Dry desulfurization and urea solution direct injection denitrification device for flue gas of sintering machine

A sintering machine, flue gas technology, applied in the direction of separation methods, climate change adaptation, climate sustainability, etc., can solve the problems of high operating costs, secondary pollution, waste of manpower and material resources, etc., to achieve low investment and operating costs, and system use Long life, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

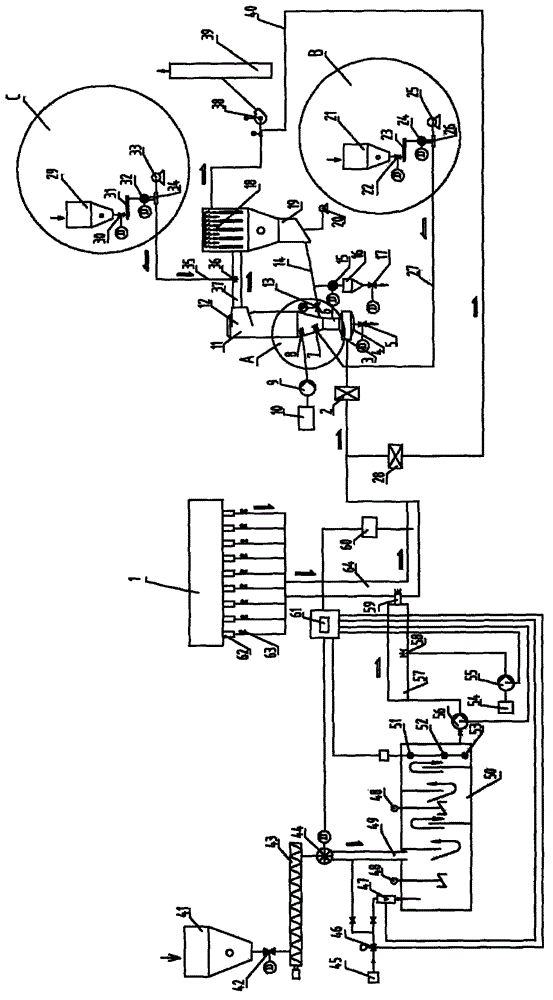

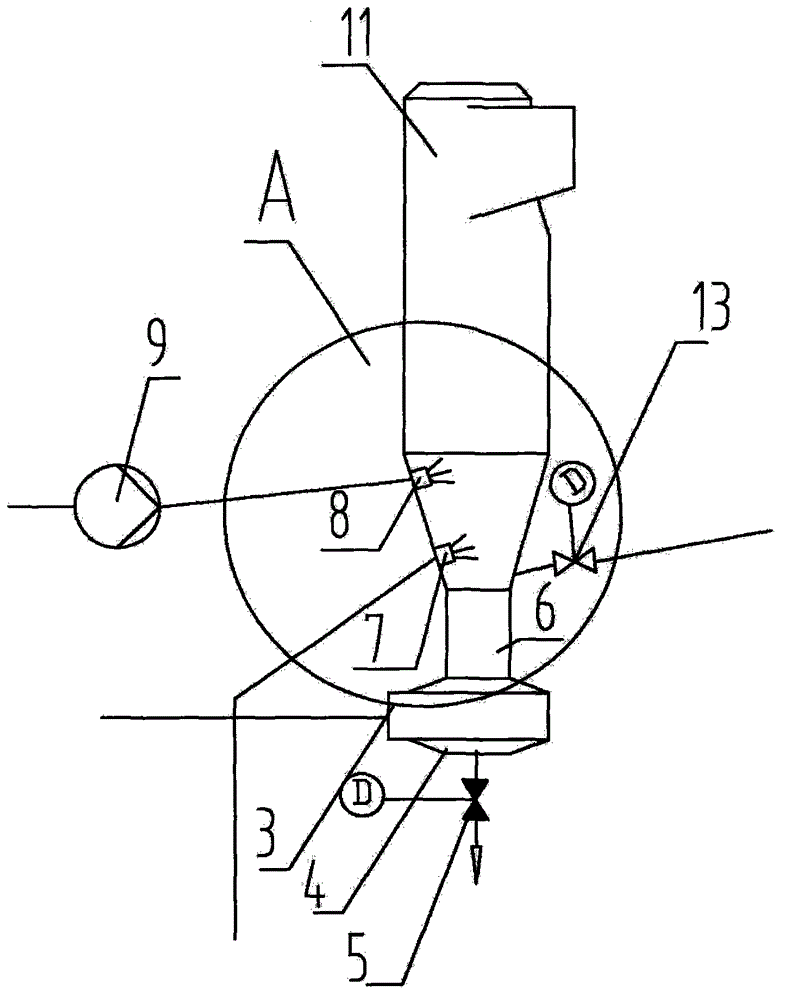

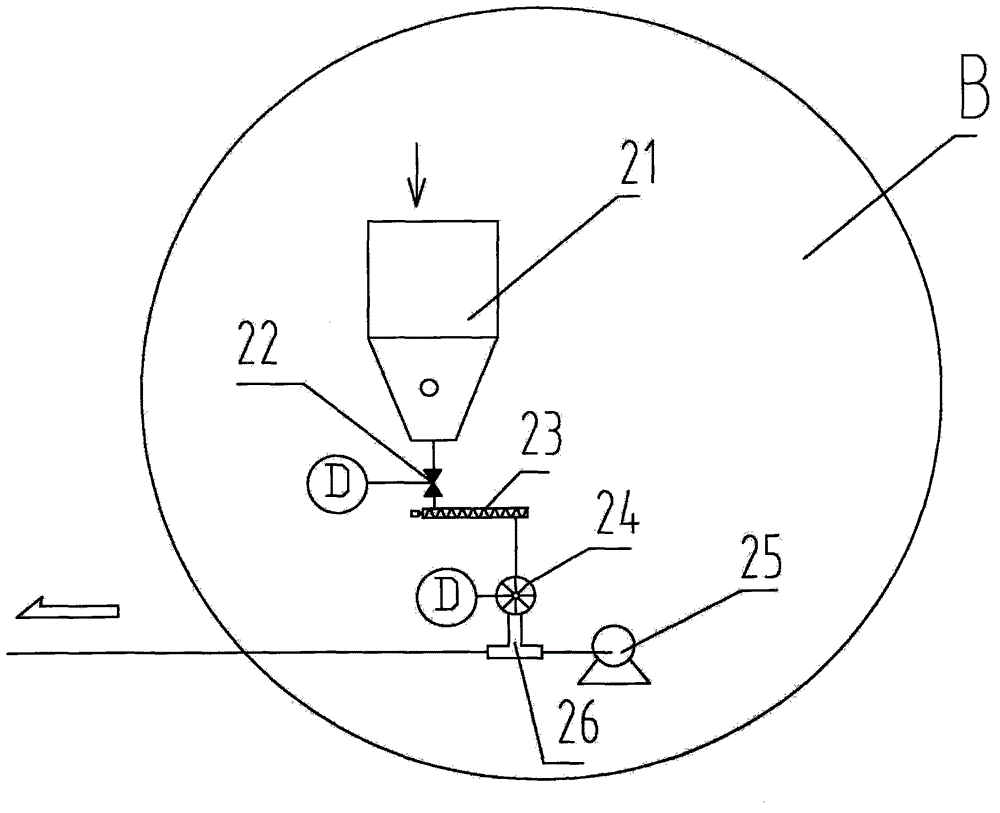

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is a sintering machine flue gas dry desulfurization urea solution direct injection denitrification device, including a sintering machine 1, a bellows 62, a flue gas online monitoring and control device 60, an electric air inlet valve 2, a reaction tower 11, and a bag dust collector device 18, fan 38, and chimney 39, characterized in that: the sintering machine 1 is sequentially connected with wind box 62, flue gas online monitoring and control device 60, electric air inlet valve 2, reaction tower 11, bag filter 18, fan 38, and chimney 39. An electric flow regulating valve 63 is connected between the bellows 62 and the flue gas online monitoring control device 60, the flue gas online monitoring control device 60 is connected to the PLC control box 61, and the PLC control box 61...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com