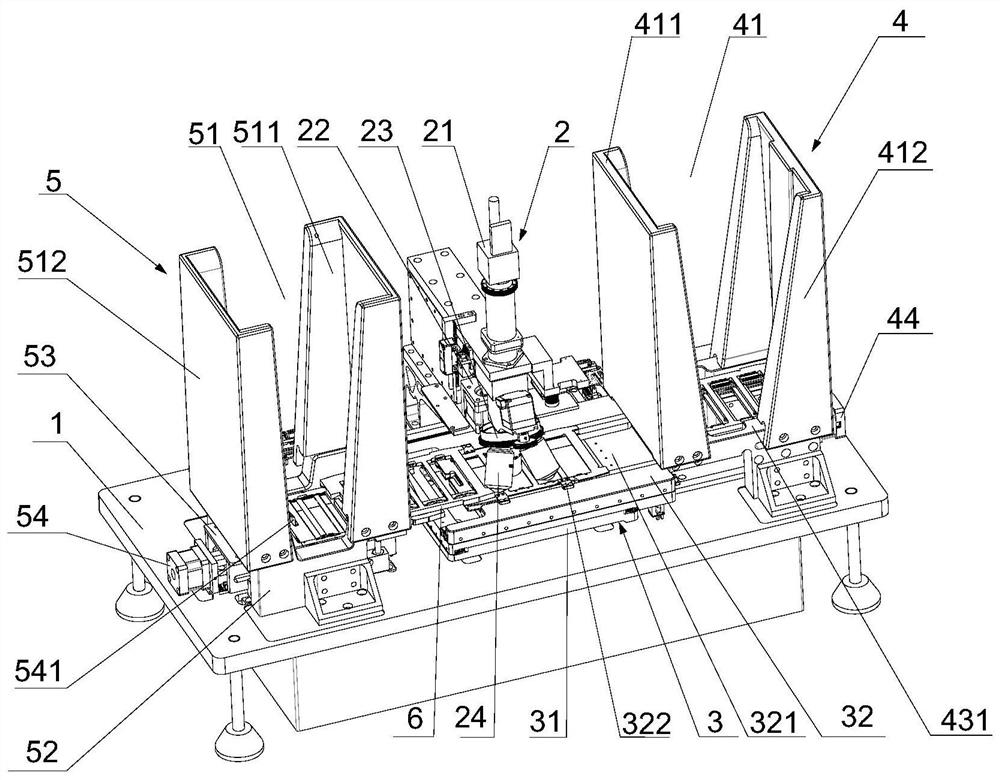

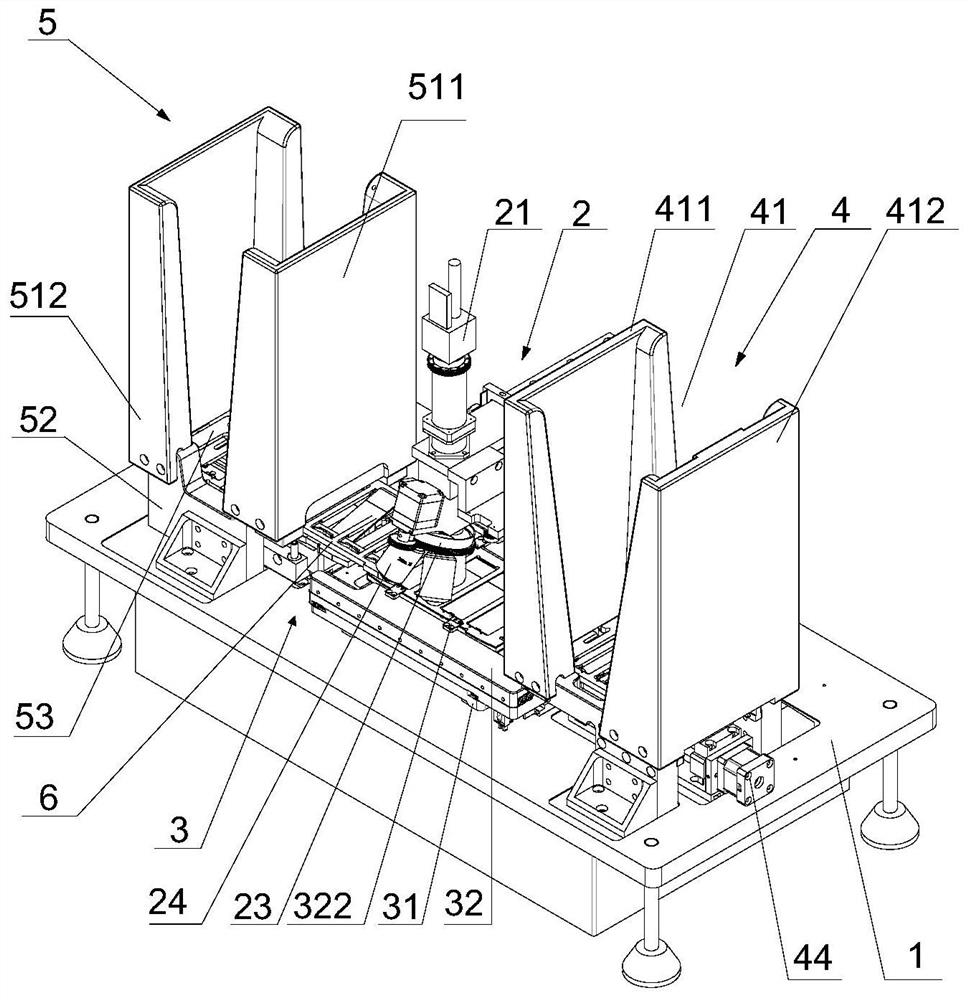

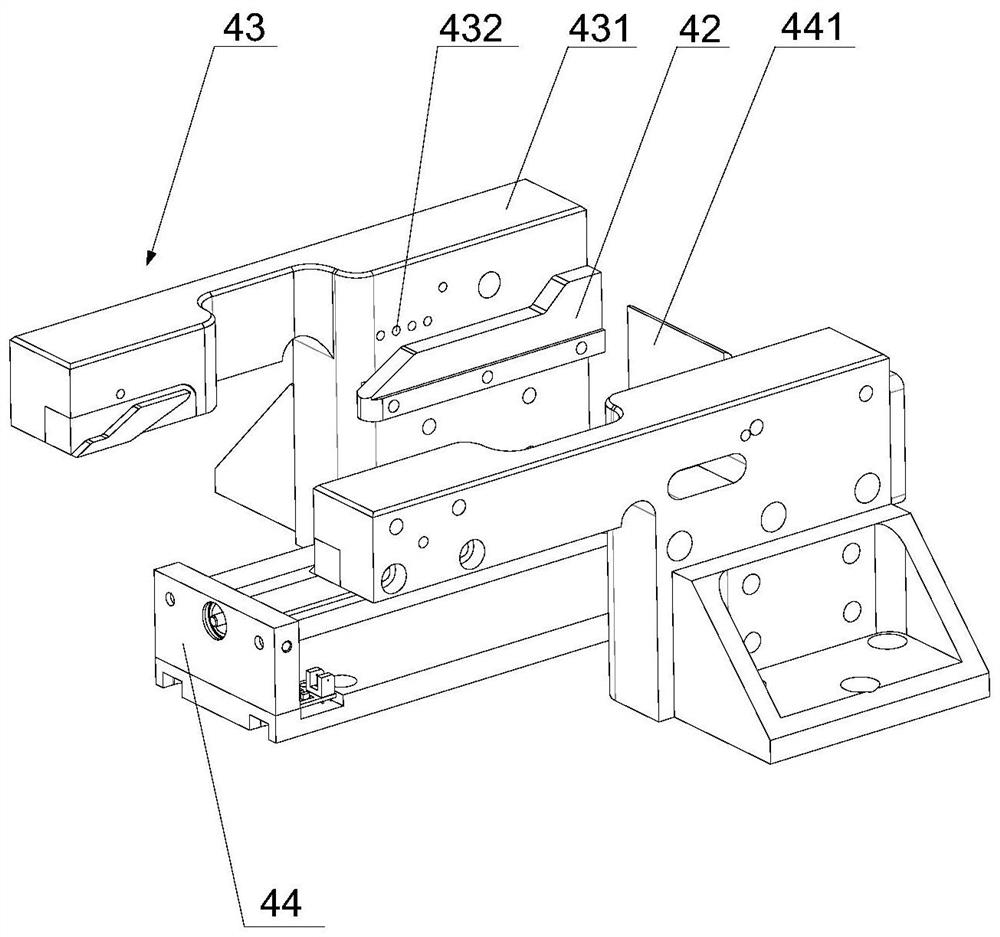

A high-throughput automatic slice scanning system and scanning method thereof

ActiveCN111596452BReduce propulsion speedAvoid damageMaterial analysis by optical meansMicroscopesComputer hardwareContinuous scanning

The invention provides a high-throughput automatic slice scanning system, which includes a base, a microscope system, an object stage, a film advancing device and a film unwinding device. The microscope system is arranged on the base, and the microscope system includes a microscope, a lifting device and an electric objective lens switching device. The stage is located below the microscope system. The stage includes an xy motion platform and a slicing disk holding device. The film feeding device is arranged on the film feeding side of the loading table, and the film feeding device includes a film feeding magazine, a slicing disk placement guide structure, a falling guide mechanism and a slicing disk feeding mechanism. The film unwinding device is arranged on the film unloading side of the stage, and the film unwinding device includes a film unloading warehouse, a slicing disk placement structure, a slicing disk lifting device and a slicing disk hook pulling device. The film feeding magazine of the present invention can accommodate a large number of slicing discs, improves the efficiency of a single scan, reduces manual intervention, and thus realizes continuous scanning of slices. The film feeding process, film unloading process and scanning movement are driven independently, which reduces the preparation time for slice handover.

