Patents

Literature

52results about How to "Guaranteed evaporation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

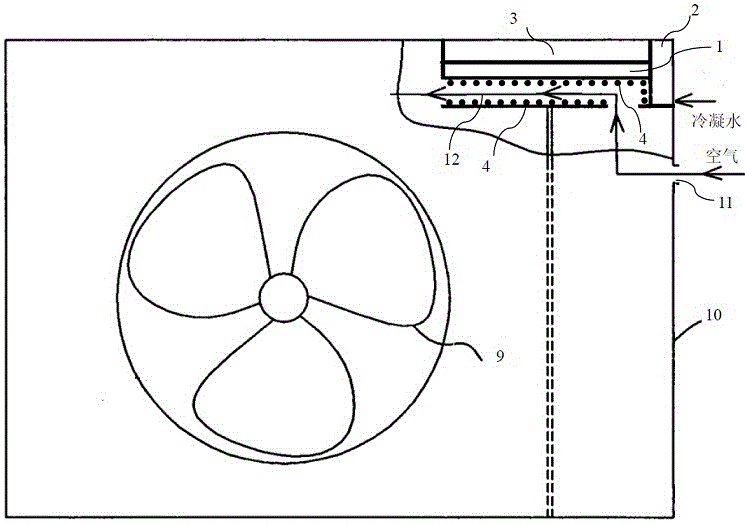

Air-conditioning condensate water utilization device

InactiveCN103542467AMeet thermal requirementsEnhance and guarantee evaporation capacityLighting and heating apparatusAir conditioning systemsCooling effectEvaporation

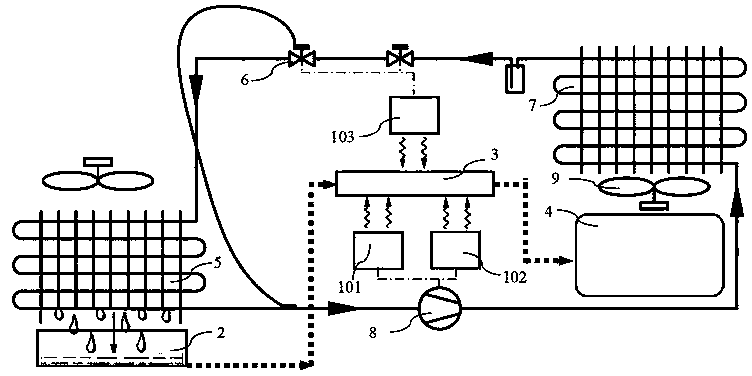

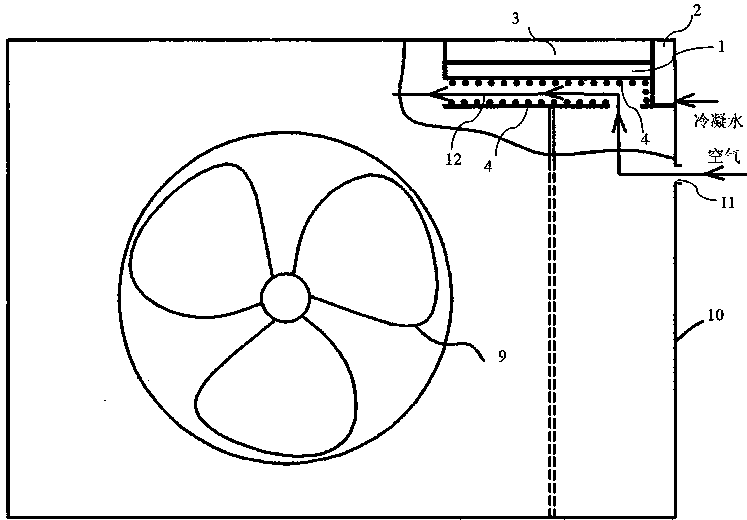

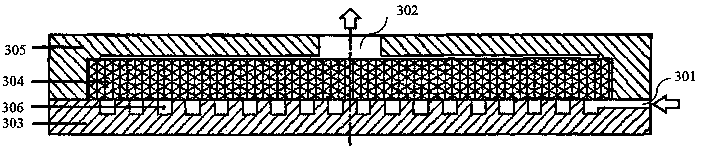

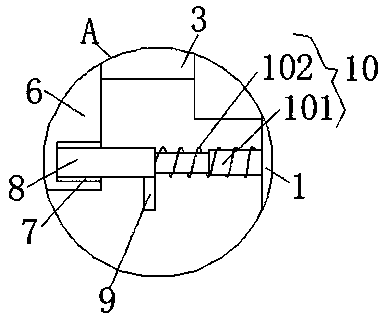

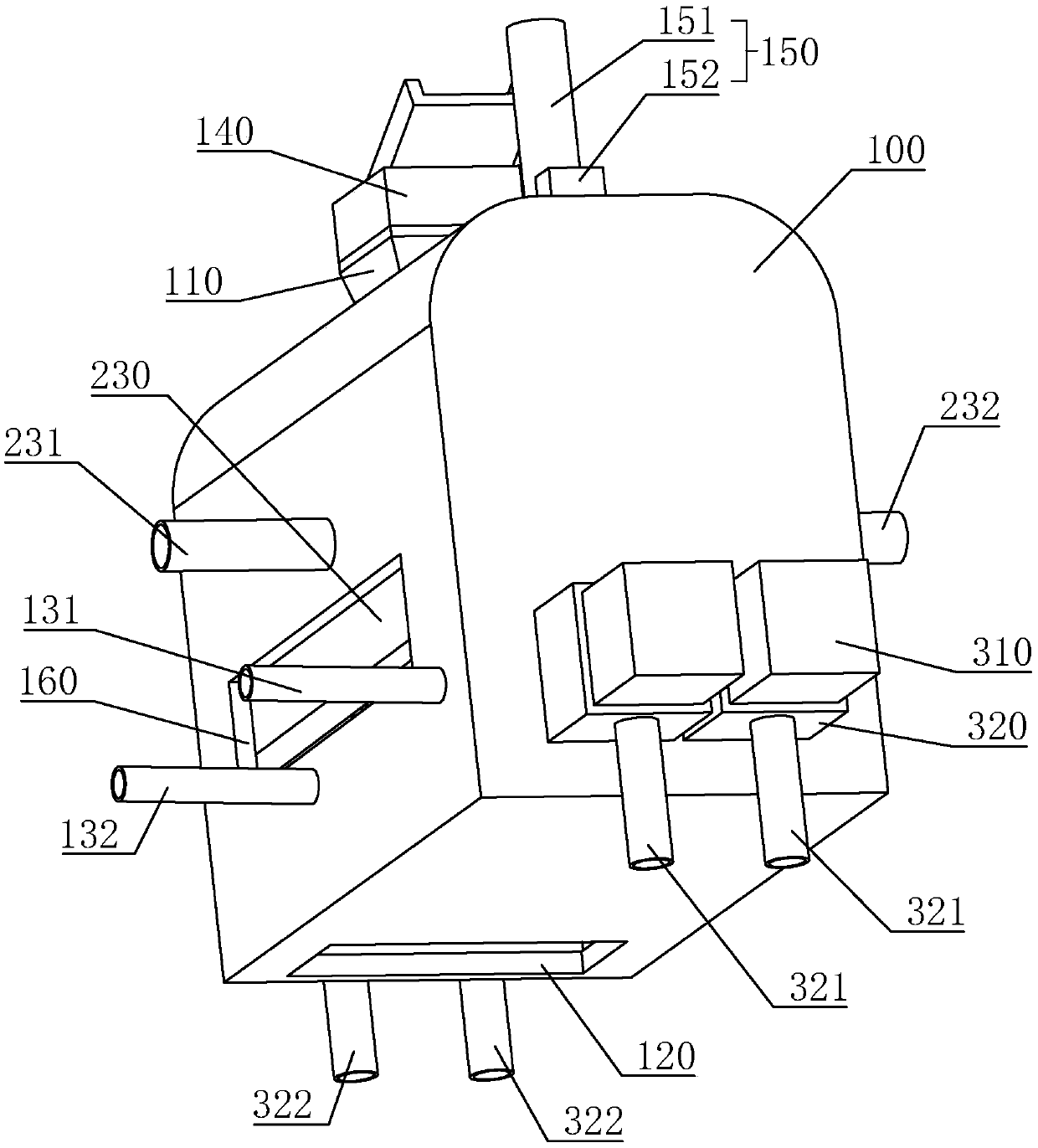

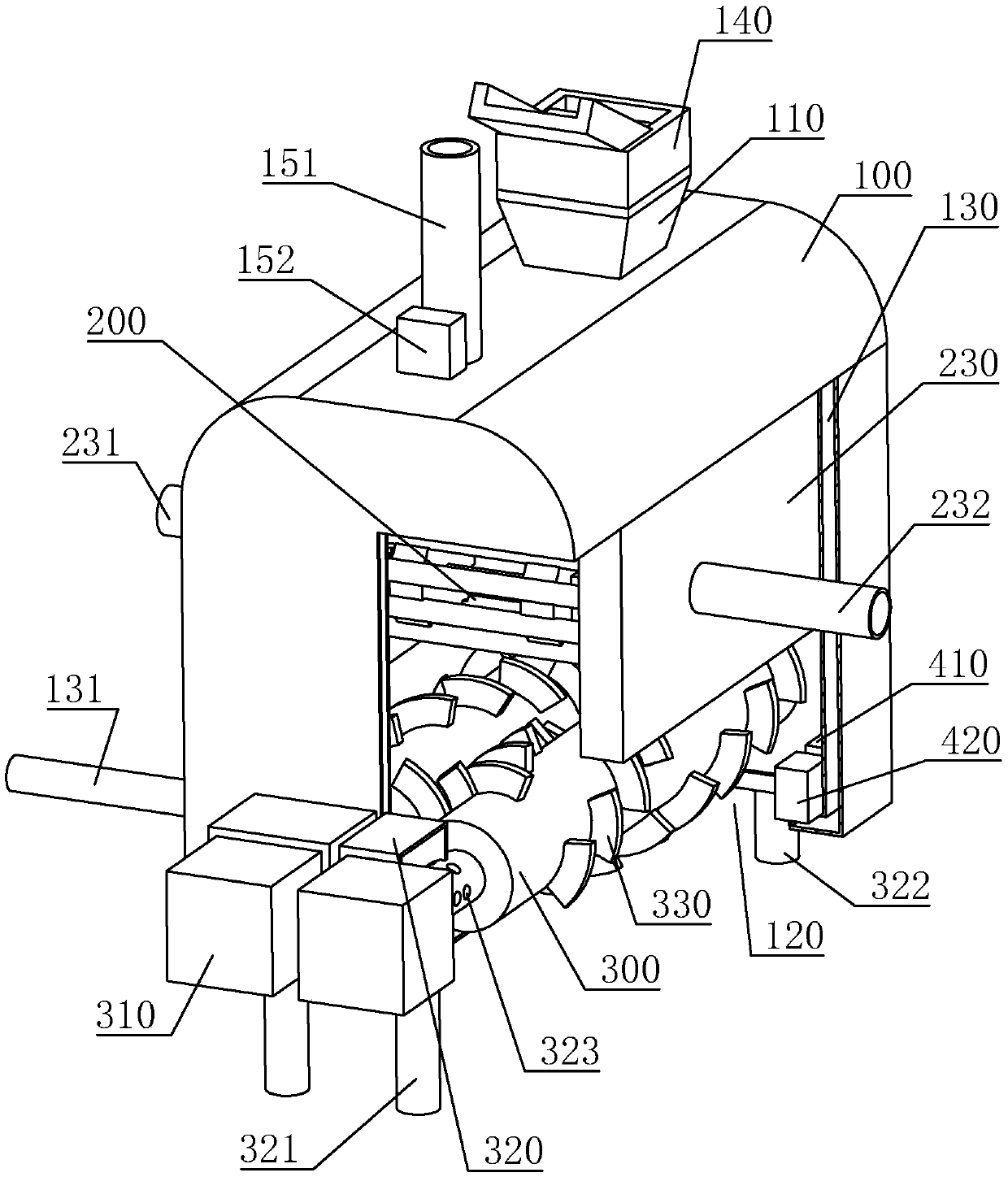

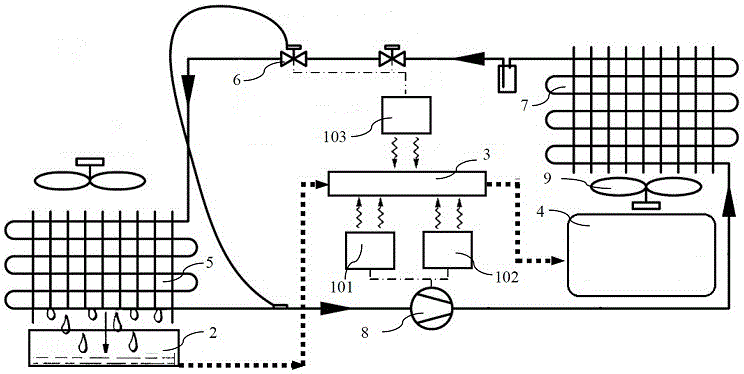

The invention provides an air-conditioning condensate water utilization device for cooling of an electronic control system of an outdoor unit. The device comprises an electric control box, a condensate water compensation container, a cooling unit and a water evaporation unit. Air conditioning condensate water flows from a water outlet pipe of a water collecting disc on the lower portion of an evaporator to a condensate water compensation container and then flows into the cooling unit after buffering and compensation, heat in the electric control box is taken away by a heating element of the cooling unit, and the condensate water flows to the water evaporation unit finally to be evaporated on the surface of an evaporation core. According to the device, the cooling capacity of an air conditioning is used, so that energy is saved; the condensate water is evaporated instead of being discharged, so that adverse effects are eliminated; self-driving of condensate water supply is achieved through the suction action of a capillary core of the cooling unit and the evaporation action of the water evaporation unit; the device has the advantages of being good in cooling effect, long in service life, low in maintenance cost, capable of achieving energy saving and emission reduction of the air conditioning and the like.

