Patents

Literature

66results about How to "Guaranteed evaporation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

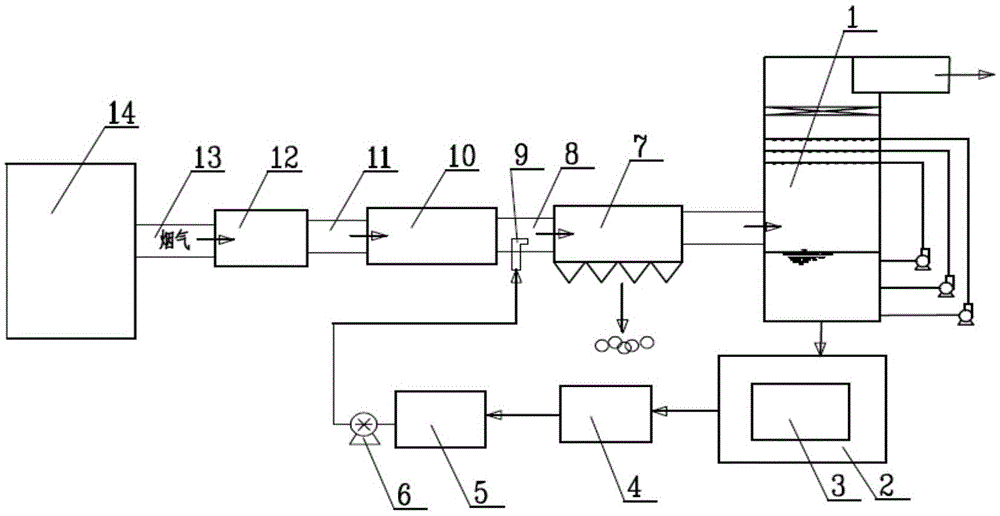

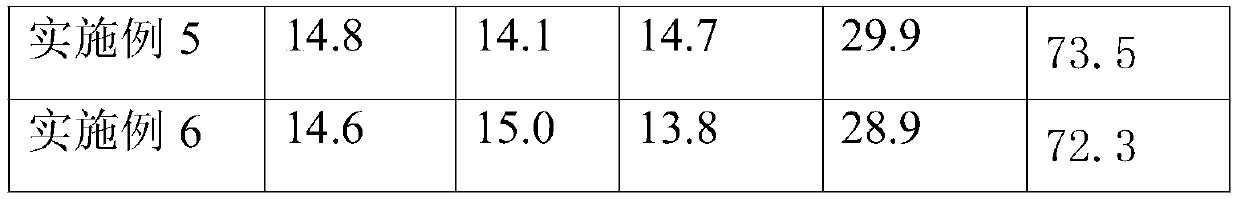

Method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in evaporation manner and device of method

InactiveCN102380278ALow running costConvenient sourceCombination devicesWater/sewage treatmentAir preheaterFlue gas

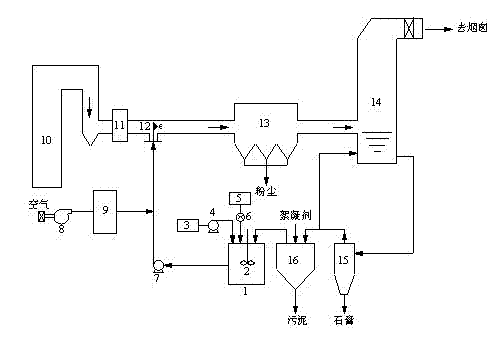

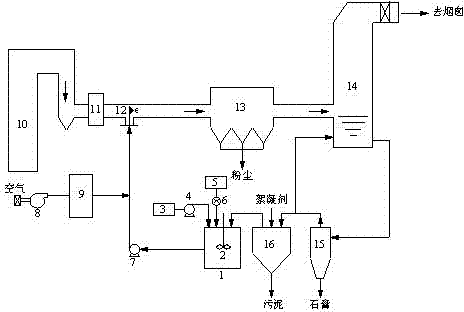

The invention discloses a method for cooperatively promoting agglomeration growth of PM (particulate matter) 2.5 and treating desulfuration wastewater in an evaporation manner and a device of the method. The method particularly includes steps that agglomeration liquor prepared by desulfuration wastewater, high polymer adhesive and wetting agent is sprayed into an inlet flue of an electric precipitator and is evaporated by the aid of heat of flue gas, in an evaporation process, the wetting agent promotes dust to enter drops of the agglomeration liquor, the high polymer adhesive is connected with PM2.5 via a polymer chain with polar groups, the grain diameter of the PM2.5 is prompted to be enlarged, so that the PM2.5 can be gathered by the follow-up electric precipitator, the desulfuration wastewater is evaporated completely, suspended matters and dissolvable pollutants in the wastewater are converted into solid to be dissolved out, and the suspended matters and the dissolvable pollutants in the wastewater, together with dust in the flue gas, are gathered by the electric precipitator. The device consists of a boiler, an air preheater, the electric precipitator, a desulfurizing tower, a hydraulic cyclone, a desulfuration wastewater clarification tank and an agglomeration liquor preparation tank, and a double-fluid atomizing nozzle is arranged in the flue between the air preheater and the electric precipitator.

Owner:SOUTHEAST UNIV

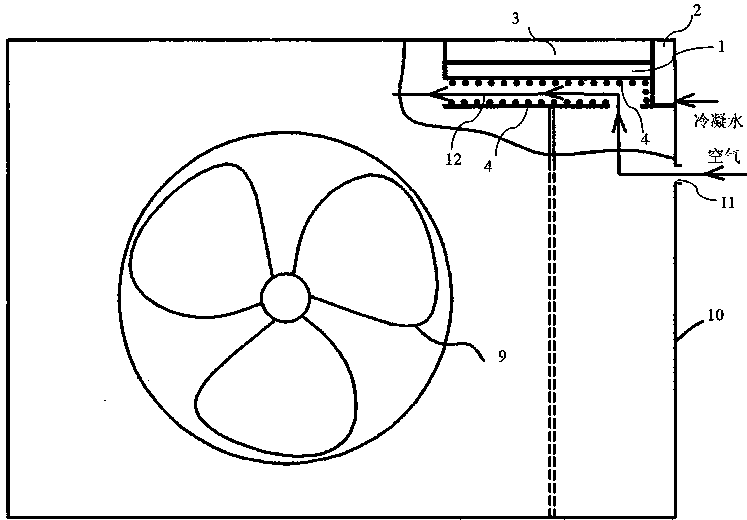

Air-conditioning condensate water utilization device

InactiveCN103542467AMeet thermal requirementsEnhance and guarantee evaporation capacityLighting and heating apparatusAir conditioning systemsCooling effectEvaporation

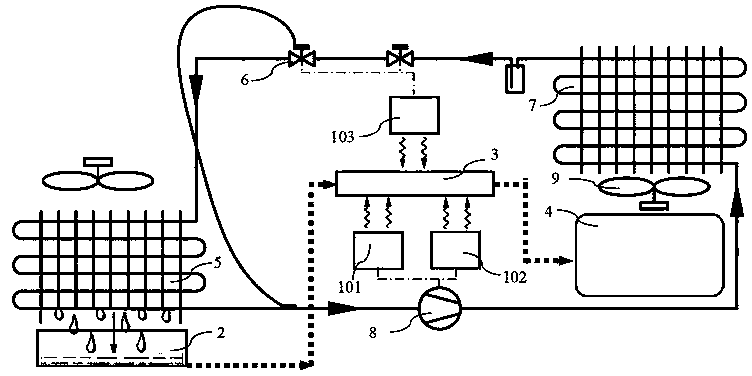

The invention provides an air-conditioning condensate water utilization device for cooling of an electronic control system of an outdoor unit. The device comprises an electric control box, a condensate water compensation container, a cooling unit and a water evaporation unit. Air conditioning condensate water flows from a water outlet pipe of a water collecting disc on the lower portion of an evaporator to a condensate water compensation container and then flows into the cooling unit after buffering and compensation, heat in the electric control box is taken away by a heating element of the cooling unit, and the condensate water flows to the water evaporation unit finally to be evaporated on the surface of an evaporation core. According to the device, the cooling capacity of an air conditioning is used, so that energy is saved; the condensate water is evaporated instead of being discharged, so that adverse effects are eliminated; self-driving of condensate water supply is achieved through the suction action of a capillary core of the cooling unit and the evaporation action of the water evaporation unit; the device has the advantages of being good in cooling effect, long in service life, low in maintenance cost, capable of achieving energy saving and emission reduction of the air conditioning and the like.