Owner:海德星科技(厦门)有限公司

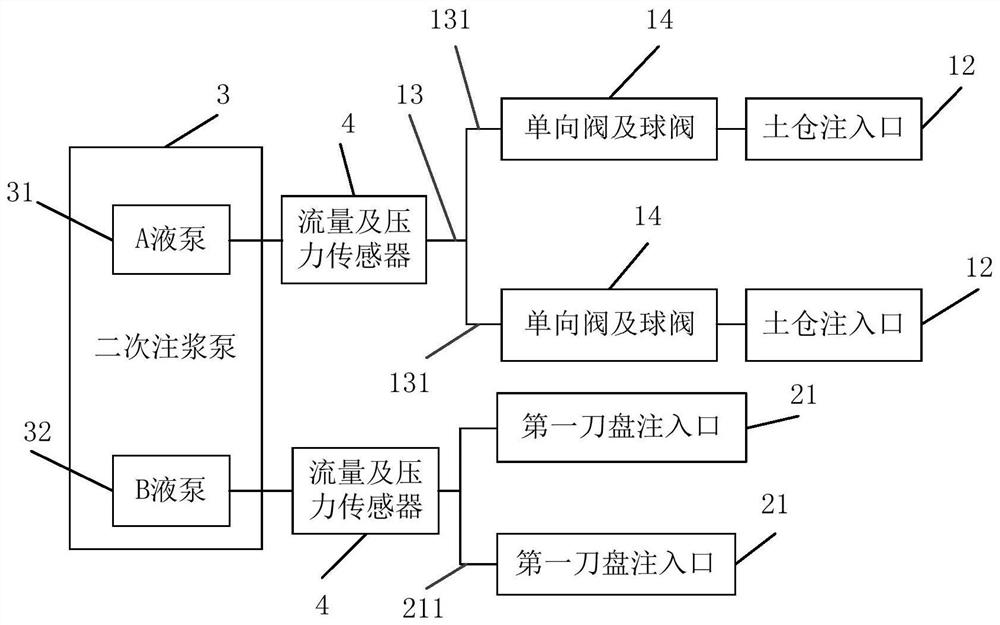

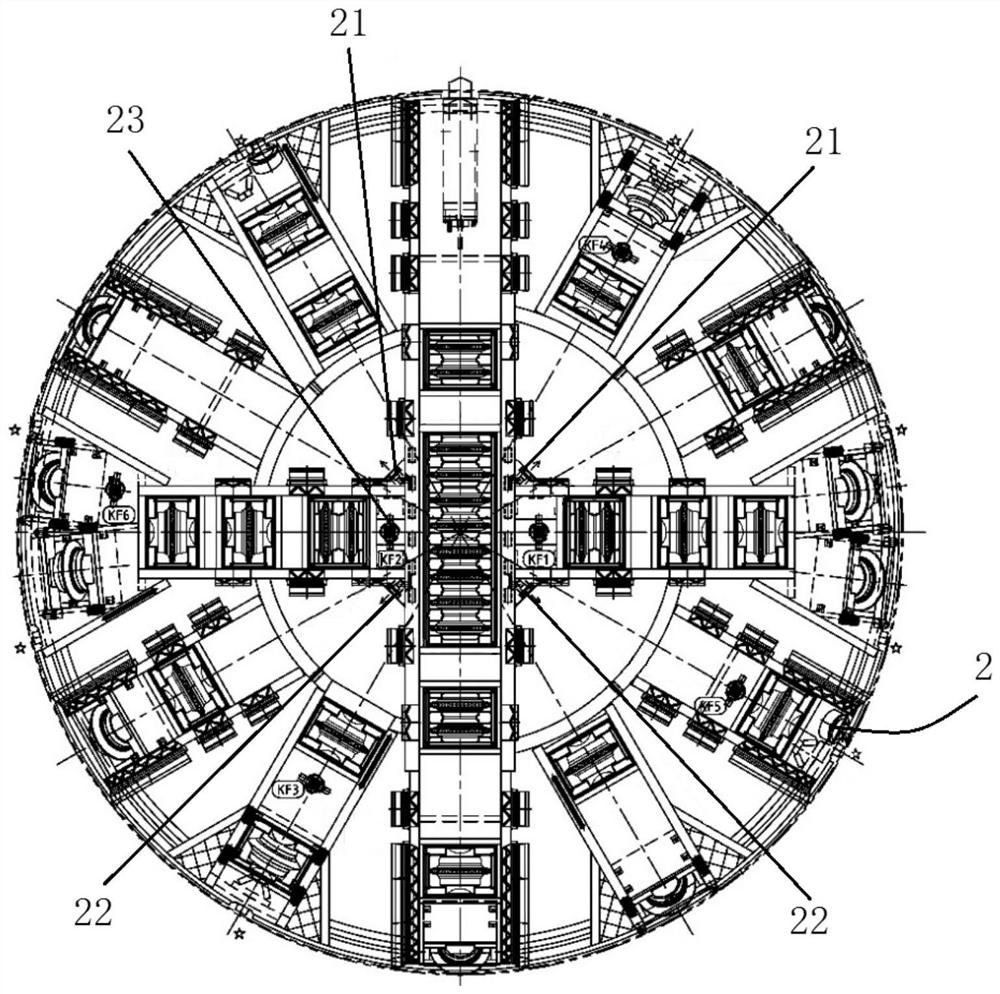

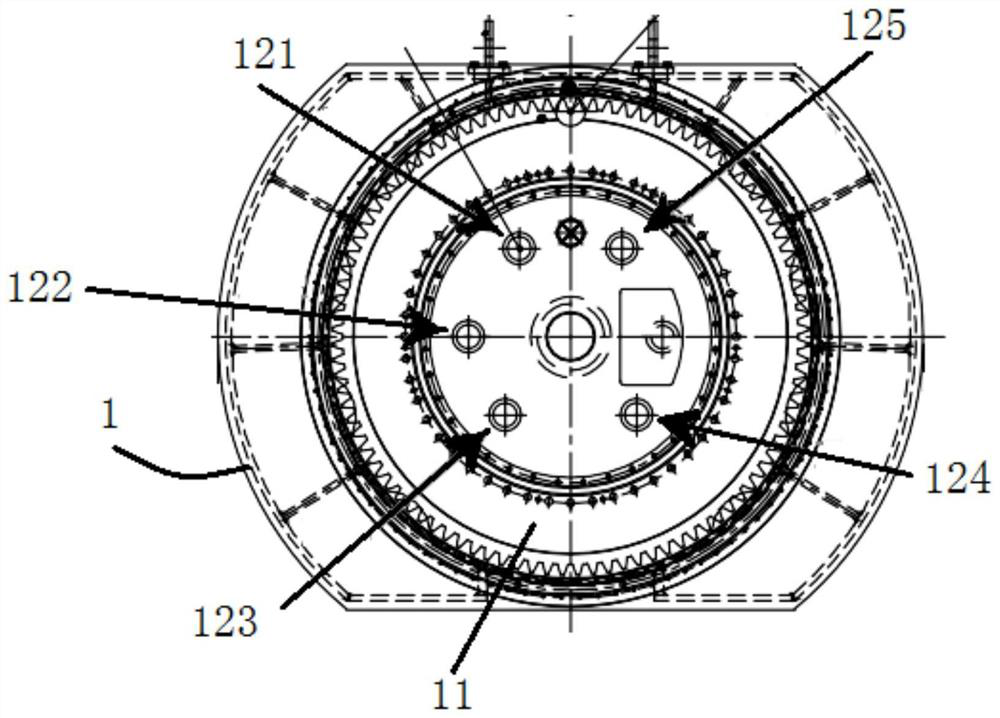

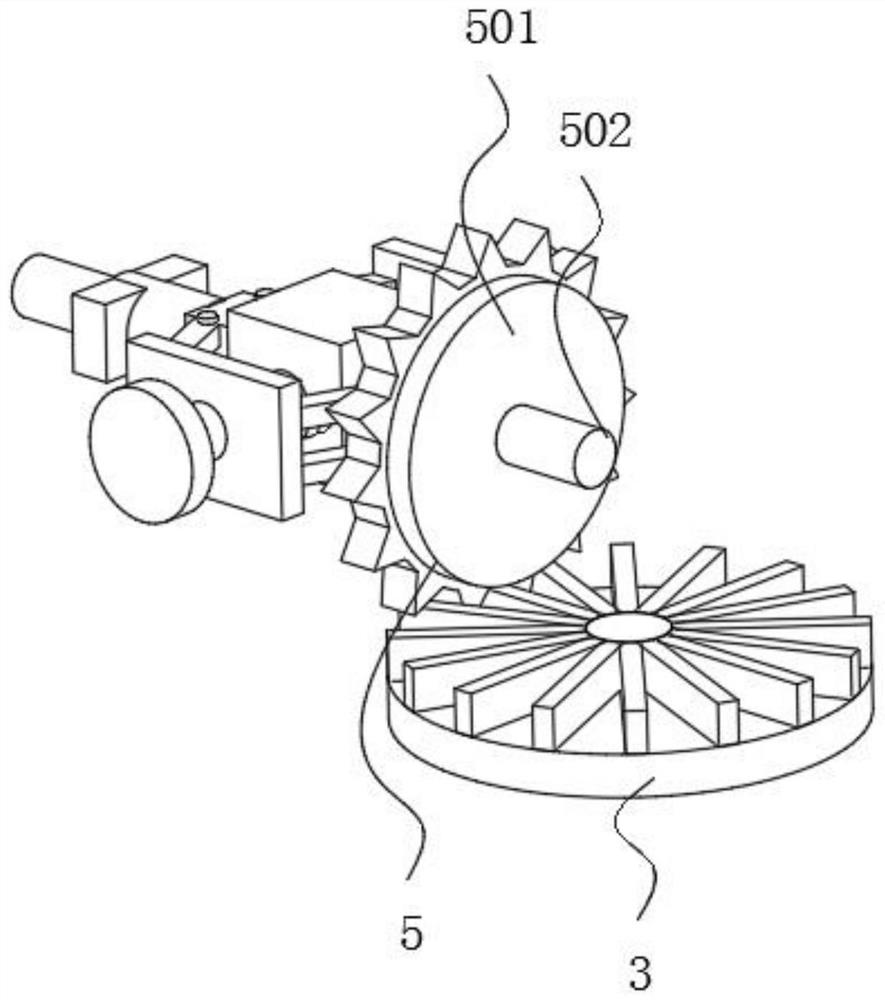

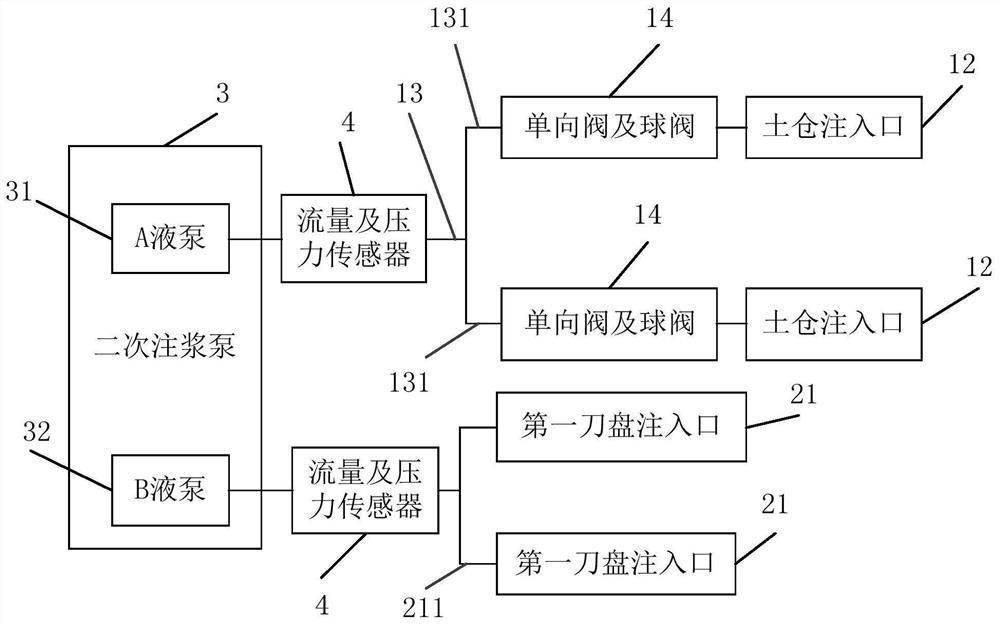

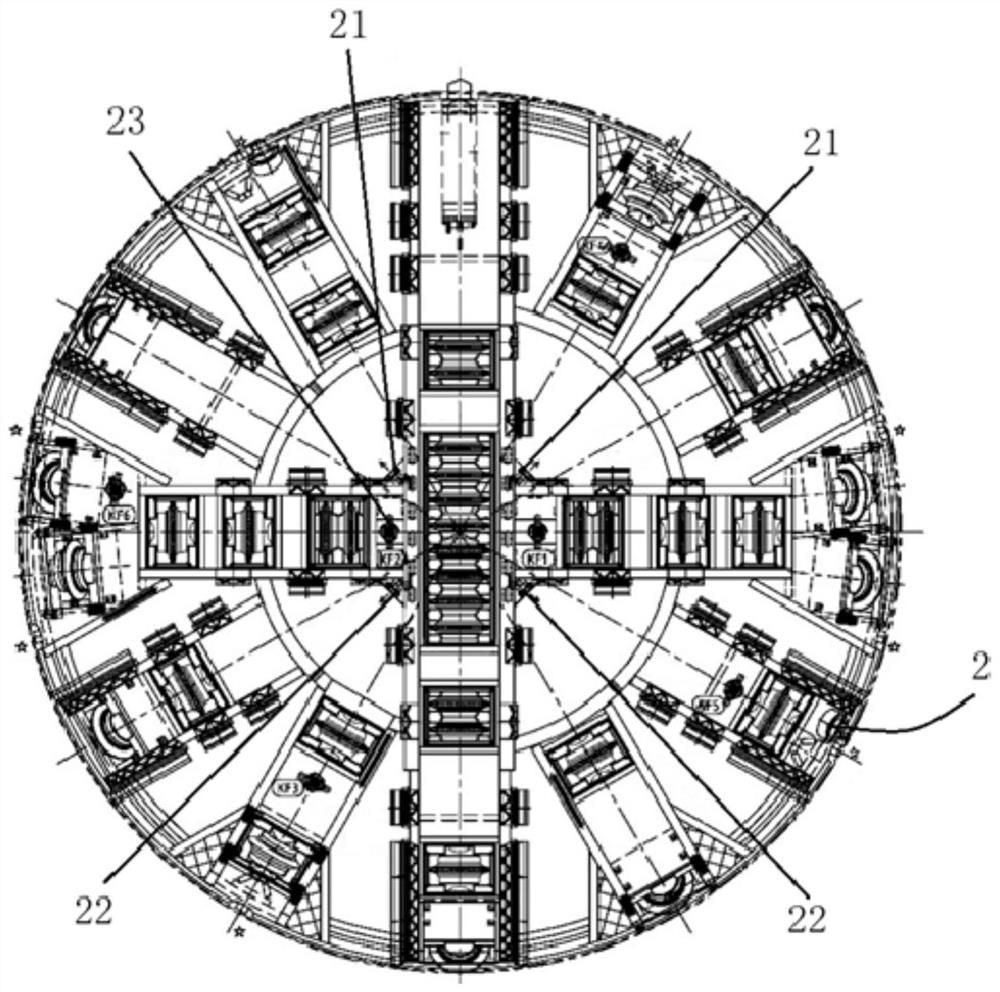

Muck improvement system of shield tunneling machine

PendingCN112253152AConstruction impactImprove flushing effectTunnelsShield tunnelingMechanical engineering

The invention relates to a muck improvement system of a shield tunneling machine. The shield tunneling machine comprises a cutterhead and a soil bin behind the cutterhead; the muck improvement systemcomprises a soil bin injection port formed in a wall plate of the soil bin, a first cutterhead injection port formed in the center of an opening of the cutterhead, and a first cutterhead injection pipe connected with the first cutterhead injection port, and further comprises a secondary grouting pump; and the secondary grouting pump comprises a liquid pump A and a liquid pump B, the water outlet end of the liquid pump A is connected with the soil bin injection port through a soil bin injection pipe in a shield body, the water outlet end of the liquid pump B is connected with the water inlet ofthe first cutterhead injection pipe, and the soil bin injection pipe is arranged in the shield body. The shield tunneling machine muck improvement system has the following beneficial effects that thesecondary grouting pump is reasonably connected into the shield tunneling machine, and secondary grouting equipment in conventional shield construction is fully utilized; and in the tunneling processof the shield tunneling machine, due to the fact that the pump energy of the secondary grouting pump is large, the scouring capacity of the secondary grouting pump to the center of the wall plate ofthe soil bin and the center opening of the cutterhead is improved, an injection opening is not prone to being blocked, and mud cakes are prevented from appearing in the center of the wall plate of thesoil bin and the center of the cutterhead.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

Environment protection type excrement and urine treatment machine

InactiveCN1197665CRelieve pressureReduce propulsion speedSludge treatment by de-watering/drying/thickeningSolid waste disposalImpellerFeces

Owner:李国民

Synthetic fiber rotary spinning system and spinning method