Owner:QINGDAO UNIV

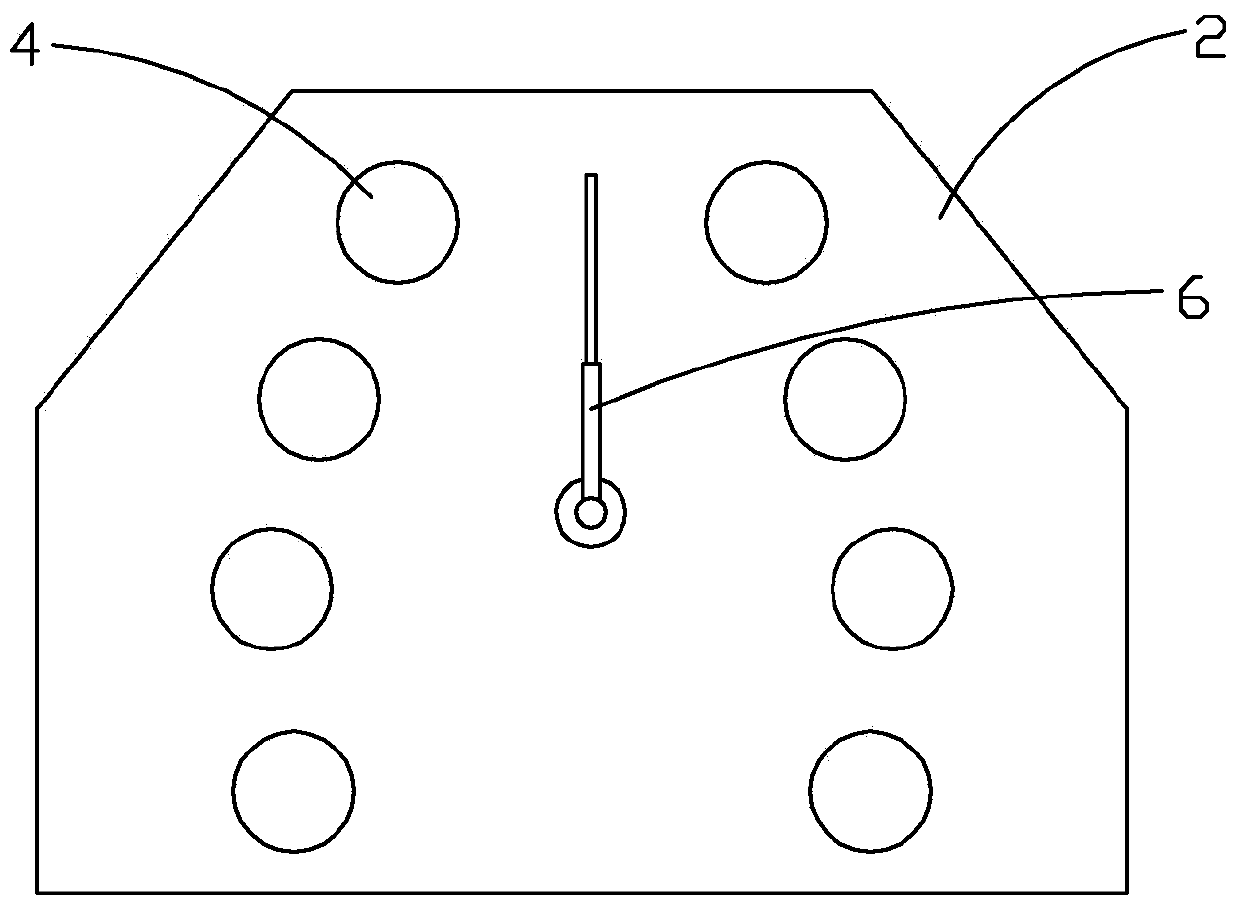

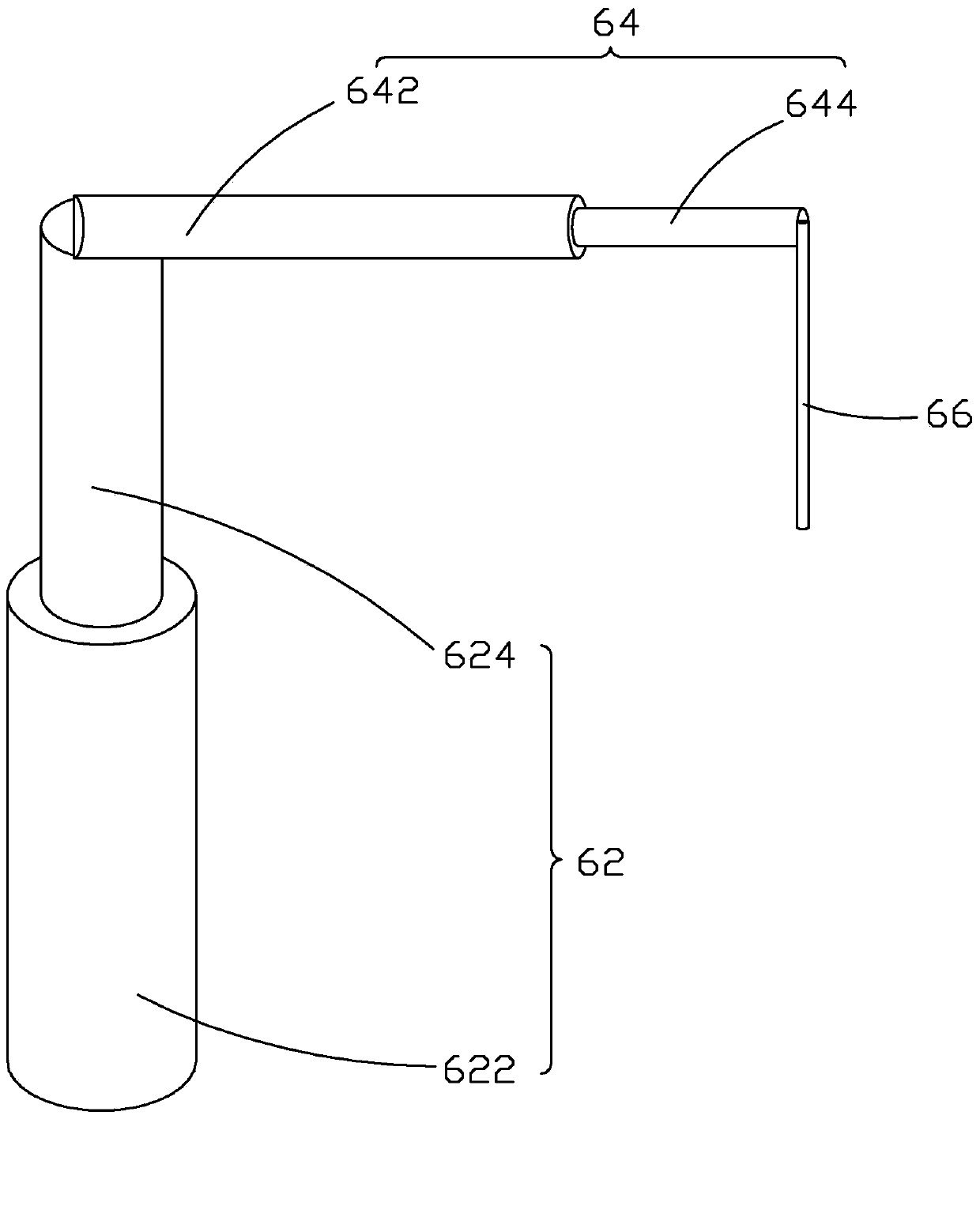

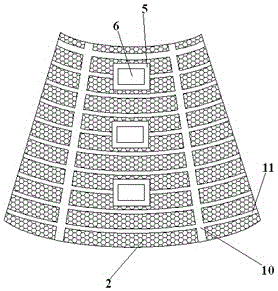

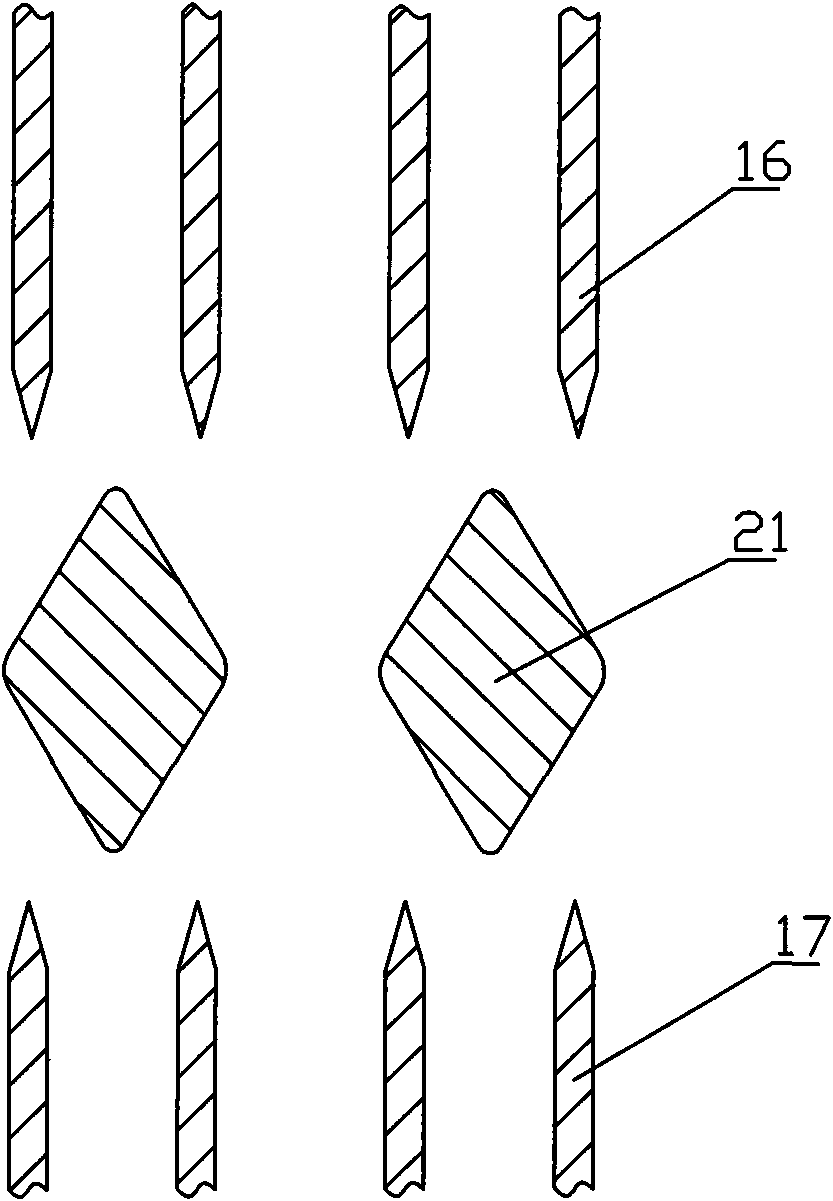

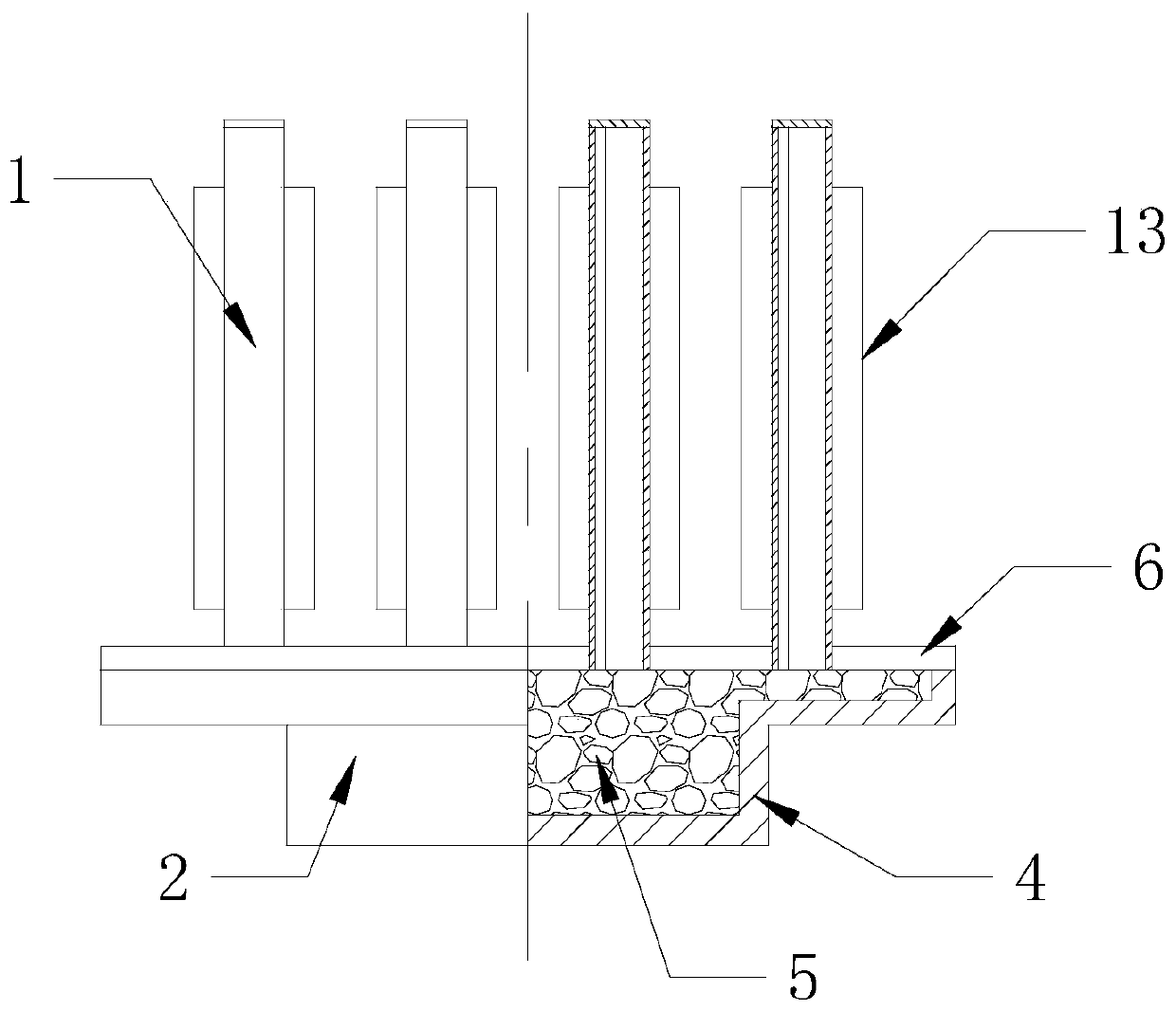

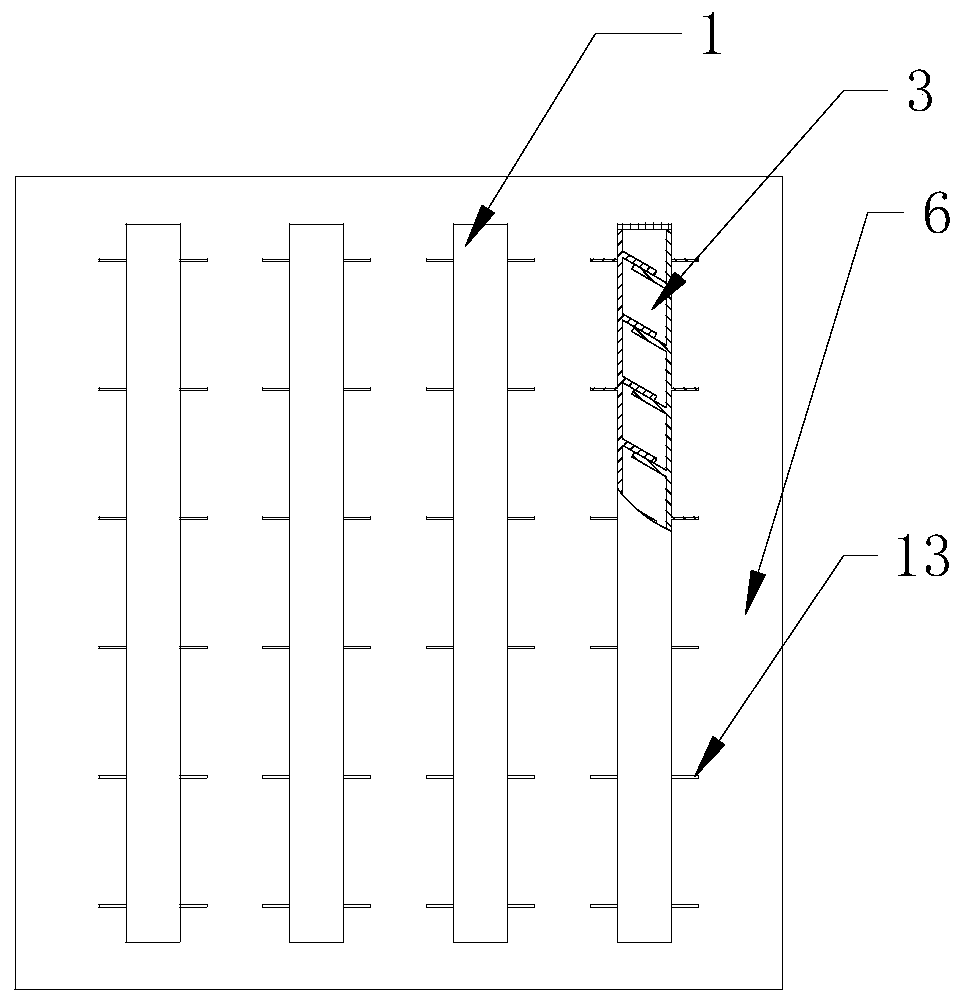

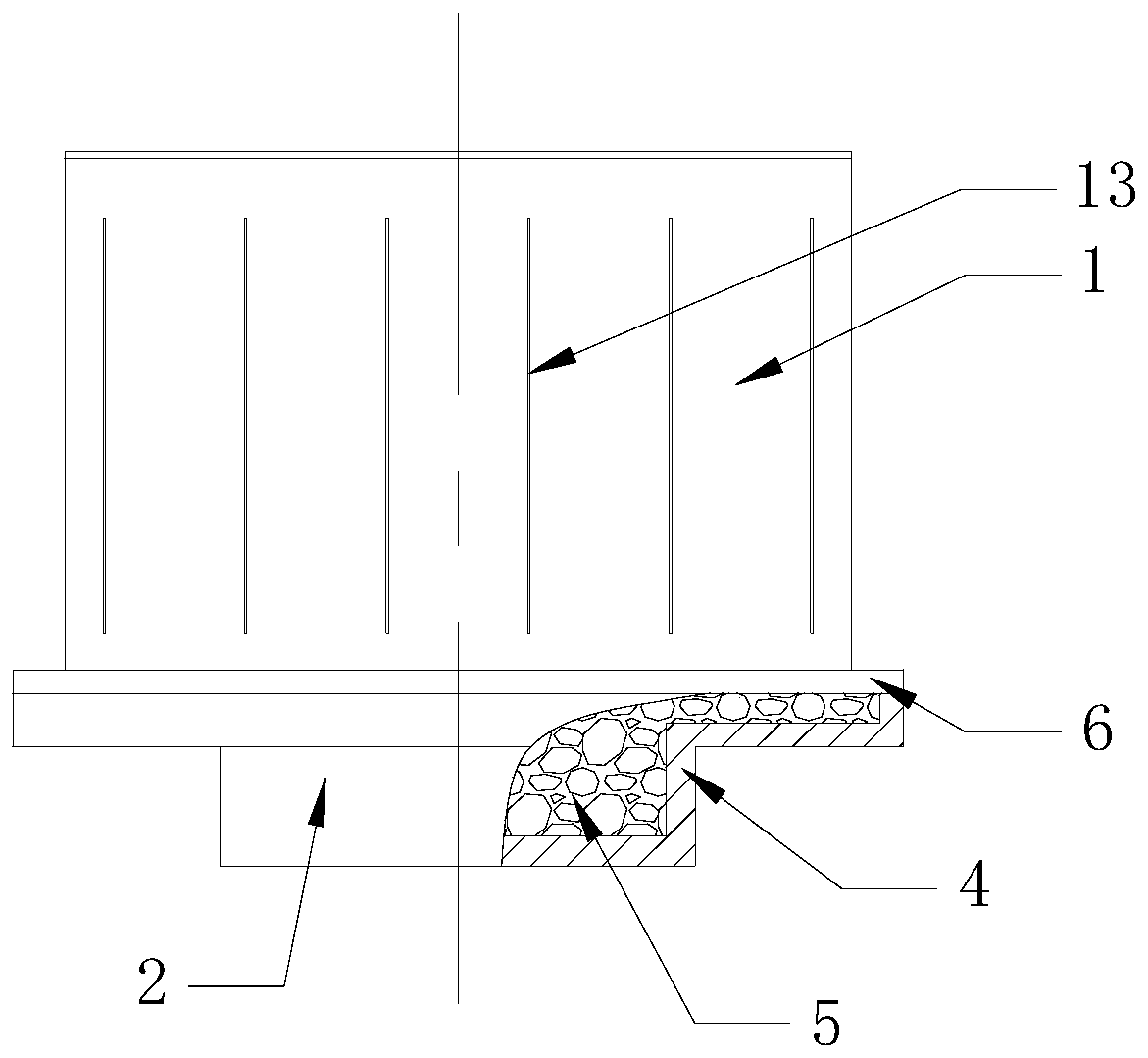

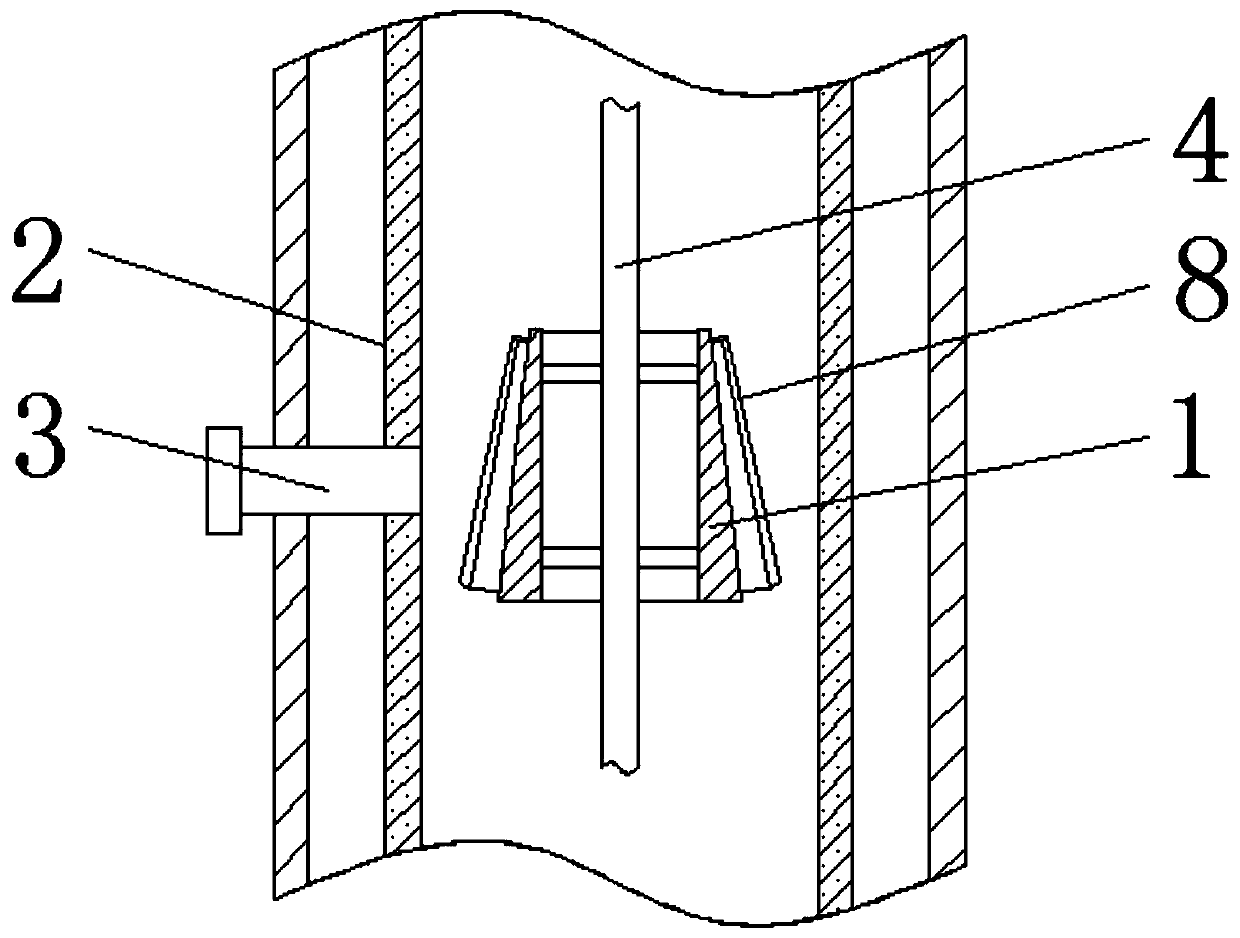

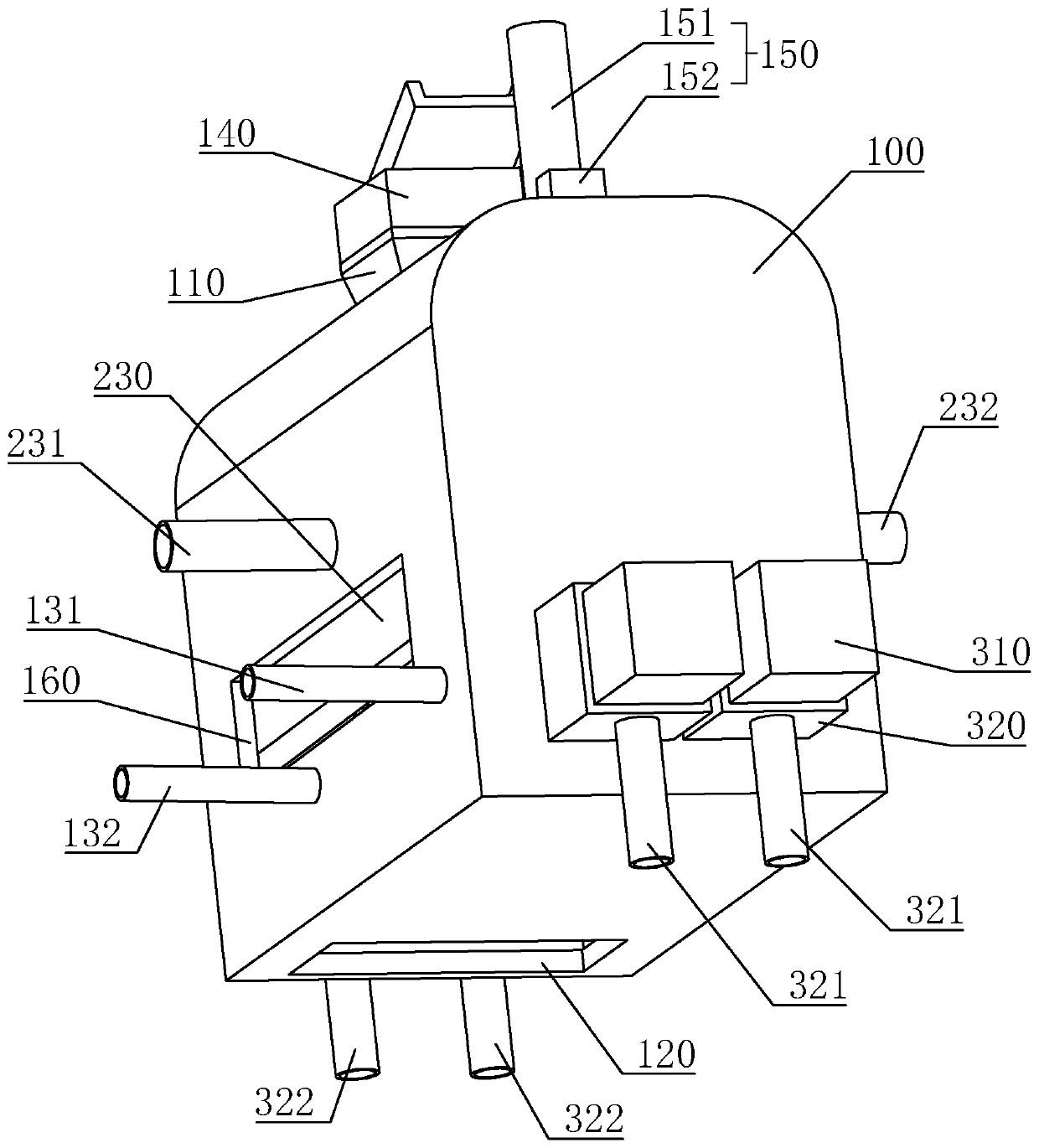

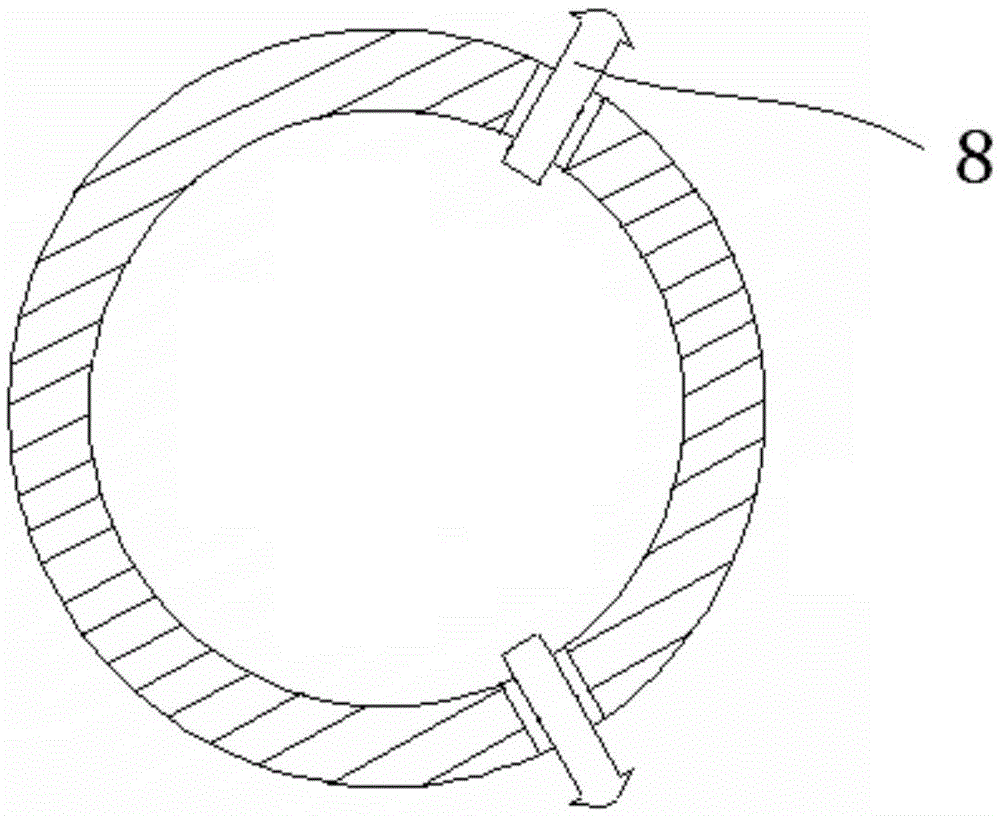

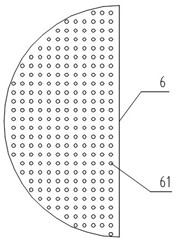

Evaporation source assembly of organic light-emitting diode (OLED) evaporator

ActiveCN103741096AIncrease profitShorten the timeVacuum evaporation coatingSputtering coatingCrucibleEvaporation

The invention provides an evaporation source assembly of an organic light-emitting diode (OLED) evaporator. The evaporation source assembly comprises a bearing platform (2), a plurality of evaporation crucibles (4) and a dredging mechanism (6), wherein the plurality of evaporation crucibles (4) are arranged on the bearing platform (2); the dredging mechanism (6) is arranged on the bearing platform (2), and comprises a vertical arm (62), a cross arm (64) and a probe (66); the cross arm (64) is vertically connected to one end of the vertical arm (62); the probe (66) is vertically connected with the free end of the cross arm (64); the vertical arm (62) is arranged on the bearing platform (2) in a scalable manner, and can rotate opposite to the bearing platform (2); the probe (66) is controlled to dredge gas outlets of the evaporation crucibles (4) through the cross arm (64) and the vertical arm (62). By adopting the evaporation source assembly of the OLED evaporator, disclosed by the invention, the gas outlets of the evaporation crucibles can be dredged under the condition of not opening a cavity of the evaporator by providing the dredging mechanism, the time is saved, the dredging efficiency is effectively improved, and the utilization rate of the evaporator is also increased.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

