Neural network-based SCR intelligent ammonia-spraying optimization method and apparatus

A neural network, BP neural network technology, applied in the field of coal-fired denitrification, to achieve the effect of improving utilization rate, improving denitrification efficiency, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

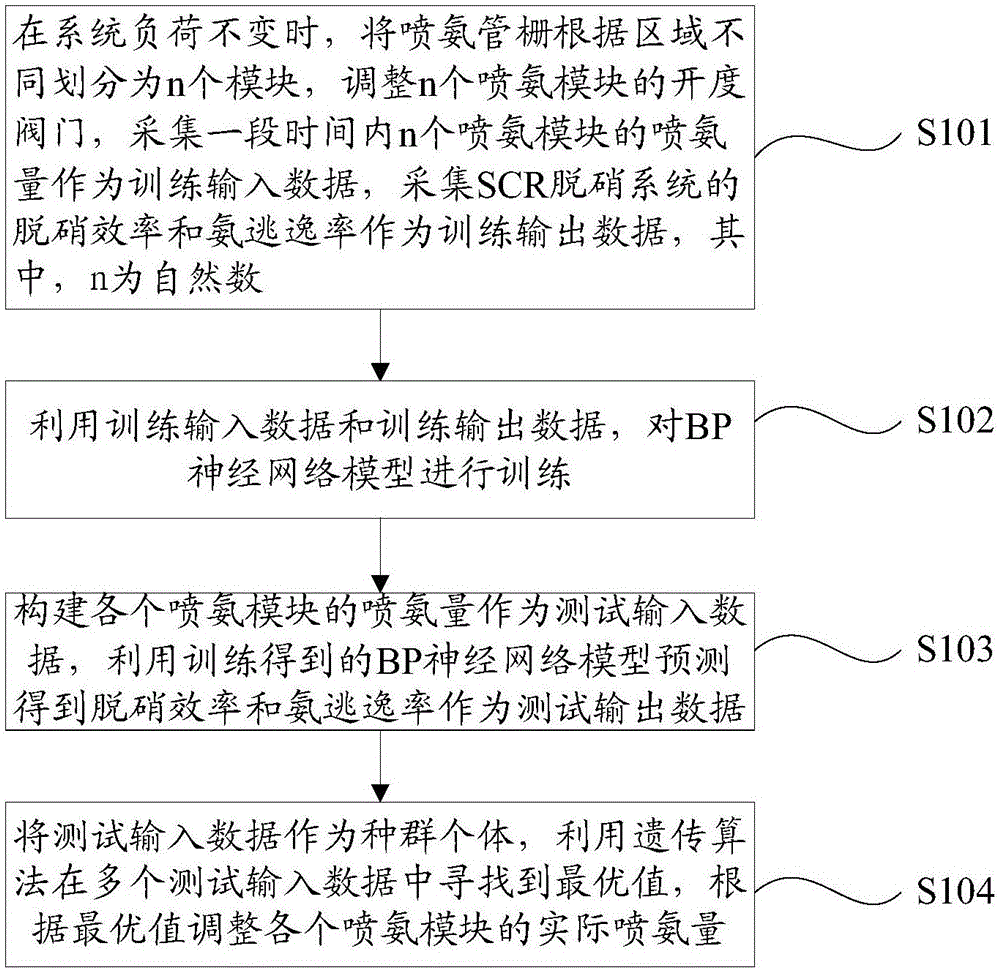

[0031] figure 1 It shows a flow chart of a neural network-based intelligent ammonia injection optimization method for SCR according to an embodiment of the present invention. like figure 1 As shown, the neural network-based SCR intelligent ammonia injection optimization method provided in this embodiment specifically includes the following steps:

[0032] Step S101, when the system load remains constant, divide the ammonia injection pipe grid into n modules according to different regions, adjust the opening valves of the n ammonia injection modules, and collect the ammonia injection volumes of the n ammonia injection modules within a period of time as training Input data, collect the denitrification efficiency and ammonia escape rate of the SCR denitrification system as the training output data, where n is a natural number.