The invention relates to the technical field of textile, and provides a synthetic fiber rotary spinning system which comprises a shell, a mounting frame is fixedly connected to the outer wall of the shell, a gear is rotatably connected to the inner wall of the mounting frame, a spraying assembly is fixedly connected to the bottom of the gear, and a maintaining assembly is connected to the outer wall of the gear in a meshed mode. The bottom of the maintaining assembly is movably connected with a speed reduction assembly. According to the synthetic fiber rotary spinning system and spinning method, the transmission teeth are in meshed connection with the gear, the rotation linear speed of the transmission teeth is the same as that of the gear, and the distance between the transmission teeth and the circle center of the gear is lengthened, so that the angular speed of the gear is slowed down; the rotating speed of the motor cannot be reduced immediately, so that the meshing position of the transmission teeth and the gear is changed, the rotating speed of the screw is reduced, and the spinning stability can be maintained due to the fact that the meshing position of the transmission teeth and the gear is variable and the angular speed is kept unchanged.

Owner:桐乡市鑫晶源纺织有限公司

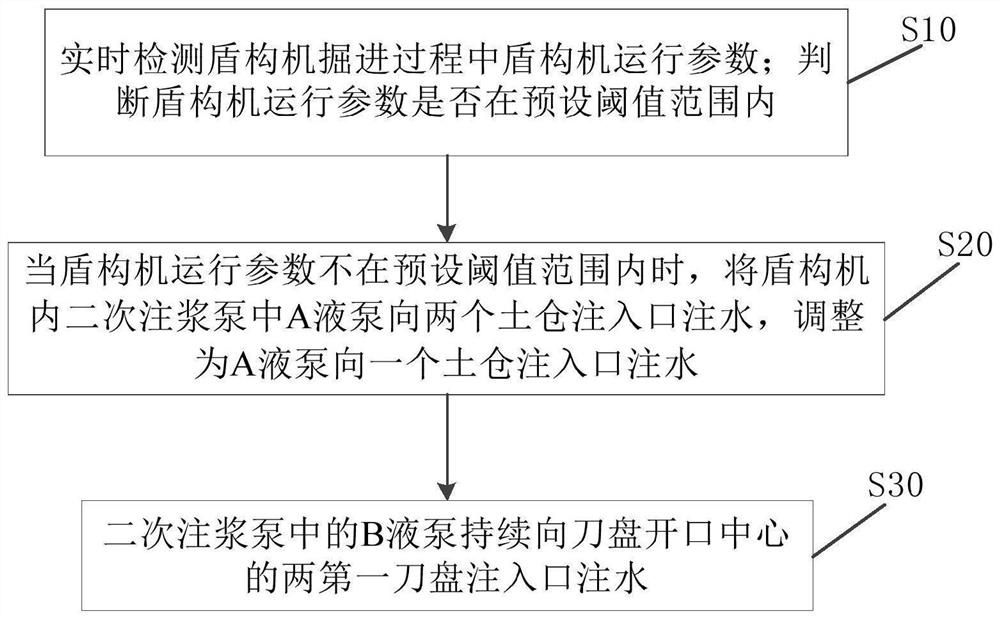

Shield tunneling machine muck improvement method

The invention relates to a shield tunneling machine muck improvement method. The method comprises the steps that shield tunneling machine operation parameters in the tunneling process of a shield tunneling machine are detected in real time; whether the shield tunneling machine operation parameters are within a preset threshold range or not is judged; when the shield tunneling machine operation parameters are not within the preset threshold range, the situation that a liquid pump A in a secondary grouting pump in the shield tunneling machine injects water into two or more soil bin injection ports is adjusted to the situation that the liquid pump A injects water into one soil bin injection port; and a liquid pump B in the secondary grouting pump continuously injects water into two first cutterhead injection ports in the center of a cutterhead opening. The secondary grouting pump is reasonably connected into the shield tunneling machine, and secondary grouting equipment in conventional shield tunneling construction is fully utilized. Due to the fact that the pump energy of the secondary grouting pump is large, the secondary grouting pump is adopted to inject water into an emergency standby injection port in the center of a soil bin wall plate and the injection port of the cutterhead opening, the scouring capacity to the center of the soil bin wall plate and the center opening of the cutterhead is improved, the injection ports are not prone to being blocked, and mud cakes are prevented from appearing in the center of the soil bin wall plate and the center of the cutterhead.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