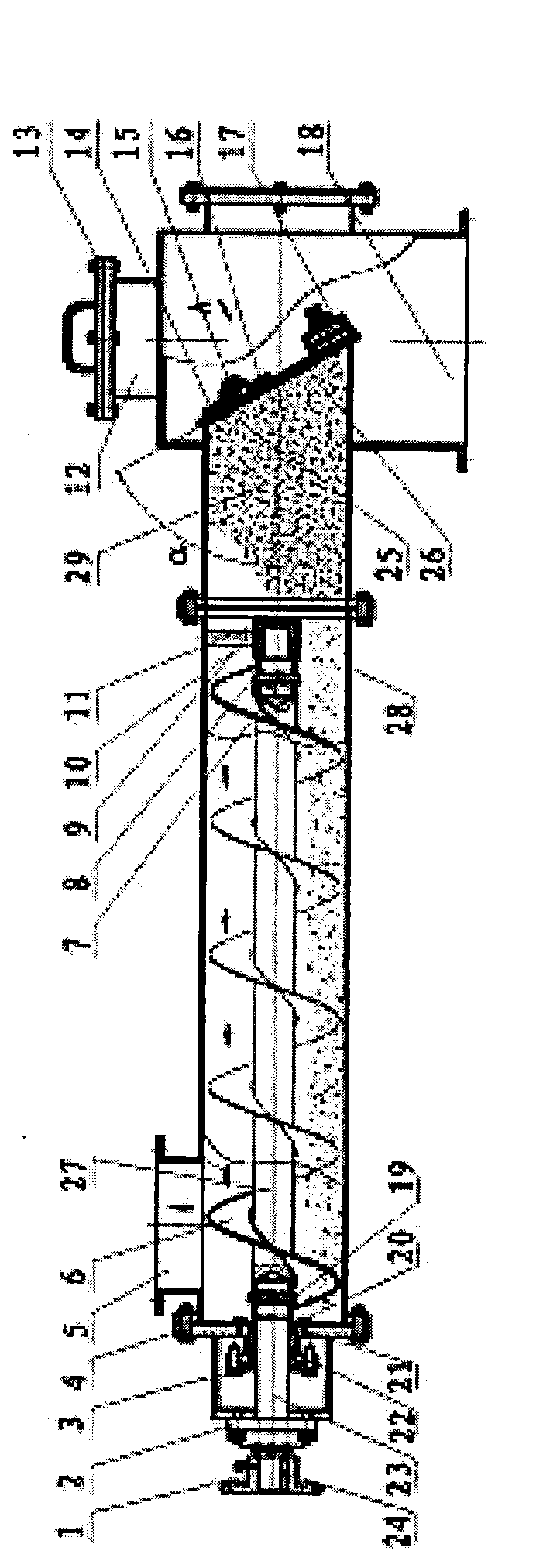

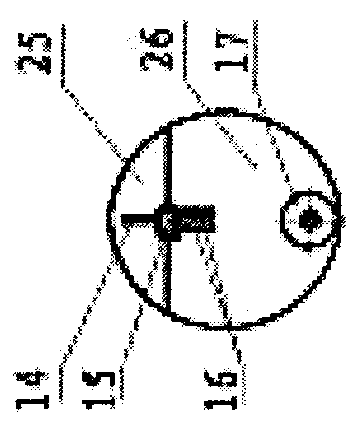

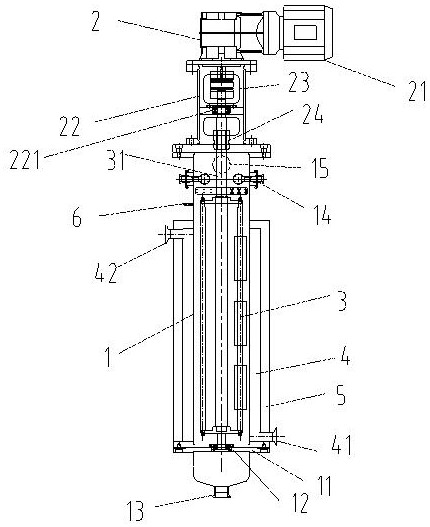

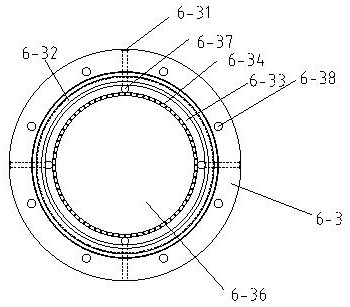

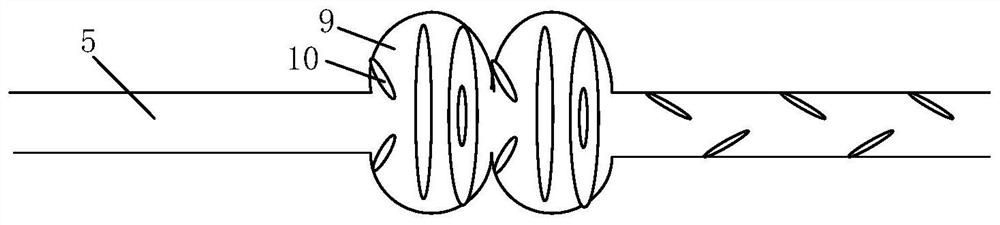

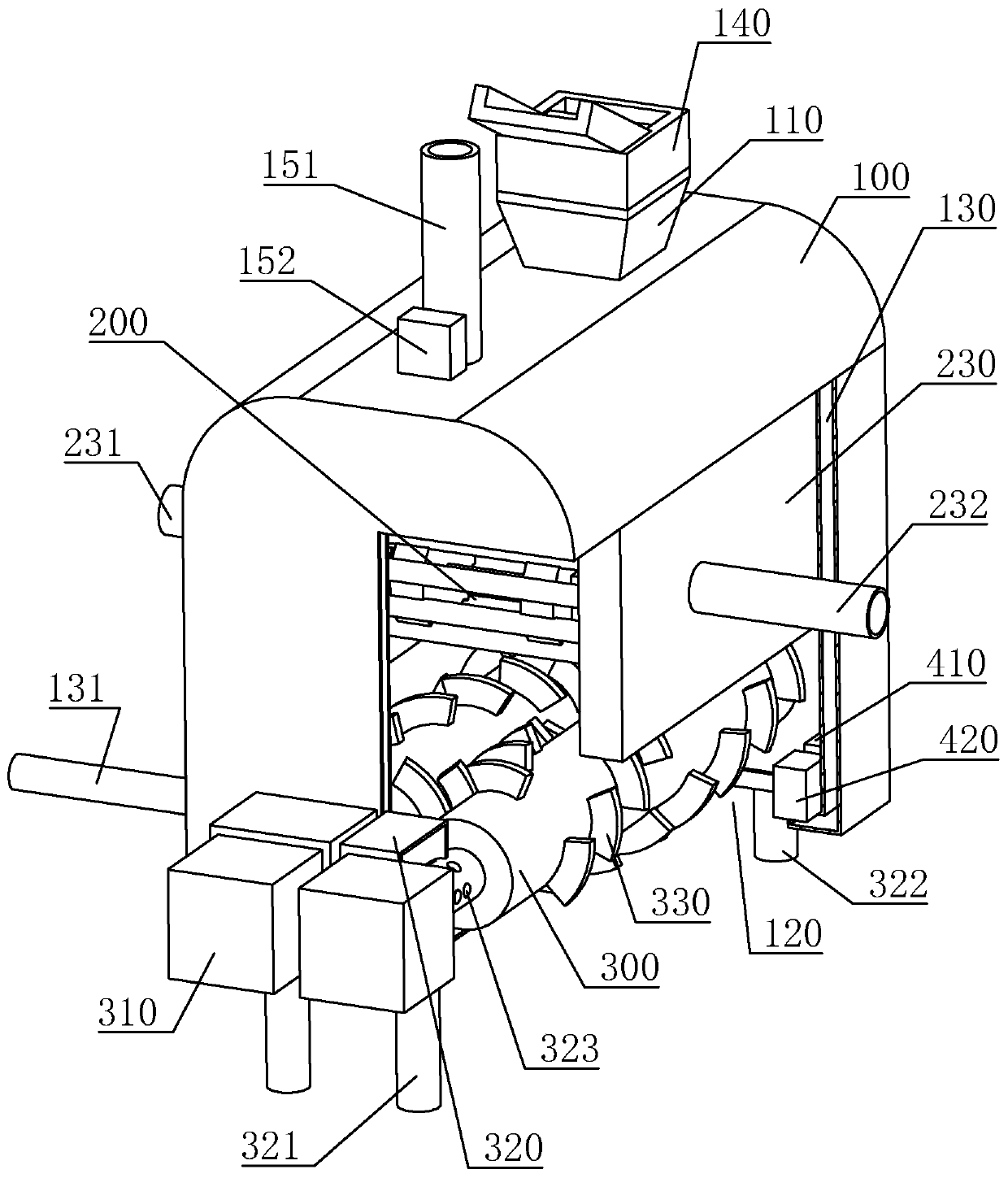

Pipeline-type material conveyor

The invention discloses a pipeline-type material conveyor, which comprises a material conveying pipeline, a material conveying packing auger and a driving construction member, wherein the material conveying packing auger is arranged in the material conveying pipeline; the driving construction member is fixedly connected with the material conveying packing auger; the tail section of the material conveying pipeline is provided with a material compaction area; the upper part of the tail end of the material conveying pipeline is provided with a fixed cover plate; the fixed cover plate is provided with a fixed hinge; the lower part of the tail end of the material conveying pipeline is provided with a movable cover plate; the movable cover plate is fixedly provided with a movable hinge; the movable hinge is hinged with the fixed hinge via a pin; the movable cover plate is also provided with an opening pressure regulation device; the material conveying packing auger is in a split structure and comprises a packing auger body, a front supporting shaft and a rear supporting shaft, wherein the front supporting shaft and the rear supporting shaft are in detachable cooperation connection with two ends of the packing auger body; the opening pressure regulation device is a balancing weight; the end surface of the tail end of the material conveying pipeline is an aslant section; and an included angle alpha between the aslant section and the central axis of the material conveying pipeline is an acute angle alfa. According to the conveyor, volatile, flammable and combustible gas doped in conveyed materials is prevented from externally leaking in the conveying process, and the conveyor has the advantages of reasonable structure and safety in use.

Owner:JINGSU HUALIANG MACHINERY

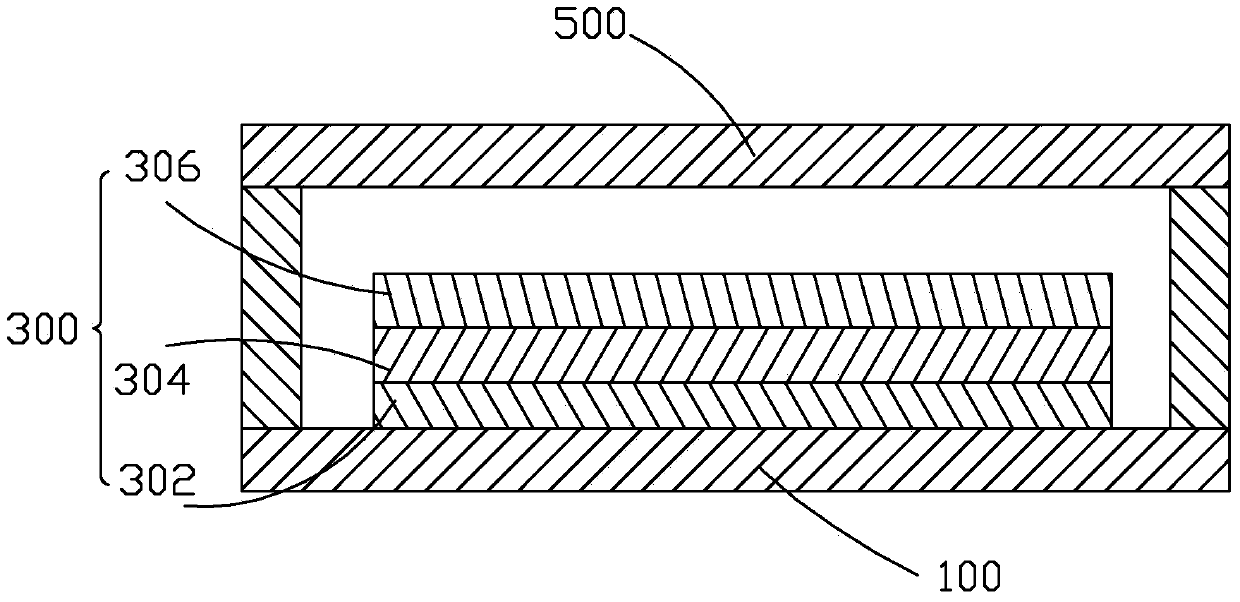

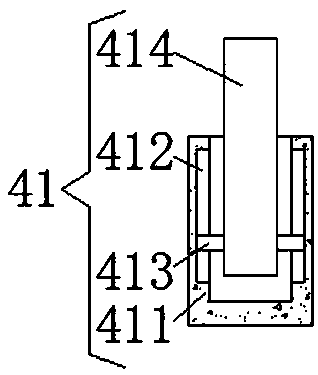

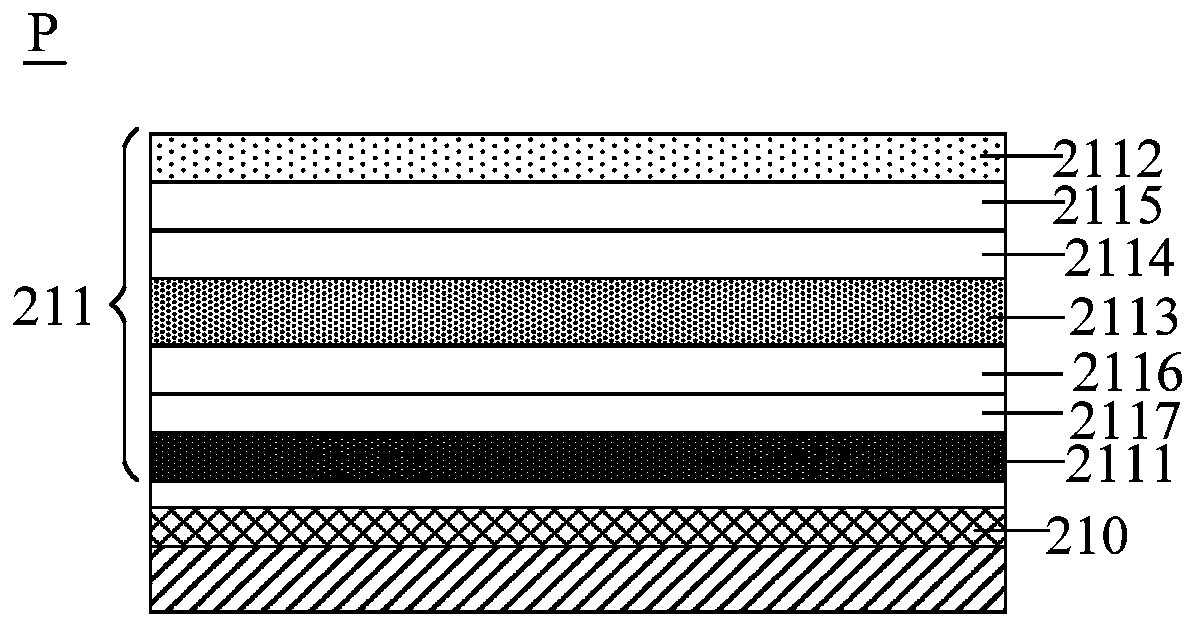

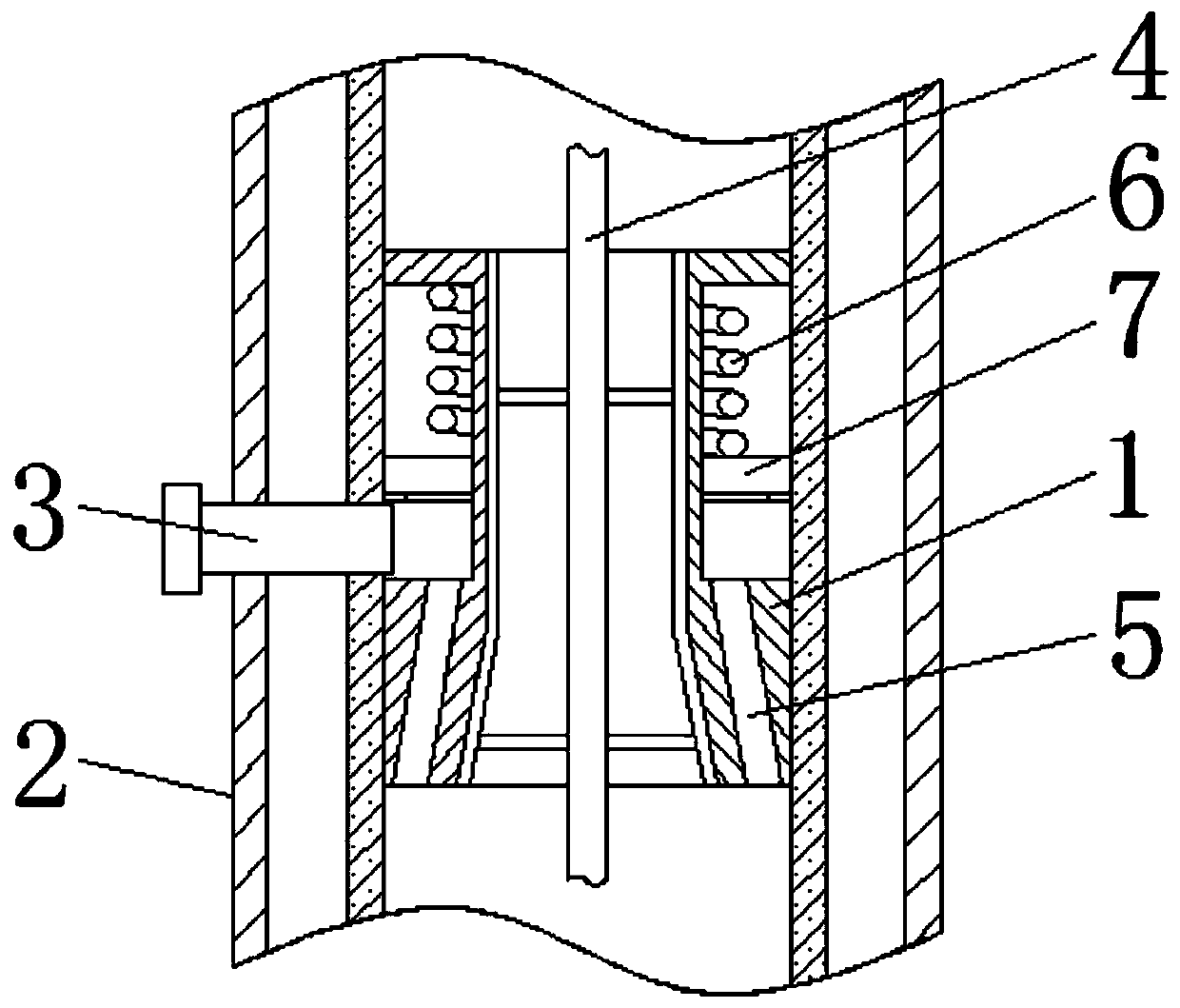

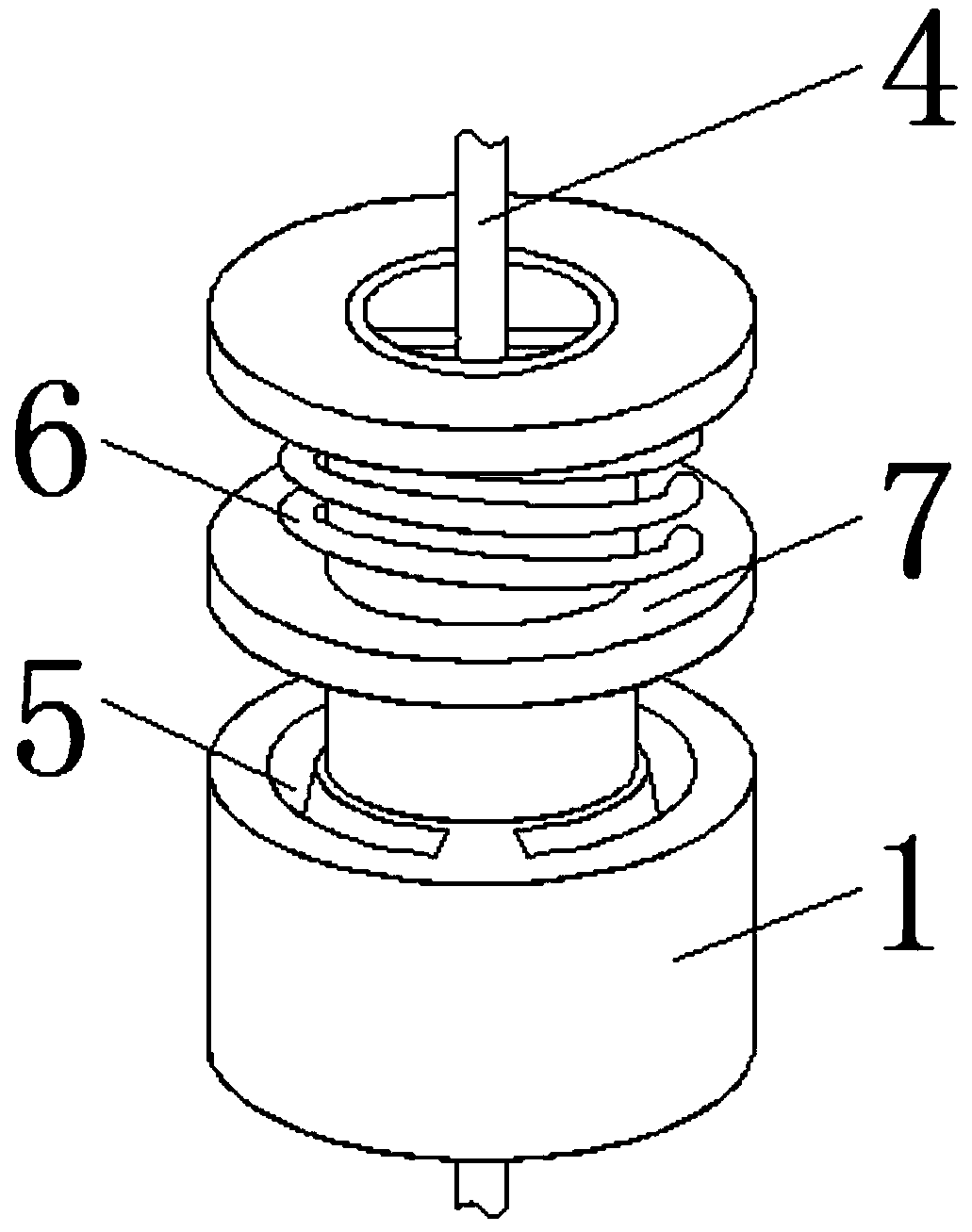

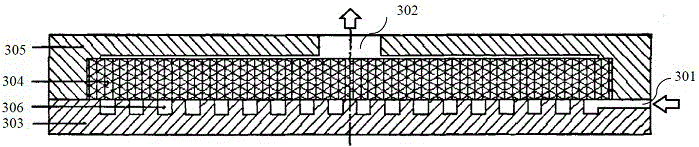

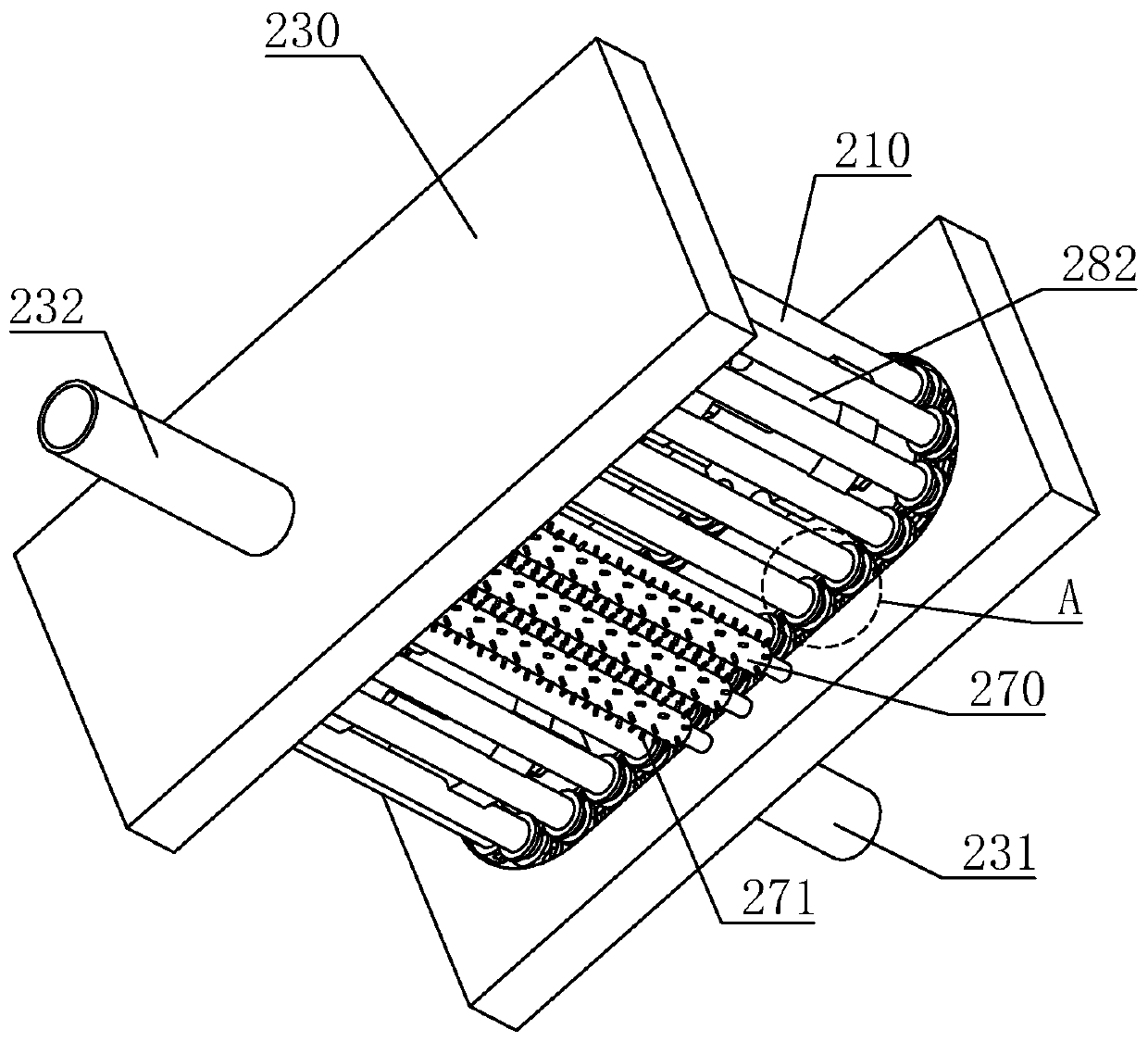

Heat pipe radiator with variable-section hot end and multiple pulsation cold ends