Owner:QINGDAO UNIV

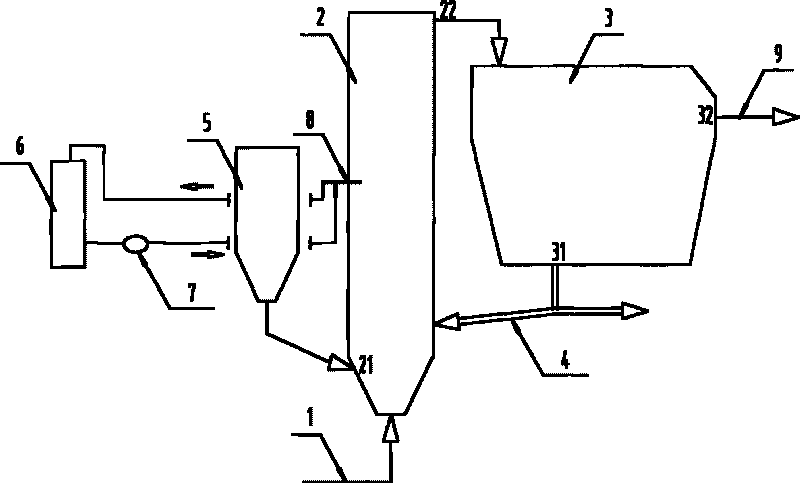

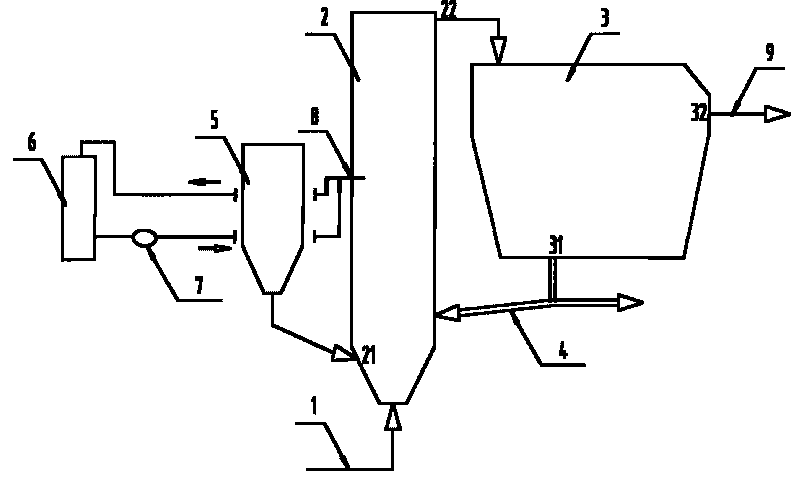

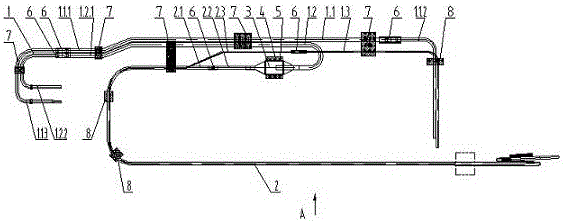

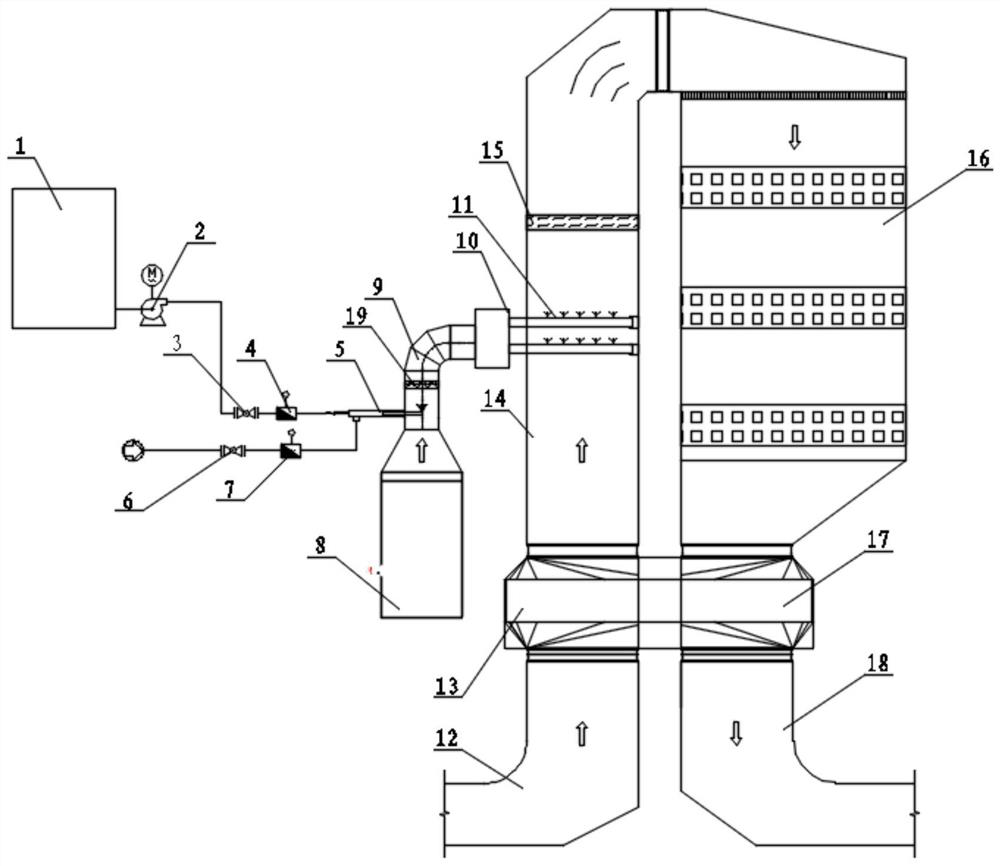

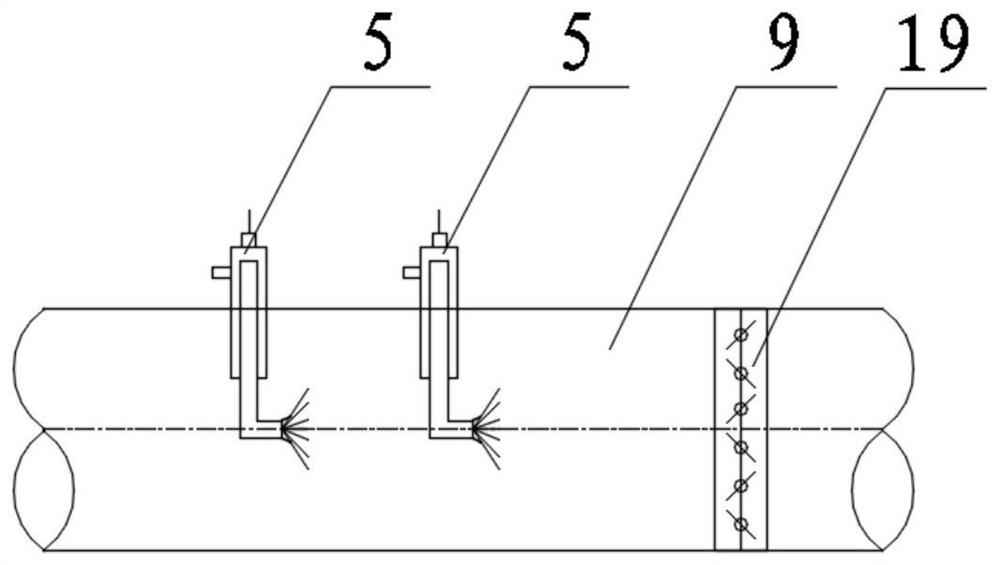

Dry-method fume gas purification method and device for synchronous desulfurization and denitrification

ActiveCN101695627AGuaranteed evaporationEnhanced mass transferDispersed particle separationPurification methodsEngineering

The invention relates to fume purification and provides dry-method fume purification method and device for synchronous desulfurization and denitrification. The purification device is provided with an inlet flue, an absorption tower, a dust collector, a material circulating air chute, an absorbent cabin, a water box, a water pump, an atomization spray gun and an outlet flue. In the invention, an additive water solution is stored in a process water box; a primary fume enters the absorption tower through the inlet flue, mixes with an absorbent added form the absorbent cabin and cycled materials returned from the material circulating air chute, and then performs cooling and moistening reaction with the additive water solution pumped by the high-pressure pump from the water box to the atomization spray gun and sprayed by the atomization spray gun to the absorption tower; the outlet fume of the absorption tower enters the dust collector, incompletely reacted materials in the fume are collected, and the major part of the fume enters a circulating fluidize bed absorption tower with the absorbent added in the absorbent cabin through the material circulating air chute to continue the reaction; circulation continues in the same way; and the fume purification is then achieved when the cleaned fume is exhausted from a chimney from the dust collector through the outlet flue.

Owner:FUJIAN LONGKING DSDN ENGINEERING CO LTD

System and method for treating high salinity wastewater

ActiveCN105417817AEconomical and efficient processingAchieving zero emissionsWater contaminantsWaste water treatment from gaseous effluentsBoiling pointSalt water

The invention discloses a treatment system and evaporating treatment method for high salinity wastewater. The treatment system comprises a desulfurization waste water conventional treatment device, a high-salinity water concentration device, a concentrated high-salinity water storage pool and an atomizer which are connected in sequence. The treatment system further comprises a high-salinity water boiling point reducing device which is arranged at any appropriate position in front of the concentrated high-salinity water storage pool. The water spraying amount of concentrated high-salinity water sprayed out of the atomizer can be adjusted. The treatment method comprises the steps that 1, after desulfurization waste water is subjected to conventional treatment, upper-layer clear water, namely, high-salinity water is collected, the high-salinity water is concentrated to be reduced, and concentrated high-salinity water is formed and stored in the concentrated high-salinity water storage pool; 2, the concentrated high-salinity water in the concentrated high-salinity water storage pool is sprayed into a flue between a hearth and a dust remover and / or the hearth through the atomizer and subjected to atomization and evaporation, and crystal substances are mixed into coal ash to be removed together, wherein the water spray amount of the concentrated high-salinity water sprayed into the flue between the hearth and the dust remover and / or the hearth is adjusted according to flue gas temperature.