Method and device for structuring tunnel by propulsion of underground box

A method for constructing tunnel by driving underground case body to advance includes installing cutting tools to front end of said case body, passing the drawing member (such as PC-steel cable) through the case body, arranging the fixing part or driving jack to the back end of case body, arranging the driving jack or fixing part at another end, and digging segment by segment.

Owner:UEMURA ENG

A kind of activated carbon grinding equipment

The invention belongs to the technical field of grinding equipment and particularly relates to activated carbon grinding equipment. The activated carbon grinding equipment comprises a hoper, a first-stage grinding device, a screening module and a second-stage grinding device. The first-stage grinding device and the second-stage grinding device conduct driving synchronously. The first-stage grinding device comprises a grinding box, a grinding rotary shaft, a grinding spiral lamina and grinding rods. The grinding rotary shaft is connected to the interior of the grinding box. The grinding rotaryshaft is provided with grooves in the length direction. Magnets I are inlaid in the grooves. The grinding rotary shaft is sleeved with a plurality of grinding rings distributed uniformly. The grindingrings are provided with magnets II. The grinding spiral lamina is fixed to the grinding rings. The screening module is used for screening out activated carbon meeting the standards and guiding activated carbon not meeting the standards into the second-stage grinding device for continuous grinding. According to the activated carbon grinding equipment, differential rotation is formed between the grinding rotary shaft and the grinding spiral lamina, the grinding time of the activated carbon is prolonged, the activated carbon is ground more sufficiently, and the grinding quality is improved.

