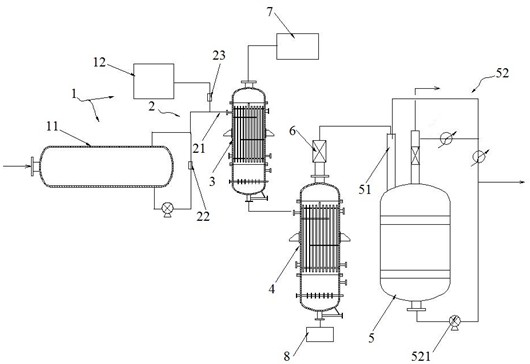

Production process and production device of electronic-grade hydrofluoric acid

An electronic grade hydrofluoric acid and production process technology, applied in the direction of hydrogen fluoride, fluorine/hydrogen fluoride, etc., can solve the problems of large economic cost, large equipment footprint, energy consumption, etc., and achieve the effect of reducing energy consumption and economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to be able to understand the technical means of the present invention more clearly and implement it according to the contents of the description, the specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

[0050] Following specific examples have described a kind of production technique of electronic grade hydrofluoric acid in detail, and this production technique mainly comprises the following steps:

[0051] Step S1, quantitatively transport the industrial-grade anhydrous hydrofluoric acid stored in the industrial-grade anhydrous hydrofluoric acid storage tank to the mixing pipeline located at the front end of the first falling film evaporation device, and simultaneously transfer the oxidant solution storage tank The oxidant solution is quantita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com