OLED evaporation mask plate

A mask plate and evaporation technology, which is applied in the field of OLED production, can solve the problems of high production cost, secondary waste, and long time consumption, and achieve the effect of high positioning accuracy and guaranteed evaporation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

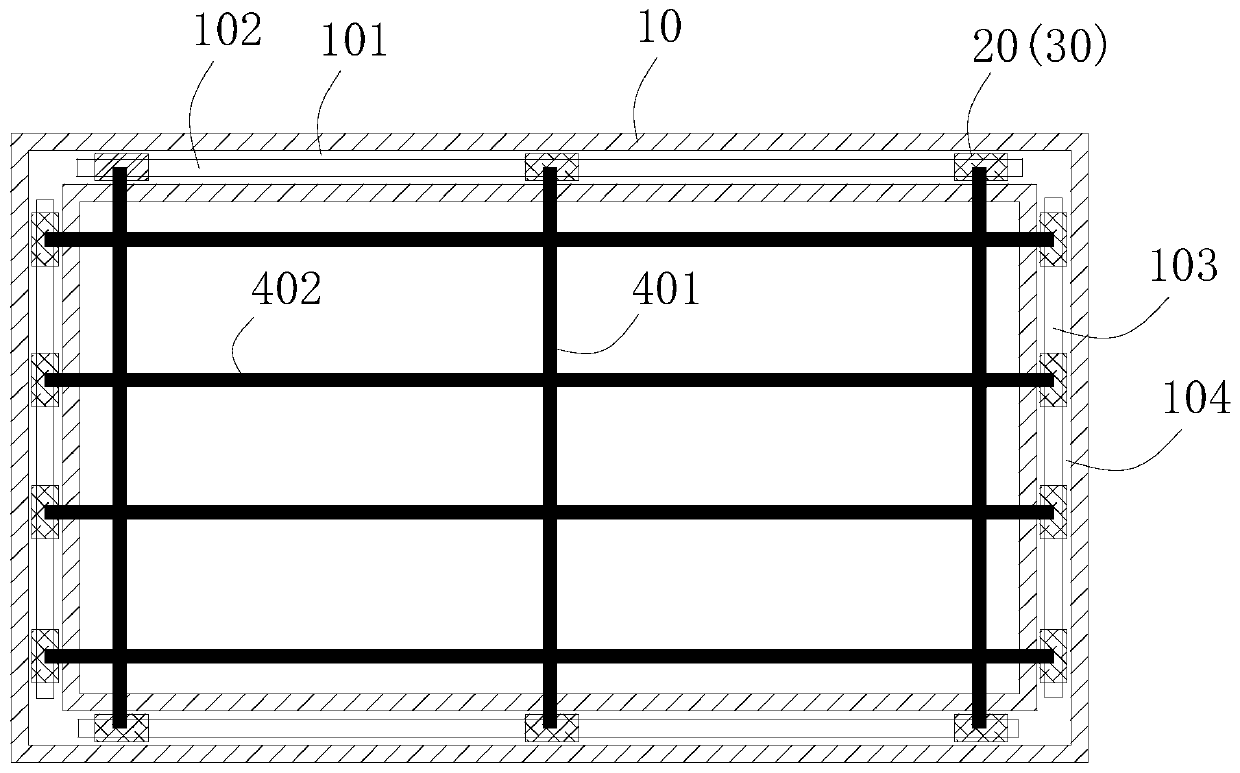

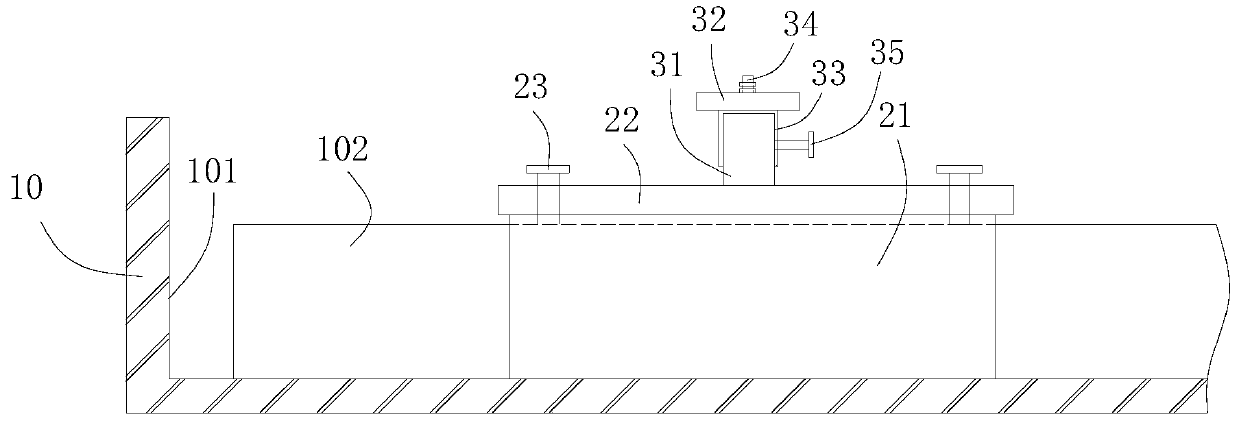

[0028] refer to figure 1 , image 3 and Figure 4 , an OLED evaporation mask, including a metal frame 10 , four horizontal metal sheets 402 and three vertical metal sheets 401 arranged on the metal frame through a positioning device 20 and a fixing device 30 .

