Method for producing adipic acid by utilizing saccharomyces cerevisiae

A technology of Saccharomyces cerevisiae and recombinant Saccharomyces cerevisiae, applied in the direction of microorganism-based methods, biochemical equipment and methods, enzymes, etc., can solve the problems of high feed cost, poor acid resistance, high energy demand, etc., to reduce pollution and facilitate recycling Simple, excellent stress resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Knockout of succinate--CoA ligase (GDP-forming) subunit alpha (LSC1) gene in BY4741

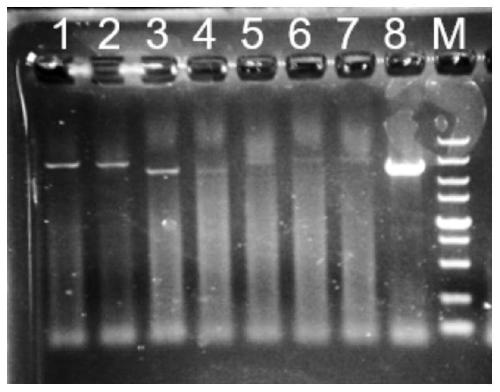

[0040] The acquisition of recombinant Saccharomyces cerevisiae LSC1 gene knockout frame: using ΔLSC1-pUG6-F and ΔLSC1-pUG6-R as primers and pUG6 vector as a template, a DNA fragment with a size of 1700bp was amplified by PCR reaction, and the fragment was separated at the beginning and end The 50 bp upstream and downstream of the LSC1 gene ORF box on the BY4741 genome are homologous sequences. The PCR product was purified and kept for future use.

[0041] Transformation of recombinant Saccharomyces cerevisiae gene knockout frame: Inoculate a single colony of Saccharomyces cerevisiae BY4741 activated on the plate into a 100mL Erlenmeyer flask containing 10mL YPD liquid medium, and then inoculate it at a speed of 250r min -1 , cultured overnight on a shaker at 30°C as fresh seed solution, transferred to a 250mL Erlenmeyer flask containing 50mL YPD medium at 1%, and cultivated...

Embodiment 2

[0046] Example 2: Construction of recombinant plasmids and acquisition of recombinant Saccharomyces cerevisiae

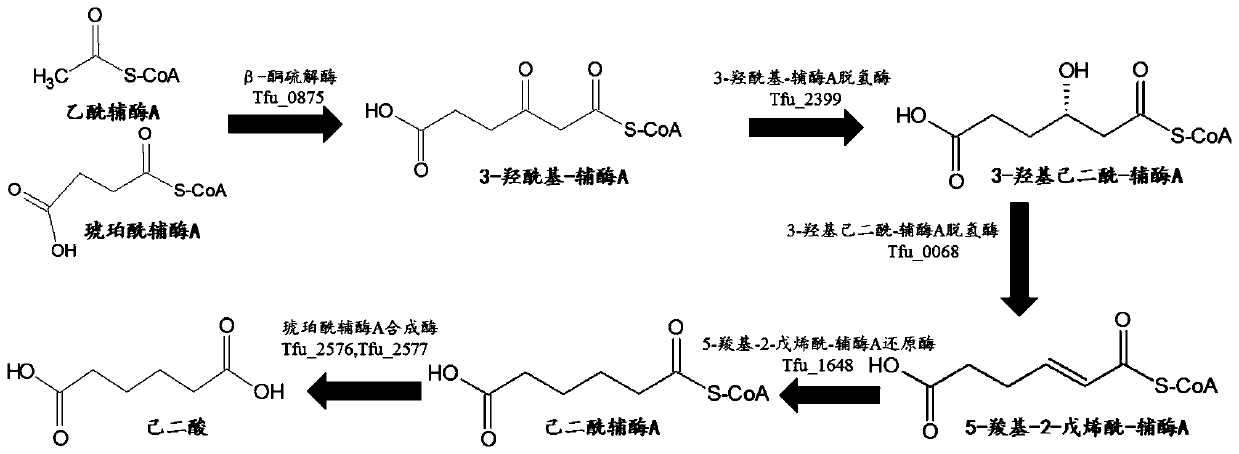

[0047] The sequences of Tfu_0875, Tfu_2399, Tfu_0068, Tfu_1648, Tfu_2576, Tfu_2577 have been published in NCBI.

