System and method for detecting measurement accuracy of sulfur trioxide and sulfuric acid steam in flue gas

A technology of sulfur trioxide and detection system, which is applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of no standard gas and no evaluation of steam, and achieve the purpose of improving the accuracy of measurement, ensuring stability and ensuring evaporation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

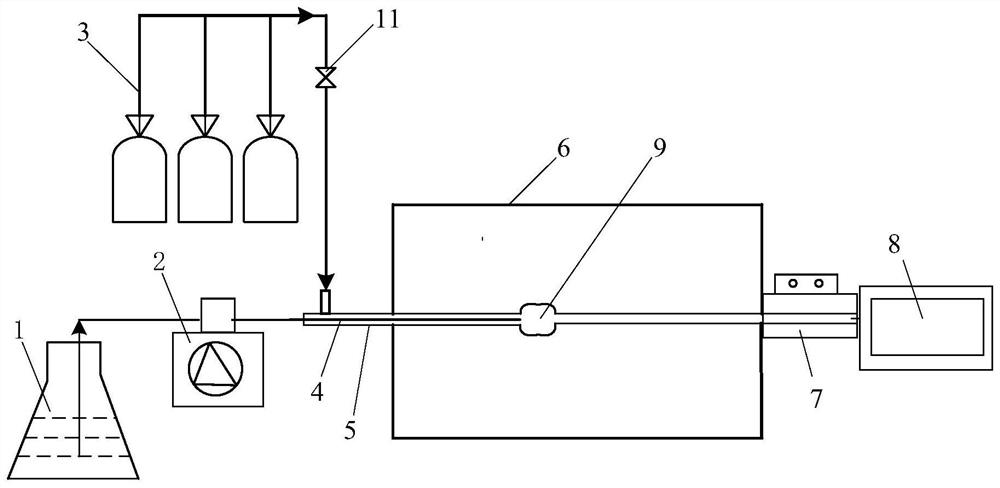

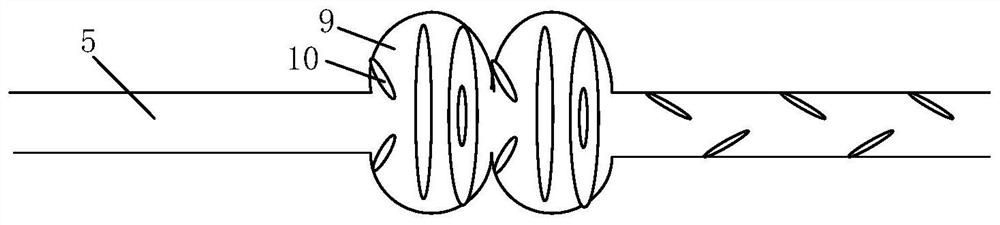

[0069] The diameter of the capillary 4 adopted in this embodiment is 0.5 mm, the inner diameter of the evaporation tube 5 is 10 mm, the diameter of the circular buffer device 9 is 30 mm, the temperature of the first section temperature control zone of the heating furnace 6 is 300 ° C, the second section The temperature in the temperature control zone is 350°C, and the temperature in the third temperature control zone is 300°C; the heat preservation device 7 at the outlet of the evaporator tube 5 controls the outlet smoke temperature to 300°C, and the capillary tube 4 is inserted into the circular buffer device 9 of the evaporator tube 5 at the far left side. Arranged in the evaporating tube 5 such as figure 2 A turbulent mixing device 10 composed of several plates is shown.

[0070] In actual use, the flue gas flow rate of the simulated flue gas on the test bench is 5L / min, the concentration of the prepared dilute sulfuric acid is 0.97g / L; the delivery speed of the pump 2 is...

Embodiment 2

[0075] The parameters of each structure adopted in this embodiment are as described in Embodiment 1.

[0076] In actual use, the total gas volume of the simulated flue gas on the test bench is 1.5L / min, and the concentration of the prepared dilute sulfuric acid is 0.97g / L. Adjust the delivery speed of pump 2 to 0.10ml / min, and the delivery time to 30min.

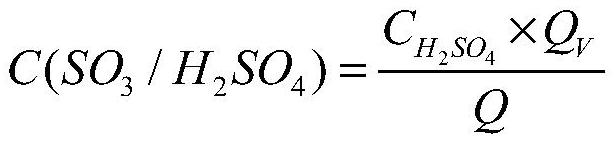

[0077] Dilute sulfuric acid was evaporated under the above conditions, and SO in the prepared simulated flue gas 3 / H 2 SO 4 The vapor reference concentration can be obtained by the formula:

[0078] (0.97g / L×0.10ml / min)×1000 / 1.5L / min=64.67mg / m 3

[0079] pass figure 1 as shown in SO 3 Measuring device 8, SO in the present embodiment 3 The measuring device 8 adopts the isopropanol absorption method to sample and measure, and measure and calculate the SO in the flue gas 3 / H 2 SO 4 The steam concentration is 47.86mg / m 3 . SO obtained from the above calculation 3 / H 2 SO 4 Vapor concentration reference value 64...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com