Owner:高境 +1

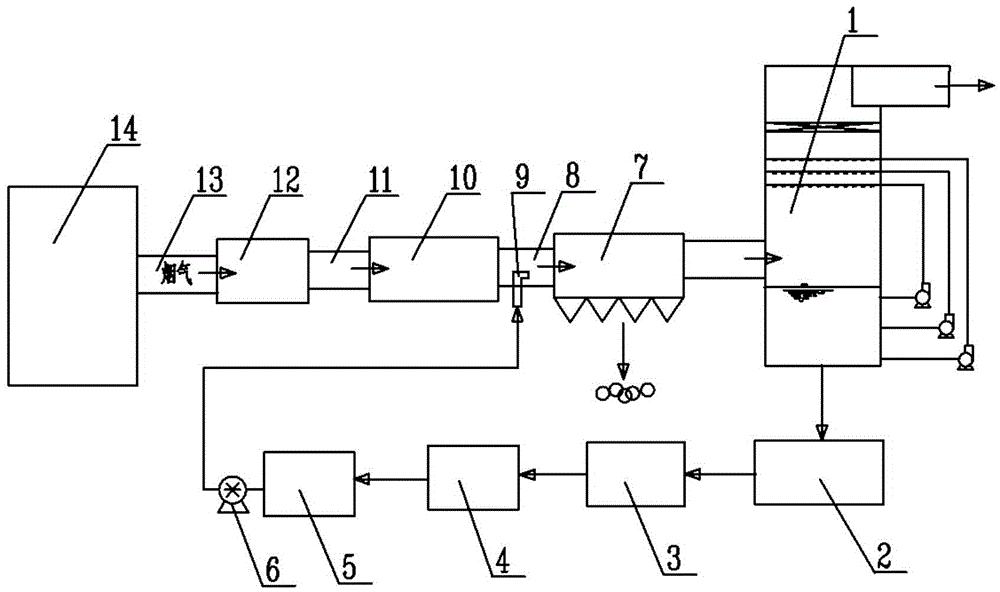

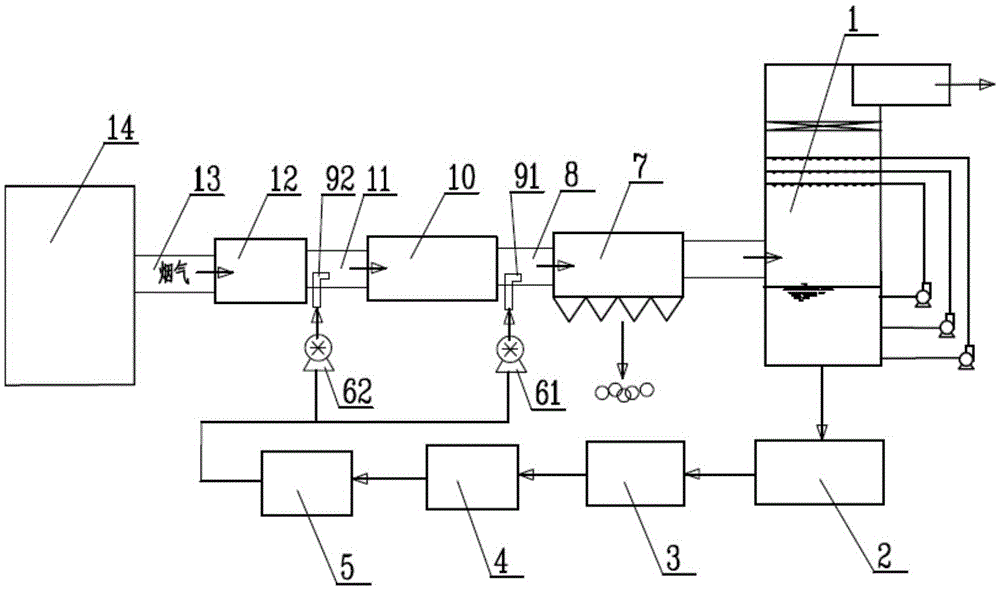

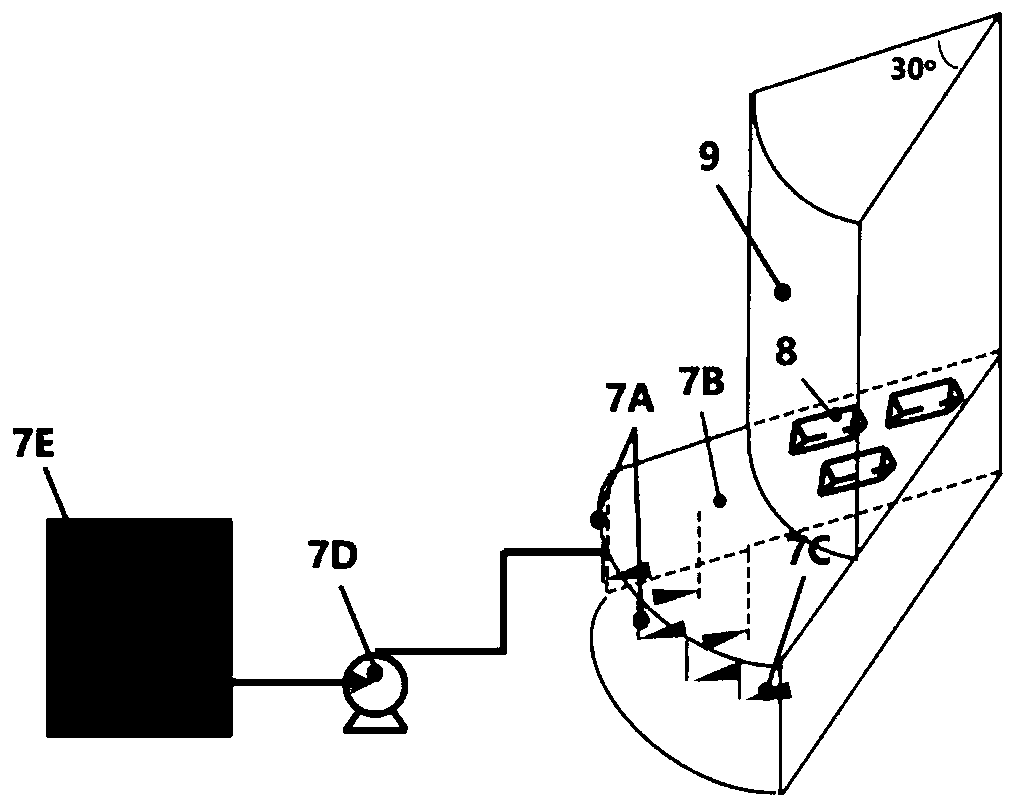

Desulfurized wastewater spray evaporation treatment device with bypath system

PendingCN106115829APrecise control of spray volumeAchieving zero emissionsWater/sewage treatmentWaste water treatment from gaseous effluentsAir preheaterEvaporation

The invention provides a desulfurized wastewater spray evaporation treatment device with a bypath system and relates to zero-emission treatment of desulfurized wastewater of a thermal power plant. The desulfurized wastewater spray evaporation treatment device is provided with a bypath flue subsystem, a desulfurized wastewater spray evaporation subsystem and a control unit; the bypath flue subsystem is provided with a bypath flue, a bypath flue regulating valve and a high-temperature flue gas nozzle; the desulfurized wastewater spray evaporation subsystem is provided with a spraying device, a desulfurized wastewater pipeline regulating valve and a water pump; the control unit is provided with a control processor, a bypath flue electric executing mechanism, a desulfurized wastewater pipeline electric executing mechanism, a bypath flue flow transmitter, a bypath flue temperature transmitter, an air pre-heater outlet flue flow transmitter, an air pre-heater outlet flue temperature transmitter, a desulfurized wastewater pipeline flow transmitter and a desulfurized wastewater pipeline temperature transmitter. The desulfurized wastewater spray evaporation treatment device has a relatively good effect of heat exchange on desulfurized wastewater, is safer and more reliable and saves more power; the desulfurized wastewater spray evaporation treatment device has no nitrogen oxide standard-exceeding risks, a simple structure and no heat exchange loss and partial resistance. Power units including a draught fan and the like do not need to be additionally arranged so that the cost is low.

Owner:福建龙净环保智能输送工程有限公司

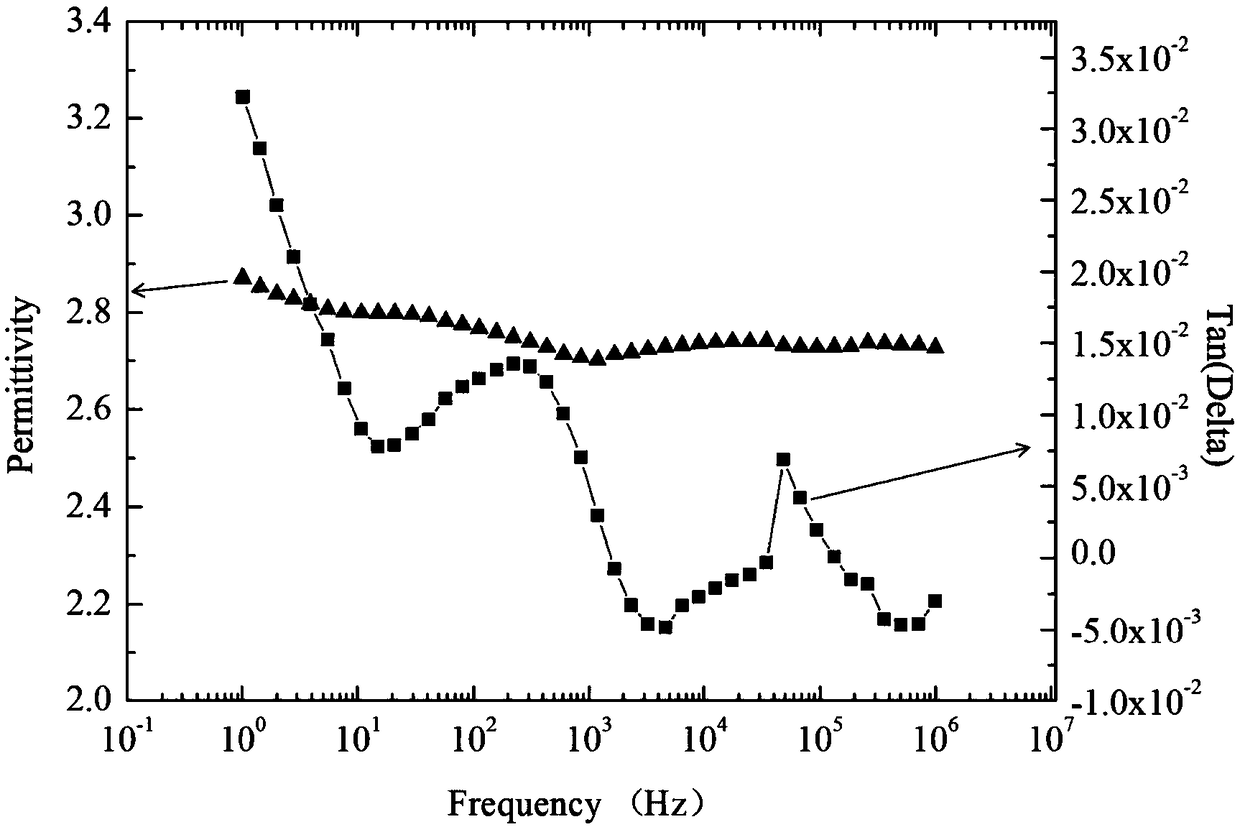

Preparation method of glass fiber reinforced quartz ceramic

The invention discloses a preparation method of a glass fiber reinforced quartz ceramic. According to the preparation method, quartz powder with different particle diameters is uniformly mixed with glass fibers according to different proportions at first so as to obtain A; an appropriate amount of polyvinyl alcohol and water are added to A for granulation; glass fibers or woven fiber cloth is placed in a cavity of a molding die, and the gap is filled by the powder after the granulation; after completion, mixing and pressing are carried out to prepare a quartz ceramic body; and the quartz ceramic body is dried and then sintered at a high temperature to prepare the glass fiber reinforced quartz ceramic. The prepared glass fiber reinforced quartz ceramic has a relatively low dielectric constant and can be adjusted in a small range; and silicon sol is solidified by sintering after immersion, so that the strength of the glass fiber reinforced quartz ceramic is ensured.

Owner:江苏泰芯源科技有限公司

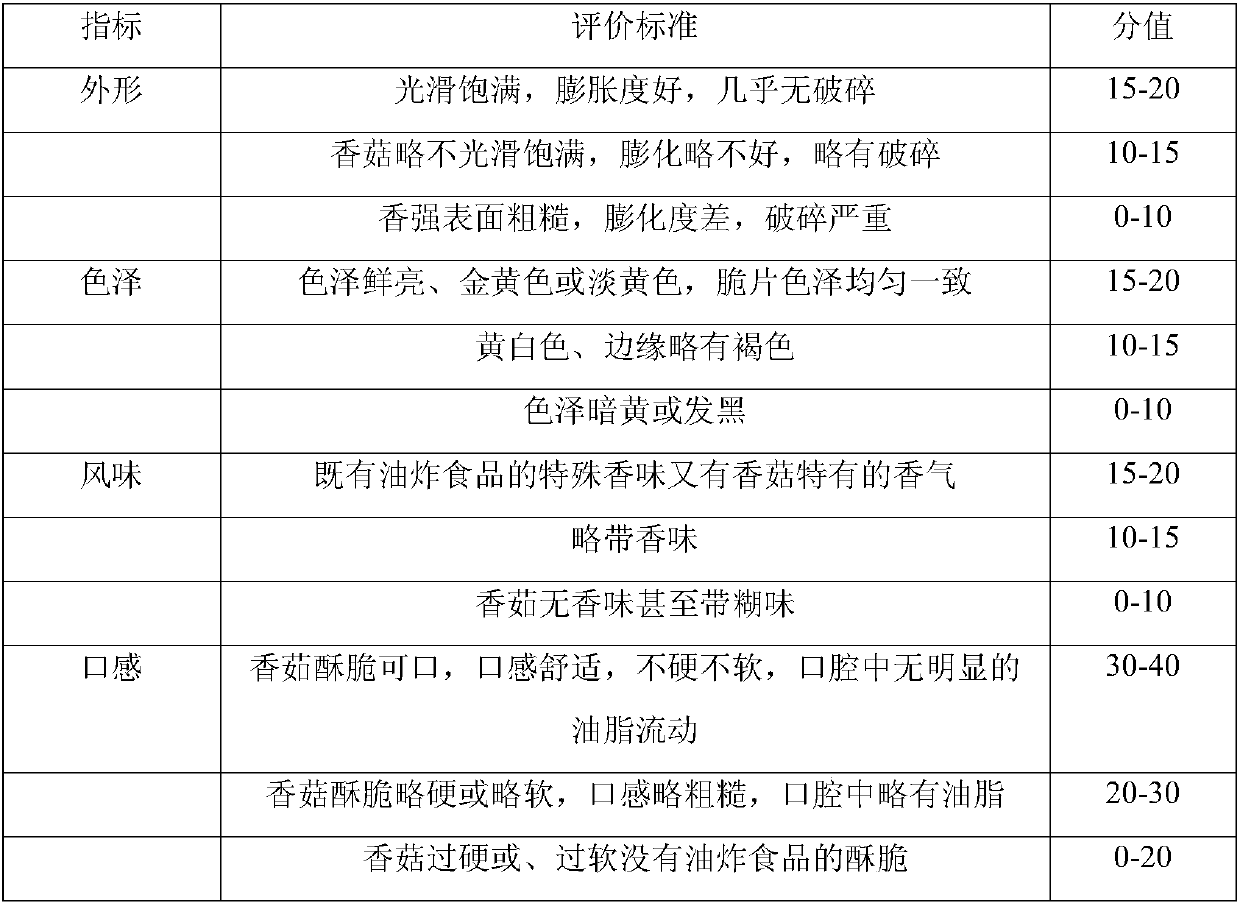

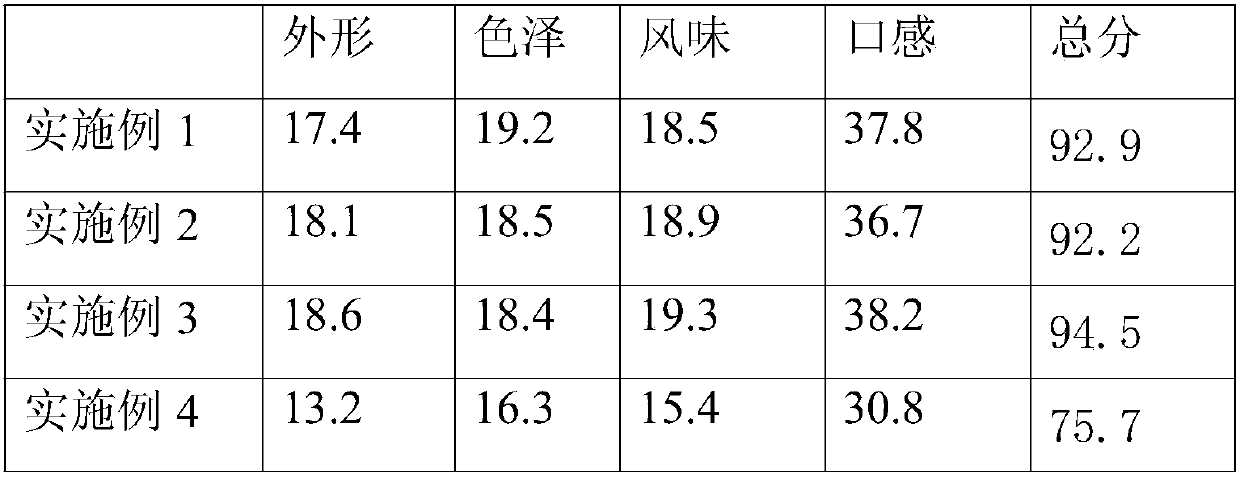

Processing method of shiitake mushroom crispy chips

InactiveCN107751981AIncrease the fragranceInhibitory activityFood ingredient functionsFlavorShiitake mushrooms

