Sludge reduction device

A sludge and shell technology, applied in the direction of dewatering/drying/concentrating sludge treatment, can solve the problem of high treatment cost, and achieve the effect of ensuring evaporation effect, ensuring evaporation effect and reducing treatment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

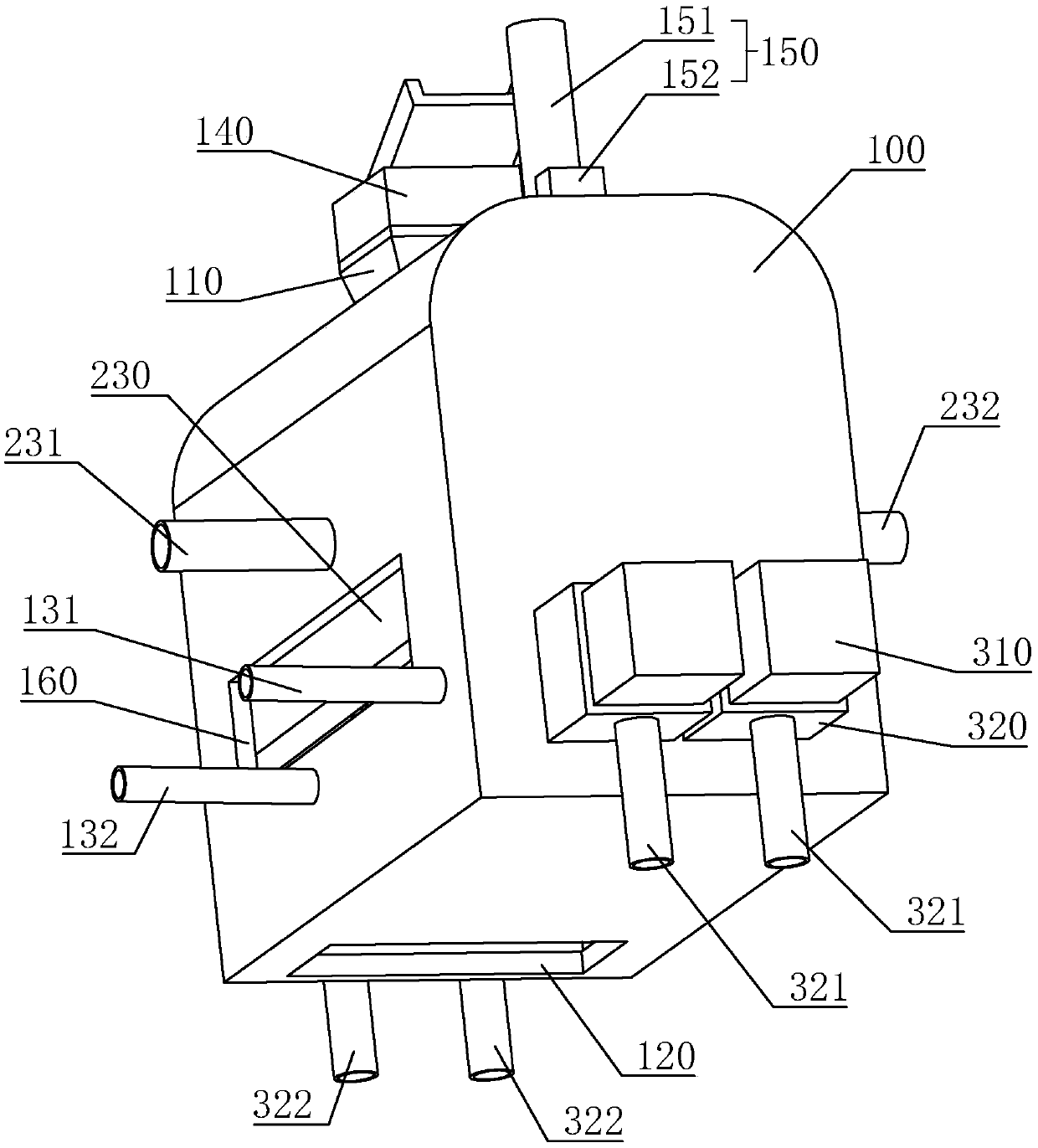

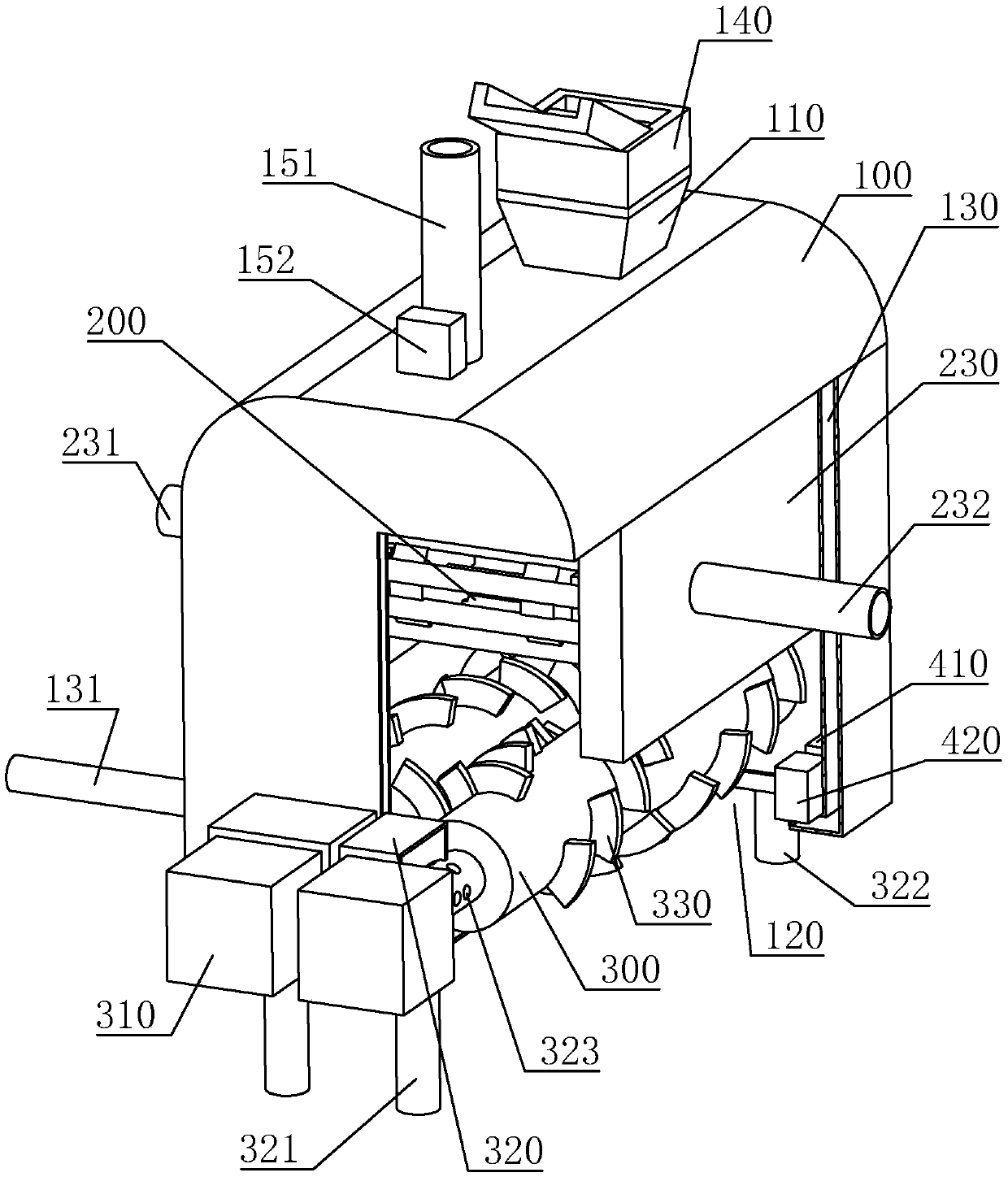

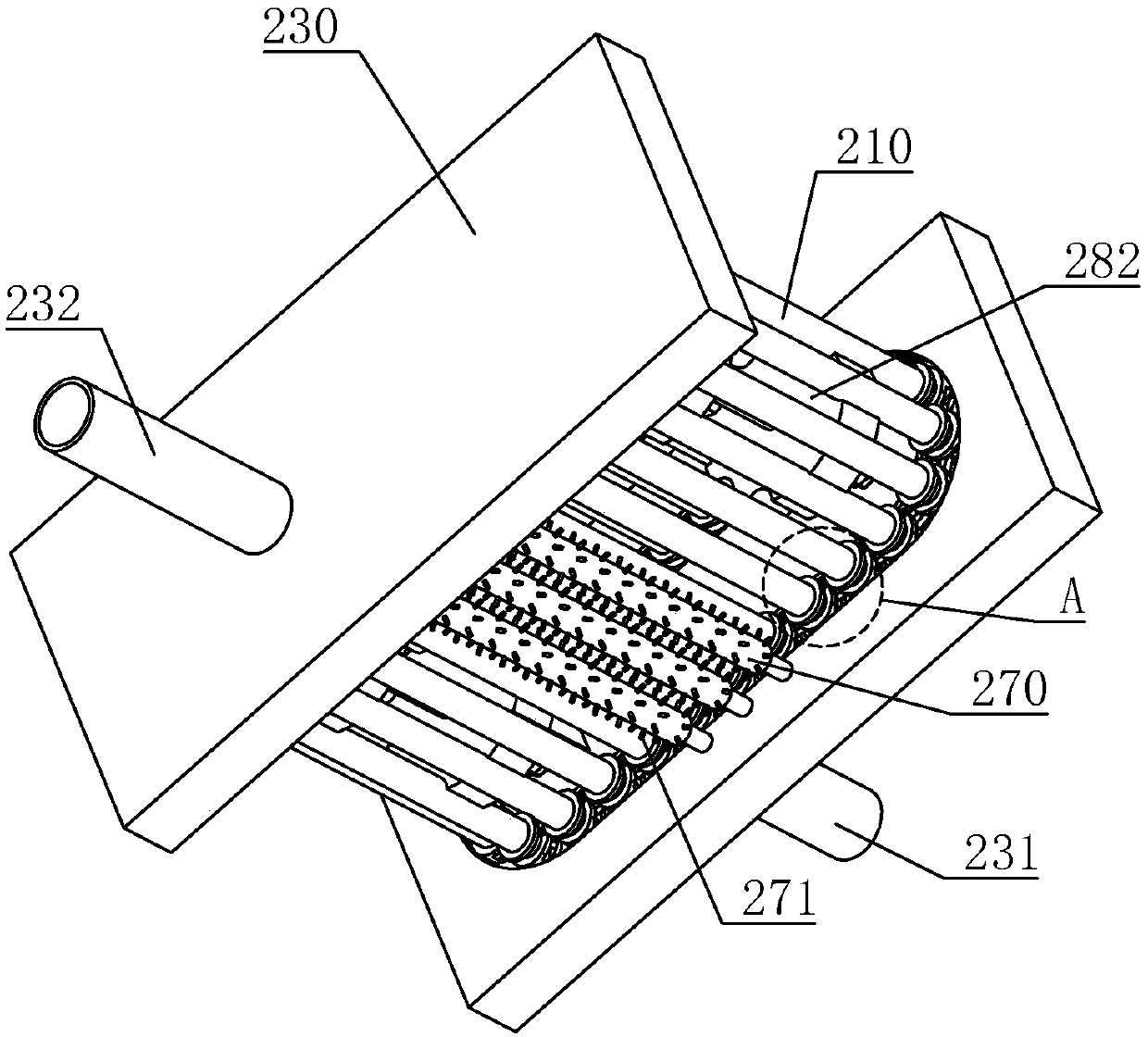

[0041] A sludge reduction device, referring to figure 1 , figure 2 , including a housing 100, a feed inlet 110 located on the upper side of the housing 100, and a discharge outlet 120 located on the lower side of the housing 100, the side wall of the housing 100 is a hollow structure, and the inside of the side wall of the housing 100 is formed cavity 130 , and a third inlet pipe 131 and a third outlet pipe 132 are installed on the casing 100 . Heat-insulating glass observation windows 160 are installed on both sides of the casing 100, and heat-insulating glass is installed inside it. An extruder 140 for extruding sludge is installed at the feed inlet 110, and an air extraction structure 150 is arranged on the top wall of the housing 100. The air extraction structure 150 includes an air extraction pipe 151 and an air exhaust fan 152, 151 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com