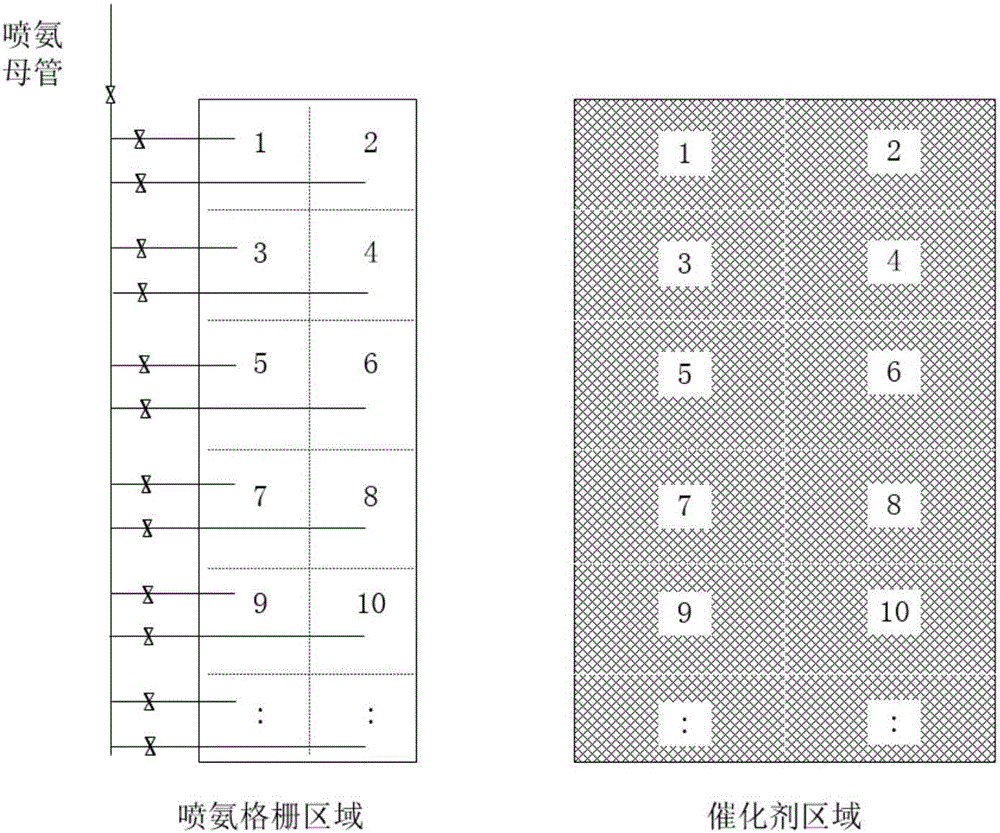

[0033] like figure 2 The schematic diagram of the ammonia injection grid area and catalyst area partition module shown in the diagram divides the amm...

Embodiment 2

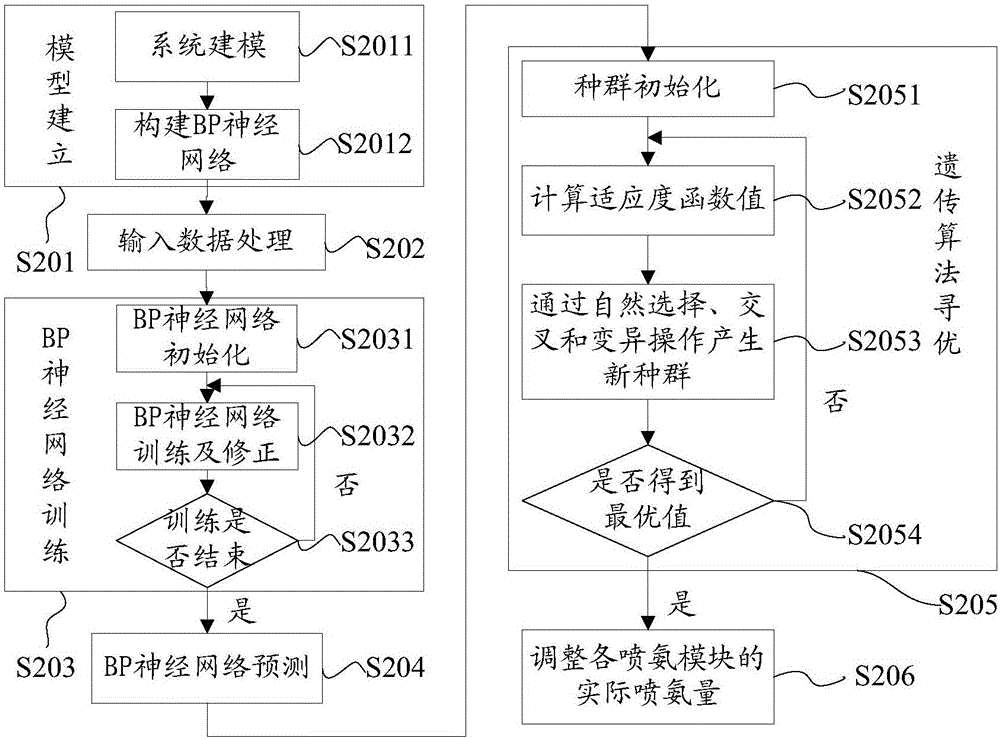

[0044] image 3 It shows the flow chart of the neural network-based SCR intelligent ammonia injection optimization method according to the second embodiment of the present invention. like image 3 As shown, the neural network-based SCR intelligent ammonia injection optimization method provided in this embodiment specifically includes the following steps:

[0045] Step S201, model building.

[0046] Step S2011, system modeling.

[0047] Number the n nozzle modules equally divided into n nozzle modules from 1 to n, keep the system load constant, continuously adjust the opening valves of each module, collect the respective ammonia injection volumes of the n nozzles within a period of time, and set n nozzle modules at time t The ammonia injection volume of the module is respectively {x 1 (t),x 2 (t),x 3 (t)...x n (t)}, and these n variables are also input variables at this time. The output variable is the ammonia escape rate y of the SCR denitrification system 1 (t) and d...

Embodiment 3

[0118] Figure 5 A functional block diagram of a neural network-based SCR intelligent ammonia injection optimization device according to Embodiment 3 of the present invention is shown. like Figure 5 As shown, the neural network-based intelligent ammonia injection optimization device for SCR provided in this embodiment specifically includes: an acquisition module 301 , a normalization module 302 , a training module 303 , a prediction module 304 , and an optimization module 305 .

[0119] The acquisition module 301, when the system load is constant, divides the ammonia injection pipe grid into n modules according to different regions, adjusts the opening valves of the n ammonia injection modules, and collects the ammonia injection volume of the n ammonia injection modules within a period of time as Training input data, collecting the denitrification efficiency and ammonia escape rate of the SCR denitrification system as the training output data, where n is a natural number.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com