Anti-medicine strip bonding device and medicine strip processing method

A technology for bonding devices and drug strips, which is applied to explosives processing equipment, explosives, offensive equipment, etc., can solve the problems of negative impact on performance test results, high loss rate of bonded clumps, easy bending and deformation of drug strips, etc., to achieve guaranteed Dispersibility, ease of handling, and safety benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

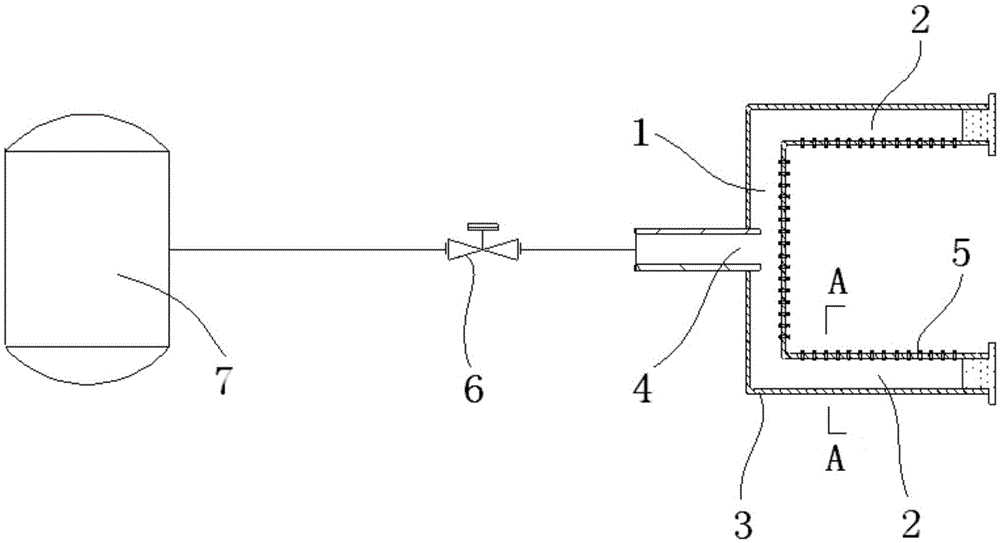

[0071] Such as figure 2 As shown, the device for preventing sticking of medicinal sticks in this embodiment includes an air supply system 7 , a wind speed regulating valve 6 and a "U"-shaped ventilation pipe 3 . The "U"-shaped ventilation tube 3 includes a trachea 1 and two ends of the trachea extend perpendicular to the trachea to form a side trachea 2 . The air pipe 1 is provided with an air inlet 4 , and the inner wall 2 is provided with a number of air outlet holes 5 .

[0072] The air supply system 7 is mainly composed of an air compressor and an air storage tank with automatic pressure display and control functions. The air supply system is equipped with a pressure relief and explosion-proof valve.

[0073] The wind speed regulating valve 6 regulates the air flow of the blowing pipe by controlling the size of the valve, and the regulating valve has a scale display and has a memory function at the same time.

[0074] "U" type air pipe 3 adopts copper material, the tota...

Embodiment 2

[0079] Utilize the device among the embodiment 1 and THP99-200KG pressure medicine hydraulic press (manufacturer: Tianjin Tianduan Press Co., Ltd.) to process test medicine bar.

[0080] Test drug strip formula: the main components are NC and some high-energy additives (RDX and HMX), and the solvent (mixed solvent of acetone, ethanol, and ethyl acetate) is about 25% by mass.

[0081] The wind speed regulating valve is adjusted to a pressure of 7MPa, that is, the pressure at each blowing nozzle is controlled at 7Mpa.

[0082] Specific steps: Before the stretching machine works, turn on the air supply system of the stretching auxiliary device, check the air tightness of the pipeline, and open the wind speed regulating valve. At this time, the regulating valve will automatically adjust to the small test scale of the product (the pressure is 5MPa). After the wind speed of the blowing nozzle is stable for 1 to 2 minutes, start the stretching machine to press the medicine, and start...

Embodiment 3

[0084] This embodiment differs from Embodiment 1 in that:

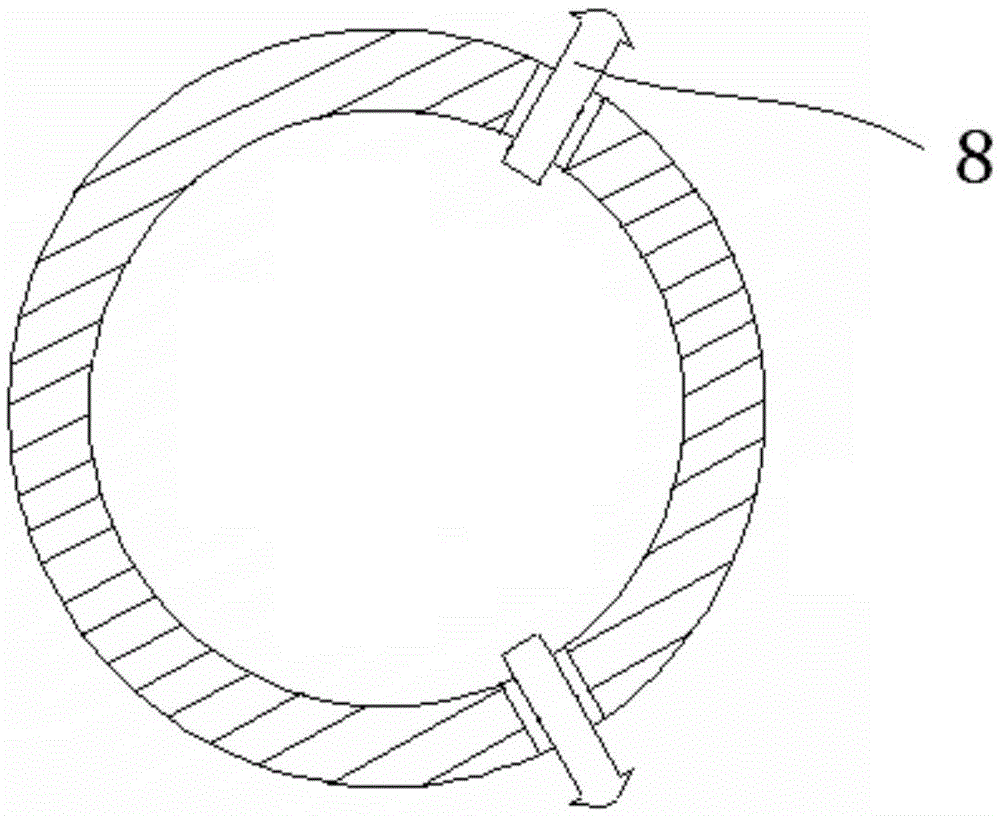

[0085] Such as Figure 4 As shown, the inner wall of the "U"-shaped ventilation pipe 3 is provided with three exhaust holes 5, and the interval between adjacent air outlet holes 5 is 8 mm. The included angle between the air outlet directions of two adjacent rows of conical blowing nozzles is 60°. Each tapered air blowing nozzle 8 adopts copper material, length 5mm, wall thickness 1mm, cone angle 45 °.

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com