Owner:金寨智行知识产权运营有限公司

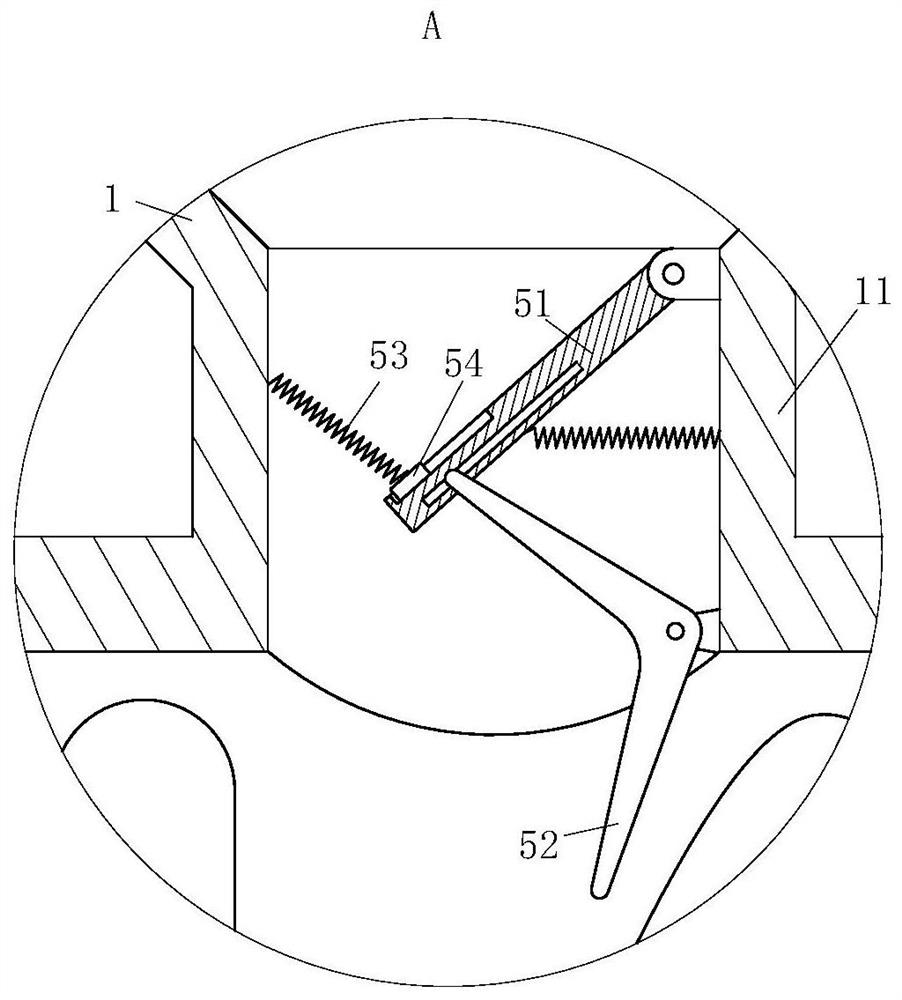

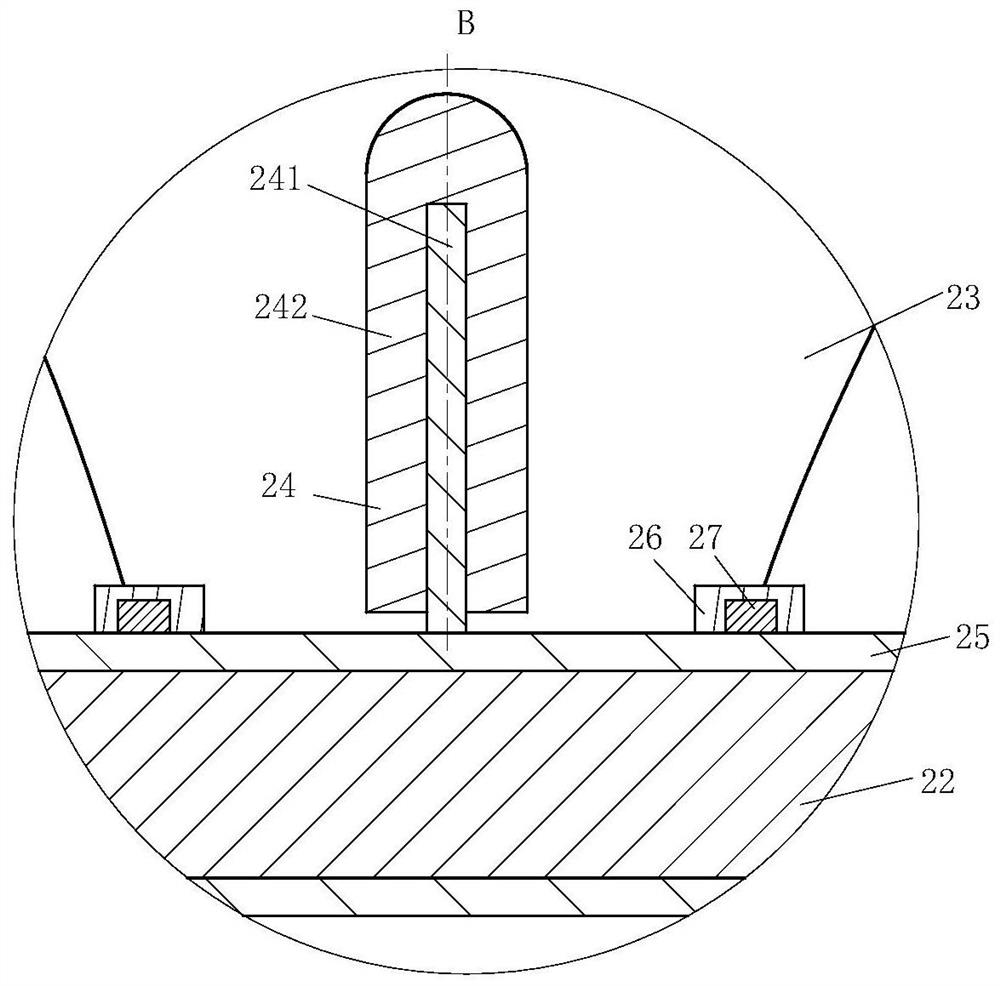

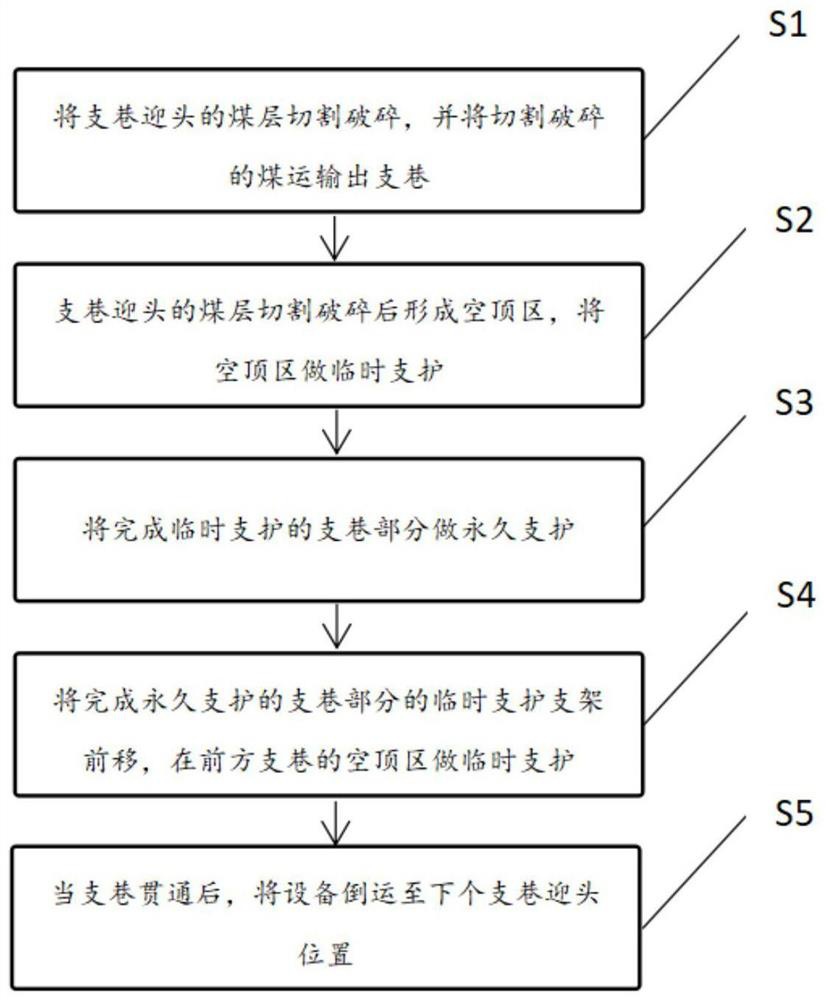

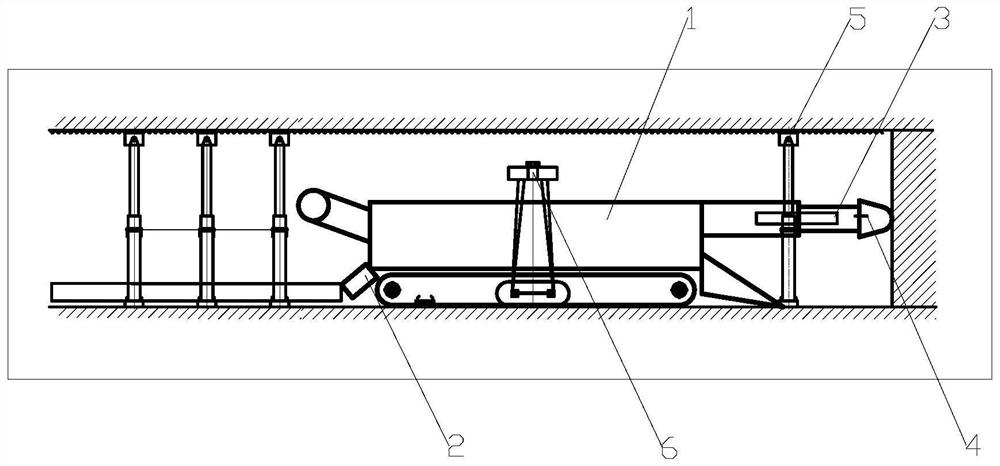

Rapid excavation method of branch roadway in continuous mining and continuous charging working face

ActiveCN113756830BImprove mining efficiencyReduce mechanical damageUnderground chambersMine roof supportsControl systemControl engineering

The present invention relates to a rapid excavation method for continuous mining and continuous charging working face support roadway, including: step S1 cutting falling coal, step S2 supporting the empty roof area, step S3 permanent support, step S4 moving the support forward, step S5 equipment backward transport, in step S2 S1 is equipped with a self-propelled belt-type transfer vehicle of a fully mechanized excavator. The front end of the fully mechanized excavator is provided with a hardness detection device and a stress detection plate. In step S2, a portal bracket and a portal crawler frame transfer vehicle are configured. In step S3 A single-arm rocker is arranged, and in step S5, a bracket carrier is arranged. In the present invention, the control system selects the initial propulsion speed and the initial cutting speed of the fully mechanized excavator according to the hardness of the coal seam in the branch road, and the control system controls and adjusts the comprehensive excavator according to the comparison between the real-time stress of the fully mechanized excavator and the standard preset range stress value set inside the control system. The propulsion speed and cutting speed of the excavator realize the mining process of intelligent control and adjustment, and maximize the mining efficiency while ensuring the stable operation of the fully mechanized excavator.

Owner:鄂尔多斯市绿矿技术服务有限公司

A Water Breakthrough Time Prediction Method for Edge Water Gas Reservoirs

ActiveCN105631529BReduce propulsion speedForecastingDesign optimisation/simulationThermodynamicsSoil science

The invention belongs to the petroleum and natural gas development technical field and discloses an edge water gas reservoir water breakthrough time prediction method. The method includes the following steps that: edge water gas reservoir geological data and analysis test data are obtained; a three-dimensional geological model under combination modes of four kinds of heterogeneous reservoir stratums is established, and a gas area and an edge water area of an edge water gas reservoir are divided, and a virtual well is established in the gas area of the edge water gas reservoir; and the gas well water breakthrough time of the edge water gas reservoir under the combination modes of the different kinds of heterogeneous reservoir stratums can be accurately predicted through using response relationships between the gas well water breakthrough time and the heterogeneous feature parameters of the reservoir stratums. The method can be used for guiding the adjustment of gas reservoir development work systems. With the method adopted, the output of a well which is to be subject to water breakthrough can be decreased timely, and production pressure difference can be controlled; the advance speed of edge-bottom water can be effectively slowed down; and therefore, technical support can be provided for long-term stability of edge water gas reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and system of operating an automotive harvester

Owner:BLUE LEAF I P INC

Process for arranging drill holes in spontaneous combustion coal seam to implement nitrogen injection and grouting fire prevention and extinguishing

PendingCN113863973AReduce the amount of drilling workImprove efficiencyDust removalFire preventionDrill holeMining engineering

The invention discloses a process for arranging drill holes in a spontaneous combustion coal seam to implement nitrogen injection and grouting fire prevention and extinguishing. The process comprises the following steps that 1) units are divided according to the trend and the inclination of a coal face and three conditions of a goaf; 2) one-hole dual-purpose drill holes are drilled in the open-off cut position of the coal face; 3) after the one-hole dual-purpose drill holes in each unit section enter the goaf, the one-hole dual-purpose drill holes are merged into a nitrogen injection pipeline system; 4) according to the stoping advance speed and the divided units, one-hole dual-purpose drill holes of the next unit are constructed and arranged in advance; and 5) after the one-hole dual-purpose drill holes of the next unit are merged into the nitrogen injection pipeline system, nitrogen injection of the one-hole dual-purpose drill holes of the previous unit is stopped, and then the one-hole dual-purpose drill holes of the previous unit are merged into a grouting system. The problems that in an existing nitrogen injection process, the phenomena that pipe supporting and pulling are difficult, and pipe breaking occurs are prone to occurring, meanwhile, nitrogen is prone to being lost and diffused along the open-off cut of the stoping face, the purpose of inhibiting spontaneous combustion of the goaf cannot be achieved, and the nitrogen injection range and precision cannot be accurately mastered can be solved.