[0029] In this embodiment, the metal frame 10 is a rectangular frame, and a rectangular groove 101 with a width of about 10 mm and a depth of about 5 mm is provided in the frame of the two length directions, and a width of about 101 is arranged in the frame of the two width direction. 10 mm rectangular groove 104 with a depth of about 5.1 mm. The outer edges of the rectangular groove 101 and the rectangular groove 104 are provided with main scale marks with an accuracy of 1 mm. Two parallel first transverse guide rails 102 are arranged in the rectangular groove 101 , and two parallel longitudinal first guide rails 103 are arranged in the rectangular groove 104 . The first guide rails 102, 103 are T-shaped, the bott...

Embodiment approach 2

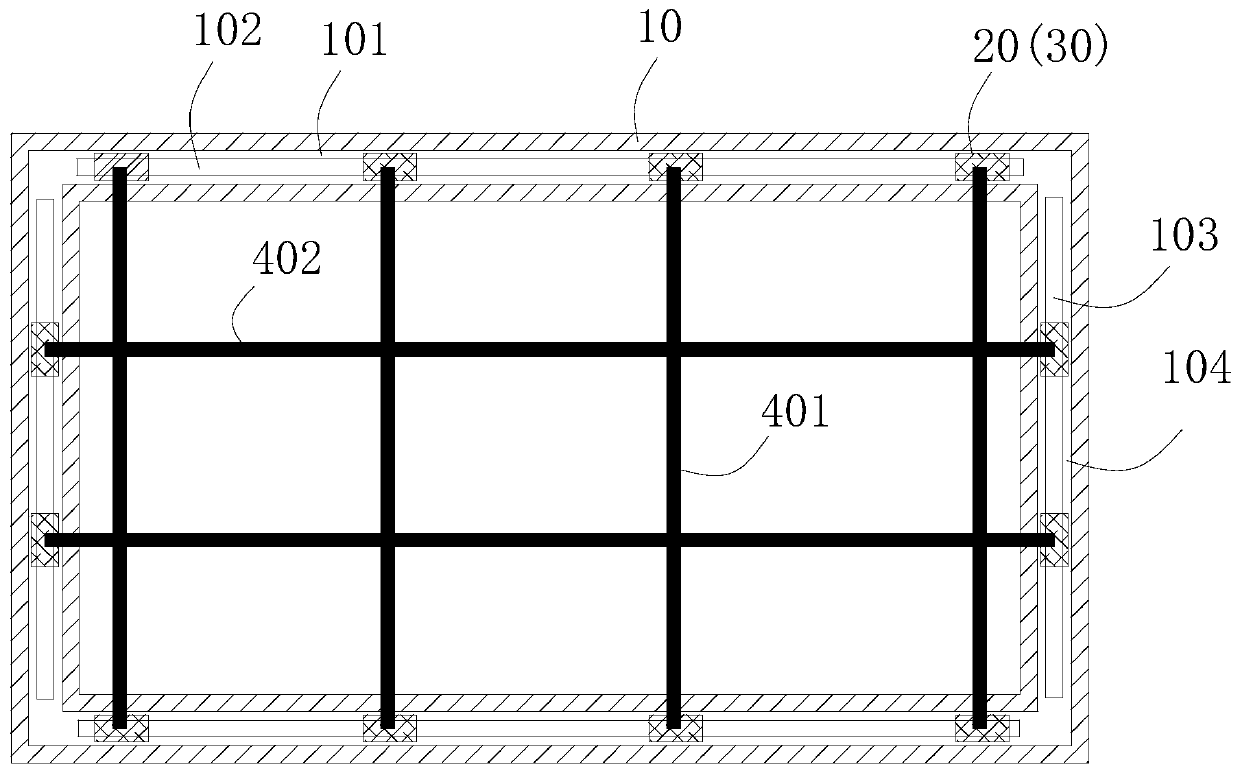

[0038] refer to figure 2 , Embodiment 2 has basically the same structure as Embodiment 1, the only difference is that two horizontal metal sheets 402 and four vertical metal sheets 401 are provided on the metal frame, and two horizontal metal sheets 402 and four vertical metal sheets 401 forms nine mask units.

[0039] Embodiment 2 is a modification made on the basis of Embodiment 1. It is only necessary to adjust the position of the positioning device in Embodiment 1 and increase or decrease the number of horizontal and vertical metal sheets to obtain the design of Embodiment 2.

[0040] In other embodiments, it can also be deformed into various product shapes as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com