Negative pressure evaporation and step-by-step feeding method of nickel sulfate solution

A negative pressure evaporation, step-by-step feeding technology, applied in nickel sulfate and other directions, to achieve the effect of stable heating temperature, simple operation and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

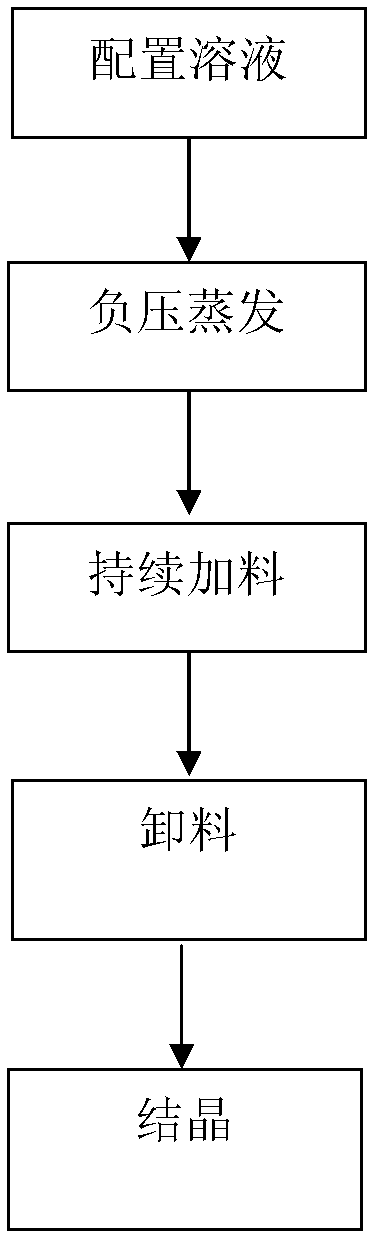

[0016] As shown in accompanying drawing, a kind of nickel sulfate solution negative pressure evaporation step-by-step feeding method comprises the following steps:

[0017] 1. Prepare the solution: Prepare the nickel sulfate solution to be produced so that the concentration is 75-95g / L.

[0018] 2. Negative pressure evaporation: open the feed pipe valve switch, inject the nickel sulfate solution into the negative pressure evaporation device to the feed limit liquid level, close the feed pipe valve, turn on the heating device to heat the negative pressure evaporation device, and turn on the negative pressure Table, start the vacuum machine, evacuate to -0.01--0.01MPa, keep it for about 1h, raise the temperature of the liquid to about 100°C, and then decompress to keep the pressure in the negative pressure evaporation device at 0.4MPa, and then 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com