Low-temperature flash evaporation, concentration and crystallization integrated and zero-discharge process for treating desulfurization wastewater through concentrated liquid reflux

A technology of concentrated crystallization and low-temperature flash evaporation, which is applied in water/sewage treatment, neutralized water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of insufficient output of two-effect and three-effect evaporation, and reduce equipment investment Cost, high salt content, effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

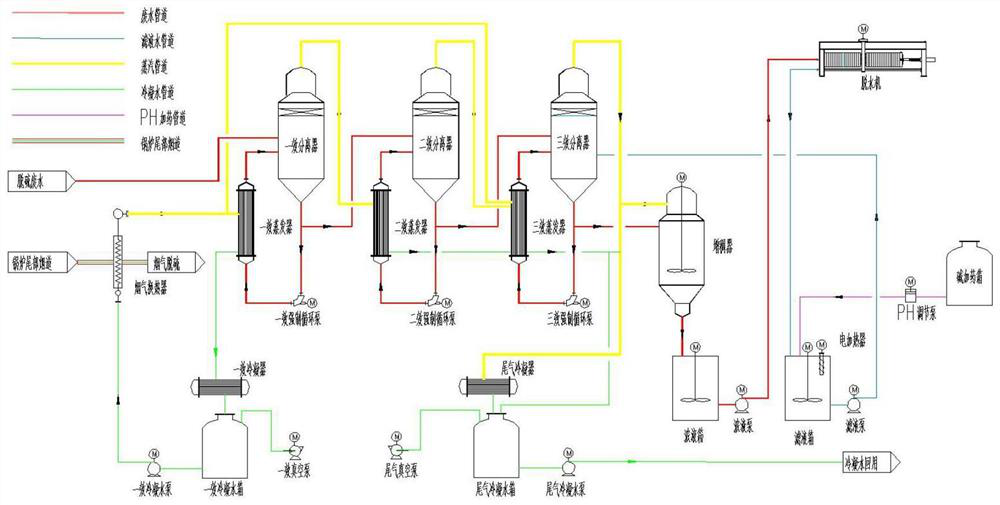

[0027] refer to figure 1, a zero-emission process for the integration of low-temperature flash evaporation, concentration, crystallization, and concentrated liquid reflux treatment of desulfurization wastewater, including flue gas heat exchange system, low-temperature multi-effect evaporation system, condensate water system, solid-liquid separation system, filtrate reflux and electric heating system It is connected with PH adjustment system, flue gas heat exchange system, low temperature multi-effect evaporation system, solid-liquid separation system, filtrate return and electric heating system in sequence, and flue gas heat exchange system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com