Owner:YAOJIE COAL ELECTRICITY GROUP

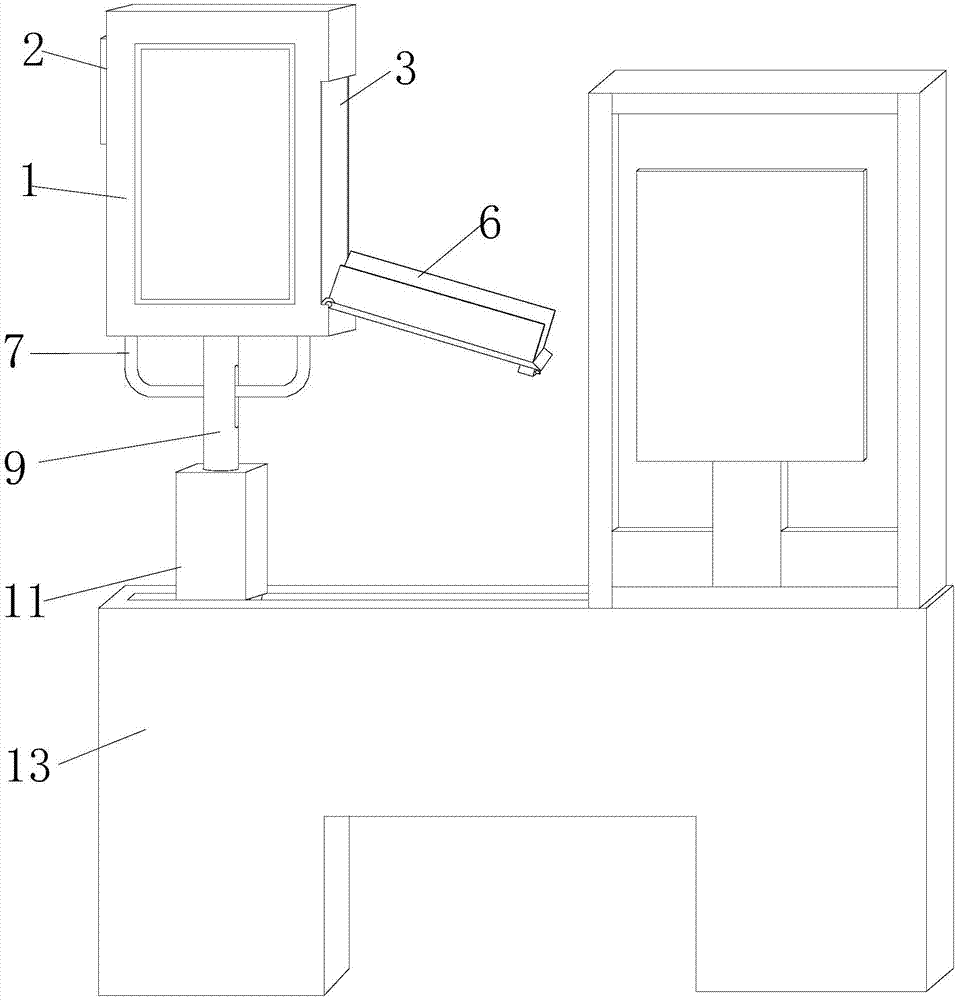

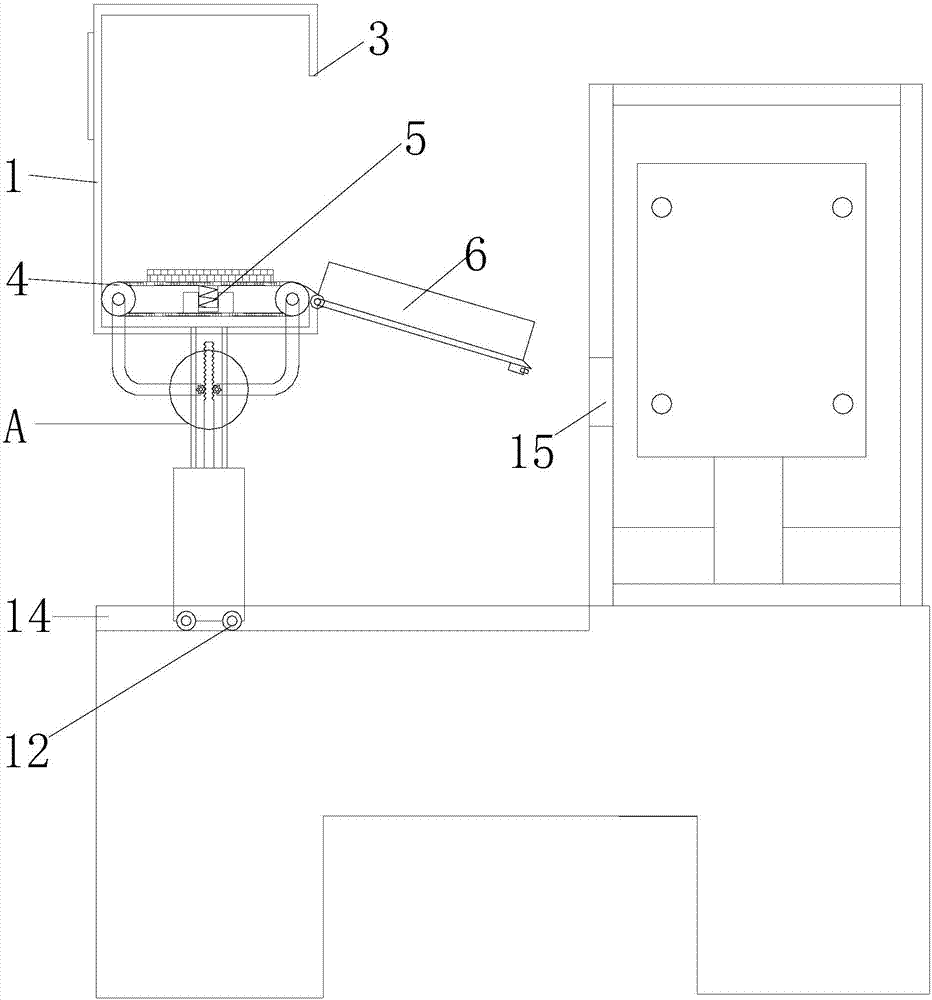

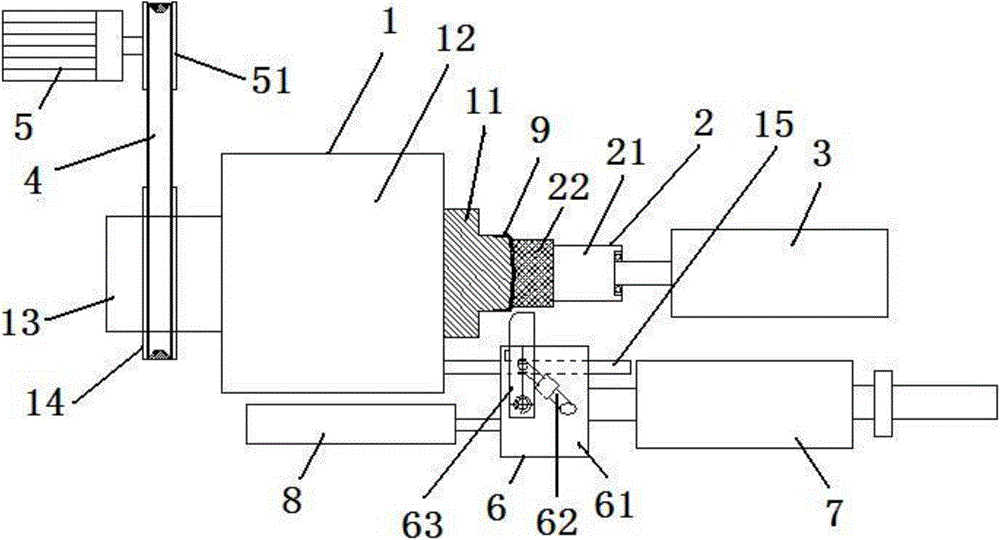

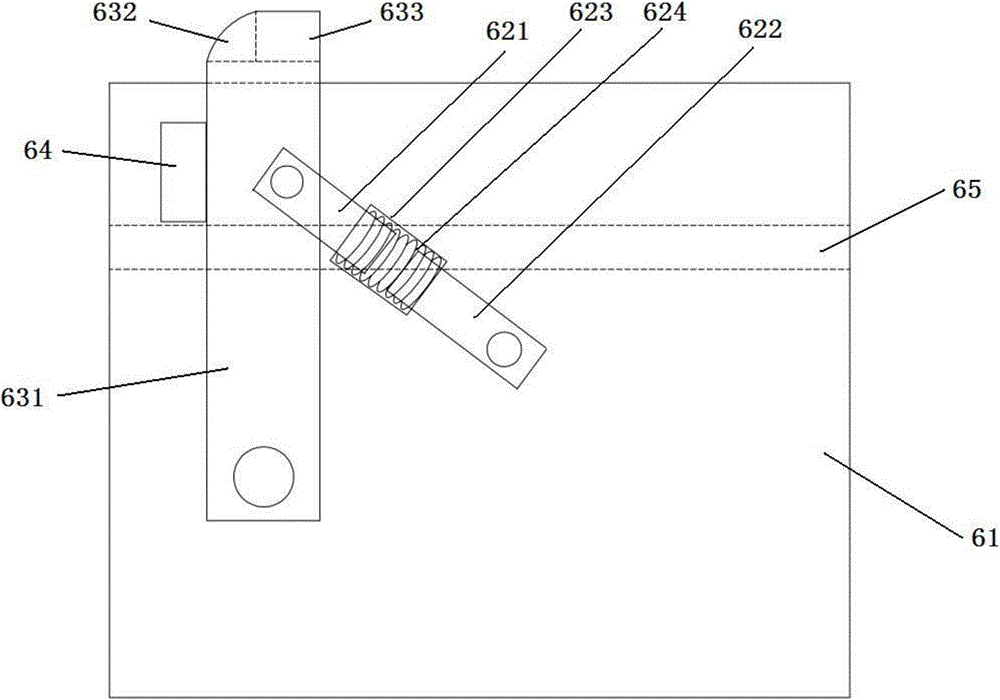

A kind of automatic turning outer circle device and automatic turning processing method of bowl-shaped plug

ActiveCN104014818BPrecise processingImprove production efficiencyTurning toolsFeeding apparatusEngineeringMachining

The invention discloses a device for automatically turning the outer circle of a bowl-shaped plug and a method for automatic turning. According to the device for automatically turning the outer circle of the bowl-shaped plug and the method for automatic turning, the working efficiency is high, the production cost is low and the machining error is small. The device for automatically turning the outer circle of the bowl-shaped plug comprises a bowl-shaped plug installation device, a bowl-shaped plug jacking device, a pneumatic jacking cylinder, a rotary connecting piece, an electric motor, a turning tool installation device and a pneumatic turning tool propelling cylinder, wherein the electric motor is connected with the bowl-shaped plug installation device through the rotary connecting piece, the bowl-shaped plug jacking device is connected with the pneumatic jacking cylinder, the turning tool installation device is connected with the pneumatic turning tool propelling cylinder, the axis of the bowl-shaped plug installation device and the axis of the bowl-shaped plug jacking device coincide, the turning tool installation device is located on one side of the axis of the bowl-shaped plug installation device, a limiting rod is arranged on the bowl-shaped plug installation device, and the turning tool installation device is connected with the limiting rod in a sliding mode. The device for automatically turning the outer circle of the bowl-shaped plug and the method for automatic turning have the advantages that the production efficiency and the working efficiency are improved, the machining efficiency is improved, production cost is reduced, the accuracy of automatic turning is improved, the machining error is lowered, and abrasion of a turning tool is reduced.

