Metal film evaporation equipment for film capacitor processing

A film capacitor and metal film technology, applied in the field of metal film evaporation equipment for film capacitor processing, can solve the problems of uneven layers, time-consuming, inconsistent evaporation thickness, etc., to improve processing efficiency, rapid cooling and cooling, Guaranteed effect of evaporation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

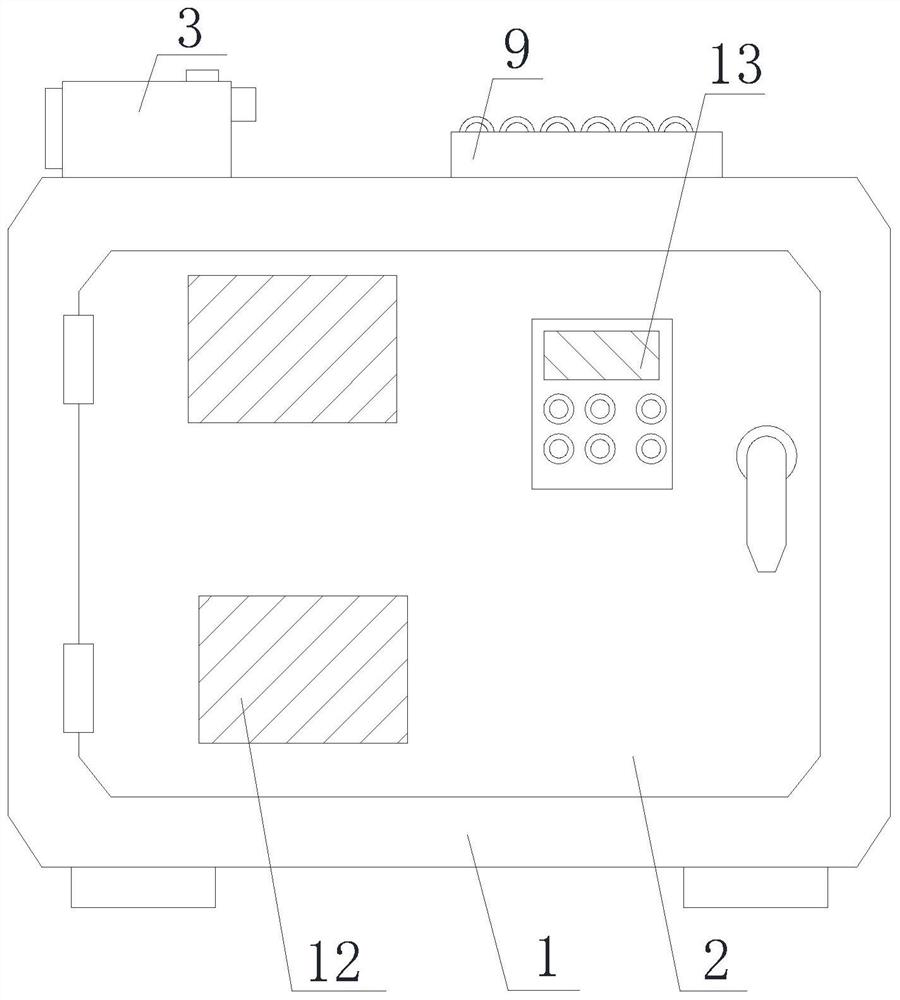

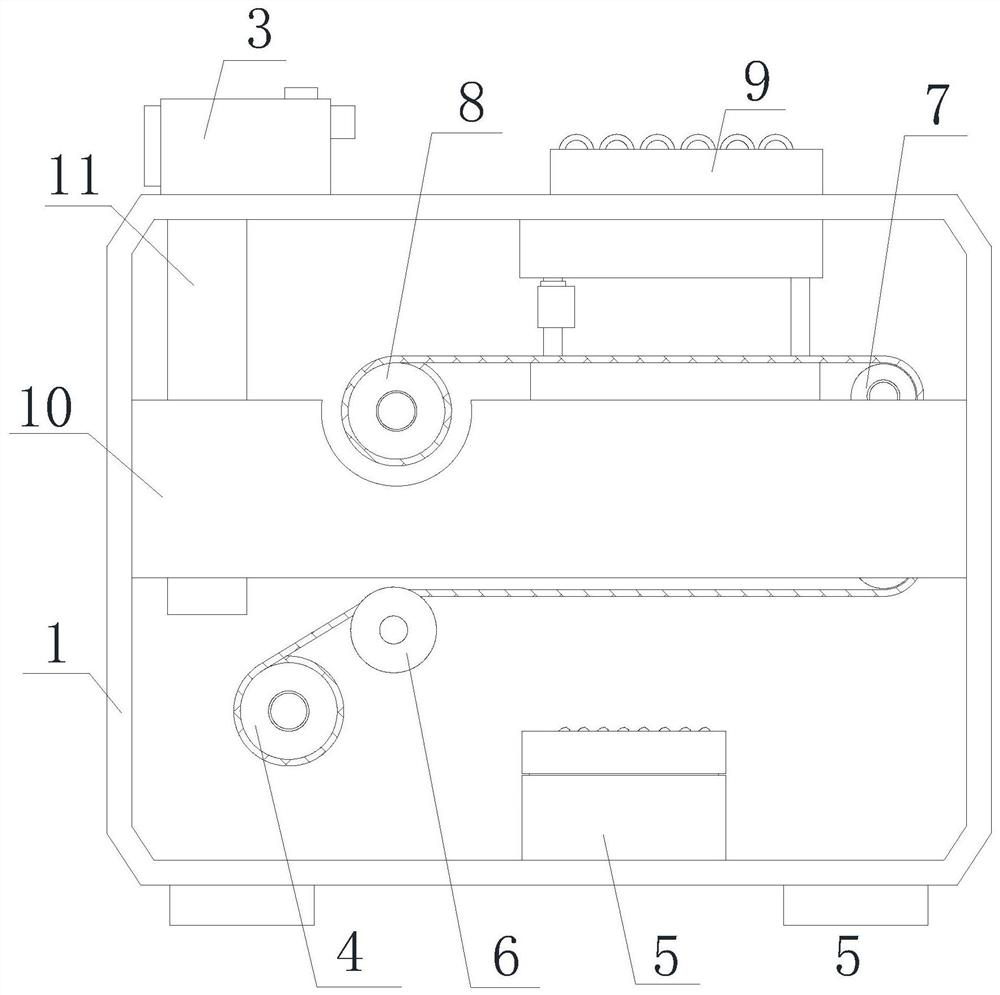

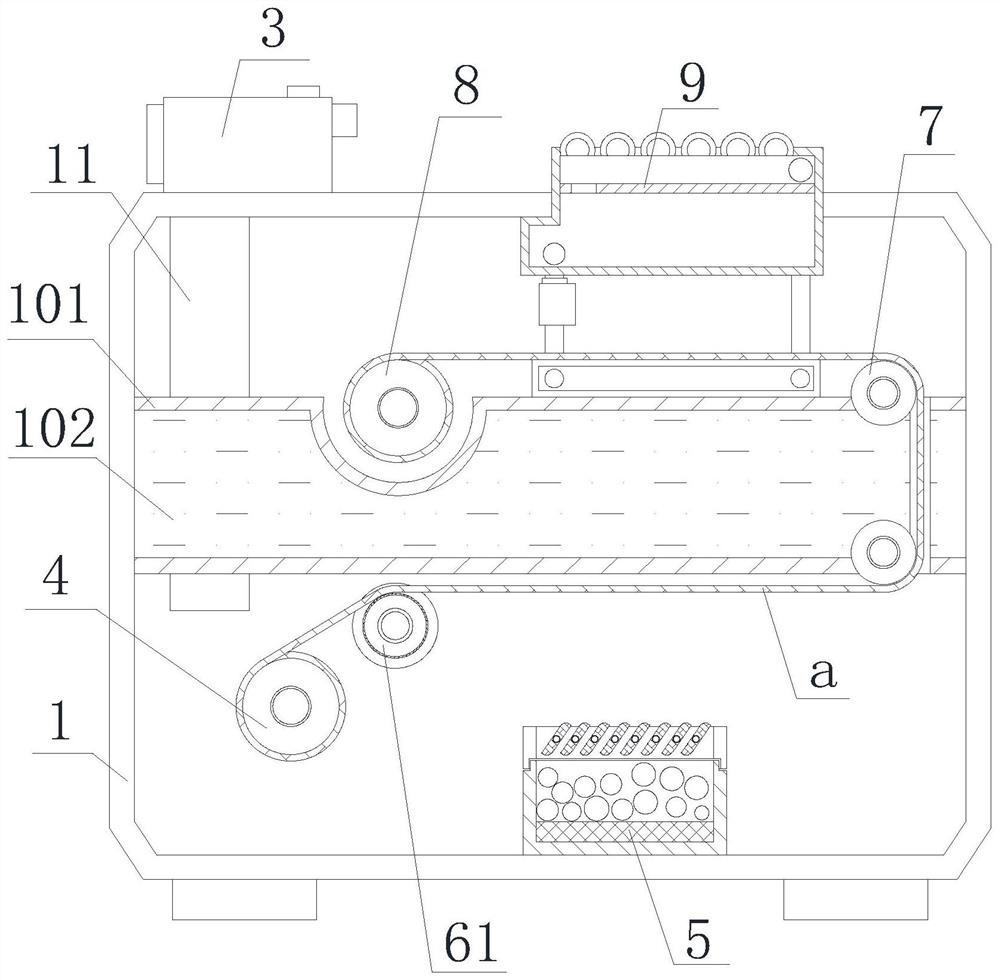

[0032] Attached below Figure 1-7 The present invention is further described with embodiment:

[0033] A metal thin film evaporation equipment for film capacitor processing, comprising an outer box 1, a plurality of supporting feet installed on the lower end of the outer box 1, and a box door 2 installed on the front wall of the outer box 1, the plurality of supporting feet ensure the stability of the equipment, and the box The setting of the door 2 is convenient to open the outer box 1, take out and put in the film a and the evaporation source, the upper end of the outer box 1 is equipped with a vacuum machine 3, and the input end of the vacuum machine 3 is equipped with a vacuum tube 11, The lower end of the vacuum tube 11 extends to the lower part of the inner cavity of the outer box 1, and the vacuum machine 3 is started to extract the air in the inner cavity of the outer box 1 to prevent the air from affecting the evaporation of the film, which is conducive to improving t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com