The invention belongs to the technical field of food processing and in particular relates to a processing method of shiitake mushroom crispy chips. The processing method comprises the following steps:preparing materials, protecting color, curing, immersing, quickly freezing, carrying out oil frying in vacuum and removing oil. According to the shiitake mushroom crispy chips prepared by the processing method, a color protection technology and hot soup are matched with spices with a certain ratio to prepare the shiitake mushroom crispy chips, the brittleness reaches 3400g, the moisture content is low and is only 1.3 percent and the oil content is 23.5 percent, so that the crispiness of the shiitake mushroom crispy chips is extremely ensured; the shiitake mushroom crispy chips have a smooth and full appearance, good expansion degree, are hardly broken, have bright color and luster and are golden yellow or light yellow; the crispy chips have uniform and consistent color and luster, have aspecial flavor of oil-fried foods and also have a special aroma of shiitake mushrooms; and the shiitake mushrooms are crispy and palatable, have a comfortable mouthfeel and are neither hard nor soft,and no obvious oil flows in an oral cavity.

Owner:贵州省印江自治县梵净山生态菌业有限公司

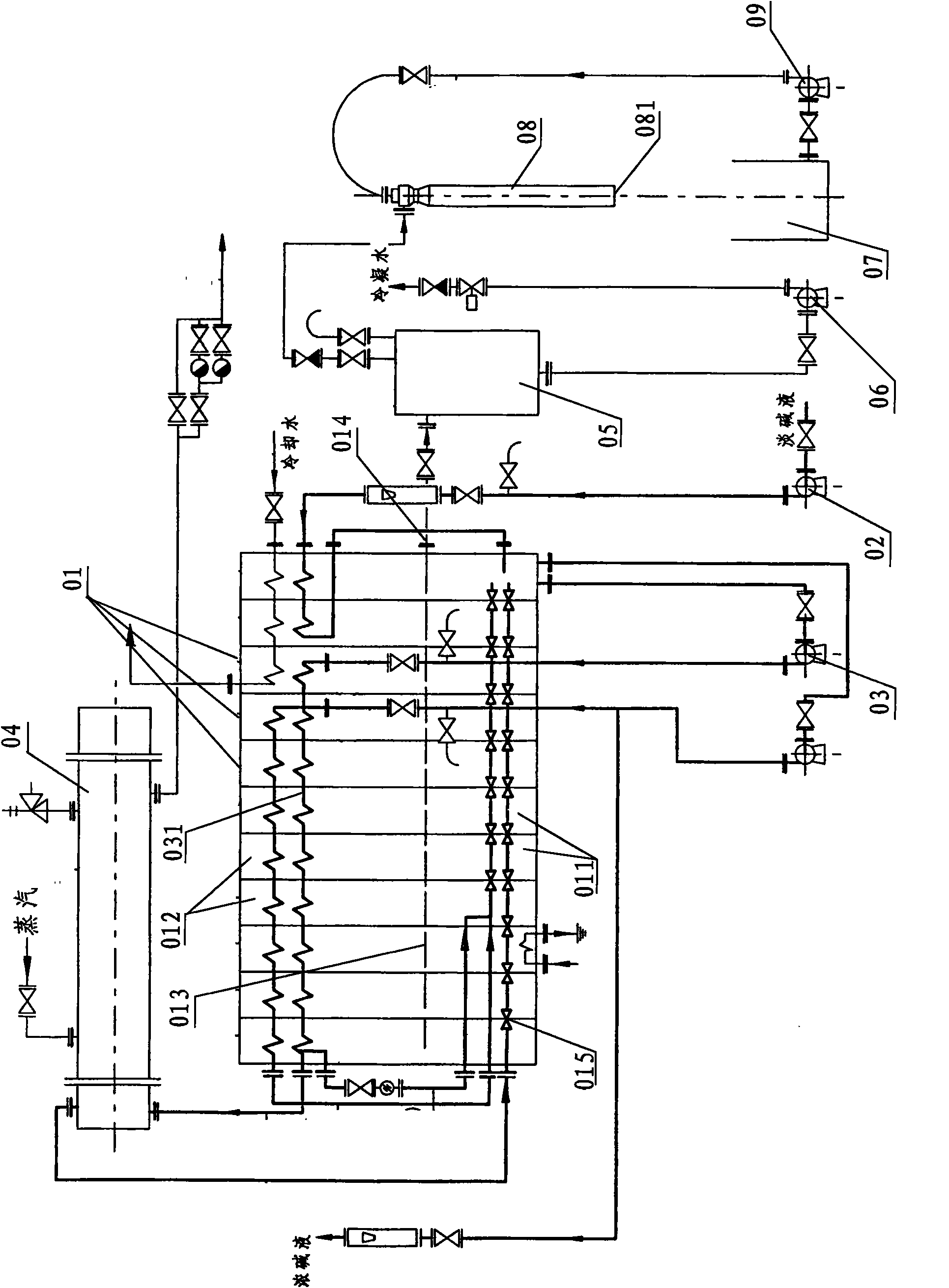

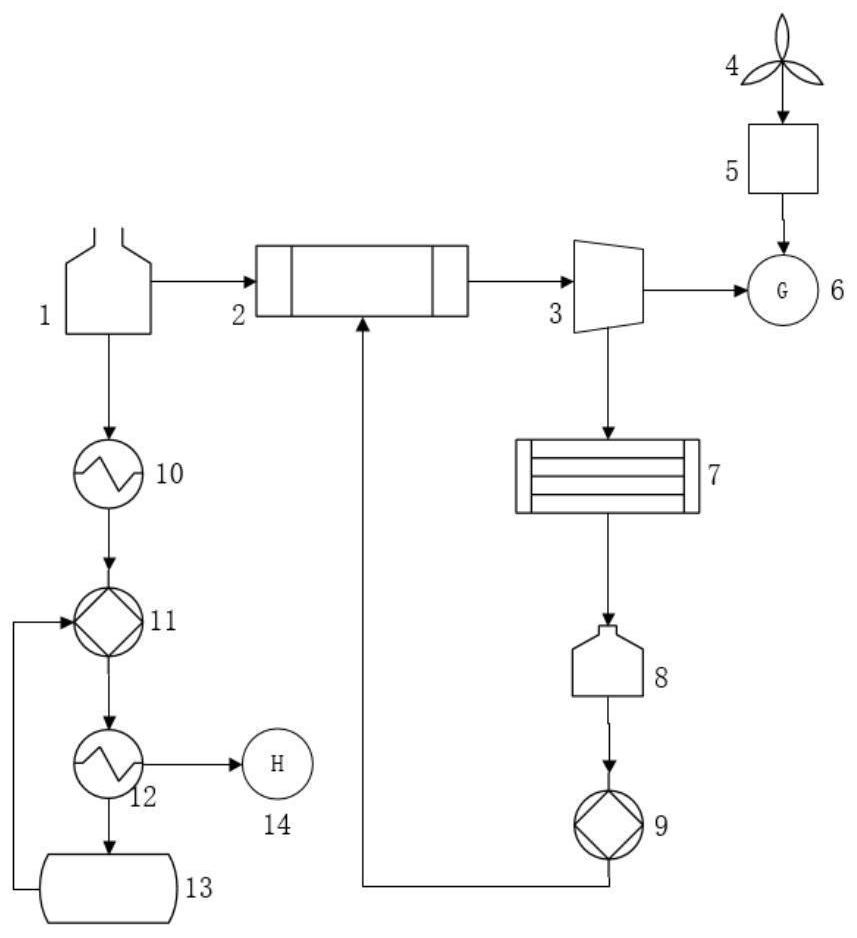

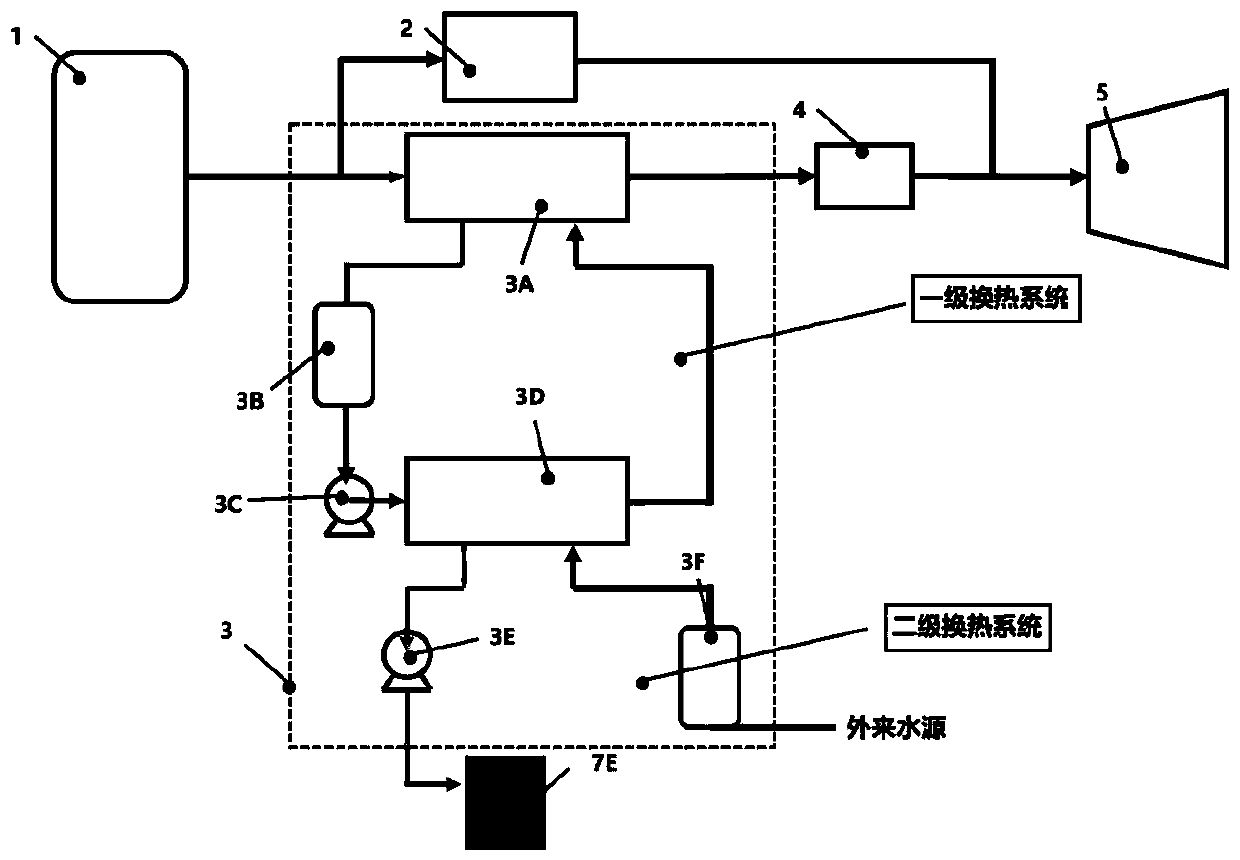

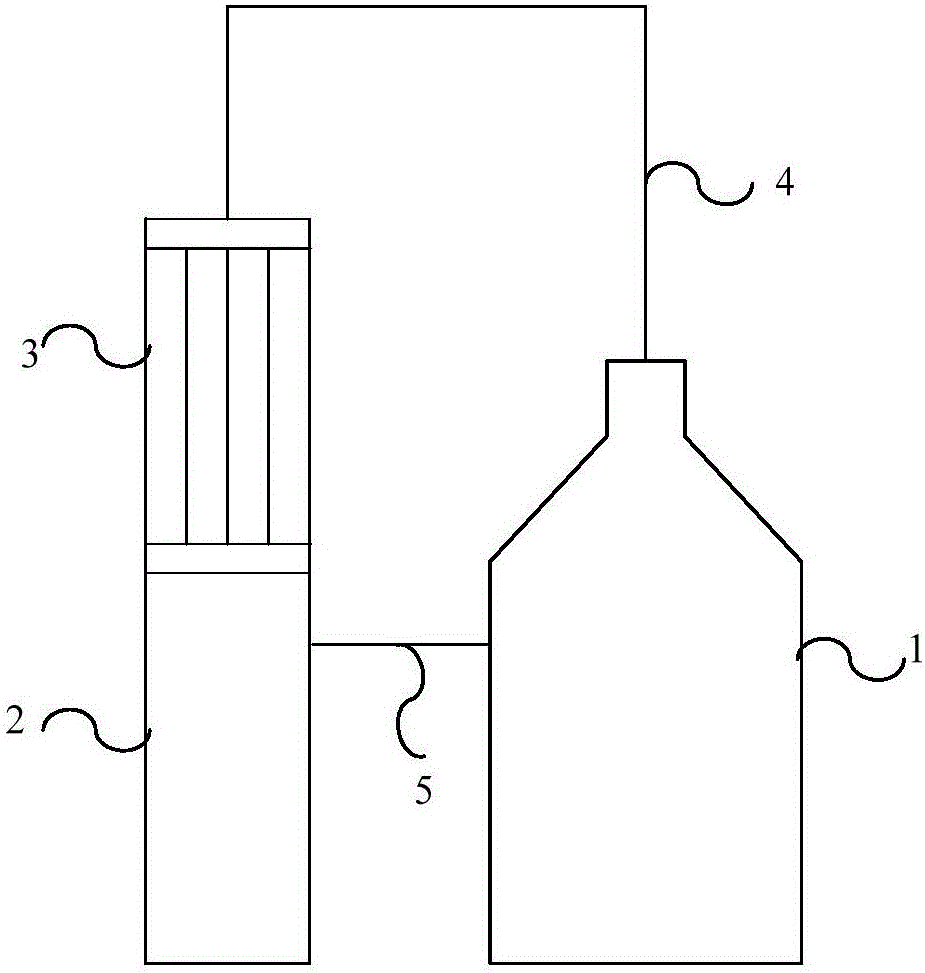

Desulfurization wastewater zero discharge treatment system and desulfurization wastewater zero discharge treatment process

PendingCN109231330AAchieving zero emissionsRealize cascade utilizationWater/sewage treatmentWaste water treatment from gaseous effluentsEvaporationEngineering

The invention relates to a desulfurization wastewater zero discharge treatment system and a desulfurization wastewater zero discharge treatment process, aiming at solving the technical problems that the existing desulfurization wastewater zero discharge treatment system and desulfurization wastewater zero discharge treatment process are long in process flow, high in investment cost and high in operation and maintenance costs, and cause flue corrosion and safety hazards due to the use of a flue evaporation technology. The system provided by the invention comprises a boiler tail flue system, anda pretreatment system, a concentration reduction system and a high-efficiency tail liquid treatment system which are sequentially connected, wherein the pretreatment system is used for removing calcium and magnesium hardness and solid suspended matters in the desulfurization wastewater; the concentration reduction system is used for carrying out concentration reduction on the pretreated desulfurization wastewater; the high-efficiency tail liquid treatment system is used for carrying out atomization