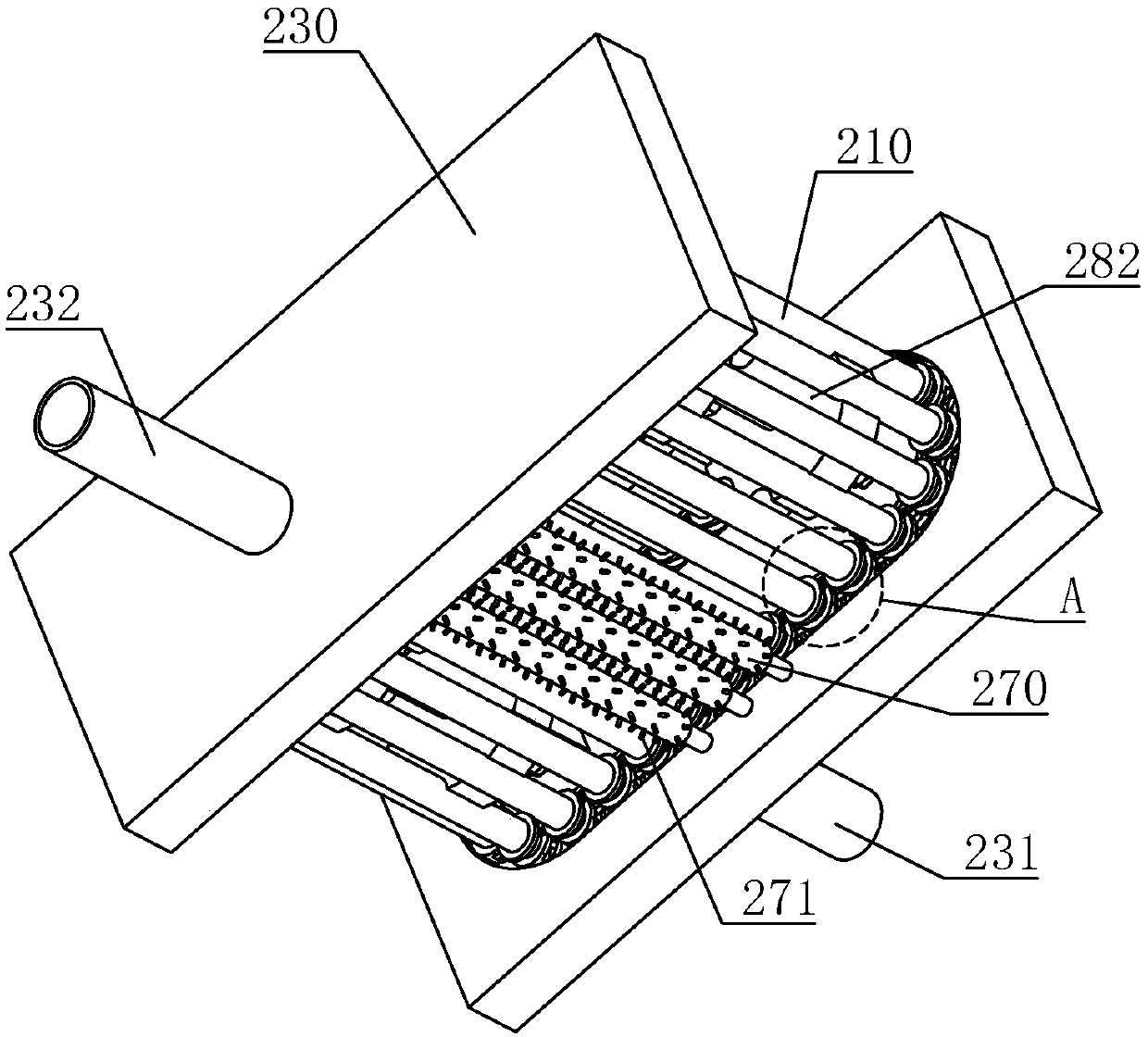

The invention provides a heat pipe radiator with a variable-section hot end and multiple pulsation cold ends. The heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends comprises the pulsation cold ends and the hot end. The heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends is characterized in that each pulsation cold end is a heat dissipating plate internally provided with multiple pulsation channels, the hot end is a hollow cavity, the cavity is filled with a working medium and a capillary liquid absorbing core, an upper cover plate of the hot end hollow cavity is provided with multiple cold end connectors, each cold end connector is provided with one pulsation cold end, and the pulsation channels of the pulsation cold ends communicate with the hollow cavity of the hot end. The heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends is simple in structure, easy to manufacture and capable of being transversely and vertically used, the variable-section structure is adopted, so that the pressure bearing capacity of heat pipes can be improved, especially the heat dissipating area of the cold ends is increased, the two thermal processes of evaporation and condensation adopt a pulsation heat transferring mode and a porous medium heat transferring mode correspondingly, the heat transferring performance and the medium transferring performance are effectively improved, backflow is uniform, the temperature uniformity is good, and the heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends is suitable for industrial manufacturing.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Electric mosquito-repellent incense device for conveniently turning mosquito-repellent incense sheet

The invention discloses an electric mosquito-repellent incense device for conveniently turning the mosquito-repellent incense sheet, which comprises an electric mosquito-repellent incense device mainbody, wherein both the left side face and the right side face of the electric mosquito-repellent incense device body are clamped with rotating devices; the left end of the rotating devices are fixedlyconnected with a movable rod; the right end of the rotating devices are fixedly connected with U-shaped plates; the upper surface and the lower surface of the inner wall of the U-shaped plates are fixedly connected with the first telescopic devices; the opposite ends of the two first telescopic devices are fixedly connected with extrusion plates; and the right side surface of the movable rod is provided with two clamping grooves. The electric mosquito-repellent incense device which is convenient for flipping mosquito-repellent incense sheets realizes the turnover of mosquito-repellent incensesheet, through the combined action of the movable rod, the rotating shaft, the bearing, the U-shaped plates, the first spring, the first telescopic rods and the extrusion plates. The process that theheating plate is heated for such a long time that the mosquito repelling liquid in the other side of the mosquito-repellent incense sheet volatilizes out is avoided, thereby the volatilization effectof the mosquito-repellent liquid is ensured, and the mosquito-repellent effect of the electric mosquito-repellent incense device main body is ensured.

Owner:HUANGSHAN LISHEN COMMODITY

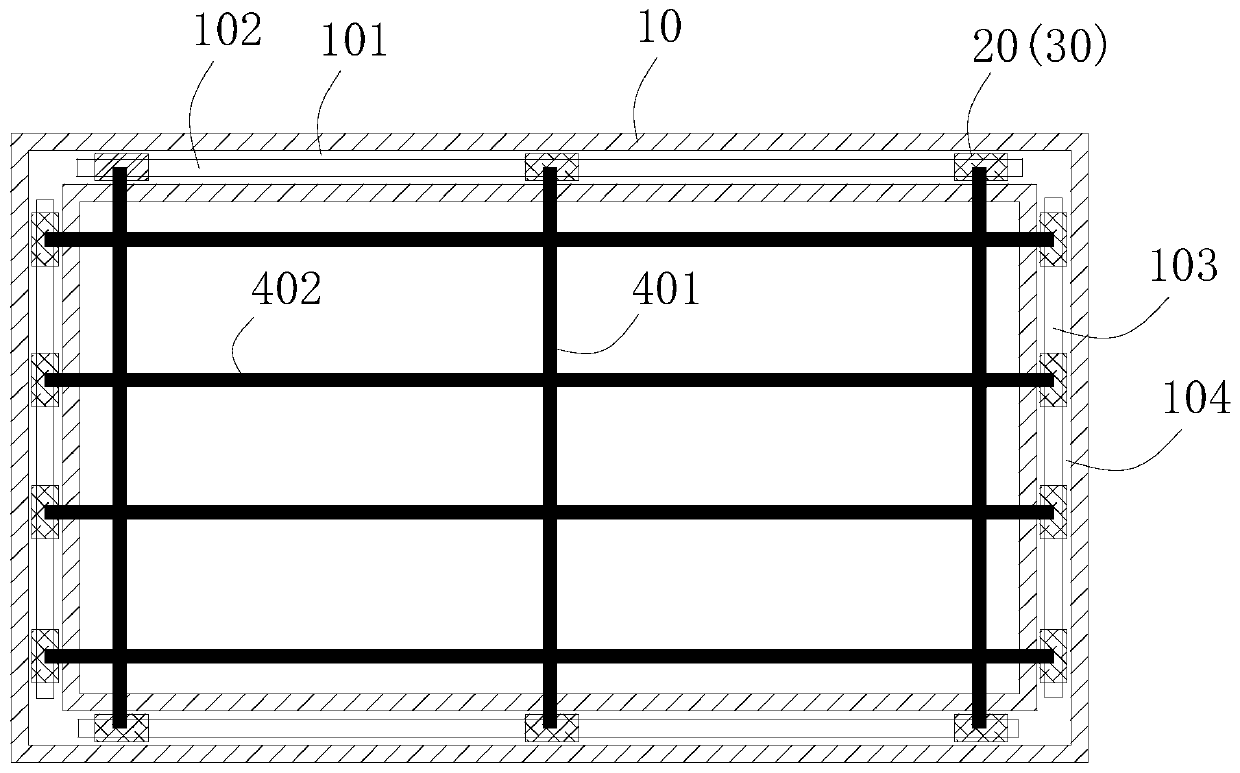

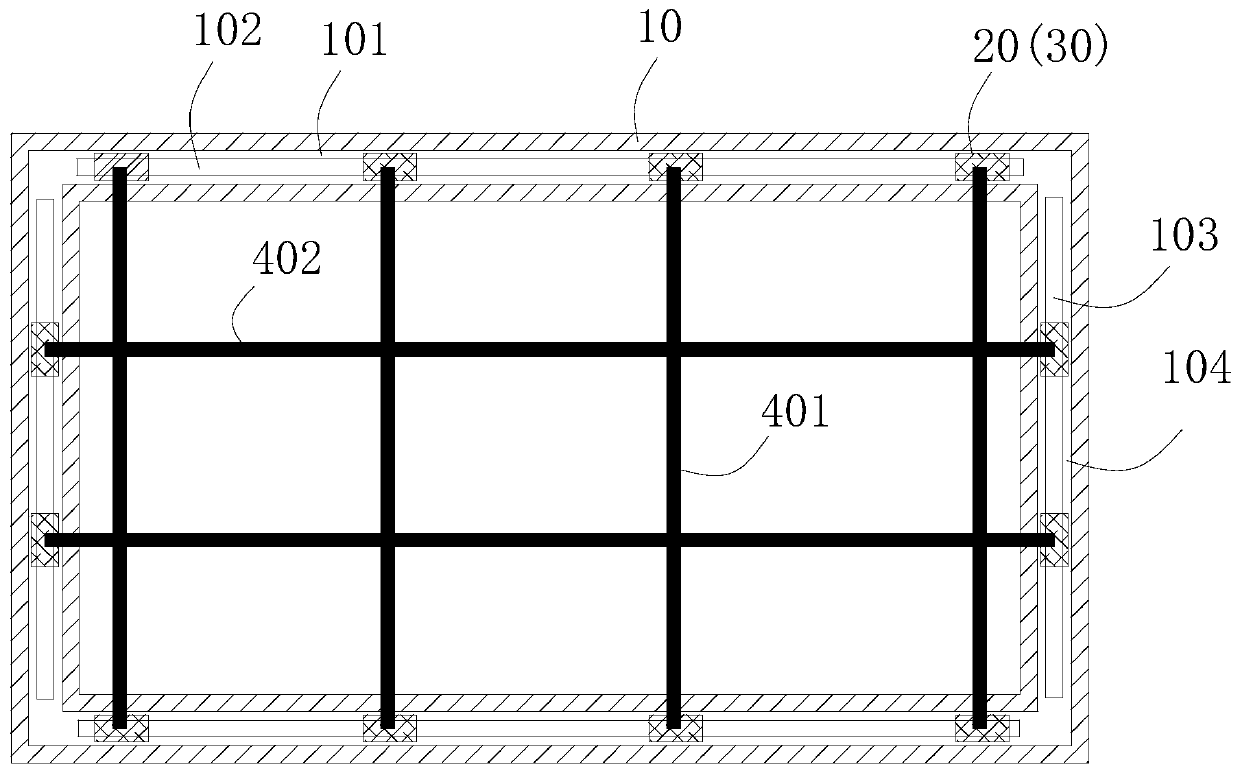

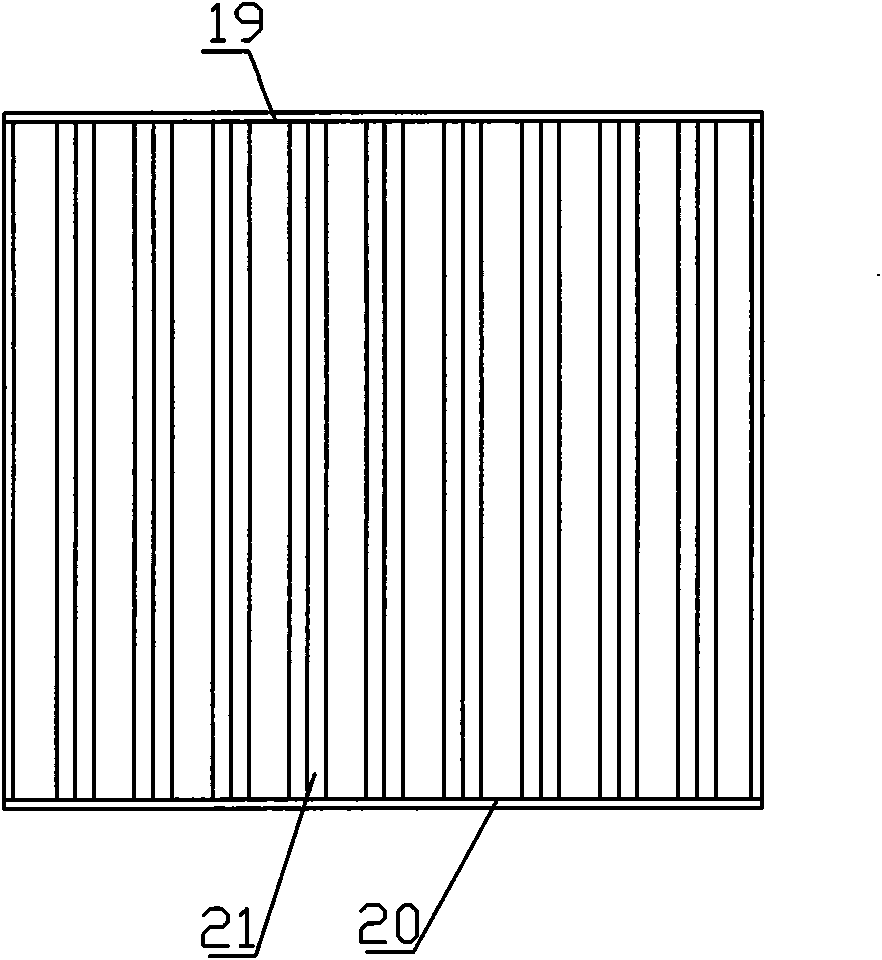

OLED evaporation mask plate

PendingCN110184565ARealize diversified productionHigh positioning accuracyVacuum evaporation coatingSolid-state devicesTransverse grooveEvaporation

The invention discloses an OLED evaporation mask plate. A pair of longitudinal grooves and a pair of transverse grooves are formed in two opposite side frames of a metal frame. First guide rails are arranged in the grooves, and main scale marks are arranged on the edges of the grooves. Sheet metal is arranged in the longitudinal grooves and the transverse grooves through positioning devices, and can slide along the first guide rails. Auxiliary scale marks and fixing devices are arranged on the positioning devices, the sheet metal is precisely positioned through cooperation of the main scale marks and the auxiliary scale marks, and the tightness of the sheet metal can be adjusted through the fixing devices. The transverse and longitudinal positions of the sheet metal in the metal frame areadjustable, the evaporation mask plate with any rectangular pattern can be formed, evaporation process of multiple specifications can be completed through one evaporation mask plate, and diversified production of products is achieved.

Owner:江苏壹光科技有限公司

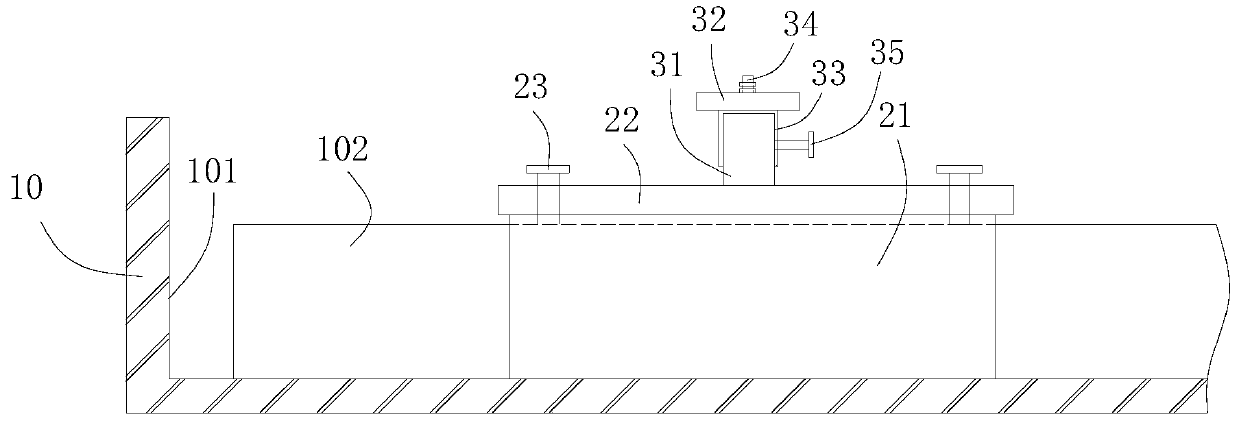

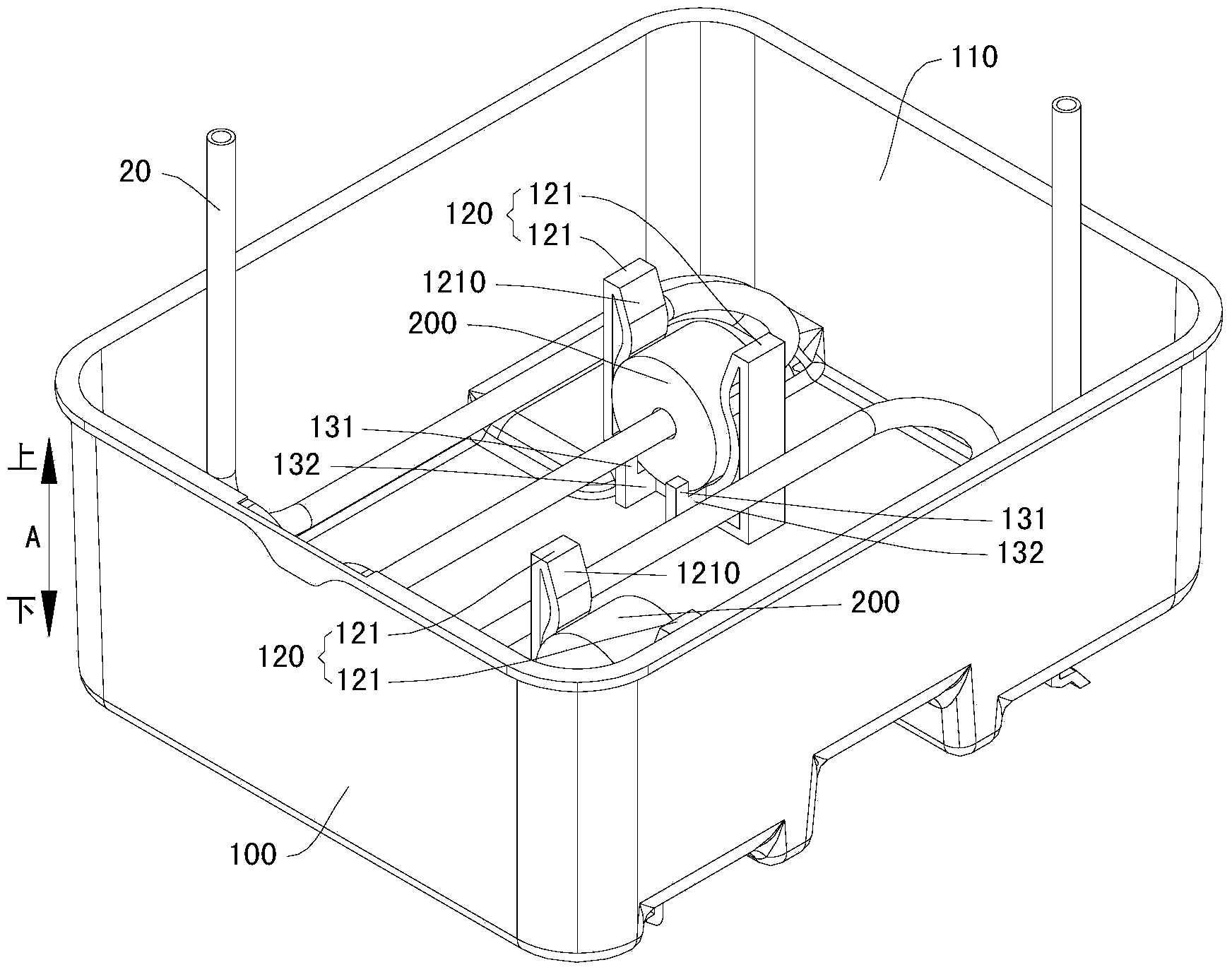

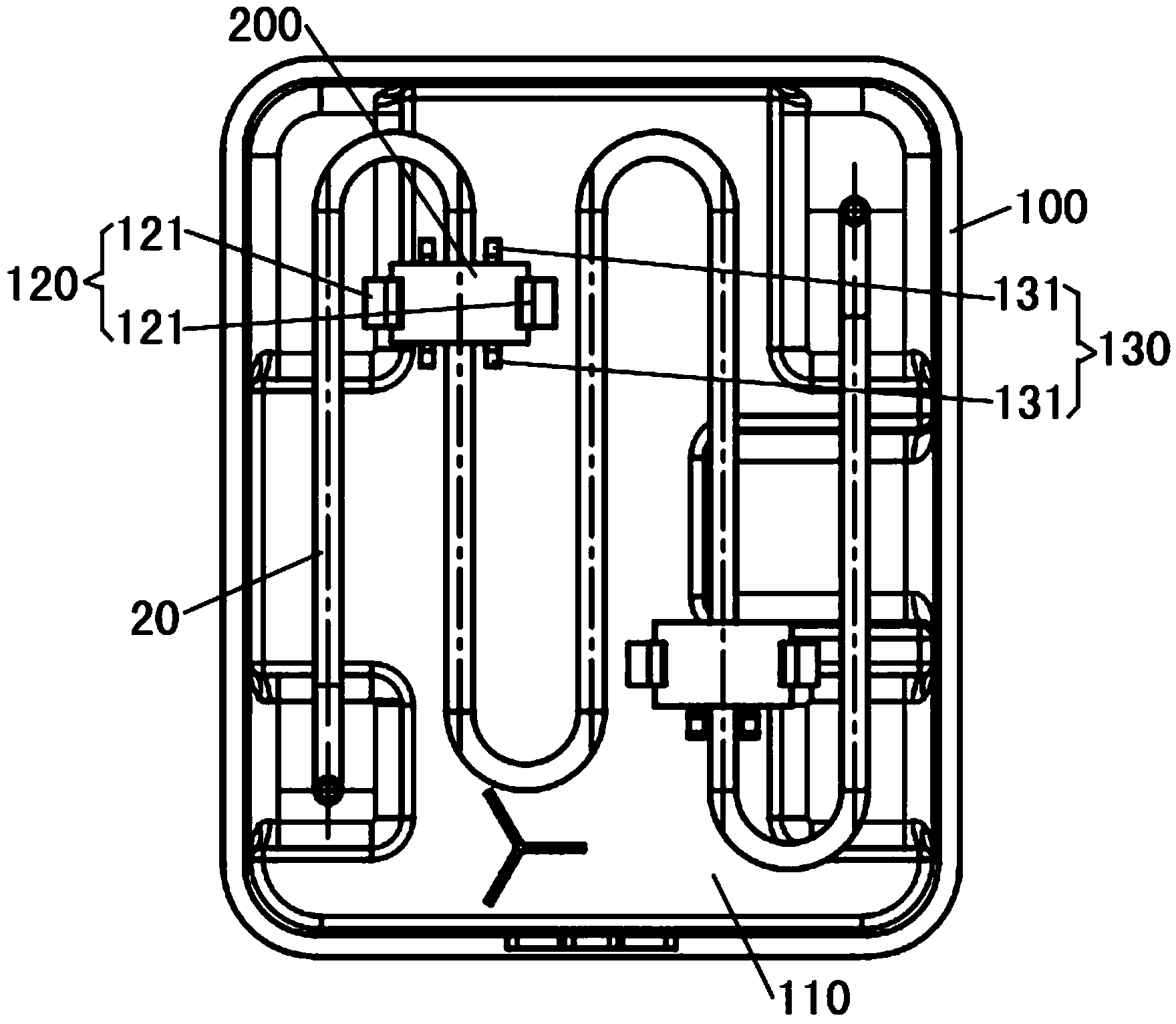

Water pan for refrigerator and refrigerator with same

ActiveCN104296463AImprove stabilityGuaranteed evaporation effectLighting and heating apparatusRefrigeration devicesEvaporationRefrigerated temperature

The invention discloses a water pan for a refrigerator and a refrigerator with the same. The water pan for the refrigerator comprises a pan body and a plurality of shock absorption parts. A water reception cavity is limited in the pan body, a water reception port communicated with the water reception cavity is arranged on the pan body, a plurality of buckles groups are arranged on the inner wall of the pan body, and each buckle group comprises two elastic buckles opposite to each other and arranged at intervals. The shock absorption parts are clamped between every two elastic buckles of the buckle groups, and tube via holes used for fixing a condensing tube of the refrigerator are arranged on the shock absorption parts. The water pan has the advantages of being stable and reliable in tube fixing, good in the evaporation effect, small in noise, etc.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

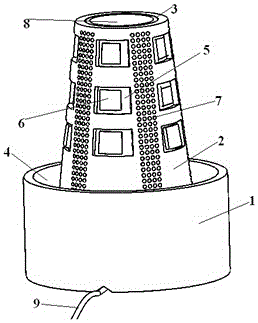

Ceramic type indoor humidifier

InactiveCN106705317AImprove gentle performanceHeating evenlyLighting and heating apparatusAir humidification systemsMetallurgyWater storage

The invention discloses a ceramic type indoor humidifier. The ceramic type indoor humidifier comprises a water storage base, a ceramic core and a heating assembly, and is characterized in that the ceramic core is arranged in the water storage base; water storage cavities are formed in the water storage base; the heating assembly is arranged on the outer surface of the ceramic core. The ceramic type indoor humidifier adopts a ceramic type structure, so that the requirements of humidifying uniformly and moderately can be met; through a porous ceramic core and by combining water absorbing cotton sleeves which are arranged in the porous ceramic core, the ceramic core can be attached with water at any time; in such a manner, water is vaporized under the heating of ceramic heating pieces; moderate performance of indoor heating is improved; the ceramic type indoor humidifier is provided with longitudinal flow channels, so that steam can flow out from different positions; transverse flow channels can fix the water absorbing sleeves and can also enhance of the attachment of the water to the ceramic core, so that a water vaporizing effect in the ceramics is ensured; according to the ceramic type indoor humidifier, the ceramic heating pieces are adopted for heating, so that the heating is uniform and a dehumidifying effect is good.

