Preparation method of nano silicon monoxide powder

A technology of silicon oxide and silicon dioxide powder, applied in silicon oxide, electrical components, battery electrodes, etc., can solve the problems of high production cost that can only be at the micron level, at most submicron level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

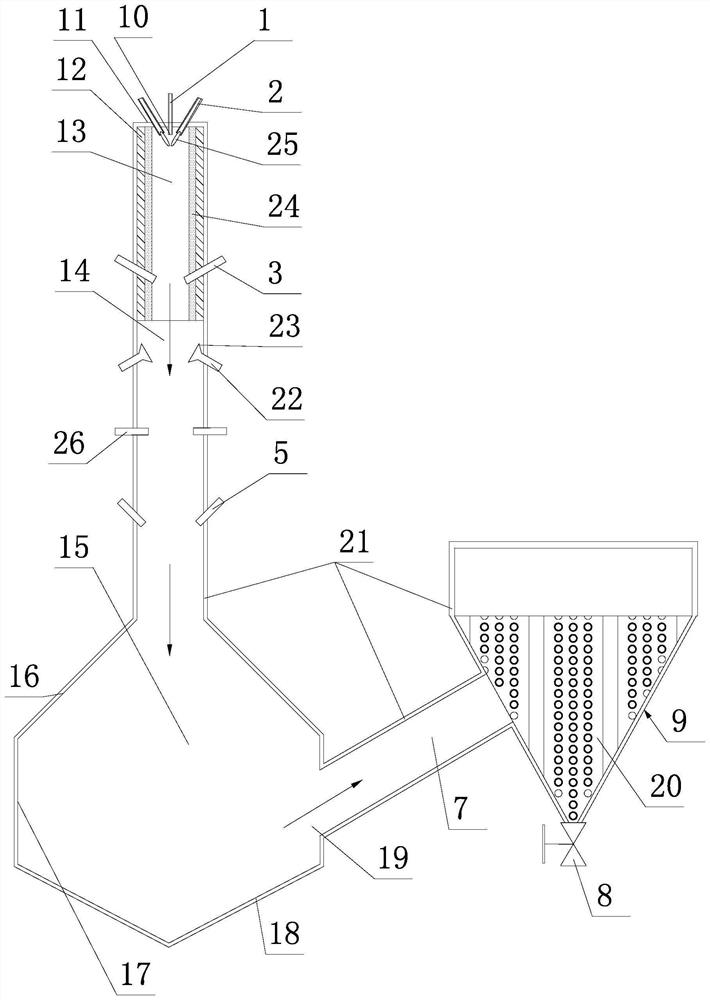

[0031] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. What needs to be declared here is that the descriptions of these specific implementations are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various specific embodiments of the present invention described below may be combined with each other as long as they do not constitute conflicts with each other.