evaporation of the concentrated tail liquid; the system and the method, which are provided by the invention, realize the zero discharge of the desulfurization wastewater by means of the pretreatment system, the concentration reduction system and the tail liquid treatment system which are sequentially connected; the waste heat of the flue gas at the tail of a boiler is utilized to realize the cascade utilization of energy in the treatment process; the system and the process have the advantages of high efficiency and energy conservation.

Owner:山西华仁通电力科技股份有限公司

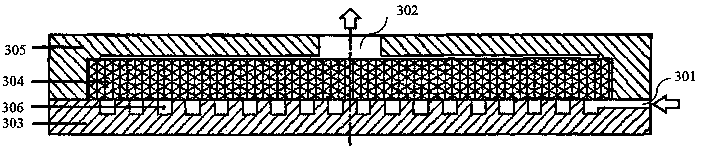

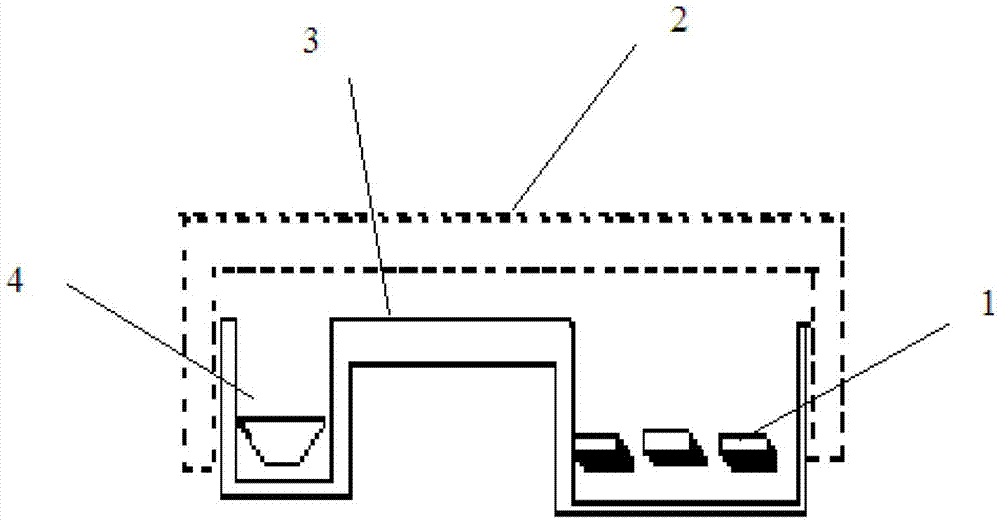

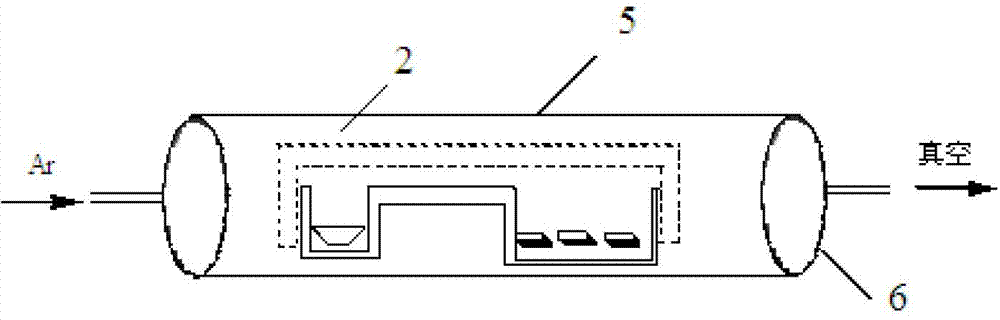

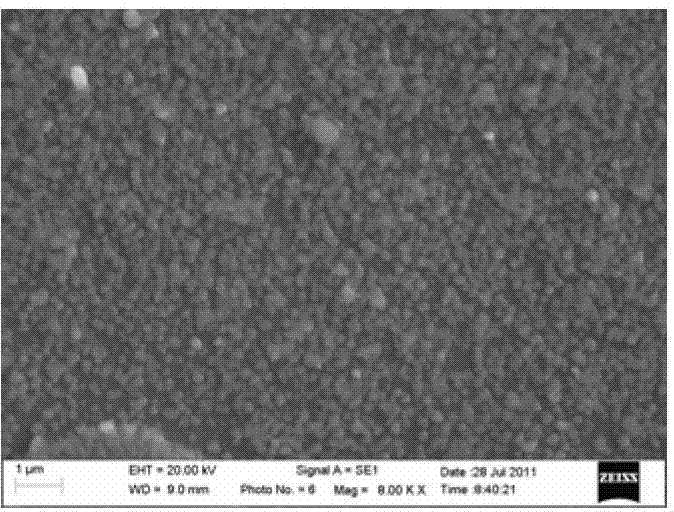

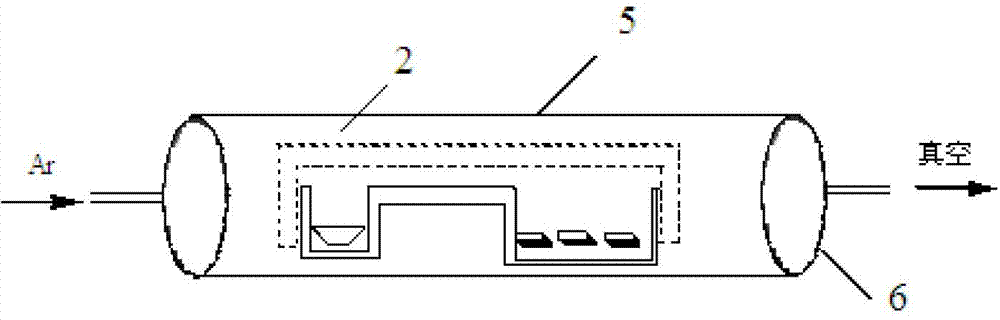

Apparatus and method for carrying out selenylation treatment on CIGS (copper indium gallium selenide) thin films and CIGS thin-film device

InactiveCN103088301AReduce leakageHigh Selenization EfficiencyVacuum evaporation coatingSputtering coatingIndiumThermal insulation

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

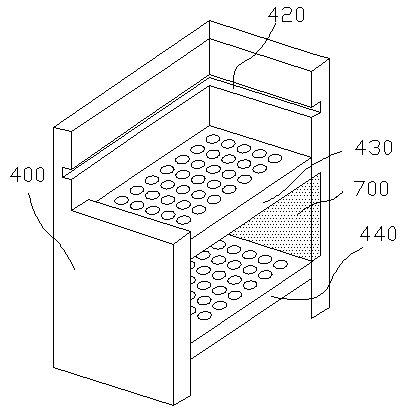

Volume-expanding evaporator

InactiveCN101613132AImprove utilization efficiencyGuaranteed evaporationWater/sewage treatment by heatingHigh energyWastewater

The invention relates to a device for sharing water from solution, in particular to a volume-expanding evaporator used in the processes of fresh water production, solution concentration, wastewater comprehensive treatment and the like. The volume-expanding evaporator comprises a multilevel evaporative condensing unit, wherein the lower part of the evaporative condensing unit is provided with an evaporating chamber, the upper part of the evaporative condensing unit is provided with a condensing chamber, and the bottom of the condensing chamber is provided with a condensation water tank; the outer part of the evaporative condensing unit is provided with a liquid feed pump, and a liquid outlet pipe of the liquid feed pump leads into the evaporating chamber of a first-level evaporative condensing unit; the evaporating chamber of the first-level evaporative condensing unit is provided with a solution outlet leading to a first circulating pump, the liquid outlet pipe of the first circulating pump passes through the condensing chambers of part or all of the evaporative condensing units and then enters a heating device, and the liquid outlet pipe of the heating device leads to the evaporating chamber of the last-level evaporative condensing unit; and the first-level evaporative condensing unit is communicated with the outside negative pressure environment. The volume-expanding evaporator has the advantages of reasonable structure, high energy utilization rate, and good evaporation and condensation effects.