Owner:ZHEJIANG HUATIAN MACHINERY

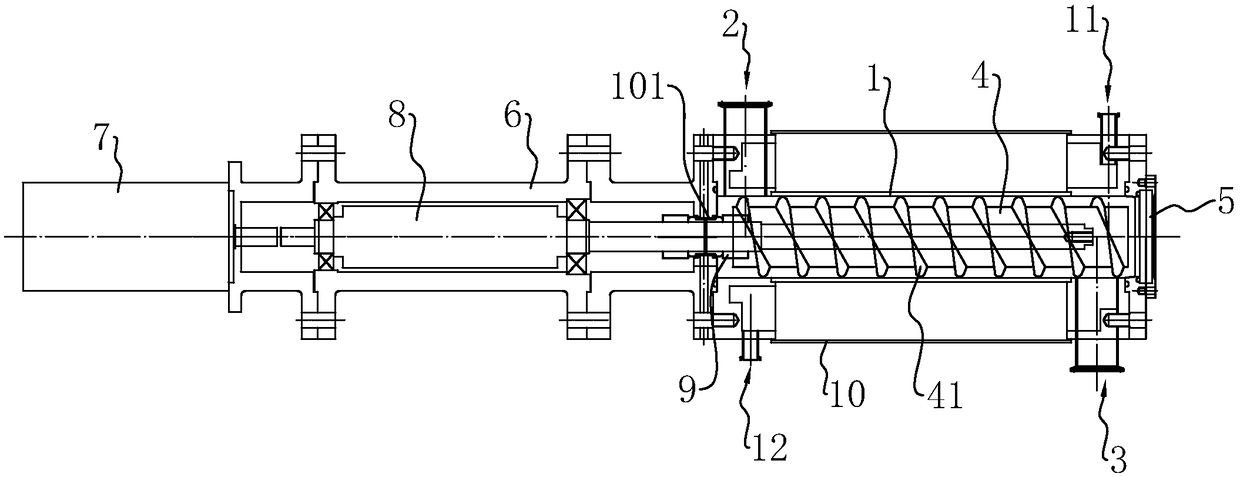

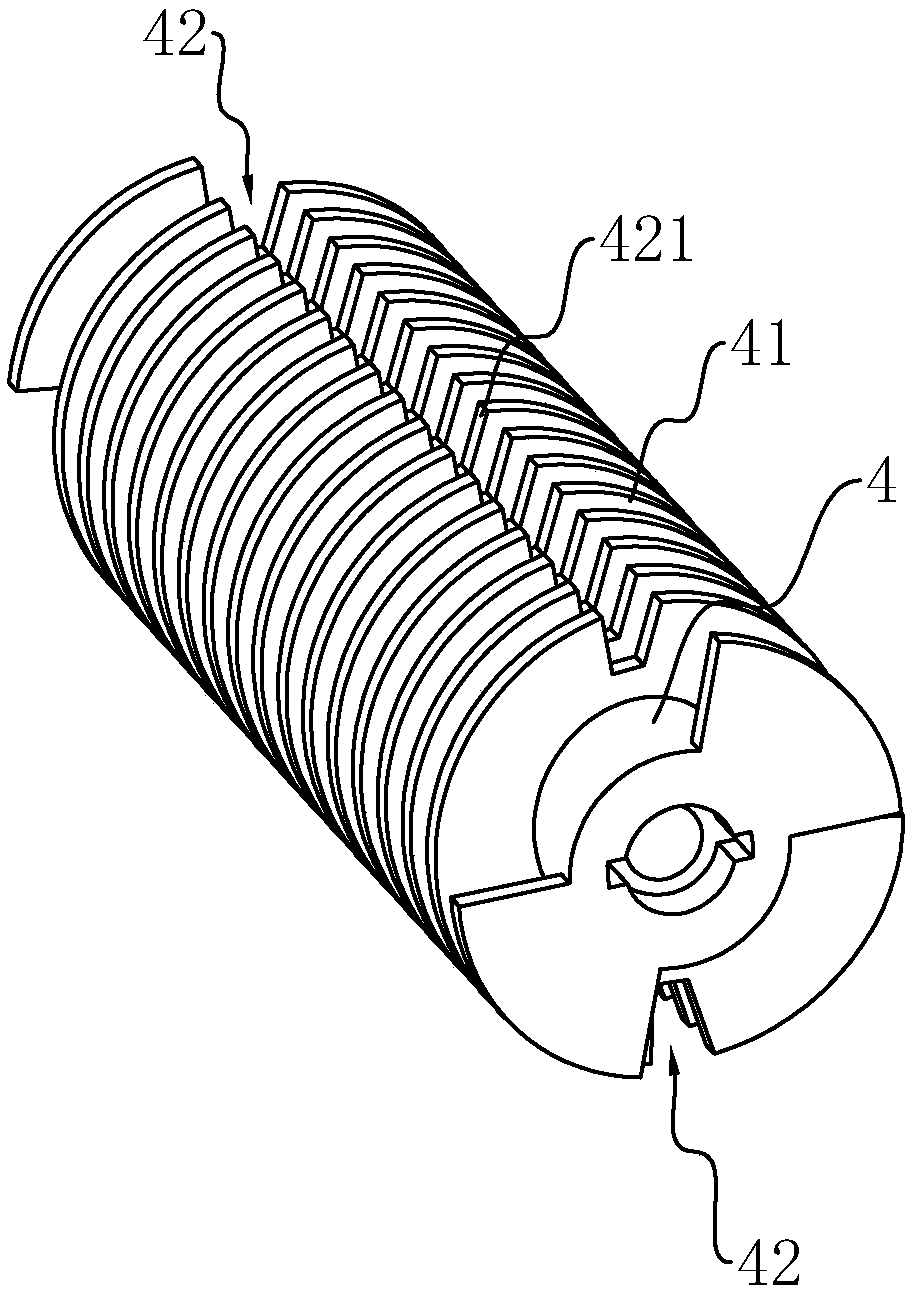

Film evaporator

InactiveCN109126171AGuaranteed evaporation effectComprehensive and adequate heatingEvaporator accessoriesOrganic solventEvaporation

The invention discloses a film evaporator, and relates to the field of solution concentration equipment. The film evaporator comprises an evaporation cylinder body with a material inlet and a materialoutlet, a pushing screw with a rotating frame arranged in the evaporation cylinder body, a drive component used for driving the pushing screw to rotate, and a heating device used for heating the evaporation cylinder body, wherein the pushing screw is at least provided with two pushing helixes, and each pushing helix is provided with a liquid guide groove. The invention provides the film evaporator, the operation is convenient, the film formation is stable, fewer bubbles are produced, an organic solvent is fully separated, and the product quality is favorably improved.

Owner:上海洁维生物工程有限公司

A kind of practice device for bow release

The invention relates to an archery practicing device. The archery practicing device is composed of a hollow sleeve and a simulation arrow shaft disposed in the sleeve, one end of the simulation arrow shaft is connected with the sleeve to form a slidable piston structure, the other end of the simulation arrow shaft is connected with a bowstring disposed at the outside of the sleeve, one end of the sleeve is sealed and provided with an aluminum thread plug, the other end of the sleeve is opened and provided with a plastic steel plug, the plastic steel plug is provided with a through hole where the simulation arrow shaft passes through. When a bow is drawn, the simulation arrow shaft is pulled out of the sleeve by the bowstring, air comes into the sleeve, when the simulation arrow shaft is shot, the simulation arrow shaft is pushed into the hollow sleeve through the bowstring, the moving speed of the simulation arrow shaft can be greatly reduced and finally the simulation arrow shaft stops in the hollow sleeve, under the function of the sleeve, the piston members and the buffer members. A learner can hold a bow and shoot an arrow using the archery practicing device, so he can have almost the same experience using an actual bow, but no arrow is shot actually, targets and large place are needless.

Owner:SHANGHAI SHIHUAN SPORTS PROD CO LTD

a syringe

ActiveCN106823068BAvoid pollutionEasy to separate productionEngine sealsInfusion syringesInjection portInjection equipment

The invention relates to the field of injection equipment, in particular to a syringe. The syringe comprises a syringe canister, a syringe piston and an entry needle; the injection port of the syringe canister is provided with a sealing part, and the connecting end of the entry needle is provided with an acicular part used for piercing the sealing part. The arrangement of the sealing part and the entry needle corresponding to the sealing part can prevent the syringe from being polluted at the mouth portion of the syringe by bacteria and improve the anti-bacteria and sterilization effect. The structure can make it convenient to produce the syringe and the entry needle separately, and accordingly the production difficulty is reduced. The sealing part is thin film integrally shaped with the syringe canister. The thin film is integrally shaped, better in leakproofness and lower in cost, and can prevent the bacteria completely with the characteristic of being disposable. Through control over resistance of push of a limiting rod, the push speed of the piston is effectively reduced, the precise control over added quantity of the syringe is improved, and the lower the push speed is, the preciser the added quantity control is.

Owner:PANZHIHUA JIUDINGZHIYUAN INTPROP OPERATION CO LTD

A blowtorch for preparing large core-diameter optical fiber base material by vad

ActiveCN107857470BPackage completelyReduce propulsion speedGlass making apparatusGlass productionEngineeringMechanical engineering

