Pipeline-type material conveyor

A technology for conveyors and materials, which is applied in the field of conveyors and can solve problems such as potential safety hazards and gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

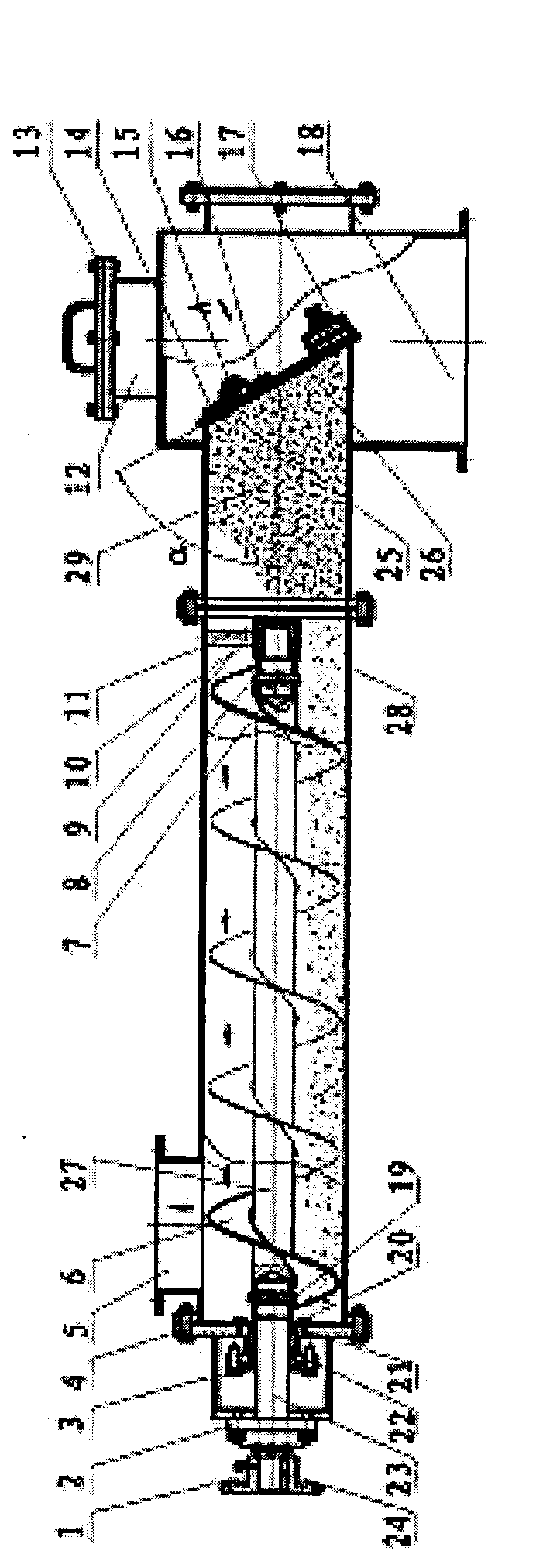

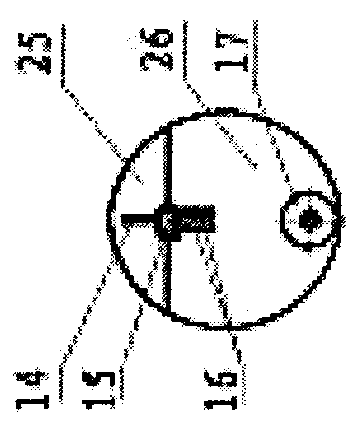

[0010] exist figure 1 , figure 2 In the conveyor with volatile, inflammable and explosive gas materials shown, the material delivery pipeline 28 is divided into two sections, wherein the front section of the material delivery pipeline is the material delivery section, and the initial end of the front section of the material delivery pipeline is fixedly connected to the shell by bolts. Shaped sealing seat 4, the interior of the side wall of the sealing seat 4 is provided with a boss, and the end faces of both sides of the boss are provided with stepped through holes, and a sealing packing 22 is installed in the stepped hole on one side. The sealing packing 22 is axially compressed by the sealing gland 3 which is firmly connected with the boss, and the sealing ring 21 is installed in the stepped hole on the other side, and the sealing gland 3, the sealing packing 22 and the sealing seat The packing sealing device composed of 4 and the sealing ring 21 play the role of sealing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com