Owner:SHANXI DATONG UNIV

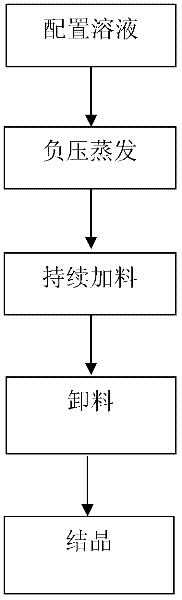

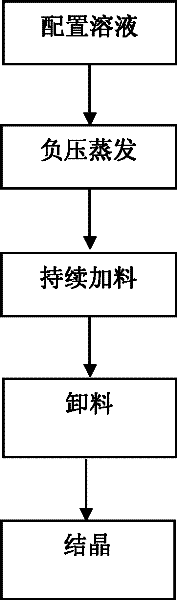

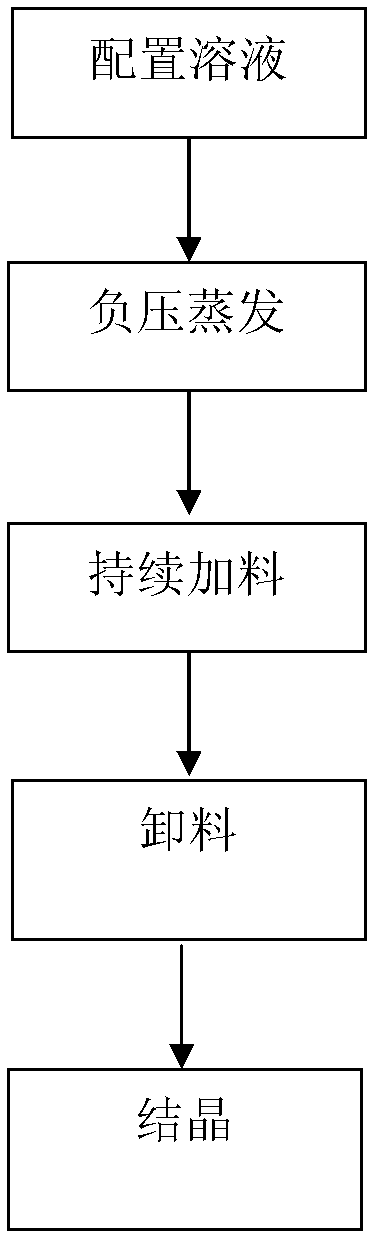

Negative pressure evaporation and step-by-step feeding method of nickel sulfate solution

The invention discloses a negative pressure evaporation and step-by-step feeding method of a nickel sulfate solution. The method comprises the following steps: preparing the nickel sulfate solution to be produced; performing vacuum pumping on a negative pressure evaporator; performing continuous heating on the solution in the negative pressure evaporator; performing cooling and crystallization on the concentrated solution; and further performing step-by-step feeding. The method is characterized in that the step-by-step feeding and the vacuum pumping operation are simultaneously performed. Therefore, the volume of the evaporation device can be fully utilized, the number of times of operation can be reduced, and the purpose of improving working efficiency can be further achieved. The method disclosed by the invention has the characteristics of fast evaporation speed, high production efficiency and simple operation, the number of equipment used by the method is small, and the equipment occupies small area, and is environment-friendly and pollution-free.

Owner:广东芳源新材料集团股份有限公司

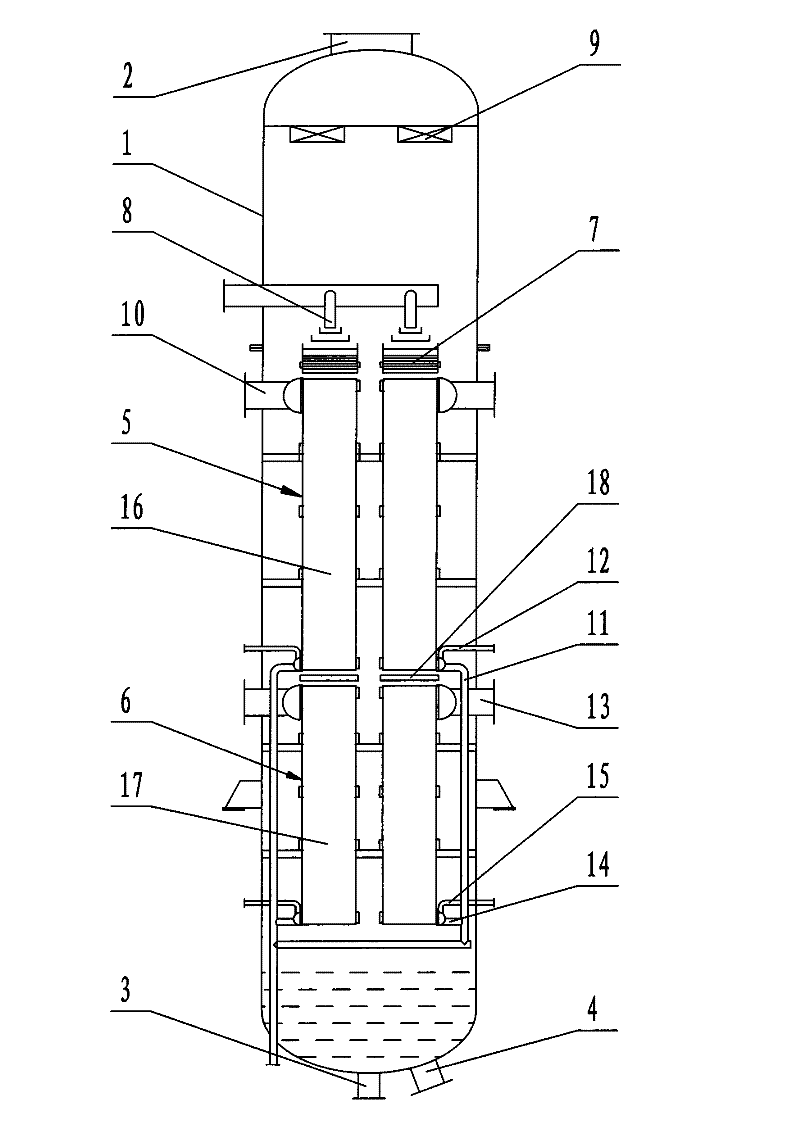

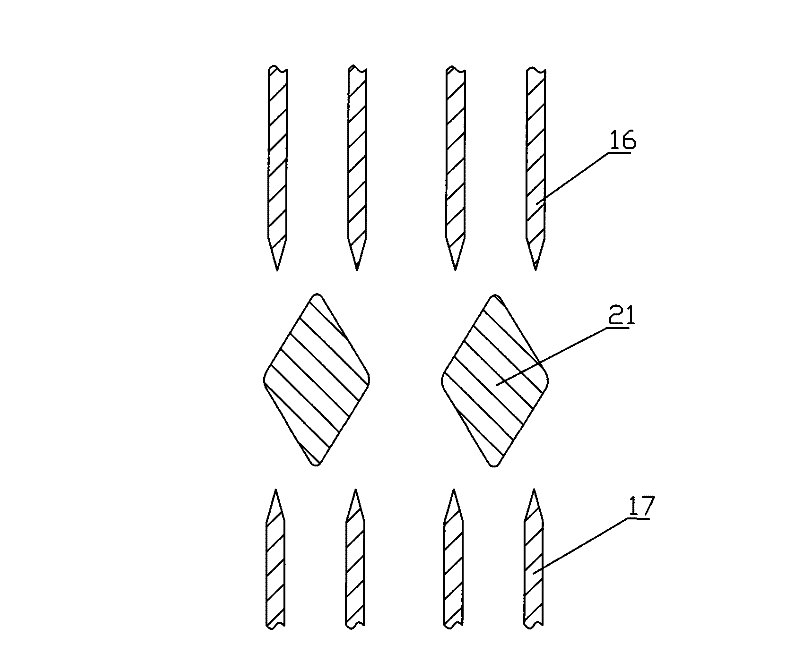

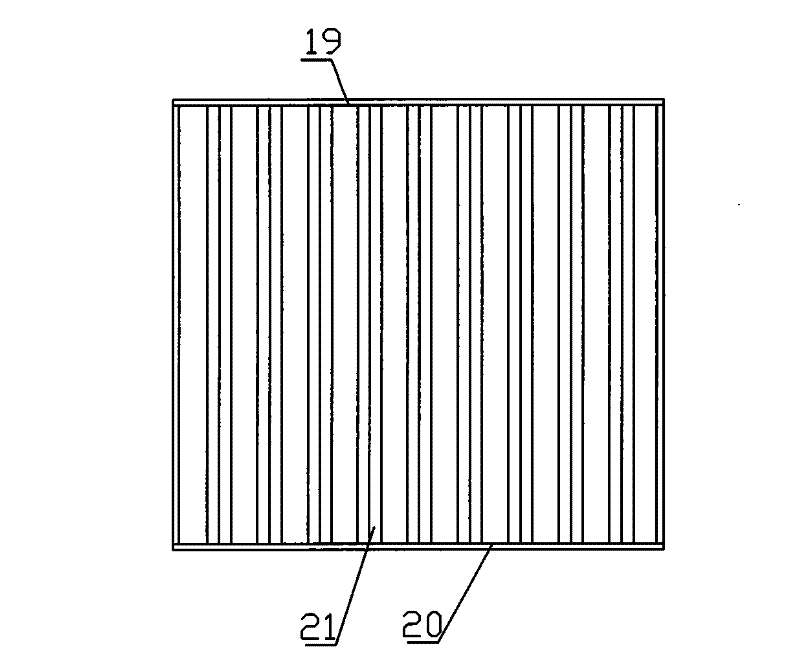

Plate-type falling film evaporator

The invention discloses a plate-type falling film evaporator which can timely discharge all the non-condensable gases, reasonably uses heat quantity and features uniform filming. The plate-type falling film evaporator comprises a shell, a vapor outlet is arranged at top of the shell, a solution outlet and circular solution outlet are arranged at bottom of the shell, the shell is internally provided with an upper heater and a lower heater, an upper layer filming device is arranged above the upper heater, the outlet of a liquid inlet tube is arranged above the upper layer filming device, a demister is arranged below the vapor outlet, the vapor inlets of the heaters are arranged at the upper ends of the heaters, a condensed water outlet is arranged at the lower ends of the heaters, and the condensed water outlet is also communicated with a non-condensable gas outlet; the length ratio of an upper heating plate composing the upper heater and a lower heating plate composing the lower heateris 5.5-6.0:4.5-4.0. The invention is applicable to places of solution evaporation.

Owner:ZHANGHUAJI SUZHOU HEAVY EQUIP CO LTD

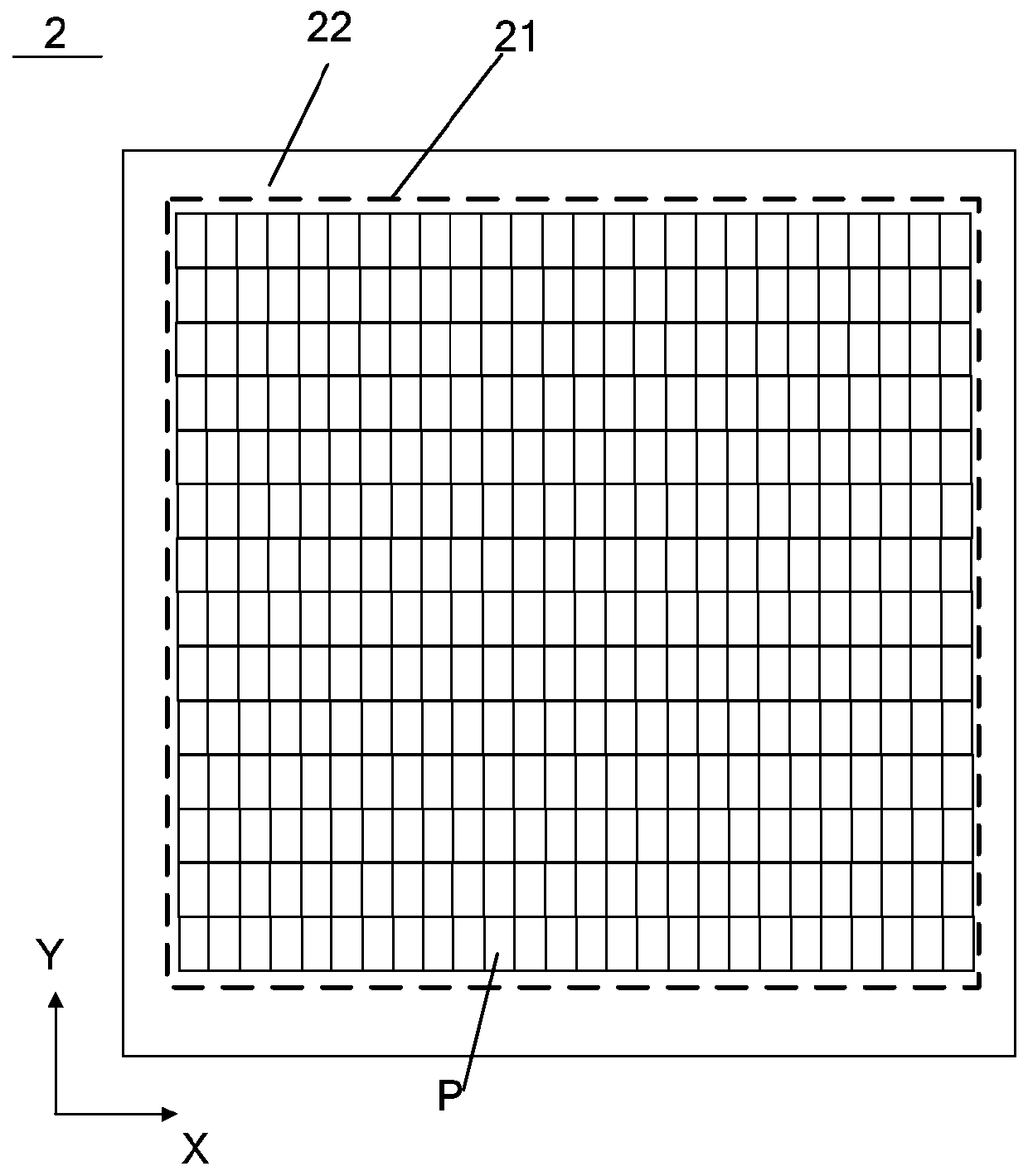

Mask plate, evaporation plating device and method, and design method of evaporation plating opening of mask plate

ActiveCN110066975AImprove alignment accuracyGuaranteed positionVacuum evaporation coatingSputtering coatingEvaporationEngineering

The invention provides a mask plate, an evaporation plating device and method, and a design method of an evaporation plating opening of the mask plate and relates to the technical field of display. The alignment accuracy between a substrate to be subjected to evaporation plating and the mask plate can be improved in the evaporation plating process. The mask plate is provided with a plurality of evaporation plating openings and at least one first detection opening. The size of the first detection opening is less than that of each evaporation plating opening. The first detection opening is arranged close to the at least one evaporation plating opening.

Owner:BOE TECH GRP CO LTD +1

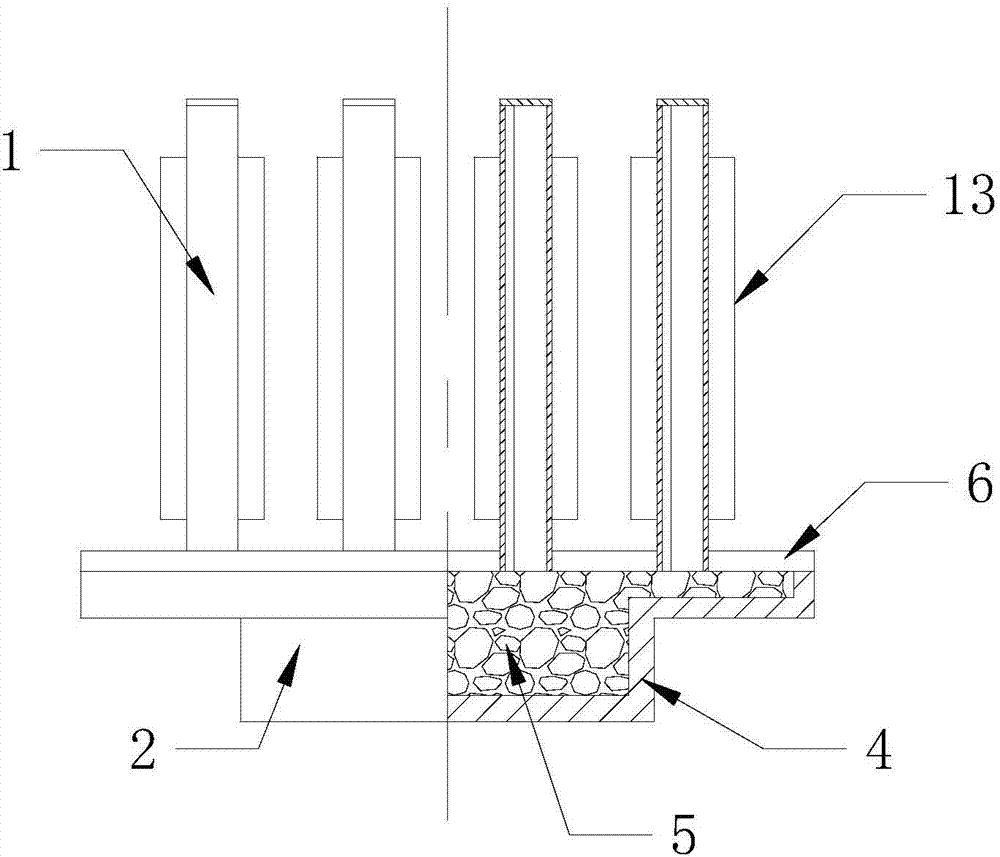

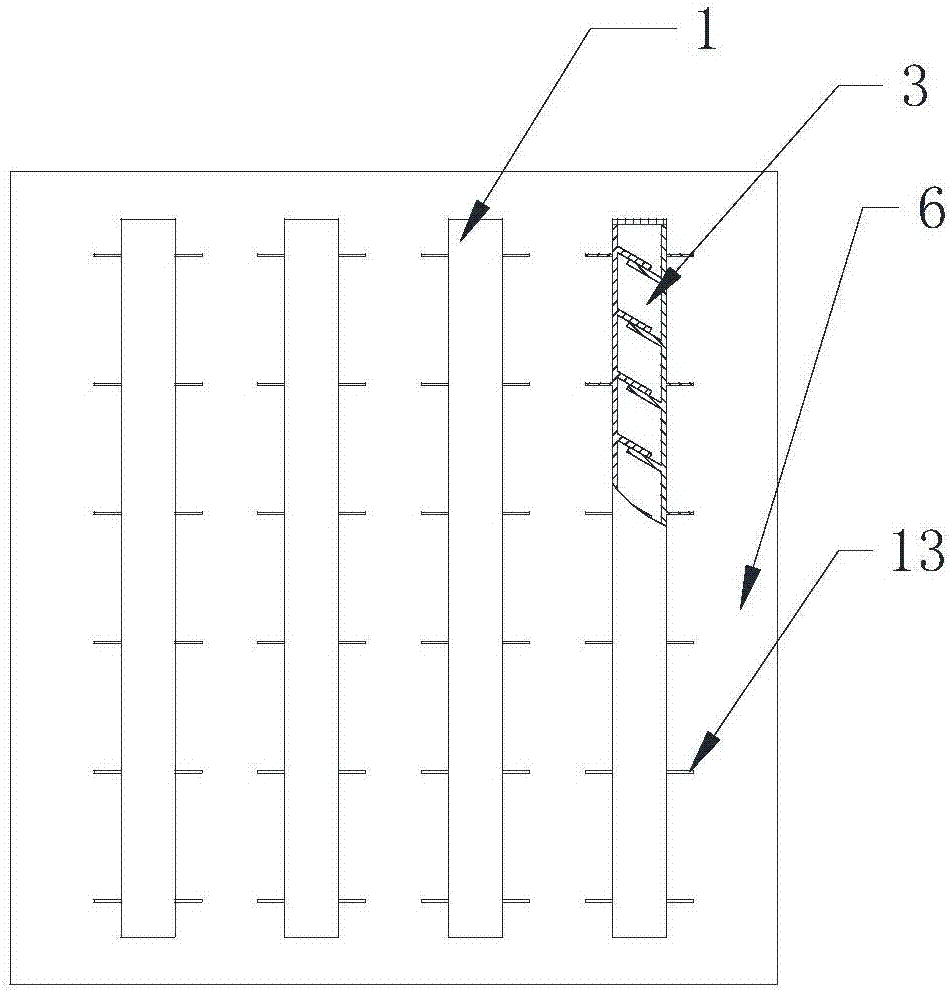

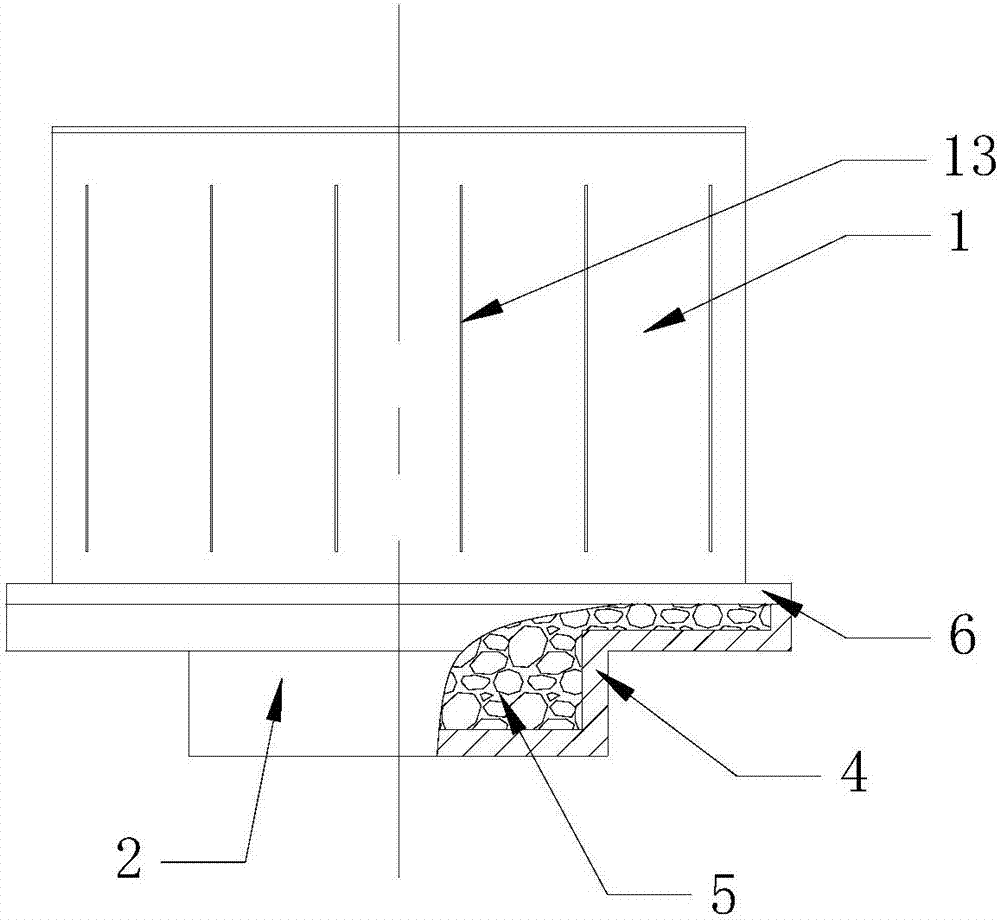

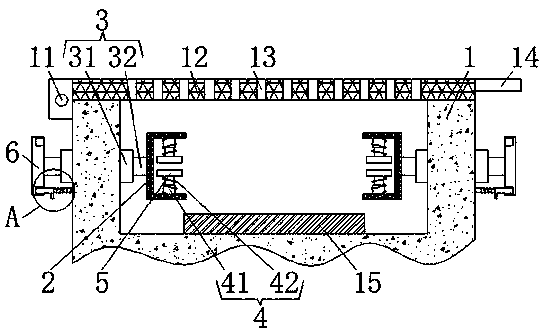

A hot-end variable cross-section multi-pulse cold-end heat pipe radiator

ActiveCN106885485BIncrease the installation locationGuaranteed evaporation effectIndirect heat exchangersPorous mediumEvaporation