Owner:镇江正宏纺织机械有限公司

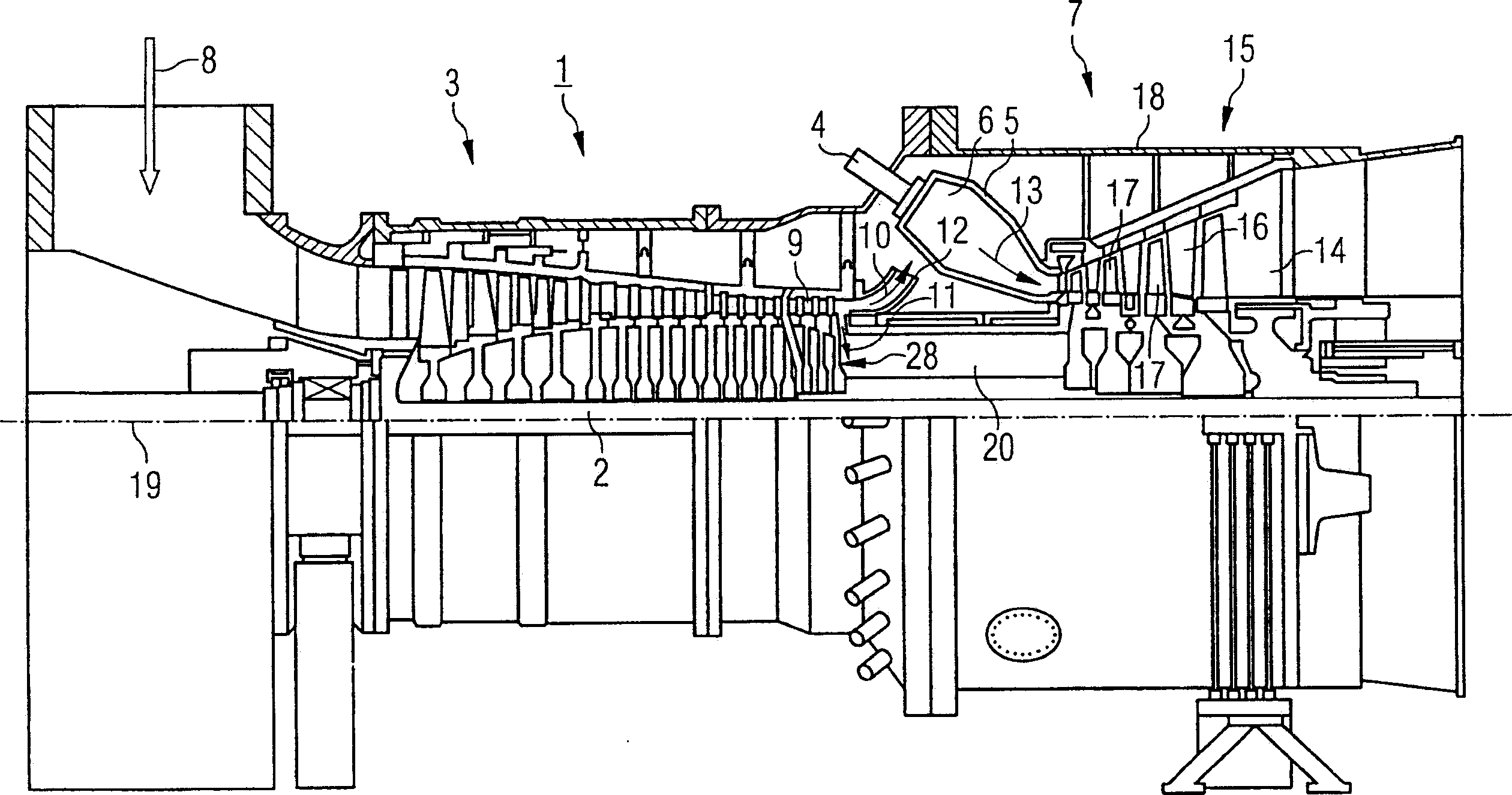

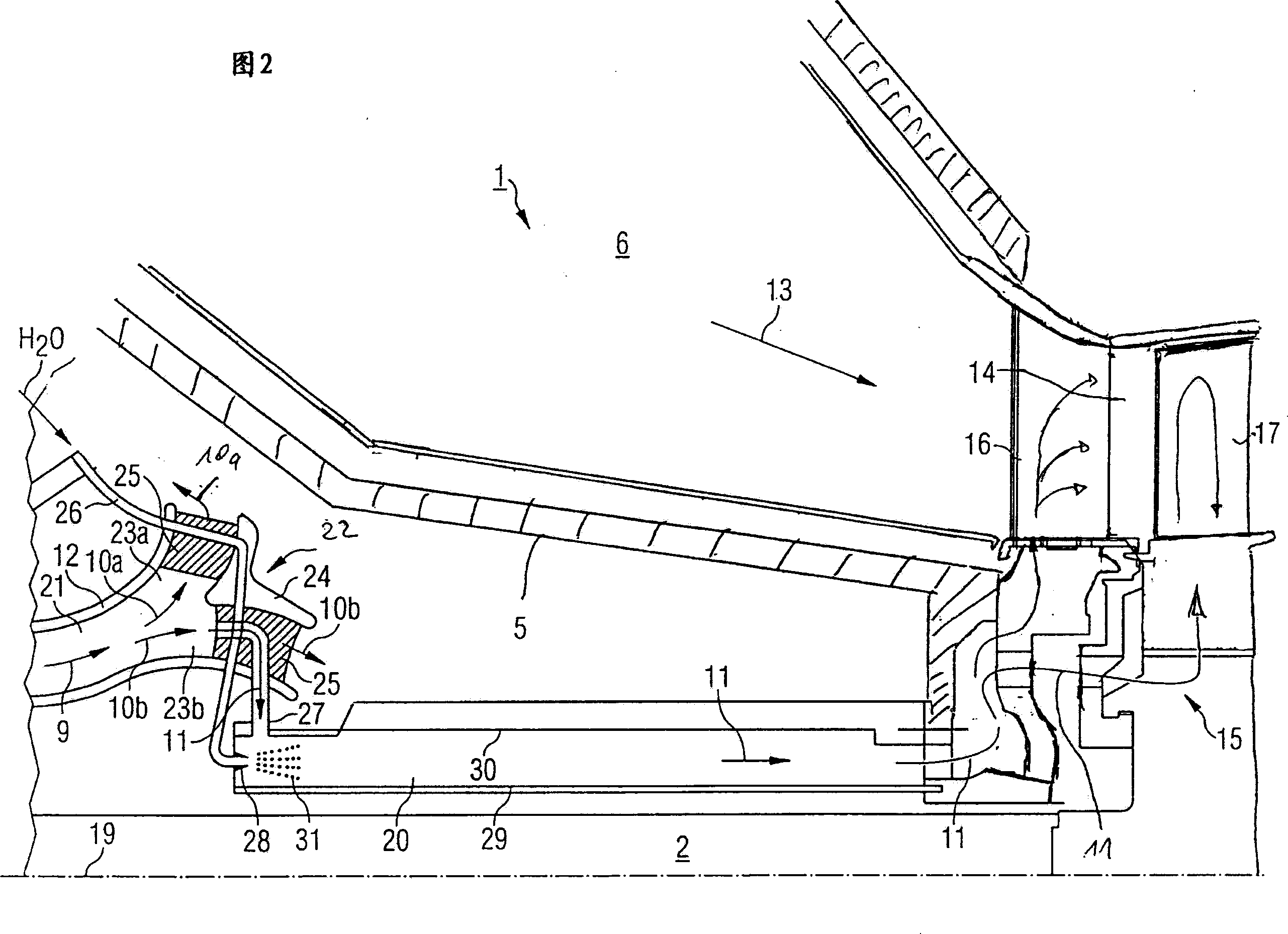

Turbine

InactiveCN1499042APrevent wettingImprove efficiencyContinuous combustion chamberEngine fuctionsCombustion chamberEngineering

Turbine comprises a rotatably mounted rotational-symmetrical rotor (2) having rotating blades (17) on its outer periphery toward which a working medium is directed, a cooling fluid produced by a compressor for cooling the guide blades (16) interacting with the rotating blades, and a channel connected to the rotor for cooling fluid. The cooling fluid in the channel is cooled by evaporating a liquid. An Independent claim is also included for a gas turbine (1) comprising the above turbine. Preferred Features: The channel runs along the rotor and is connected to the rotor so that the rotor is also cooled by the cooling fluid. The channel is an annular channel (20) formed coaxially to the rotor and having an inner side formed by the rotor surface.

Owner:SIEMENS AG

Constant-humidity air conditioner

ActiveCN103353144AEfficient take awayConstant humidityCondensate preventionLighting and heating apparatusImpellerEngineering

The invention provides a constant-humidity air conditioner comprising a condenser, an evaporator, an air duct, an impeller and an atomizer, wherein the evaporator is provided with a water pan for collecting condensed water; the evaporator and the air duct are arranged at two sides of the impeller; the atomizer is arranged in the air duct and is communicated with the bottom of the water pan through a heat exchange pipe with a pump body; the middle of the heat exchange pipe is thermally connected with the liquid inlet end of the condenser. Through raising the temperature of water in the atomizer, the humidifying effect of the atomizer is remarkable.

Owner:NINGXIA DONGWU AGROCHEM

Method for circularly reutilizing flashing secondary steam of acid bath system

InactiveCN109173311ANo consumptionReduce water consumption costsEnergy recuperation in distillationFlash distillationPlate heat exchangerCooling tower

The invention relates to a method for circularly reutilizing flashing secondary steam of an acid bath system. The method comprises the following steps: (1) respectively introducing secondary steam ofa flashing evaporation chamber V11 of the acid bath system in a viscose production system into a first-stage heat exchanger, secondary steam of an evaporation chamber V10 into a second-stage heat exchanger and secondary steam of an evaporation chamber V9 into a third-stage heat exchanger, so as to respectively generate heat exchange with circulating water in each heat exchanger; and (2) condensingthe secondary steam through heat exchangers, collecting condensed water for reuse, vacuumizing non-condensable gas in the secondary steam for reuse, introducing heater circulating water in the heat exchangers into a closed cooling tower, and cooling for reuse. According to the method, the volatilization of the peculiar smell of an acid bath evaporation system in the viscose industry is fundamentally solved, and meanwhile, the closed cooling tower adopting a special structure and technical principle can meet the requirement on the temperature of cooling water in a workshop and can stable workfor a long time, so that the water and the energy can be saved, the emission can be reduced, and the service life of process device is prolonged.

