Auxiliary distribution system and auxiliary distribution method for semiconductor manufacturing production

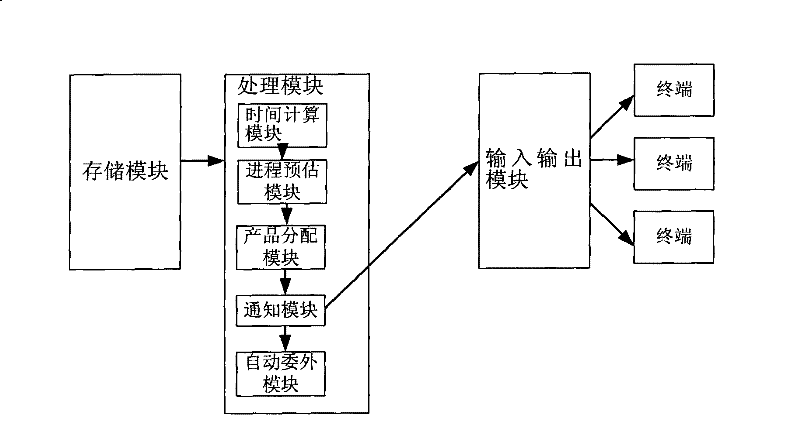

A distribution method, semiconductor technology, applied in semiconductor/solid-state device manufacturing, comprehensive factory control, comprehensive factory control, etc., can solve problems such as artificial estimation and inaccurate distribution, unsmooth product processing, customer product delivery delays, etc. , to achieve the effect of efficient and simple cooperation, lighten the load, and maximize the effectiveness of division of labor and cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0041] Example 1: Product manufacturing step estimation process

[0042]First of all, the processing module of the auxiliary distribution system first searches for product information from the database of the storage module, including product information of products that have been produced or are in production, and the database also stores the information LayerNum of the number of steps of the total process (Layer) that needs to be done , and StartTime when the product starts to be produced, and CycleTimeLayer, the average production time of each process, it is estimated that the time from the start of production to the back-end process of the product is

[0043] StartTime+LayerNum*CycleTimeLayer.

[0044] Step 2, the calculation module calculates the time for the product to enter the back-end process based on the above information, that is, according to the product production process, the current steps of the product, and the time required for each step, estimate the product ...

example 2

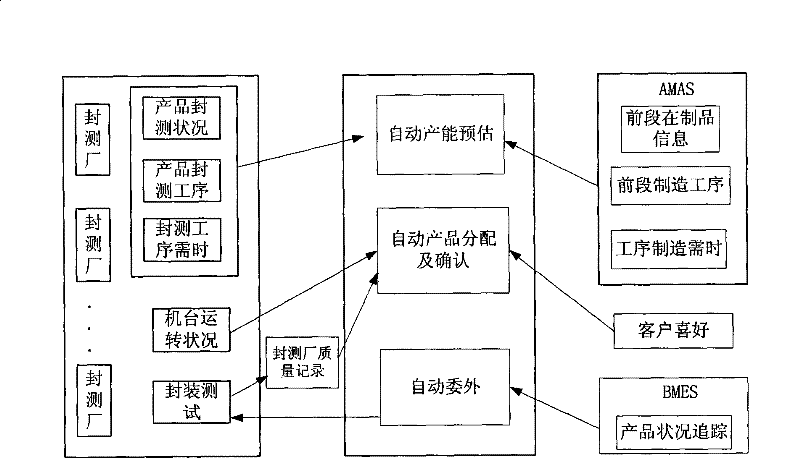

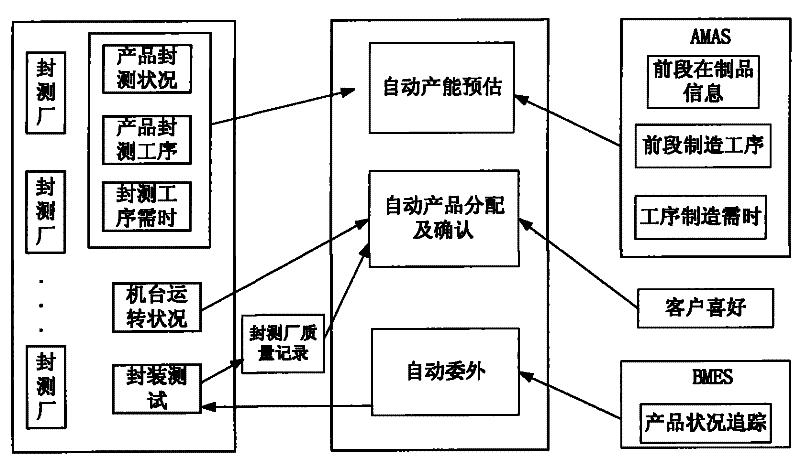

[0046] Example 2: Product allocation and confirmation process

[0047] The calculation module estimates the product information of each process step that needs to be done every day according to its current production status in the packaging and testing factory and its subsequent processes. Then, according to the business scope of each packaging and testing factory and the current and future estimated utilization status of the relevant machines in each process step in the factory, combined with the service performance of each packaging and testing factory and the differences between different customers for these packaging and testing factories The degree of preference, and finally automatically assign each product.

[0048] When the auxiliary distribution system allocates the above distribution, it retrieves the information of the product from the database, as well as the business scope of the packaging and testing factory and the current and future estimated utilization status...

example 3

[0059] Example 3: Automatic tracking process of product back-end manufacturing.

[0060] After confirmation, the auxiliary distribution system will automatically track the processing status of these products through the back-end manufacturing execution system BMES, and through data interaction with the front-end manufacturer and the back-end packaging and testing factory, the latest status and history of each product It is continuously stored in its database. Once the confirmed relevant process steps are entered, the system will automatically generate a commission order to notify the relevant personnel of the packaging and testing factory to pick up the goods and subsequent processing when the system finds that a product needs to be entered. The commission method can be in the form of Mail and / or FTP. Of course, the Mail address, FTP address and other information are all pre-defined by the relevant engineers in our factory and pre-stored in the auxiliary distribution system. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com