The invention provides a heat pipe radiator with a variable-section hot end and multiple pulsation cold ends. The heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends comprises the pulsation cold ends and the hot end. The heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends is characterized in that each pulsation cold end is a heat dissipating plate internally provided with multiple pulsation channels, the hot end is a hollow cavity, the cavity is filled with a working medium and a capillary liquid absorbing core, an upper cover plate of the hot end hollow cavity is provided with multiple cold end connectors, each cold end connector is provided with one pulsation cold end, and the pulsation channels of the pulsation cold ends communicate with the hollow cavity of the hot end. The heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends is simple in structure, easy to manufacture and capable of being transversely and vertically used, the variable-section structure is adopted, so that the pressure bearing capacity of heat pipes can be improved, especially the heat dissipating area of the cold ends is increased, the two thermal processes of evaporation and condensation adopt a pulsation heat transferring mode and a porous medium heat transferring mode correspondingly, the heat transferring performance and the medium transferring performance are effectively improved, backflow is uniform, the temperature uniformity is good, and the heat pipe radiator with the variable-section hot end and the multiple pulsation cold ends is suitable for industrial manufacturing.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

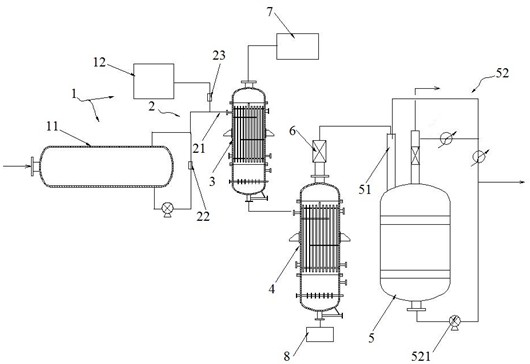

Production process and production device of electronic-grade hydrofluoric acid

ActiveCN112978680AReduce energy consumptionReduce economic costsHydrogen fluorideFluorhydric AcidDemister

The invention discloses a production process and a production device of electronic-grade hydrofluoric acid, and belongs to the technical field of production processes and equipment of electronic-grade chemicals. According to the production device, a quantitative feeding assembly is arranged on a conveying pipeline, and a structural mode that after double falling film evaporation devices are connected in series for use, an air inlet pipe on a condensing tower is connected with a second falling film evaporation device in series for use is combined; the production process comprises the following steps: quantitatively adding materials according to a molar ratio in a liquid conveying process, carrying out a falling film evaporation oxidation reaction in a first falling film evaporation device, carrying out negative-pressure low-temperature evaporation in a second falling film evaporation device, and carrying out condensation reflux in a condensing tower, so the reaction time of arsenic in hydrofluoric acid and an oxidizing agent can be shortened, and corrosion to a storage tank is avoided; meanwhile, hydrofluoric acid can be evaporated and purified in a negative-pressure low-temperature evaporation mode, the number, length and loss of the demister are reduced, and the safety of evaporation operation is improved.

Owner:LIANSHI NEW MATERIAL CORP LTD

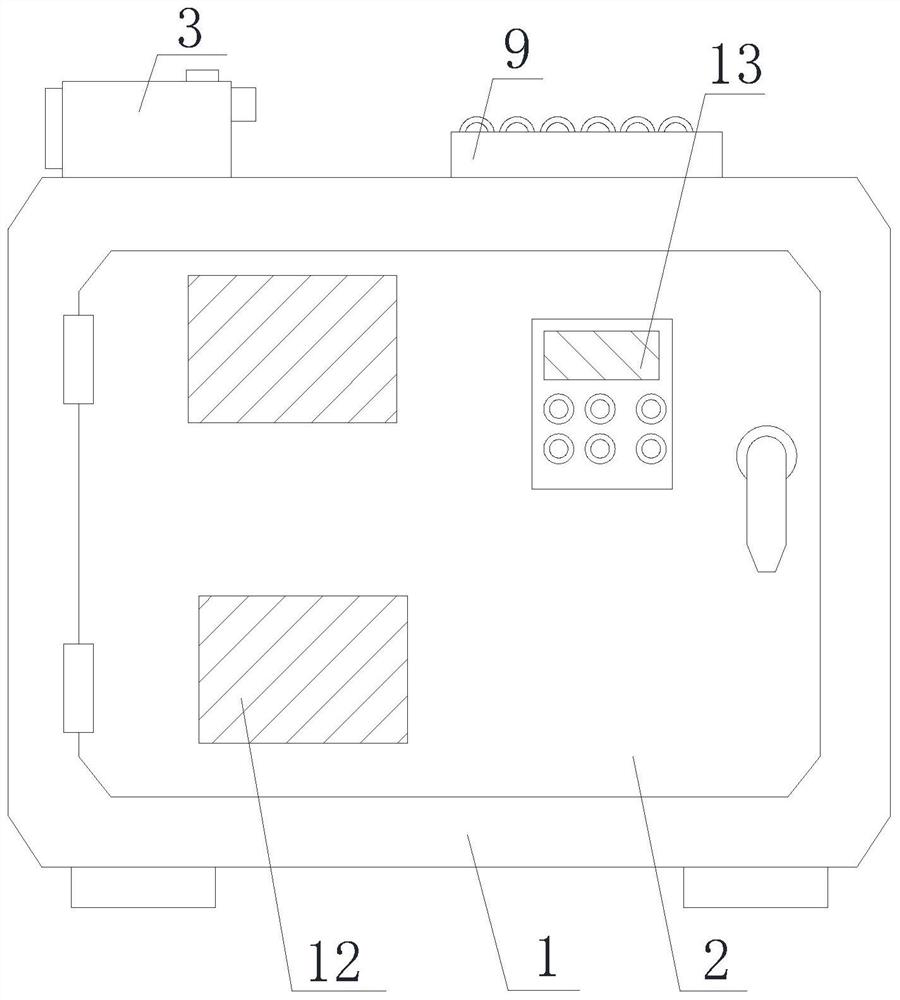

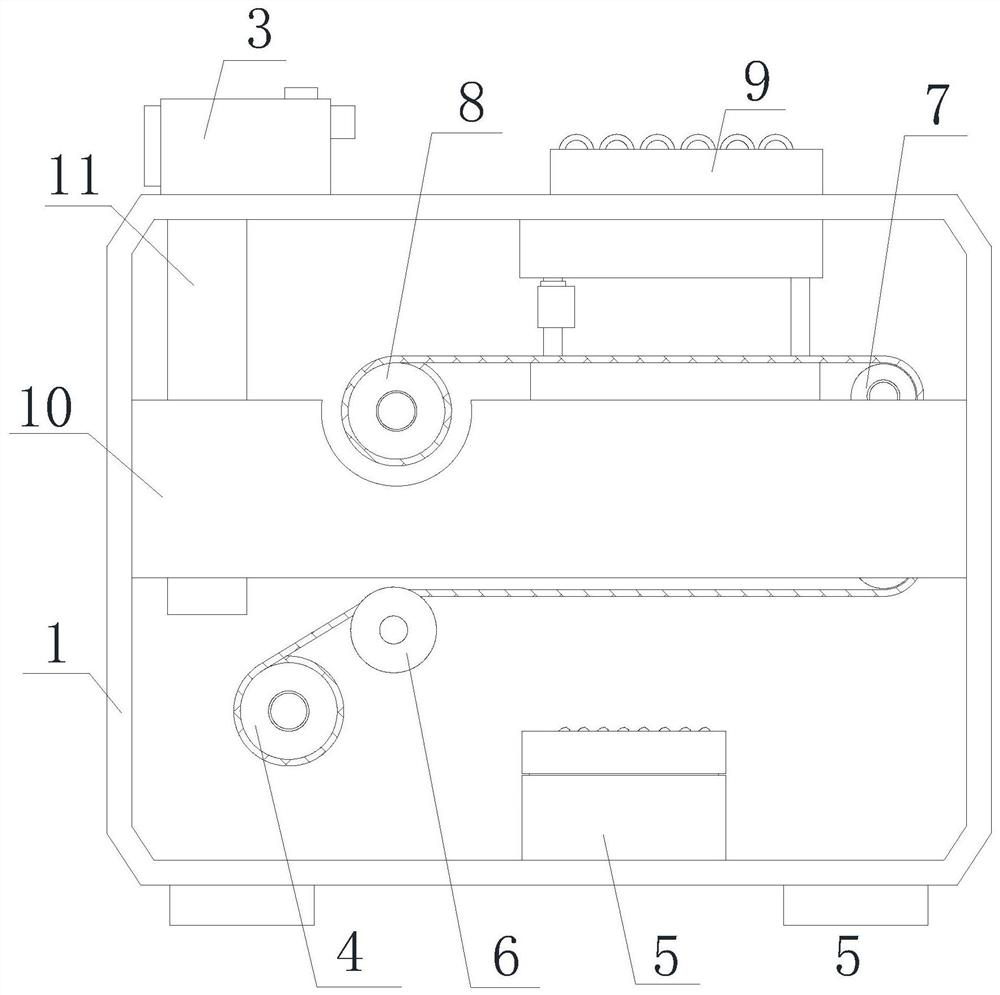

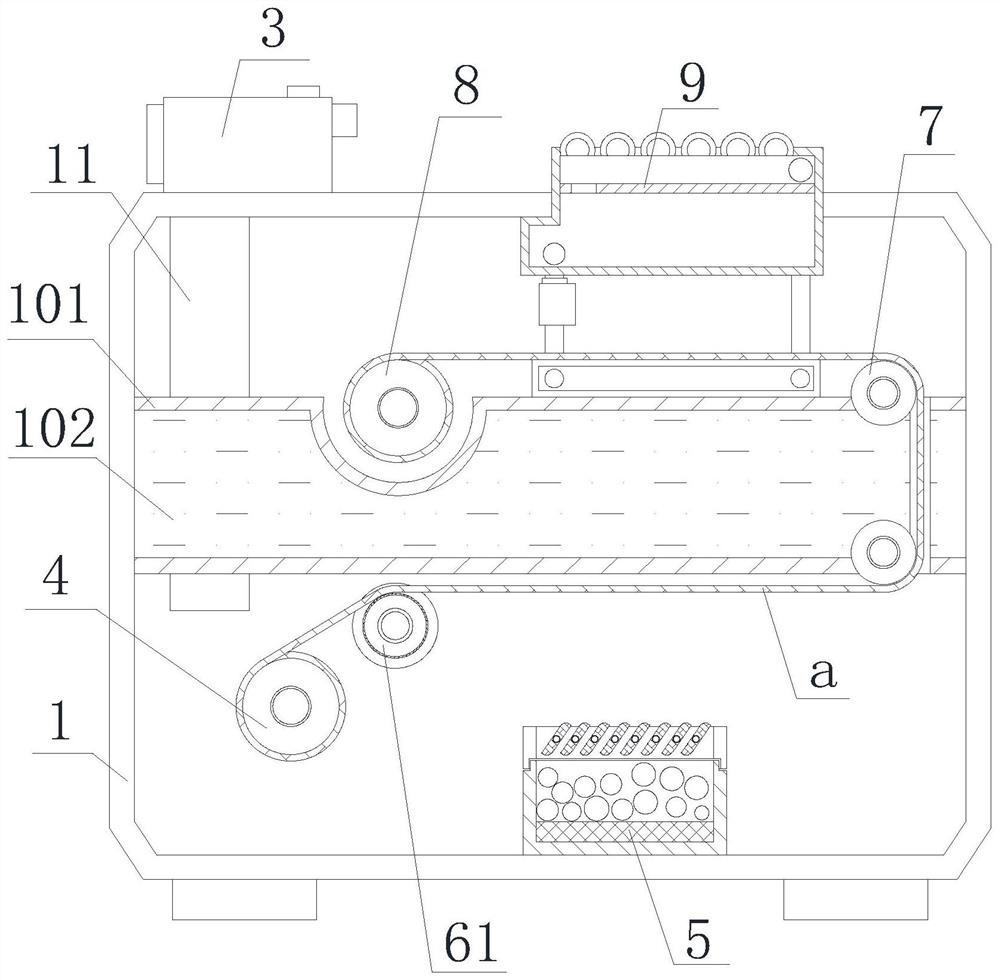

Metal film evaporation equipment for film capacitor processing

ActiveCN110205601BRealize winding and pullingGuaranteed normal processingVacuum evaporation coatingSputtering coatingThin membraneEngineering

The invention relates to capacitor processing equipment, and provides metal thin film evaporation equipment for processing a thin film capacitor. The equipment aims to solve the problems that when a traditional evaporation device is used for evaporation of a thin film, an evaporation source is uniformly heated, the evaporation thickness is not uniform, layering is not uniform, the evaporation efficiency is low and the production efficiency of the thin film capacitor is affected. The equipment comprises an outer box, a plurality of supporting legs arranged at the lower end of the outer box anda box door arranged on the front wall of the outer box, and a vacuumizing machine is arranged at the upper end of the outer box. A vacuumizing pipe is arranged at the input end of the vacuumizing machine, and the lower end of the vacuumizing pipe extends to the lower part of an inner cavity of the outer box. A thin film roll is arranged in the inner cavity of the outer box, and a thin film is wound on the thin film roll. The other end of the thin film sequentially passes through a cleaning assembly, two steering rollers and a cooling assembly and is wound on a film winding roller. The equipment is especially suitable for high-efficiency evaporation processing of the metallized thin film, and has relatively high commercial prospects.

Owner:TONGLING CITY START ELECTRONICS MFG

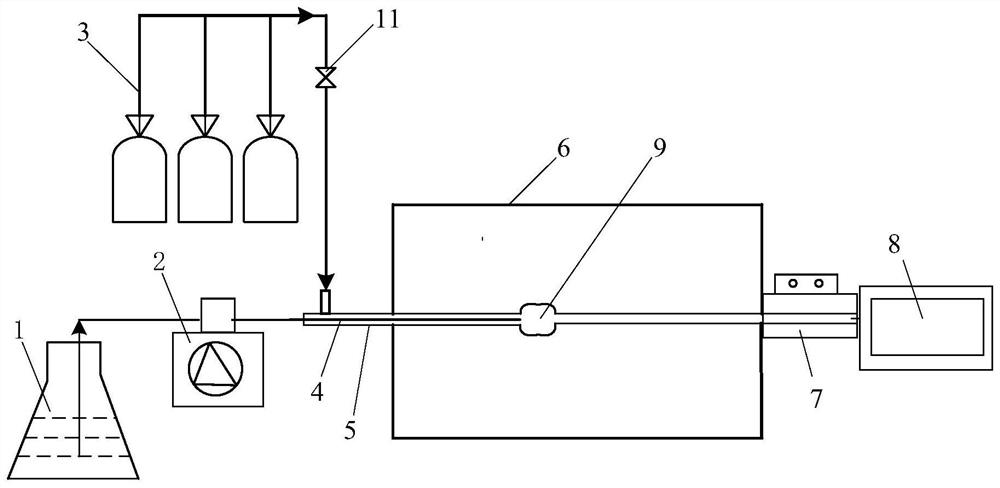

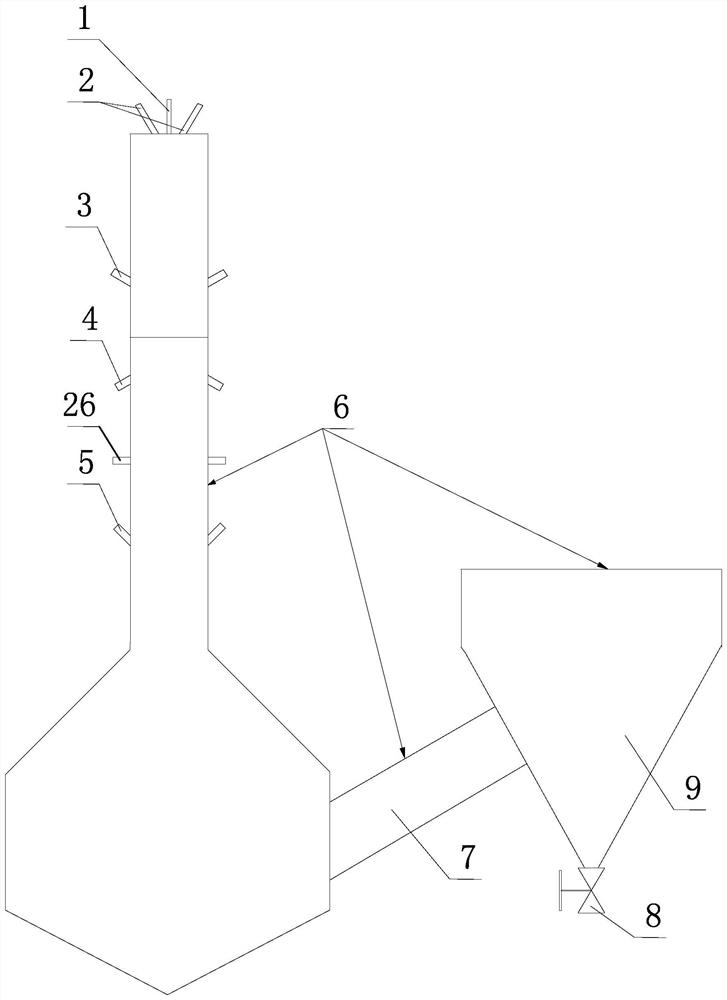

Emulsifying bacteria evaporation system

PendingCN111803976AOvercoming the problem of large particle sizeGuaranteed evaporation effectEvaporator accessoriesEvaporators with vertical tubesThermodynamicsOrganosolv

The invention discloses an emulsifying bacteria evaporation system which comprises an emulsifying section, a bacteria preparation section, an evaporation section, a quantitative transfer filtering section and a storage section which are connected through a pipeline, the emulsifying section comprises a water phase tank and an organic solvent tank, and the two tanks are mixed into an emulsifying tank in proportion; the homogenizing section is a circulating bacteria preparation section and comprises a first bacteria preparation tank and a second bacteria preparation tank which are connected in parallel, the homogenizing section further comprises a bacteria preparation machine, and a buffer tank and a coil preheating structure are sequentially arranged between the bacteria preparation sectionand the evaporation section; the evaporation section comprises at least two scraper type film evaporators, and the scraper type film evaporators are connected in series and / or in parallel under the action of pipelines and valves. According to the invention, a circulating bacteria preparation mechanism is adopted, the problem that the particle size is increased due to insufficient bacteria preparation is solved, novel evaporation is adopted, buffer preheating is matched, the evaporation effect is ensured, and meanwhile, a plurality of filtering processes are performed before finished products so that the product safety is high.