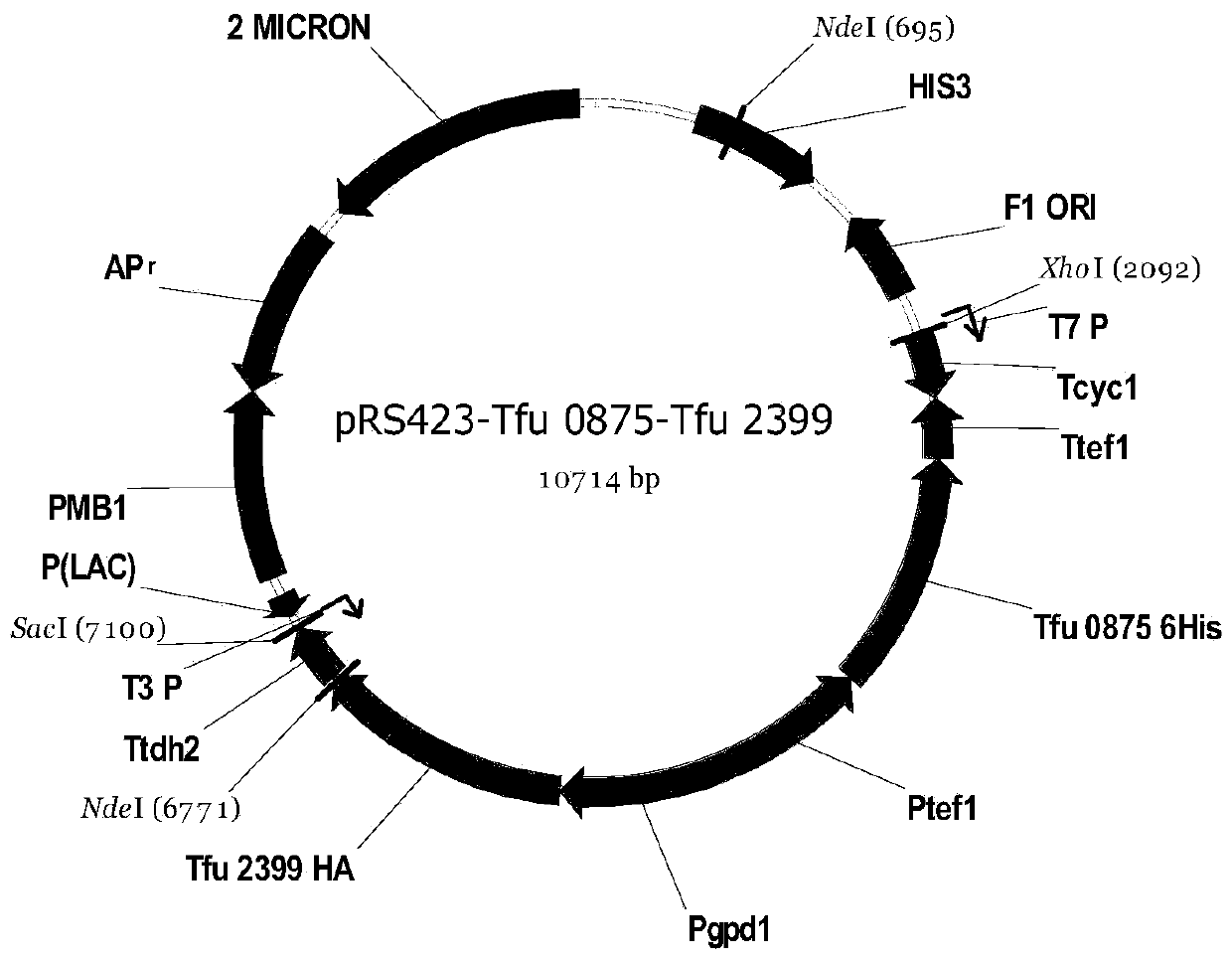

[0048] The obtained gDNA of Saccharomyces cerevisiae BY4741 was used as a template, and the primers (Table 1) with homology arms were used for PCR amplification to obtain gene fragments Tcyc1-1, Ttef1-1, Ptef1-1, Pgpd1-1, Ttdh2-1 Fragment, wherein, use primer CN9847-1-AF / R to amplify Tcyc1-1; use primer CN9847-1-BF / R to amplify Ttef1-1; use primer CN9847-1-DF / R to amplify Ptef1-1; use Primer CN9847-1-EF / R amplifies Pgpd1-1; uses primer CN9847-1-GF / R to amplify Ttdh2-1; amplifies Tcyc1-1, Ttef1-1, Ptef1-1, Pgpd1-1, Ttdh2-1 and synthetic sequences such as Tfu_0875 and Tfu_2399 fragments shown in SEQ ID NO.1, 2 are connected by homologous recombination, and each fragment is according to image 3 The full length of the sequence was ligated into the T vecto...

Embodiment 3

[0052] Embodiment 3: Shake flask fermentation of recombinant Saccharomyces cerevisiae

[0053] YPD medium: yeast extract 10g / L, peptone 20g / L, glucose 20g / L, add 2.0% agar to solid YPD medium, pH is 5.4-5.6, 121°C, high-pressure steam sterilization for 30min;

[0054] SD medium: glucose 20g, YNB medium (without (NH 4 ) 2 SO 4 1.7g), (NH 4 ) 2 SO 4 5g, add 1000mL deionized water pH=5.5, sterilize by high pressure steam at 115°C for 15min. Before inoculation, add appropriate amount of sterilized amino acid, pyrimidine and agar powder according to the selectable marker.

[0055] LB medium (in g / L): 10 tryptone + 5 yeast powder + 10NaCl.

[0056] Fermentation conditions: using SD (-Ura-His-Leu) medium as the fermentation medium, culture recombinant Saccharomyces cerevisiae at 30°C to OD 600 When it is 1.0-1.2, wash it twice with sterile water, transfer to YPD medium with 10% inoculum size and ferment for 96 hours.

[0057] Taking BY4741 wild type and LSC1 gene knockout ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com