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Combustor and stove

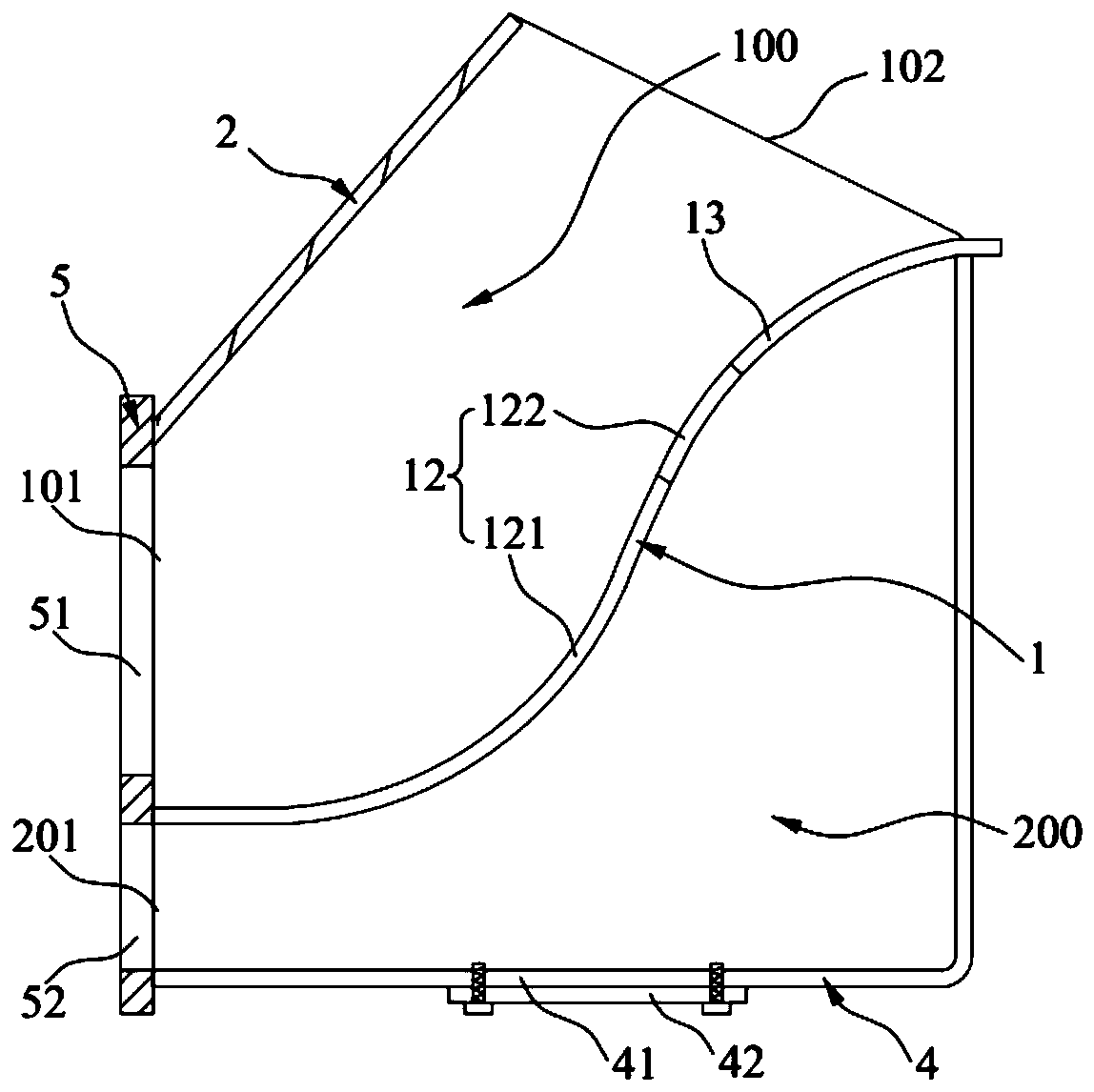

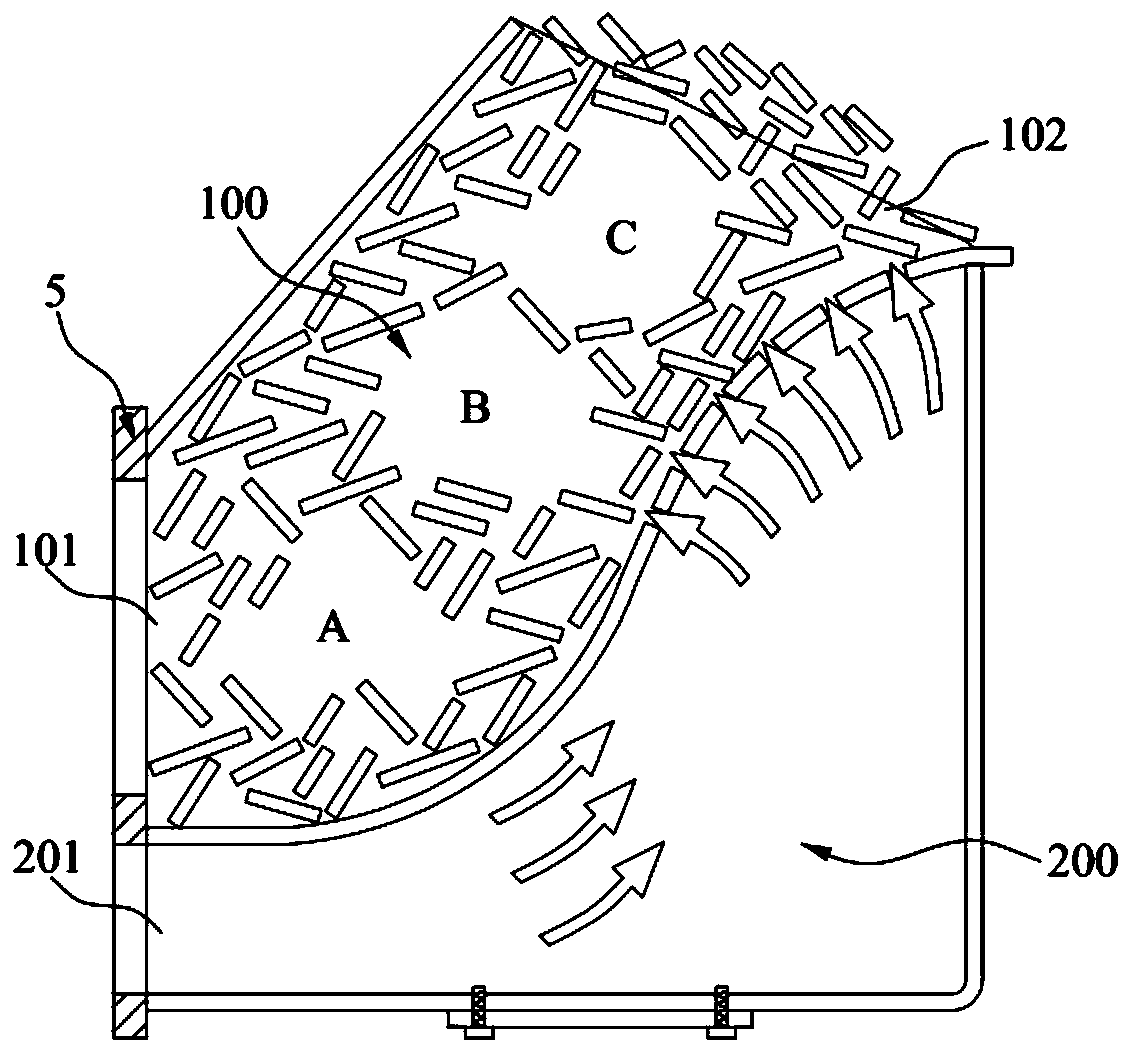

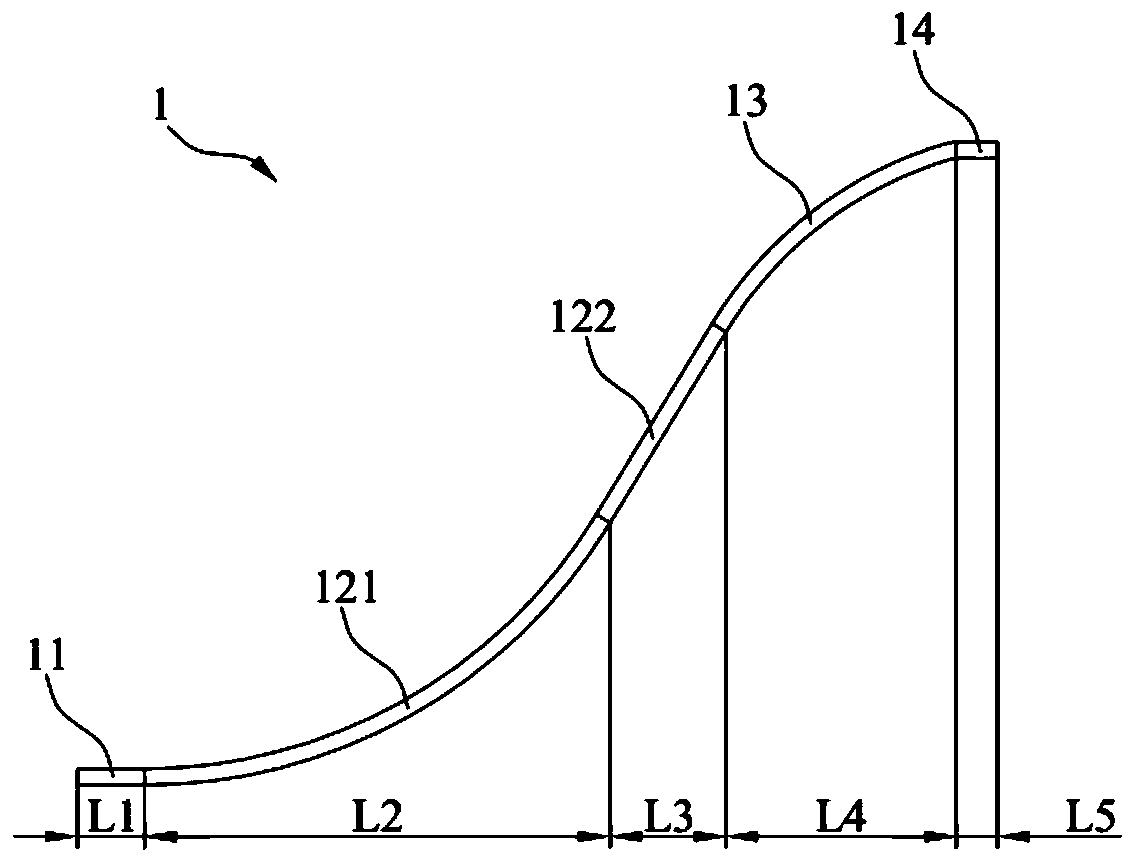

PendingCN111396862ACaptureReduce propulsion speedFluid heatersSolid fuel combustionMultifuelInterior space

The invention provides a combustor and a stove, and relates to the technical field of civil combustion equipment. The combustor comprises a shell and an air distribution plate arranged in the shell obliquely and upwards. The air distribution plate divides inner space into an upper combustion chamber and a lower ventilation chamber. The air distribution plate comprises an isolation segment and an upper convex curve segment which are sequentially connected from bottom to top, and multiple first ventilation holes are dispersedly arranged on the upper convex curve segment. A fuel feed opening andan ash discharging opening are formed in the low end and the high end of the upper combustion chamber in the oblique direction of the air distribution plate. A primary air inlet is arranged at one endof the lower ventilation chamber. By means of the combustor, sufficient combustion of fuel can be achieved, discharging of CO, NOx and other pollutant gas is effectively reduced, the residua carbon quantity in ash is reduced, smokeless combustion is achieved, ash clearing is smooth, and the combustion requirement of multiple kinds of fuel can be met.

Owner:YANKUANG GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com