Owner:苏州岑途智能装备科技股份有限公司

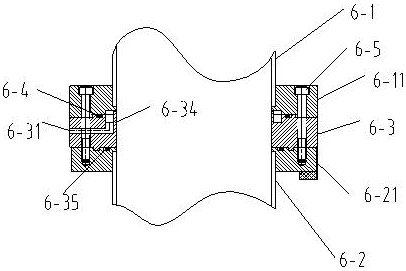

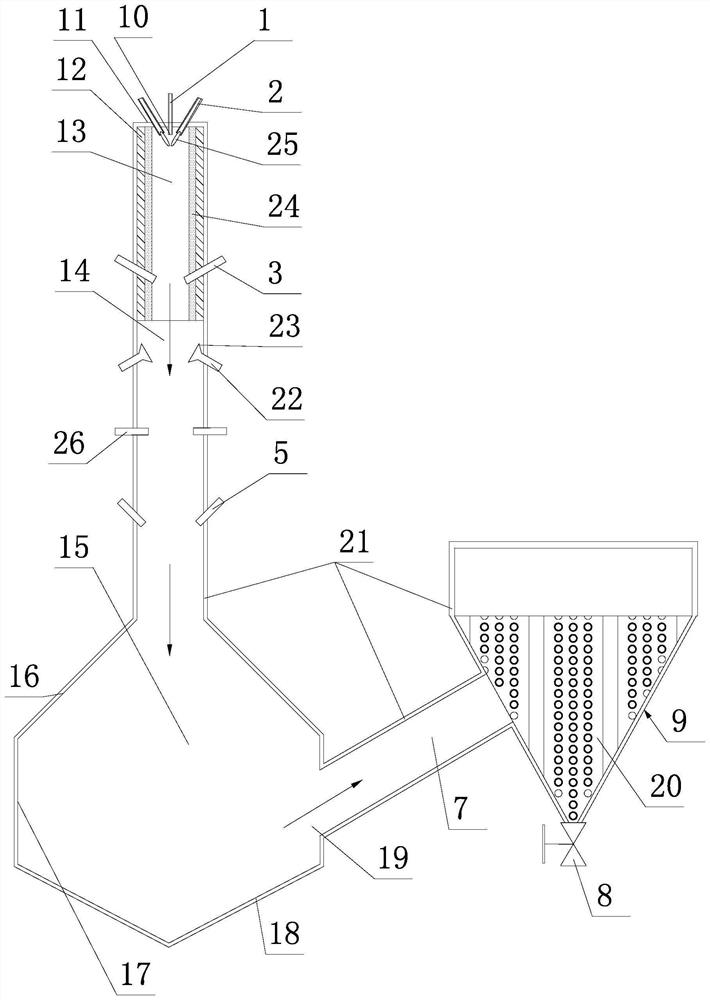

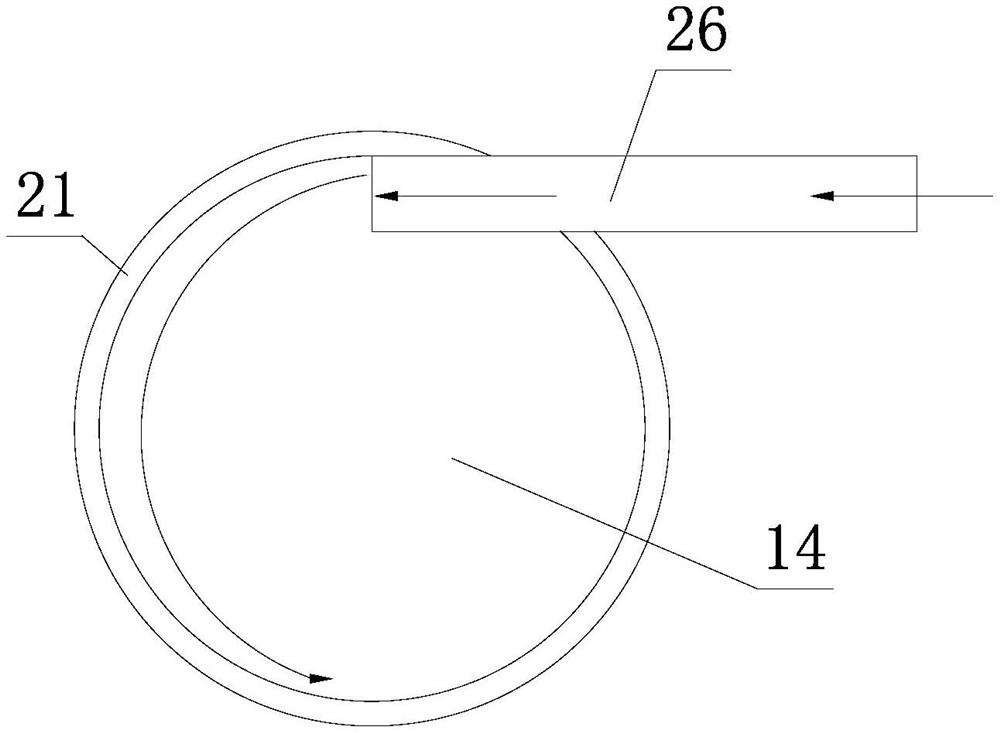

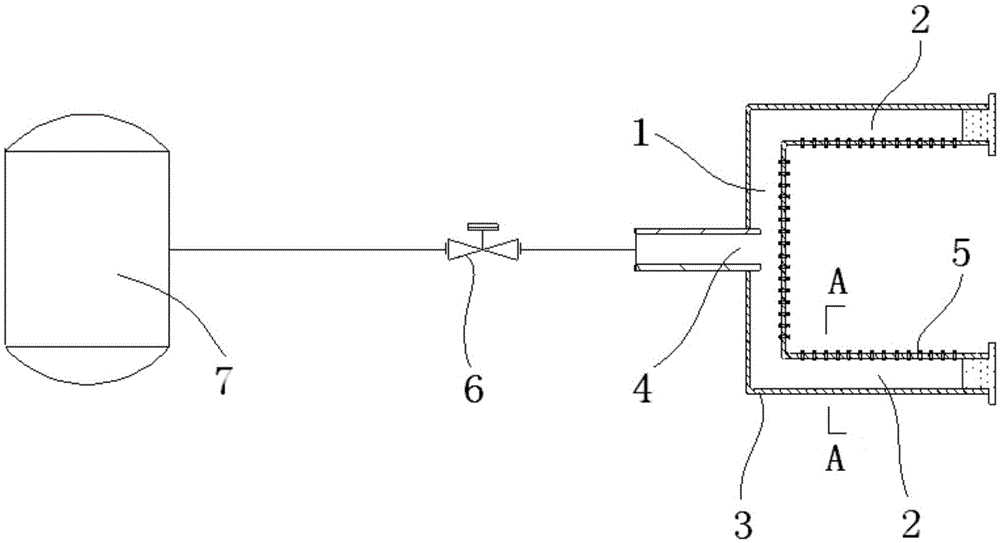

System and method for detecting measurement accuracy of sulfur trioxide and sulfuric acid steam in flue gas

PendingCN113049759ANo condensationGuaranteed stabilityMaterial analysisTemperature controlGas cylinder

The invention provides a system and a method for detecting the measurement accuracy of sulfur trioxide and sulfuric acid steam in flue gas. The system is reasonable in design, simple in structure, convenient in detection and reliable in result. The system comprises a heating furnace, an evaporation tube penetrating through the heating furnace, a capillary tube arranged in the evaporation tube, and a dilute sulphuric acid bottle and a simulated flue gas bottle which are arranged at the input end of the evaporation tube; a circular buffer device is arranged in the middle of the evaporation pipe; the dilute sulphuric acid bottle is connected with the input end of the capillary through the pump; the other end of the capillary extends into the inlet of the circular buffer device through the input end of the evaporation pipe; a flue gas flow control valve is arranged on the simulated flue gas cylinder; the heating furnace adopts a three-section temperature control heating furnace, and is sequentially provided with a first-section temperature control area for preheating dilute sulphuric acid, a second-section temperature control area for completely evaporating the dilute sulphuric acid and a third-section temperature control area for preserving heat of SO3 / H2SO4 steam from an inlet to an outlet; and the circular buffer device is positioned in the second-section temperature control area.

Owner:XIAN THERMAL POWER RES INST CO LTD

Distributor for film evaporators

The invention relates to the field of film evaporation equipment, and discloses a distributor for film evaporators. The distributor comprises a distributing pipe, an evaporator, a feeding pipe and a stirring rotating shaft, the distributing pipe is movably sleeved at the top of an inner cavity of the evaporator, and the side surface of the evaporator is fixedly sleeved with the feeding pipe positioned at the distributing pipe. According to the distributor for film evaporators disclosed in the invention, the distributing pipe is provided with a groove, the through groove, a spring, and a pistonring are adopted for cooperation, so that materials added into the evaporator through the feeding pipe firstly enter the space of the groove, are uniformly mixed and dispersed, and then uniformly flow to the inner wall of the evaporator through the through groove, so that the materials can be quickly heated by utilizing the evaporator, and the evaporation efficiency is improved; meanwhile, the kinetic energy of the materials entering the groove is converted into the elastic potential energy of the spring, so that when the materials are shifted to the inner wall of the evaporator, the reboundrate of the materials is small, rising steam is effectively prevented from driving part of the materials to move upwards, and the evaporation quality of the materials is guaranteed.

Owner:台州恒裕科技有限公司

Rust and residue removing treatment method for inner wall of wire and pipe evaporator pipeline

InactiveCN104764358AGuaranteed evaporation effectGuaranteed blowing effectNon-rotary device cleaningEngineeringNitrogen gas

The invention discloses a rust and residue removing treatment method for the inner wall of a wire and pipe evaporator pipeline. The rust and residue removing treatment method comprises the steps of (1) cutting sponge strips into sponge blocks with the size being 20*15*15mm; (2) soaking the sponge blocks with oil and rust removers for 1-5 seconds; (3) clamping the sponge blocks with tweezers and stuffing 1-3 sponge blocks into the opening of the evaporator pipeline; (4) aligning the head of a nitrogen gun to the opening of the evaporator pipeline and blowing the sponge blocks out of the other end of the evaporator pipeline, wherein the pressure of nitrogen ranges from 0.3 mpa to 2.5 mpa. According to the invention, the sponge blocks are soaked with the oil and rust removers for cleaning the inner wall of the wire and pipe evaporator pipeline, and the blowing effect is guaranteed by controlling the blowing time and the blowing pressure; the whole clearing process is scientific and controllable and residues in the pipeline can be reduced to 0.02 milligram per square meter so that the evaporation effect of a wire and pipe evaporator can be guaranteed.

Owner:HEFEI GREAT WALL REFRIGERATION TECH

Preparation method of nano silicon monoxide powder

ActiveCN114349011AIncrease contact surfaceGuaranteed continuous productionCell electrodesSilicon oxidesNano siliconSilicon monoxide

The invention discloses a preparation method of nano silicon monoxide powder, which comprises the following steps of: continuously feeding silicon powder, spraying silicon dioxide powder, entering working medium gas and preparing the nano silicon monoxide powder in a closed cavity: feeding from a silicon powder feeding pipe of which the upper part is communicated with a silicon powder feeding device; silicon powder at the outlet of the silicon powder feeding pipe is evaporated in the evaporation chamber by crossed plasma arc moments generated by a plurality of plasma guns which are arranged on the circular top plate and are electrically communicated with water to obtain silicon steam; a plurality of silicon dioxide powder injection pipes of the reaction chamber inject silicon dioxide powder, working medium gas in a working medium gas inlet pipe enters the reaction chamber and can drive powder to rotate, and silicon dioxide powder and silicon powder formed by cooled silicon steam are cooled, react with each other and then are conveyed to a condensation chamber at the lower part to be further condensed and reacted; the nanometer silicon monoxide powder is formed. The method is high in production efficiency, and the prepared silicon monoxide powder is reasonable in particle size distribution, high in sphericity degree and good in dispersity.

Owner:JIANGSU BOQIAN NEW MATERIALS

Sludge reduction device

InactiveCN109626790AReduce processing costsAchieve the effect of moistureSludge treatment by de-watering/drying/thickeningWaste processingSludge

The invention relates to the technical field of solid waste processing devices, and relates to a sludge reduction device which comprises a shell, a feed port in the upper side of the shell, and a discharge port in the lower side of the shell. A conveying belt is arranged at the position, located on the lower side of the feed port, in the shell. The conveying belt comprises a plurality of hollow pipes and hinges which are alternately arranged in parallel. Thermal medium boxes are arranged on the inner wall of the shell. The two thermal medium boxes are provided with a first inlet pipe and a first outlet pipe respectively. Rails are arranged on the side walls of the thermal medium boxes. The hollow pipes are arranged on the rails. The thermal medium boxes are provided with driving assembliesfor driving the hollow pipes to move. The top wall of the shell is provided with a suction structure. The sludge reduction device has the advantages that a thermal medium is introduced into the thermal medium boxes through the first inlet pipe, heat is transmitted between the hollow pipes and the sludge when the hollow pipes convey the sludge, and the effect of evaporating sludge water is achieved; by means of the device, heating and dewatering can be conducted on the sludge through a low-grade heat source, and the sludge reduction processing cost is reduced.

Owner:ZHEJIANG JINMO ENVIRONMENT TECH CO LTD

Air Conditioning Condensate Utilization Device

InactiveCN103542467BMeet thermal requirementsGuaranteed evaporation effectLighting and heating apparatusAir conditioning systemsCooling effectEvaporation

The invention provides an air-conditioning condensate water utilization device for cooling of an electronic control system of an outdoor unit. The device comprises an electric control box, a condensate water compensation container, a cooling unit and a water evaporation unit. Air conditioning condensate water flows from a water outlet pipe of a water collecting disc on the lower portion of an evaporator to a condensate water compensation container and then flows into the cooling unit after buffering and compensation, heat in the electric control box is taken away by a heating element of the cooling unit, and the condensate water flows to the water evaporation unit finally to be evaporated on the surface of an evaporation core. According to the device, the cooling capacity of an air conditioning is used, so that energy is saved; the condensate water is evaporated instead of being discharged, so that adverse effects are eliminated; self-driving of condensate water supply is achieved through the suction action of a capillary core of the cooling unit and the evaporation action of the water evaporation unit; the device has the advantages of being good in cooling effect, long in service life, low in maintenance cost, capable of achieving energy saving and emission reduction of the air conditioning and the like.

Owner:QINGDAO UNIV

Sludge reducing device

ActiveCN109942170AReduce processing costsAchieve the effect of moistureSludge treatment by de-watering/drying/thickeningSludgeLower grade

The invention relates to the technical field of solid-waste treatment equipment, and relates to a sludge reducing device. The sludge reducing device comprises a shell, a feeding port formed in the upper side of the shell and a discharging port formed in the lower side of the shell. A conveying belt is arranged at the position, located on the lower side of the feeding port, in the shell and comprises a plurality of hollow pipes and hinges which are arranged in parallel at intervals, thermal medium boxes are arranged on the inner wall of the shell, and a first inlet pipe and a first outlet pipeare mounted on the two thermal medium boxes respectively. Rails are arranged on the side wall of the thermal medium boxes, the hollow pipes are arranged on the rails, driving assemblies for driving the hollow pipes to move are arranged on the thermal medium boxes, and an air extracting structure is arranged on the top wall of the shell. The sludge reducing device has the advantages that a thermalmedium is introduced into the thermal medium boxes through the first inlet pipe, the hollow pipes carry out indirect heat transfer with sludge while conveying the sludge, the function of evaporating sludge moisture is achieved, thermal dehydration can be carried out on the sludge through a low-grade heat source, and the treatment of sludge reducing is reduced.

Owner:ZHEJIANG JINMO ENVIRONMENT TECH CO LTD

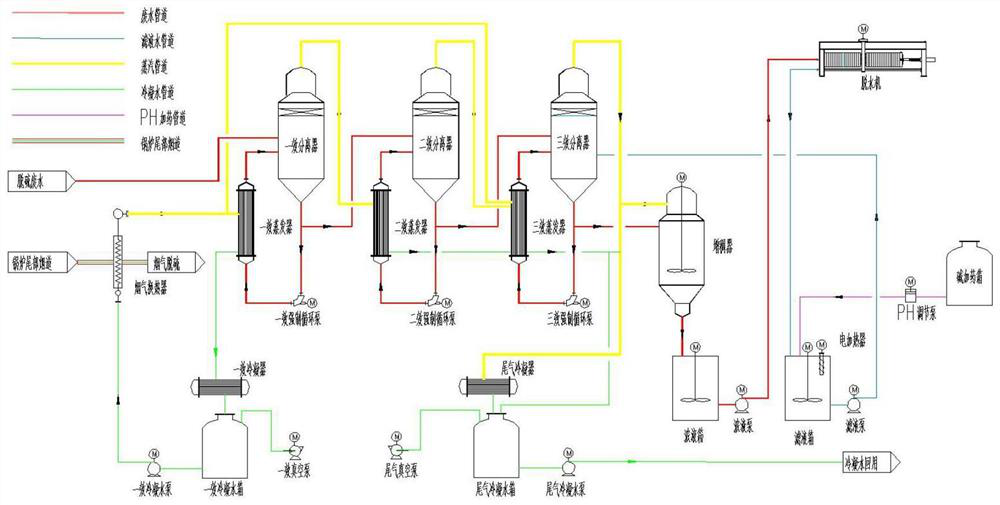

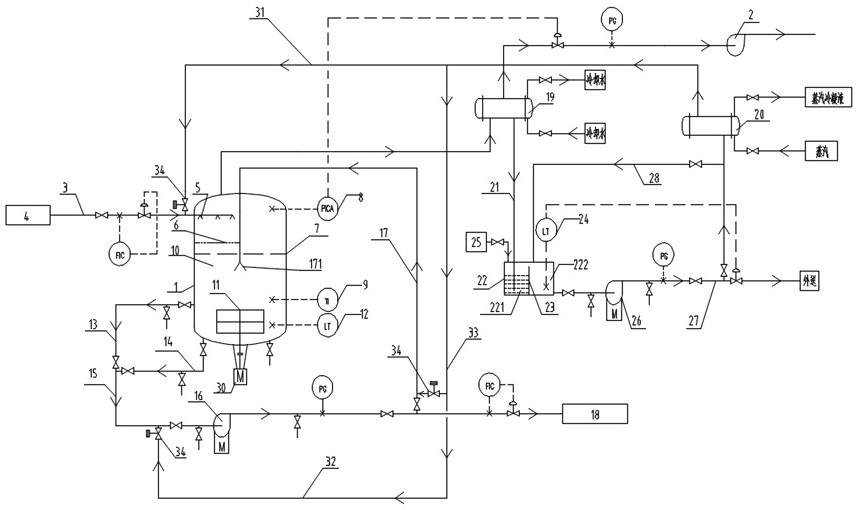

Low-temperature flash evaporation, concentration and crystallization integrated and zero-discharge process for treating desulfurization wastewater through concentrated liquid reflux

PendingCN114604924AImprove corrosion resistanceLower pH valueWaste water treatment from gaseous effluentsWater/sewage treatment by neutralisationFlue gasWastewater

The invention discloses a zero-discharge process for treating desulfurization wastewater by integrating low-temperature flash evaporation, concentration and crystallization and concentrated liquid reflux, which comprises a flue gas heat exchange system, a low-temperature multi-effect evaporation system, a condensate water system, a solid-liquid separation system, a filtrate reflux and electric heating system and a PH (potential of hydrogen) regulating system, the flue gas heat exchange system, the low-temperature multi-effect evaporation system, the solid-liquid separation system and the filtrate backflow and electric heating system are sequentially connected, the flue gas heat exchange system and the condensate water system are connected with the low-temperature multi-effect evaporation system, and the filtrate backflow and electric heating system is connected with the low-temperature multi-effect evaporation system. According to the invention, a low-temperature flash evaporation, concentration and crystallization integrated and concentrated liquid reflux process is adopted, and a traditional high-temperature flue gas drying process is cancelled, so that not only is the disadvantage of insufficient two-effect and three-effect evaporation capacity of a low-temperature multi-effect flash evaporation system overcome, but also the problems of high equipment investment cost and low energy consumption caused by high-temperature flue gas drying of concentrated water are solved. The operation and maintenance cost is high; and crystallized salt is disposed.

Owner:浙江晧月水务科技有限公司

Preparation method of an insect-proof and mildew-proof limestone coating

ActiveCN111217584BIncrease alkalinityImprove antibacterial propertiesCoatingsCelluloseDefoaming Agents

The invention discloses a method for preparing an insect-proof and mildew-proof limestone coating, which comprises a limestone base sand and an overcoat varnish. The limestone base sand is composed of water, cellulose ether, a pH regulator, rutile type titanium dioxide, fillers, Inorganic high molecular silicate, styrene-acrylic silicon high polymer emulsion, defoamer and anti-insect factor; finish varnish is composed of fluorine-modified high polymer emulsion, film-forming agent, defoamer, water, propylene glycol, anti-insect factor It is composed of adhesion aid and thickener; after preparation, the base sand layer is formed by first applying limestone base sand on the wall surface, and then coating the finish varnish on the base sand layer to form a limestone composite coating. It is not easy to breed bacteria, makes it difficult for molluscs to attach, and is environmentally friendly and harmless.

Owner:浙江博星化工涂料有限公司

Anti-medicine strip bonding device and medicine strip processing method

ActiveCN103896694BGuaranteed evaporation effectReach an acceptable levelExplosive working-up apparatusSolventAtmospheric pressure

The invention relates to a device for preventing adhesion of medicinal strips and a method for processing the medicinal strips. The device comprises an air pipe, wherein two side air pipes are formed by the vertical extending of two ends of the air pipe, the air pipe and the two side air pipes form a U-shaped vent pipe, an air inlet is formed on the air pipe, and a plurality of air outlets are formed on the inner side wall of the U-shaped vent pipe. Alternatively, the device comprises an air pipe, wherein side air pipes are formed by the vertical extending of two ends of the air pipe, the air pipe and the side air pipes form a rectangular vent pipe, an air inlet is formed on the air pipe, and a plurality of air outlets are formed on the inner side wall of the rectangular vent pipe. According to the method for processing the medicinal strips, the air pressure at the outlet of each conical blowing nozzle is 0-10 Mpa. With the device provided by the invention, the flow rate of air at the conical nozzle can be adjusted to control the solvent volatilization speed according to the formula of a product, and therefore the adhesion of the medicinal strips can be prevented.