Owner:唐山三友远达纤维有限公司

Energy-saving and environmental-protecting type air suction tube assembly of split type refrigeration evaporator

InactiveCN106016844AIncrease contact areaReduce the temperatureMechanical apparatusDomestic refrigeratorsEngineeringRefrigeration

The invention discloses an energy-saving and environmental-protecting type air suction tube assembly of a split type refrigeration evaporator. The energy-saving and environmental-protecting type air suction tube assembly comprises an air suction tube part, an air return tube part and a liquid accumulating device. The air suction tube part comprises an air suction tube I, an air suction tube II and a transitional tube. The air suction tube I comprises an aluminum connecting tube I, a copper connector I and a copper connector II, wherein the copper connector I and the copper connector II are fixedly connected with the two ends of the aluminum connecting tube I in a sealed mode correspondingly. The air suction tube II comprises an aluminum connecting tube II and a copper connection III which is fixedly connected with one end of the aluminum connecting tube II in a sealed mode. The other end of the aluminum connecting tube II is connected with the liquid accumulating device. The air return tube part comprises a tube body, a copper tube and a capillary tube, wherein the copper tube is fixedly connected with one end of the tube body in a sealed mode and inserted into the other end of the liquid accumulating device in a sealed connection mode. One end of the capillary tube is fixedly connected with the transitional tube in the air suction tube part. The capillary tube is attached to the whole outer wall of the tube body of the air return tube part in the length direction. At one end of the tube body of the air return tube part, the capillary tube is wound on the tube body of the air return tube part. The energy-saving and environmental-protecting type air suction tube assembly of the split type refrigeration evaporator is high in shakeproof capacity, high in heat exchange efficiency, obvious in energy saving effect and capable of effectively improving the efficiency of a compressor of a refrigerator.

Owner:陈红玲

Rosa roxburghii tratt freeze-drying granule preparation method

InactiveCN107535787AReduce moistureImprove antioxidant capacityFood preservationFreeze-dryingBULK ACTIVE INGREDIENT

The invention discloses a preparation method of roxburghii freeze-dried granules, which belongs to the field of biological products. Rosa roxburghii raw juice is concentrated after pretreatment, and then subjected to a vacuum freeze-drying process to obtain the roxburghii lyophilized granules; wherein, the The concentration is vacuum concentration, and the concentration temperature is not higher than 25°C. The roxburghii freeze-dried granules obtained by the invention have less loss of active ingredients such as SOD, and the finished product has excellent quality, rich nutrition, long storage time, and is convenient for transportation and use.

Owner:今凯涟医疗科技(上海)有限公司

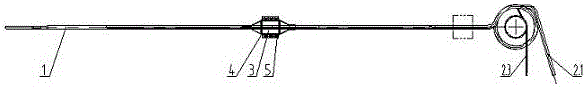

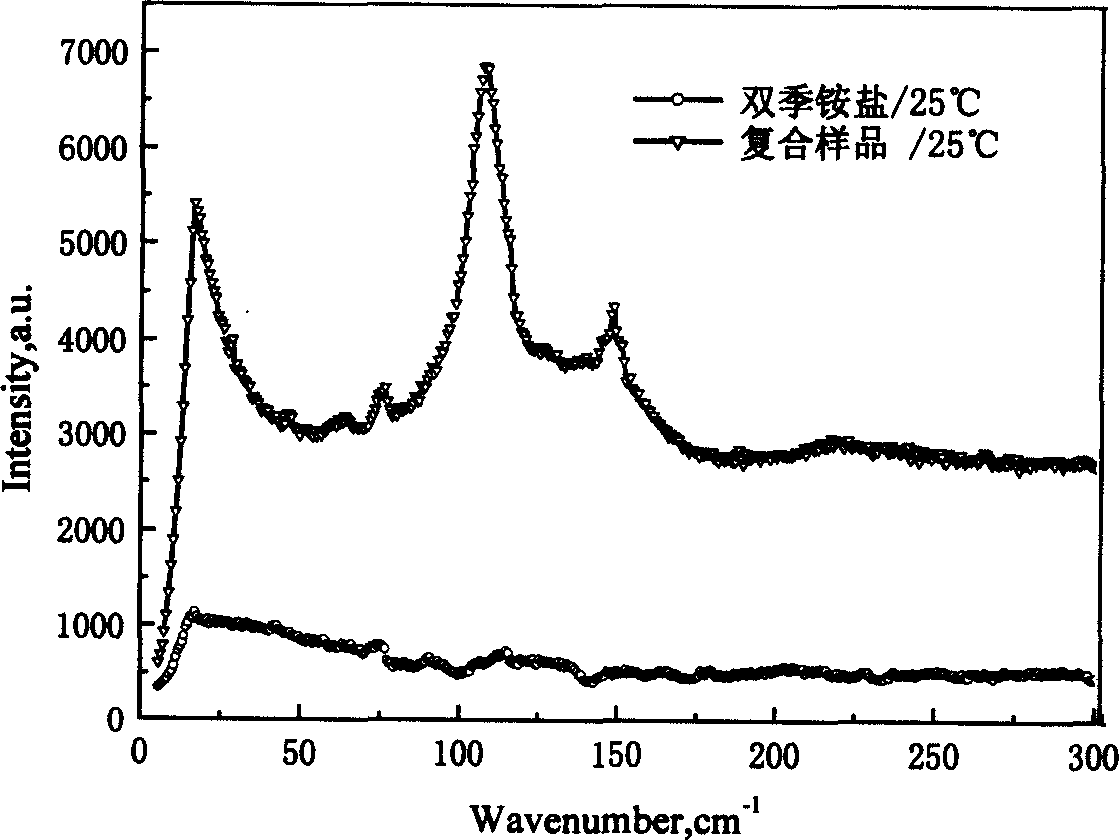

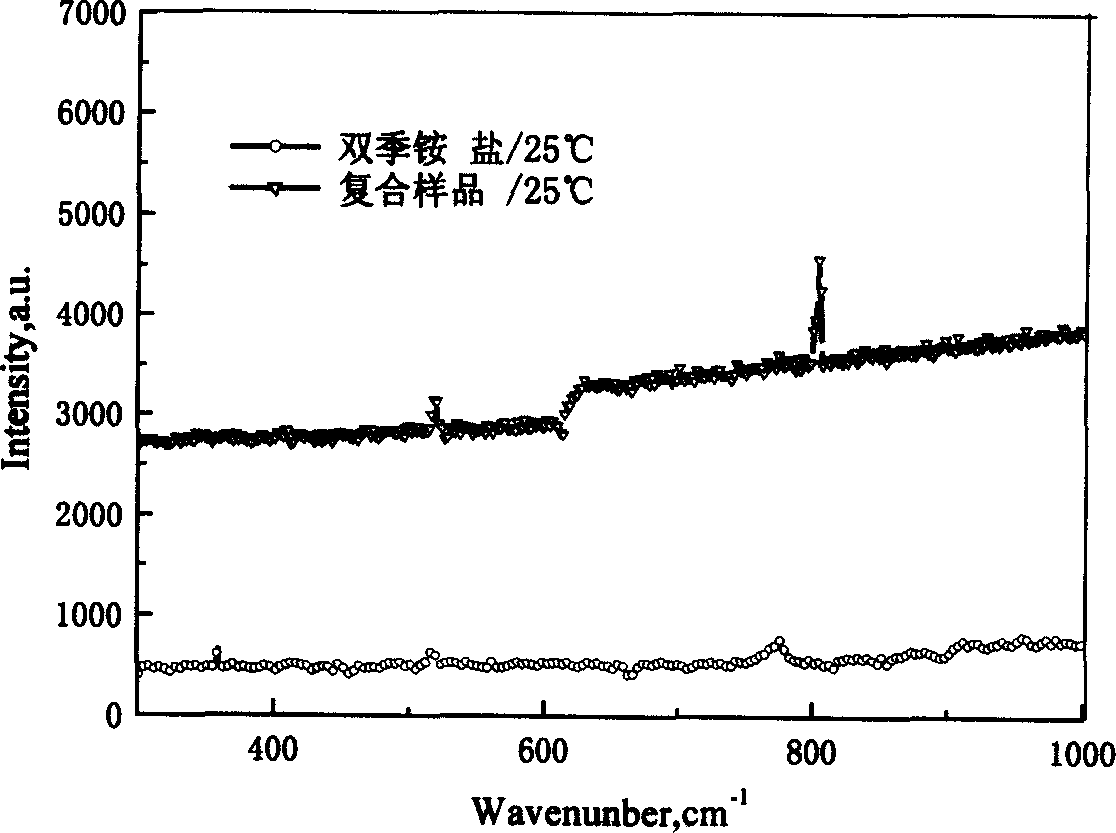

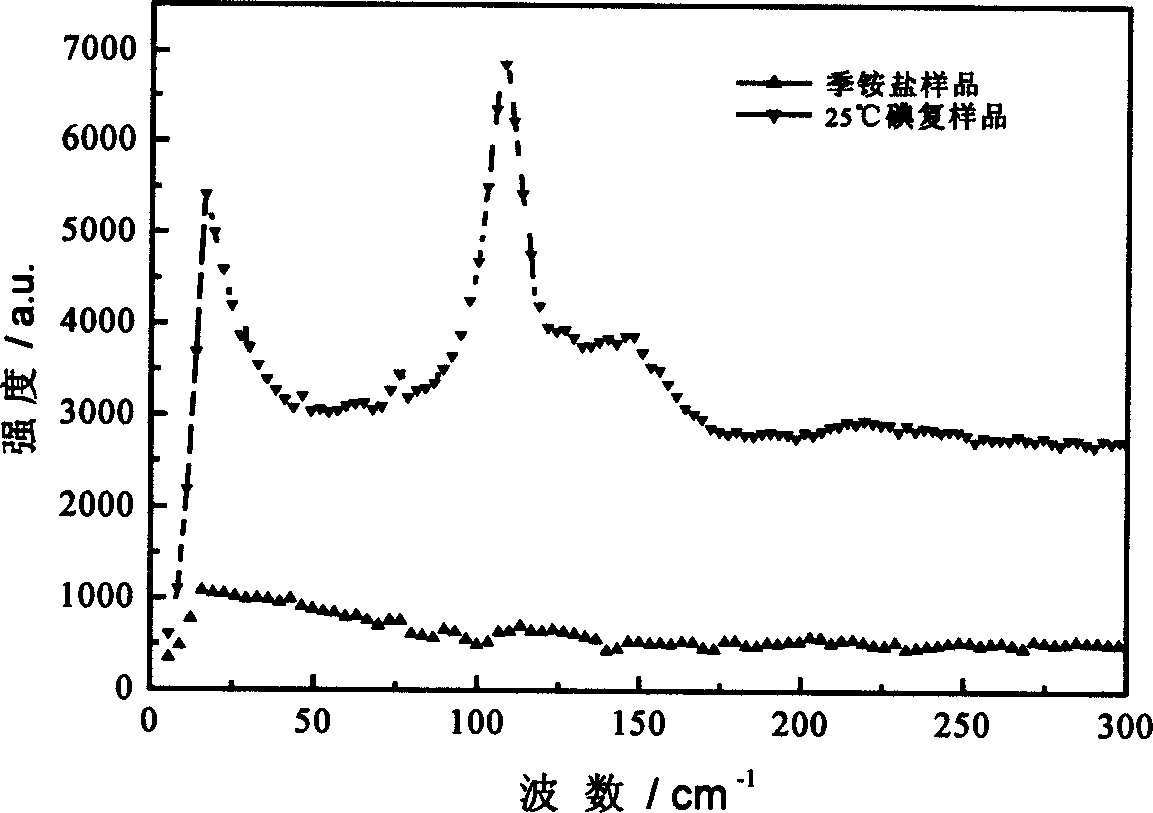

Bi-dodecyl double quaternary ammonium salt iodine attached bactericide preparation method

InactiveCN1593151AAchieve dual inactivation inhibitionNo smellBiocideAnimal repellantsVacuum pumpingRotary evaporator

The invention provides a method for preparing bisdodecyl bisquaternary ammonium salt tamed iodine germicide wherein the purpose of the invention is realized through, a, (1) charging Gemini and I2 into solvent by the mass ratio of 10(2-5), (2) dissolving iodine at 30-50 DEG C, heating to 50-60 DEG C, thermostatic reaction 3-5h, (3) charging the solution again into rotary evaporator, controlling the temperature to below deg 40 C, steaming the solvent by vacuum-pumping, obtaining thick brown liquid, (4) storing the liquid in vacuum drying oven, drying 10-13h under the condition of vacuum degree of -0.08 to -0.09MPa.

