Evaporation source assembly of organic light-emitting diode (OLED) evaporator

A technology of evaporation source and evaporation machine, which is used in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problem of abnormal film thickness or doping ratio of organic materials, abnormal OLED efficiency and light color, and cost a few Ten hours and other problems to achieve the effect of improving the dredging efficiency, ensuring the evaporation effect and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

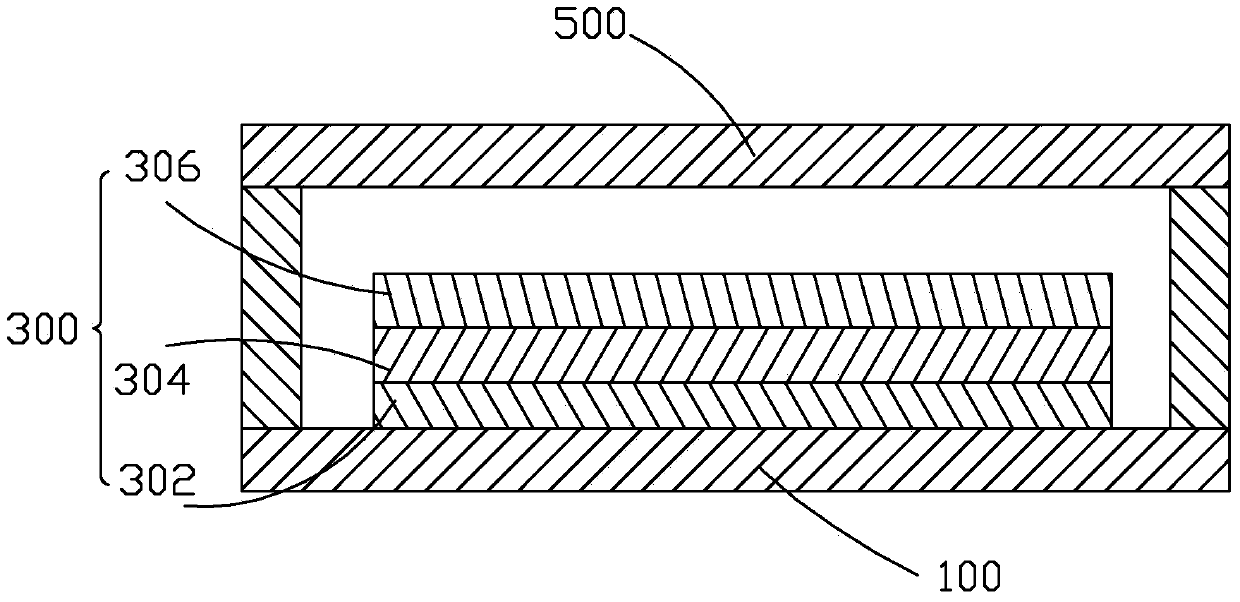

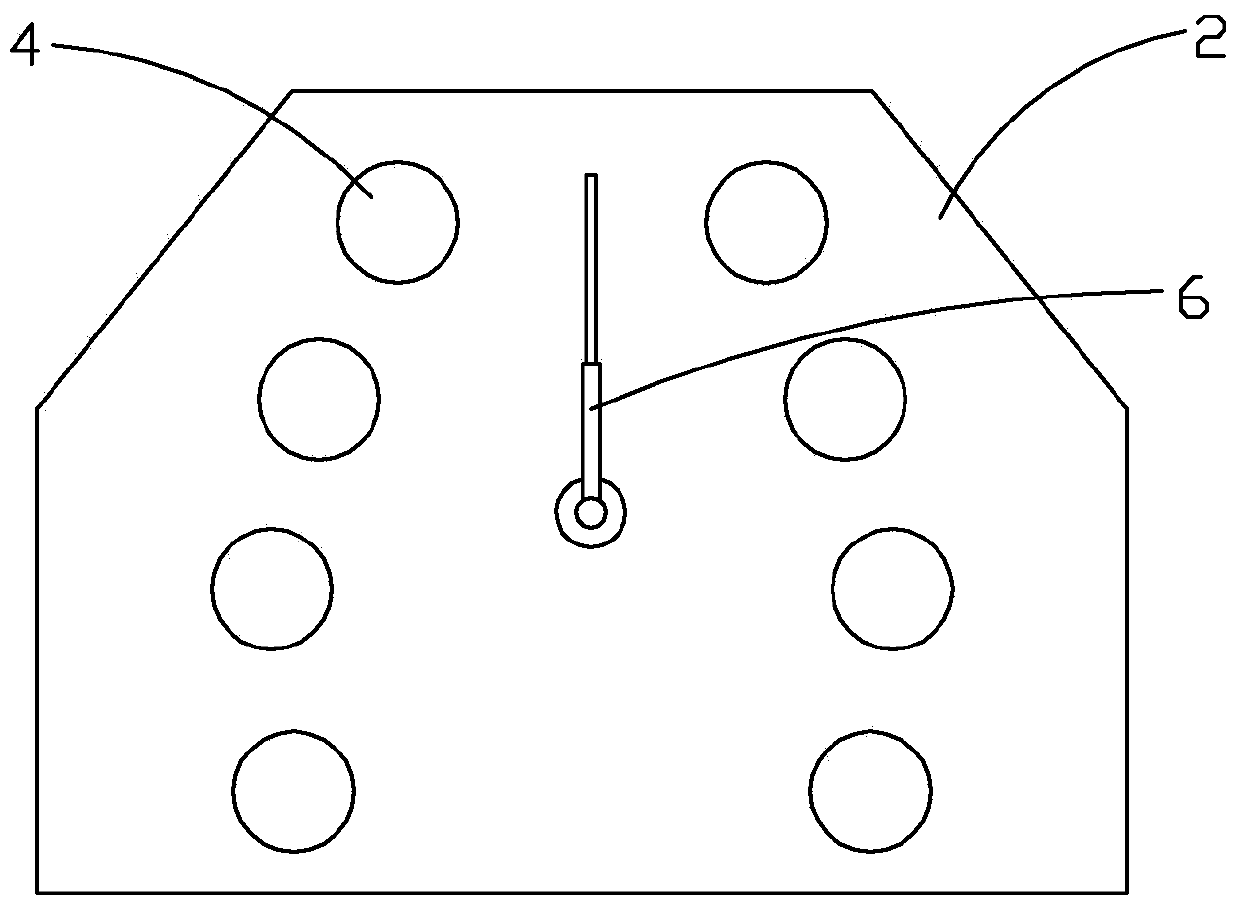

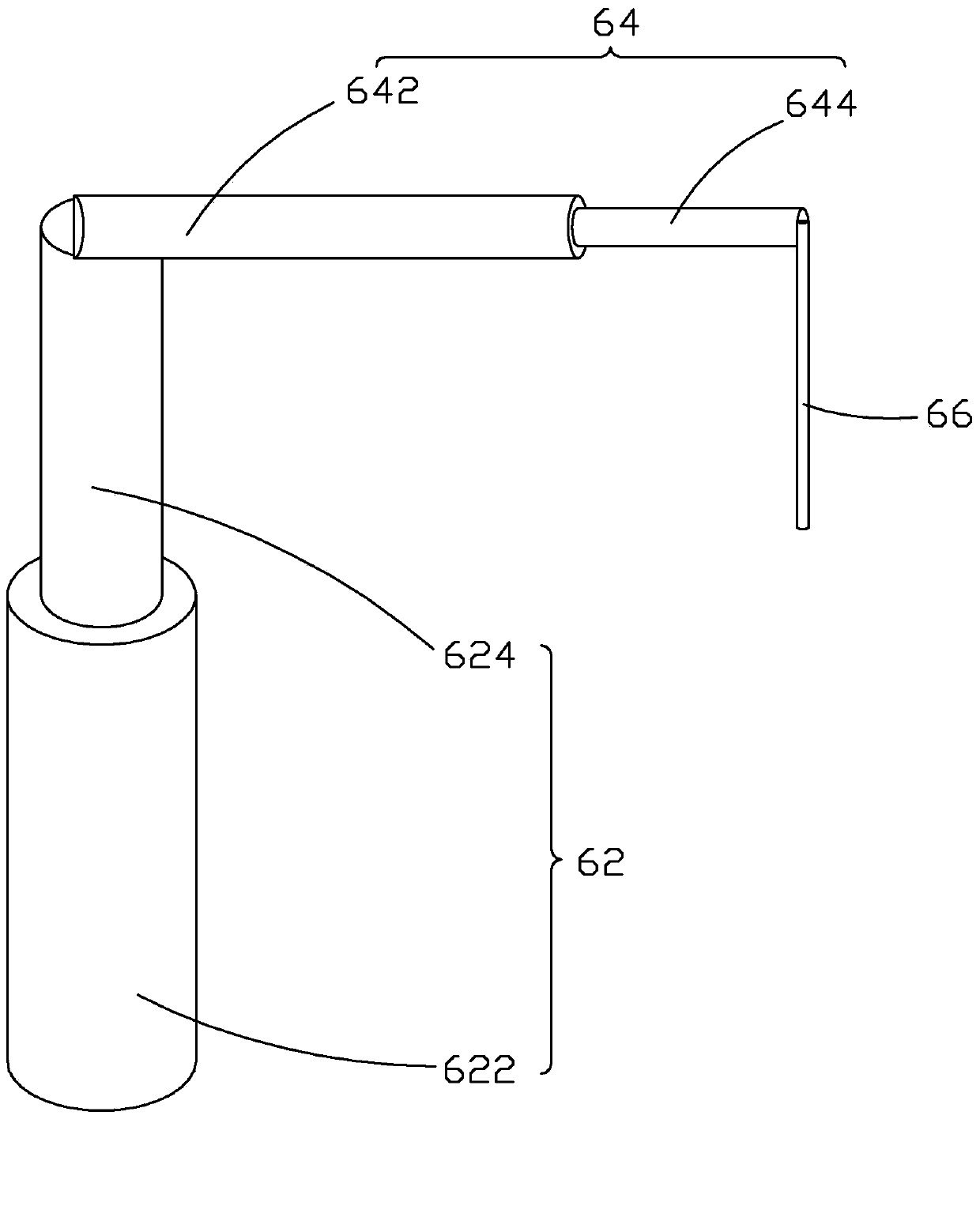

[0031] see figure 2 and image 3 , the present invention provides an evaporation source assembly of an OLED evaporation machine, comprising: a carrying platform 2, several evaporation crucibles 4 arranged on the carrying platform 2 and a dredging mechanism 6 arranged on the carrying platform 2, the dredging mechanism 6 includes a vertical arm 62, a cross arm 64 vertically connected to one end of the vertical arm 62, and a probe 66 vertically connected to the free end of the cross arm 64. Rotate, control the probe 66 to dredge the air outlet of the evaporation crucible 4 through the cross arm 64 and the vertical arm 62, and then can dredge the air outlet of the evaporation crucible 4 without opening the chamber of the evaporation machine, eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com