Brown gas type integrated solid waste incinerator

A solid waste and incinerator technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of low level of fuel cracking, long process flow, large floor space, etc. Simplified process and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

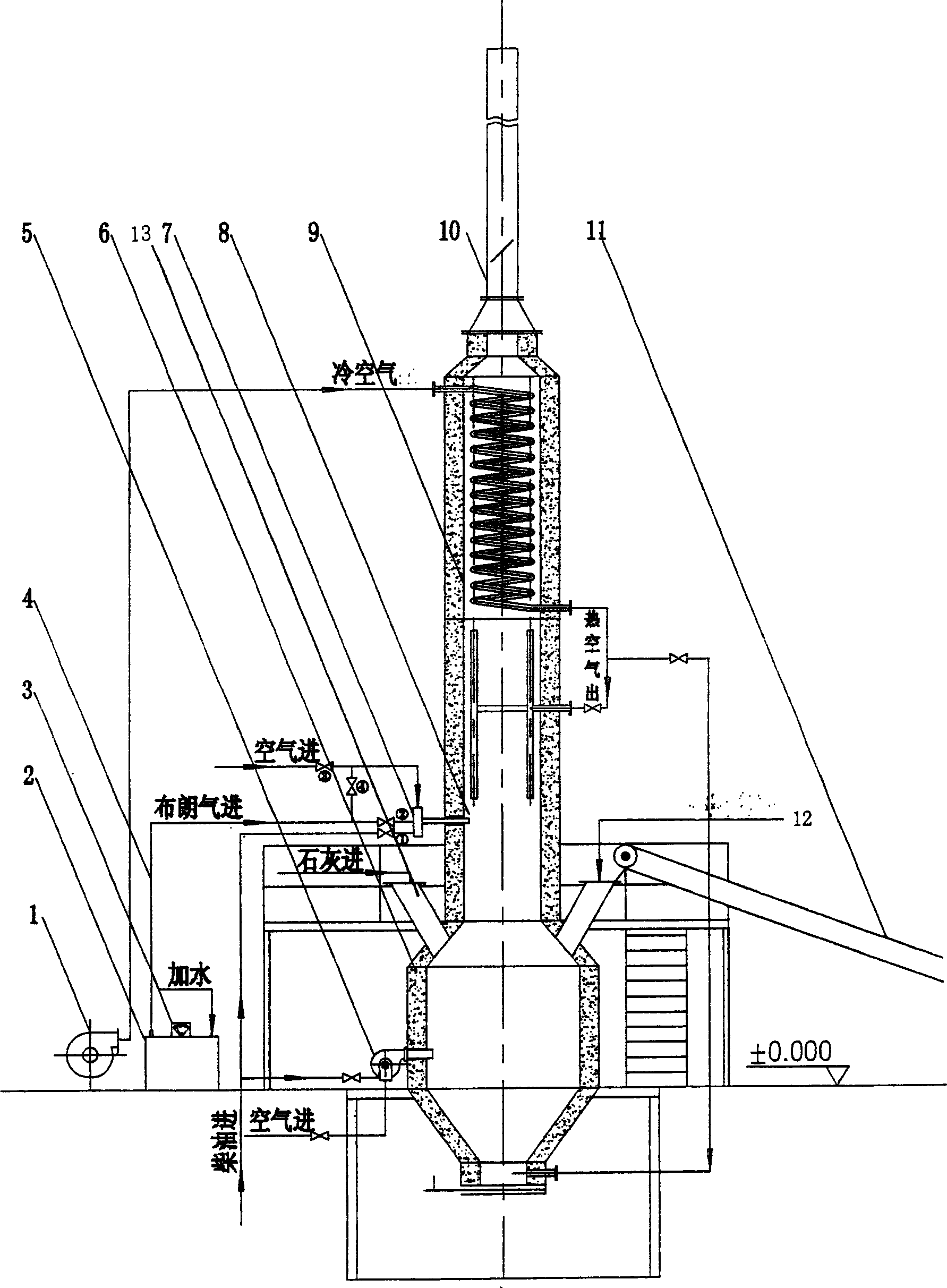

[0028] refer to figure 1 As shown, the technical key of the present invention is to install a H3000 type Brownian generator 2 between the blower 1 and the burner 5, and the water adding pipe, the ammeter 3 (300A / 24V) and the Brownian gas inlet pipe 4 are housed on this generator, Water is added to the Brownian generator 2, and the water is electrolyzed to produce Brownian gas (mixed gas of hydrogen and oxygen). A Brown gas type integrated solid waste incinerator, including a feeding belt conveyor (11), a combustion chamber (6), a burner 5, a secondary combustion chamber (8), a fuel spray gun 7, and an air-gas heat exchanger (9) , blower (1) and chimney (10); a burner (5) connected to the air inlet pipe and the diesel inlet pipe is installed on one side of the combustion chamber (6), and a slagging valve is installed on the bottom of the chamber, and a slagging valve is installed on the upper side. It is a solid waste feed inlet (12), and the other side is a lime feed inlet (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com