Owner:XIAN MODERN CHEM RES INST

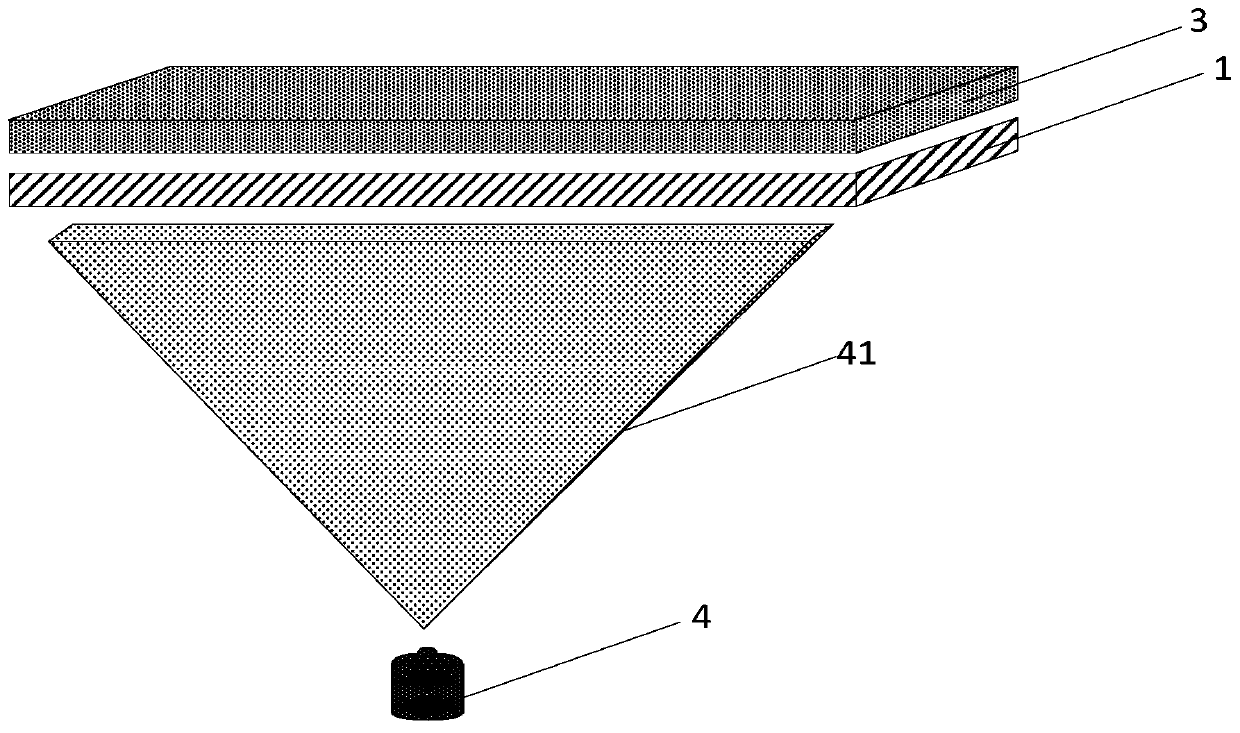

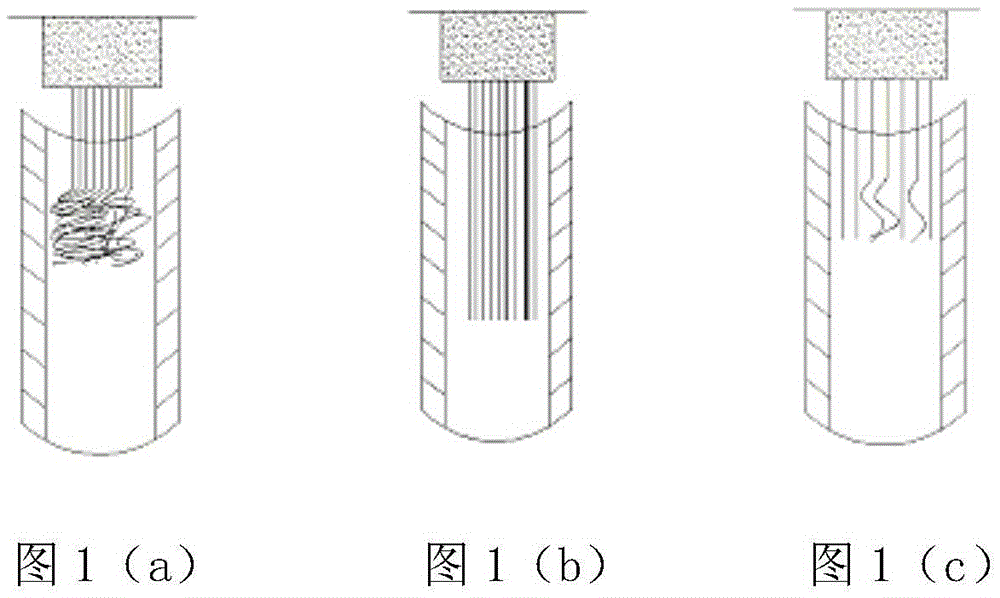

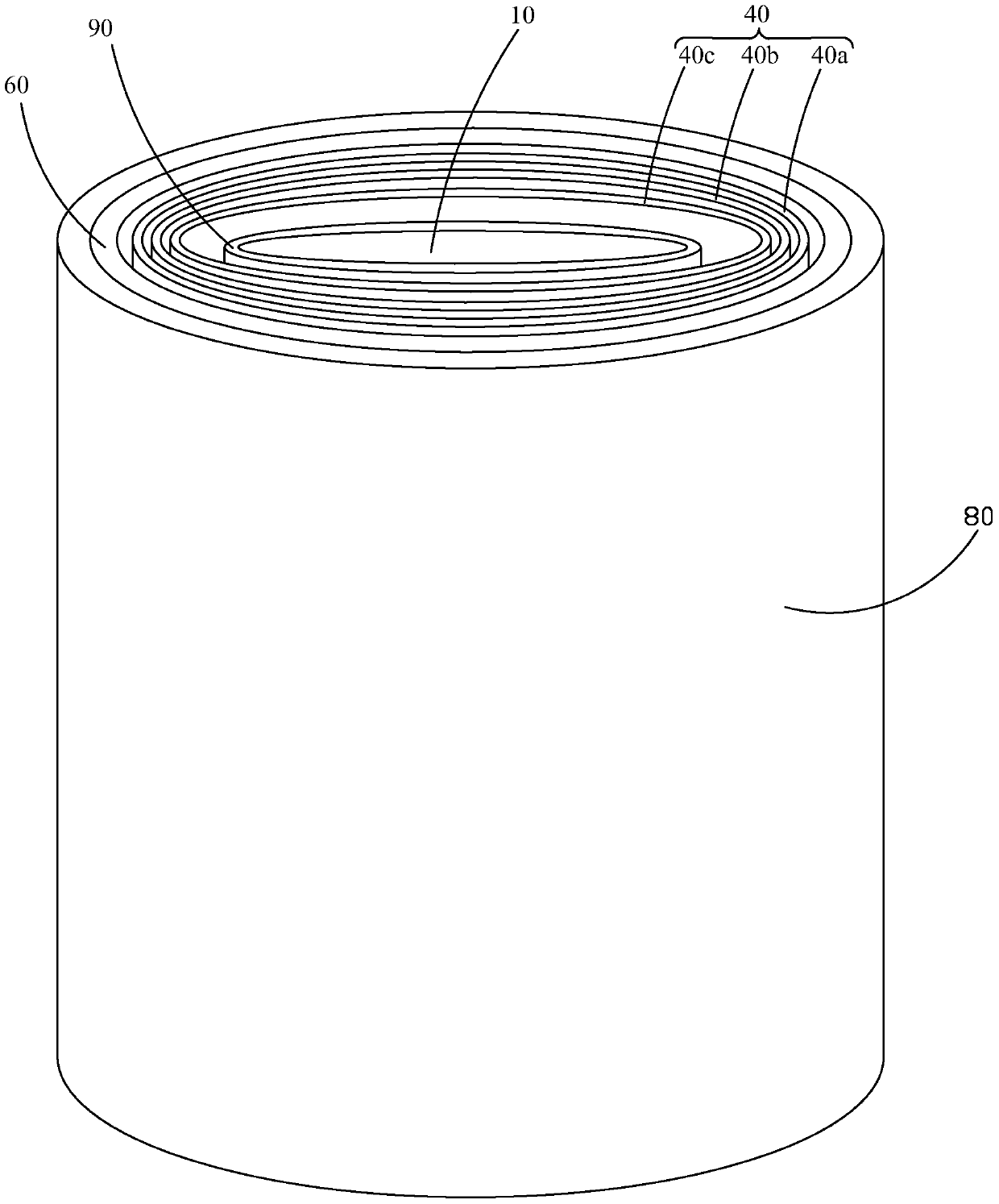

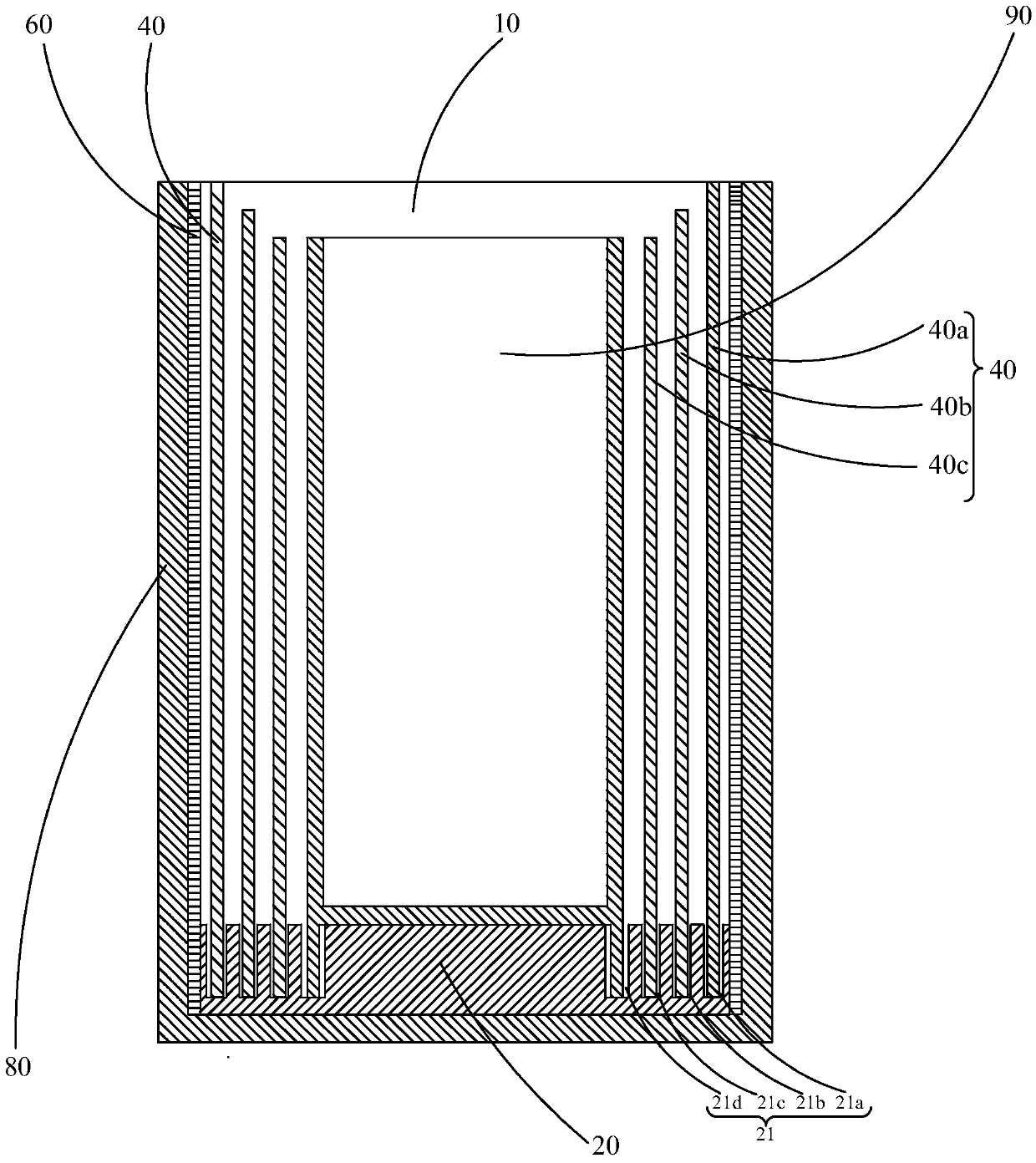

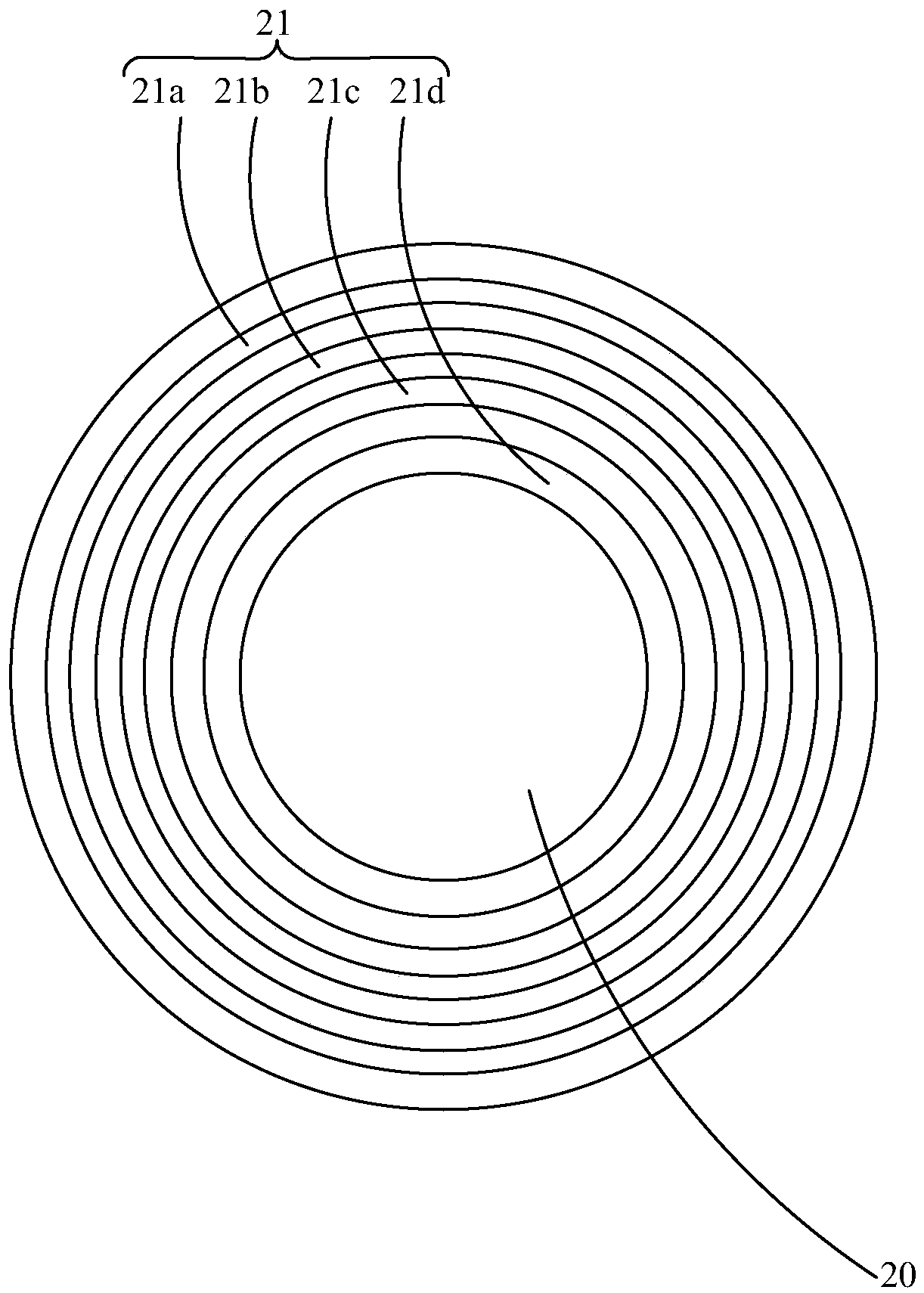

Evaporation source heating device

ActiveCN103966555BImprove thermal conductivityEvenly heatedVacuum evaporation coatingSputtering coatingCrucibleEvaporation

The invention provides an evaporation source heating device, comprising: a base, an outer casing connected to the base, a heating element arranged inside the outer casing, several metal cylinders arranged inside the heating element and installed on the base, and a plurality of metal cylinders arranged on the metal cylinder inside the crucible. In the evaporation source heating device of the present invention, several metal cylinders are arranged between the heating element and the crucible, and the several metal cylinders are installed on the base. When heating, the heat of the heating element is gradually conducted through the several metal cylinders. The heat is conducted to the crucible. Due to the good thermal conductivity of the metal cylinder, the heat distribution on it is uniform, so that the crucible is heated evenly and the evaporation effect is guaranteed.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Plate-type falling film evaporator

The invention discloses a plate-type falling film evaporator which can timely discharge all the non-condensable gases, reasonably use heat quantity and features uniform filming. The plate-type falling film evaporator comprises a shell, a vapor outlet is arranged at top of the shell, a solution outlet and circular solution outlet are arranged at bottom of the shell, the shell is internally provided with an upper heater and a lower heater, an upper layer filming device is arranged above the upper heater, the outlet of a liquid inlet tube is arranged above the upper layer filming device, a demister is arranged below the vapor outlet, the vapor inlets of the heaters are arranged at the upper ends of the heaters, a condensed water outlet is arranged at the lower ends of the heaters, and the condensed water outlet is also communicated with a non-condensable gas outlet; the length ratio of an upper heating plate composing the upper heater and a lower heating plate composing the lower heater is 5.5-6.0:4.5-4.0, and a lower layer film avaporator is disposed between the upper heater and the lower heater. The invention is applicable to places of solution evaporation.

Owner:ZHANGHUAJI SUZHOU HEAVY EQUIP CO LTD

Negative pressure evaporation and step-by-step feeding method of nickel sulfate solution

ActiveCN102557154BMaximize capacity utilizationReduce pouringNickel sulfatesVacuum pumpingEnvironmental resistance

The invention discloses a negative pressure evaporation and step-by-step feeding method of a nickel sulfate solution. The method comprises the following steps: preparing the nickel sulfate solution to be produced; performing vacuum pumping on a negative pressure evaporator; performing continuous heating on the solution in the negative pressure evaporator; performing cooling and crystallization on the concentrated solution; and further performing step-by-step feeding. The method is characterized in that the step-by-step feeding and the vacuum pumping operation are simultaneously performed. Therefore, the volume of the evaporation device can be fully utilized, the number of times of operation can be reduced, and the purpose of improving working efficiency can be further achieved. The method disclosed by the invention has the characteristics of fast evaporation speed, high production efficiency and simple operation, the number of equipment used by the method is small, and the equipment occupies small area, and is environment-friendly and pollution-free.

Owner:广东芳源新材料集团股份有限公司

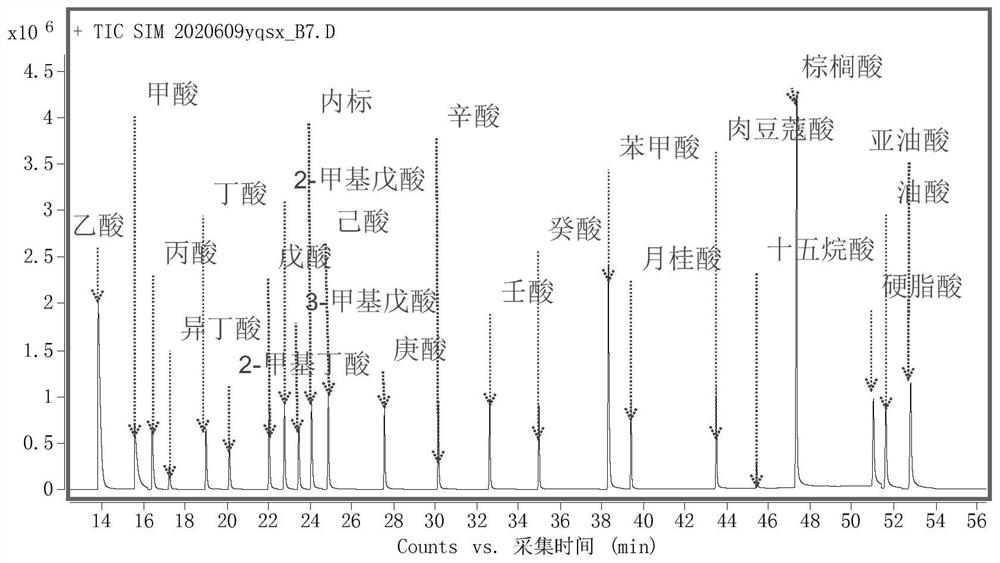

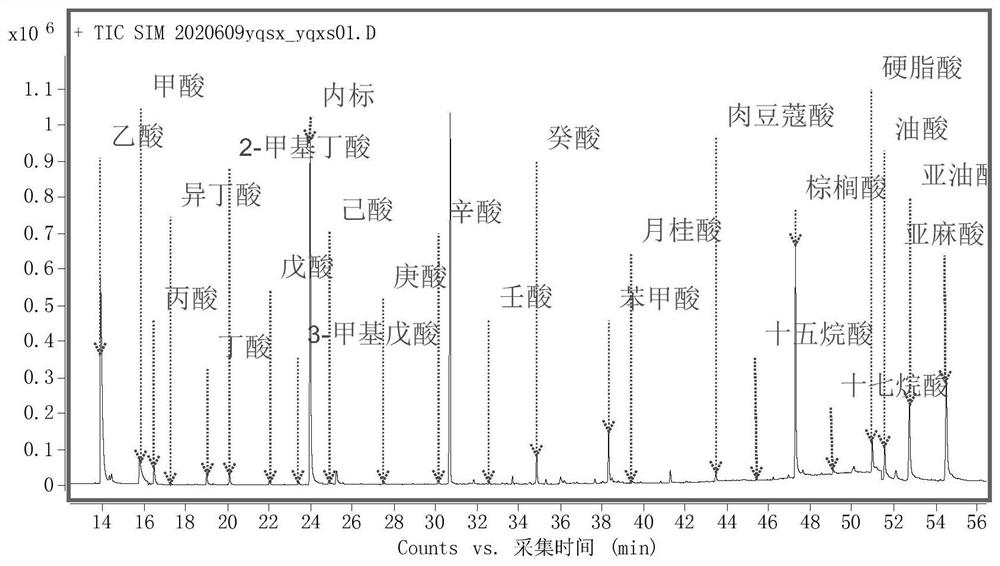

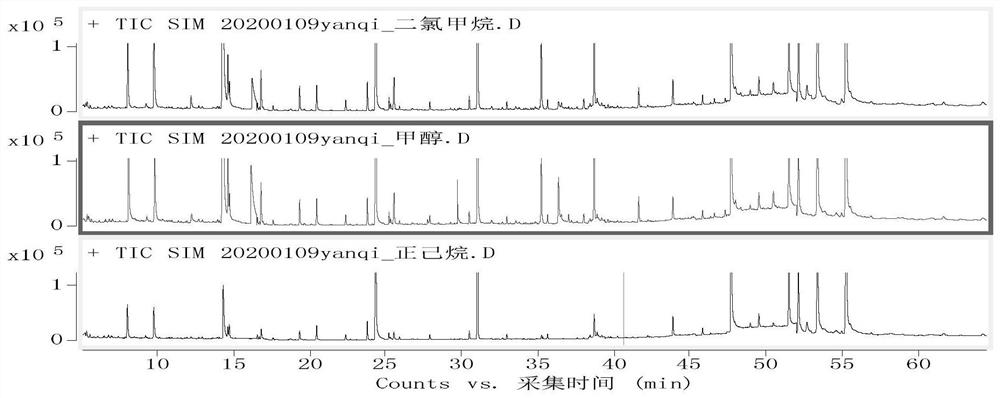

Method for determining volatile and semi-volatile organic acids in cigarette mainstream smoke

PendingCN112881556AIncrease relative volatilityHigh precisionComponent separationBiotechnologyOrganic acid

The invention provides a method for determining volatile and semi-volatile organic acids in cigarette mainstream smoke, and belongs to the technical field of cigarette chemical analysis and detection. According to the method, the content of 25 kinds of volatile and semi-volatile organic acids in mainstream cigarette smoke can be determined simultaneously by GC-MS, internal standard quantitative method, sample pretreatment without derivatization, direct extraction with dichloromethane, GCMS analysis and specific pretreatment process for samples. The precision of the method for detecting the volatile and semi-volatile organic acids in the cigarette mainstream smoke is improved, and the method has the advantages of being rapid, high in operability and convenient to process in batches.

Owner:CHINA TOBACCO SHAANXI IND

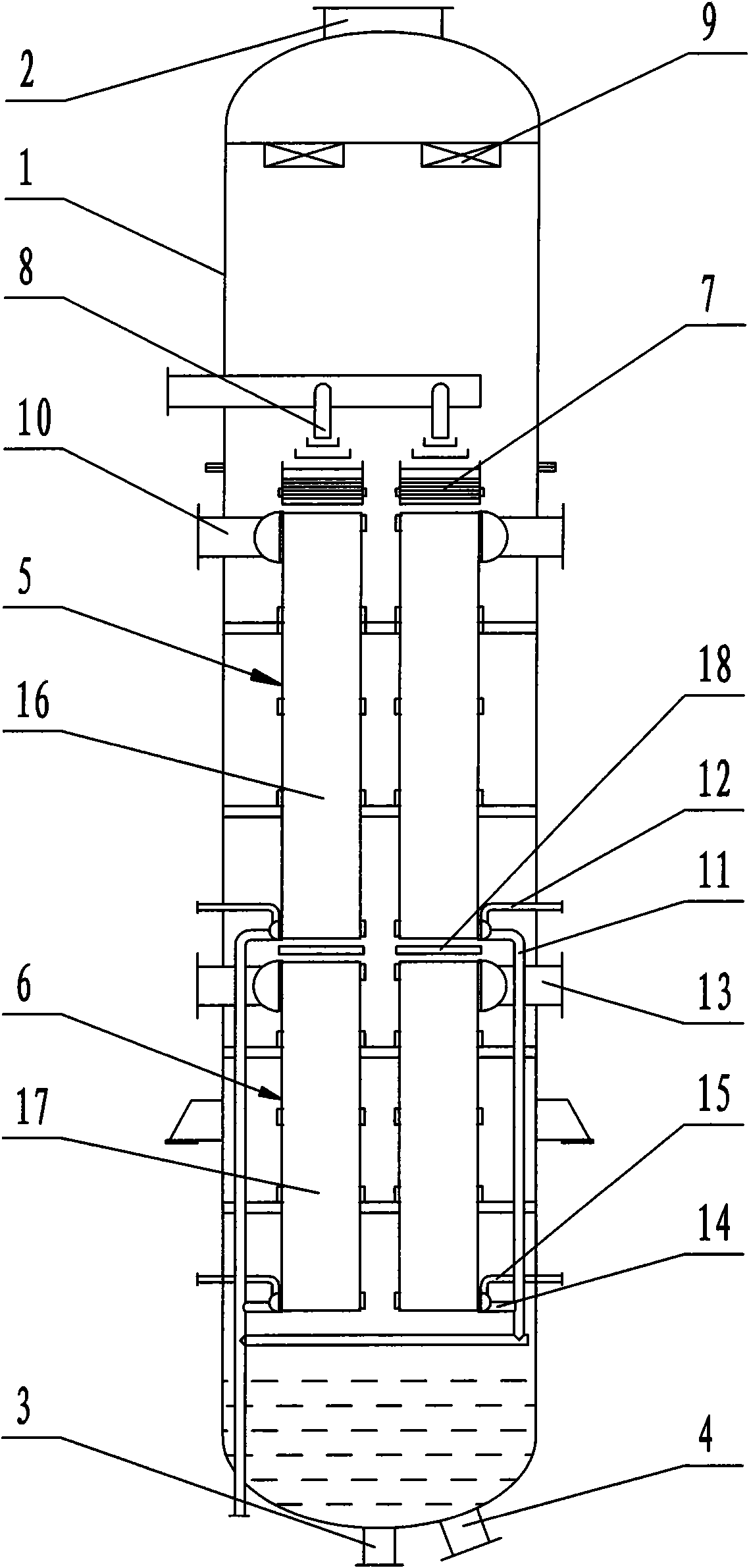

Single-chamber vacuum cooling crystallization system

PendingCN111803996AGuaranteed evaporation effectSmall footprintSolution crystallizationCrystallization by component evaporationLiquid storage tankEngineering

The invention belongs to the technical field of cooling crystallization equipment, and particularly relates to a single-chamber vacuum cooling crystallization system. The system comprises a single-chamber crystallizer, a crystallization feed liquid circulating system, a condensate circulating system and a vacuum pump, a crystallization cavity is formed in the single-chamber crystallizer, a horizontal partition plate is arranged in the crystallization cavity, the liquid level surface of the crystallization cavity is arranged below the horizontal partition plate, the crystallization feed liquidcirculating system comprises a main discharge pipe and a slurry circulating pipeline, and the condensate circulating system comprises a condenser, a heater, a condensation liquid storage tank and a pipeline for connecting the condenser, the heater and the condensation liquid storage tank. The single-chamber vacuum cooling crystallization system can be widely applied to crystallization and purification production of various inorganic and organic chemical products with large solubility curve changes, and has the characteristics of short process flow, small occupied area, low investment and flexible operation.

Owner:HENAN SHENMA NYLON CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com