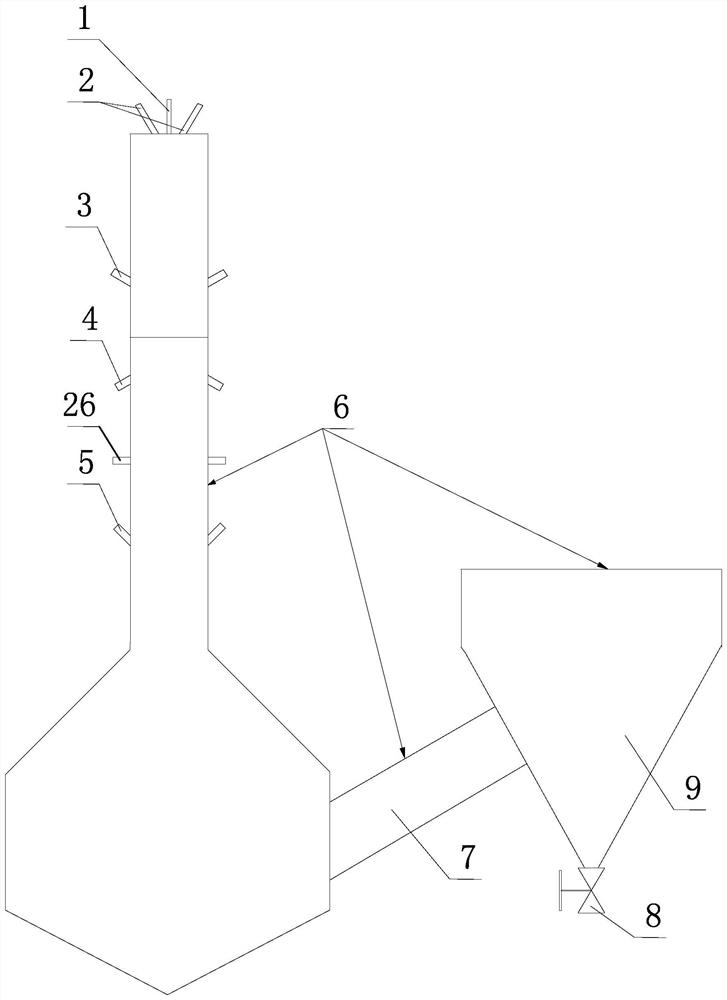

[0032] Such as figure 1 , figure 2 shown.

[0033] A kind of preparation method of nano-silicon oxide powder of the present invention, comprises the following steps,

[0034] The feeding of silicon powder, the injection of silicon dioxide powder, the entry of working fluid gas and the preparation of nano-silicon oxide powder are carried out continuously in the closed chamber 6:

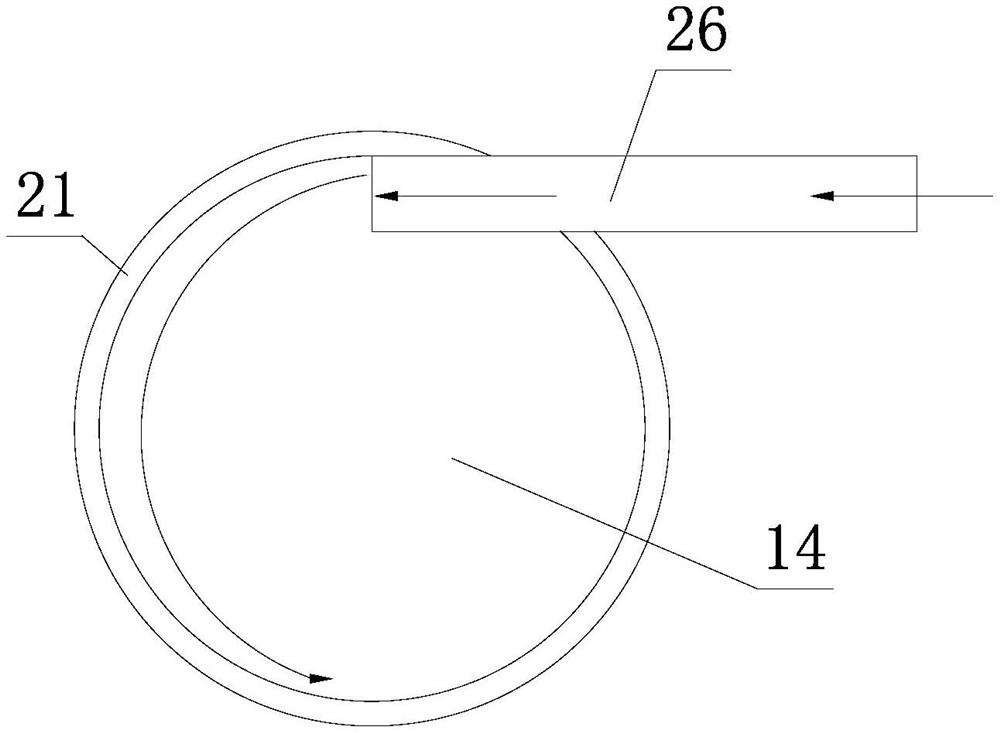

[0035] From the circular top plate 11 center of the cyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com