Owner:HARBIN INST OF TECH

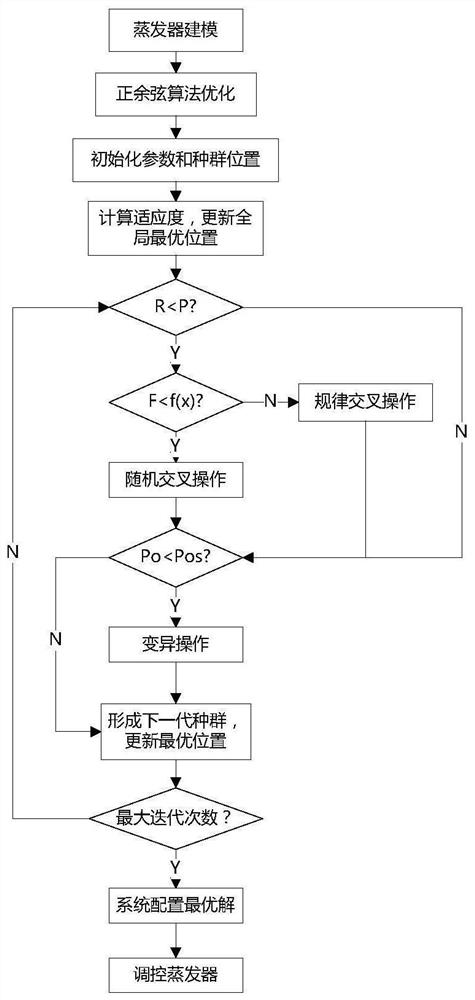

Method for regulating and controlling temperature of outlet of evaporator of ORC system

ActiveCN113485489AGuaranteed evaporationIncrease profitHeat pumpsRecuperative heat exchangersControl theoryAlgorithm optimization

The invention discloses a method for regulating and controlling the temperature of an outlet of an evaporator of an ORC system, which comprises the following steps of: firstly, modeling the evaporator in the ORC system by adopting a moving boundary method, carrying out partition integration on the evaporator, and then obtaining a model of the evaporator according to an energy conservation table and a mass conservation table; according to the evaporator model, optimizing system configuration by using a sine and cosine algorithm, and enabling various group individuals to be subjected to crossover operation according to fitness and to be sequenced and iterated to obtain an optimal configuration result; and regulating and controlling the outlet temperature of the evaporator according to an optimal configuration result. According to the regulation and control method for the outlet temperature of the evaporator of the ORC system, the energy utilization rate, the net output power and the power generation efficiency of the system are improved, and the stability is good.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Silicon-calcium capsule fertilizer and preparation method thereof

InactiveCN106187598AIncrease organic matterOrganic matter improvementMagnesium fertilisersThomas phosphate fertilisersSodium BentoniteSlag

The invention belongs to the field of agriculture, and discloses a silicon-calcium capsule fertilizer suitable for the modern agriculture and a preparation method thereof. The silicon-calcium capsule fertilizer comprises the following components: tailing slag, ammonium sulfate, agricultural magnesium sulfate, agricultural zinc sulfate, agricultural ferrous sulfate, agricultural borax, silicon dioxide, soluble starch, trace elements, bentonite, a hydrophilic polymer material, a surfactant, citric acid powder, amino acid, cortex meliae, fructus quisqualis, Chinese gall, pubescent holly root, soapberry episperm, rhizoma atractylodis, and cellulase. The silicon-calcium capsule fertilizer is practical and is capable of effectively solving the problems of insects, diseases, nutritional imbalance, low fertilizer utilization rate, and soil salinization.

Owner:河南金地宝生态肥业有限公司

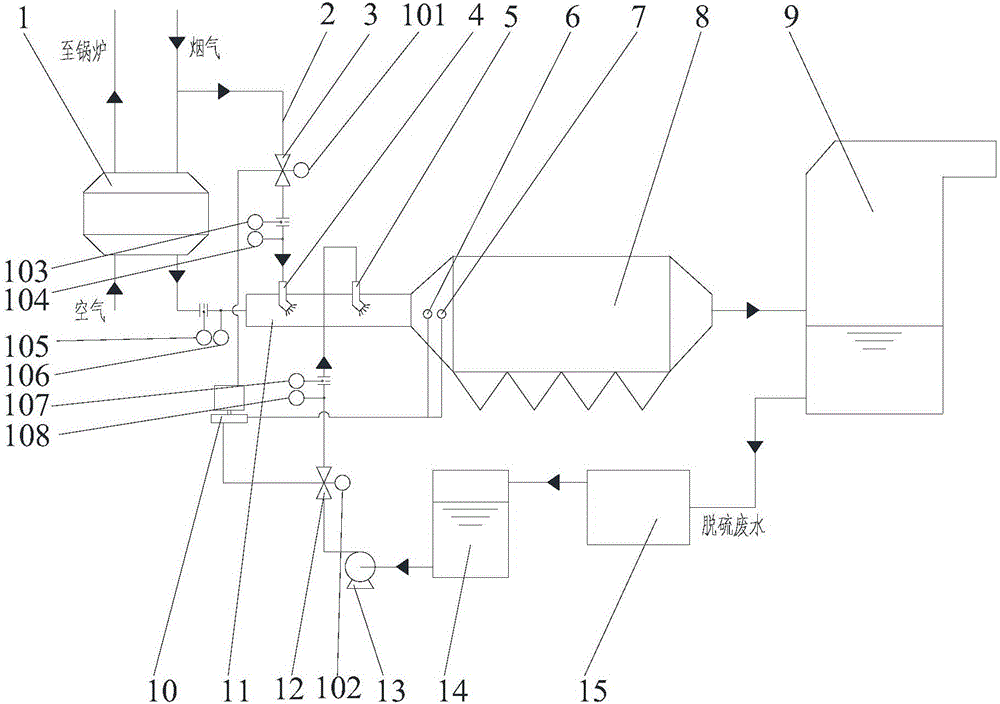

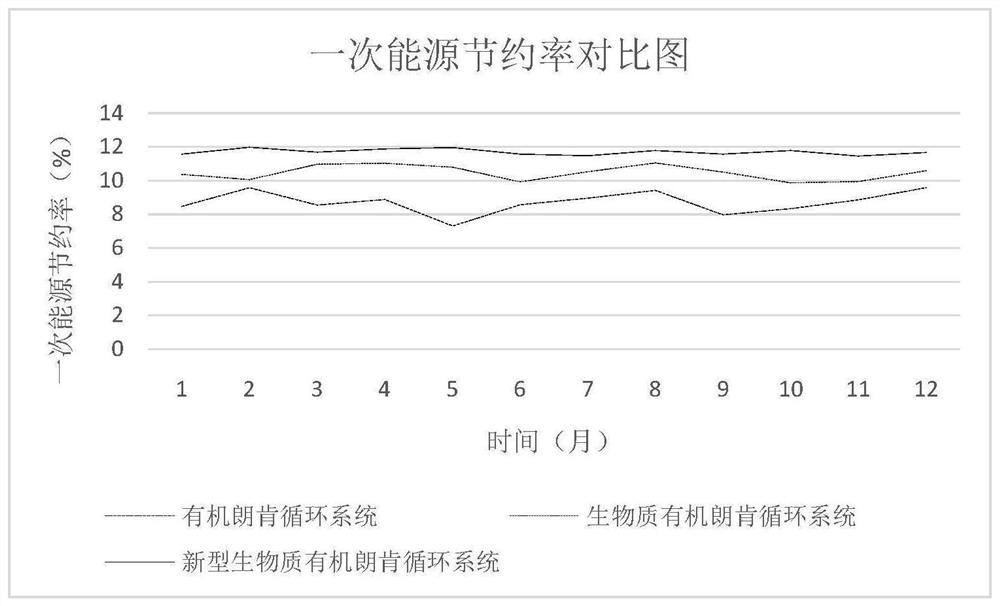

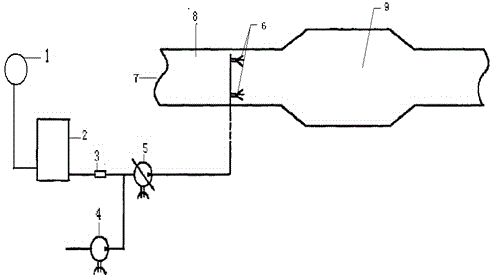

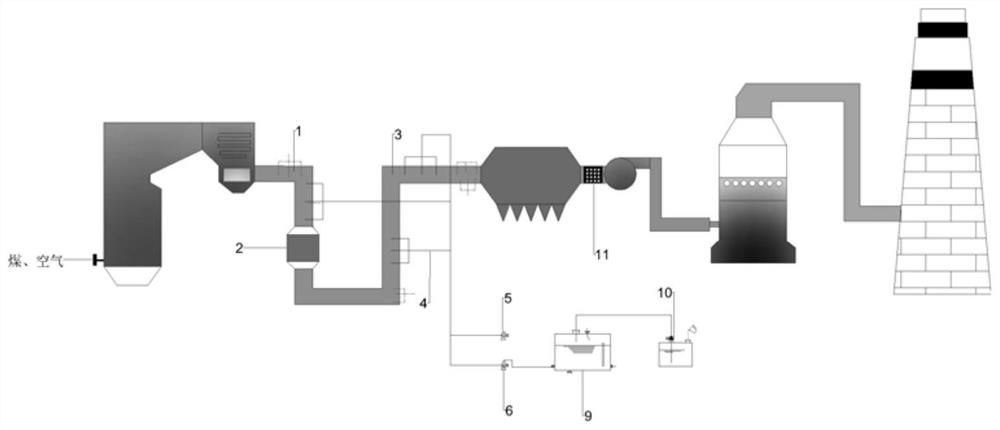

Wastewater zero discharge treatment device

InactiveCN105271587AGuaranteed evaporationSave running costDispersed particle separationMultistage water/sewage treatmentHeat engineMoisture

A wastewater zero discharge treatment device includes a logic control system, and a desulfurization tower, a pre-sedimentation tank, a filter, a clear water pump, a high pressure pump, an air preheater, a flue, a nozzle and a dust remover which are connected in turn. The wastewater zero discharge treatment device has the technical effects that treatment of desulfurization wastewater daily discharged by a heat-engine plant can be met, atomization of the wastewater is ensured, moisture is all evaporated, harmful pollutants are recycled and treated, and no adverse influence on subsequent equipment and desulfurization efficiency is caused, and the wastewater zero discharge treatment device has obvious advantages in pollution discharge control, operating cost saving and intelligent degree compared with a conventional wastewater treatment process.

Owner:TIANJIN LVJINGYUAN ENVIRONMENTAL PROTECTION TECH

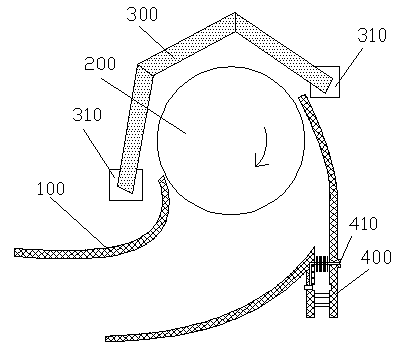

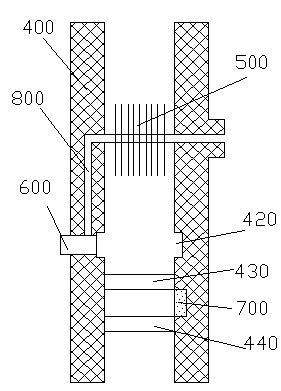

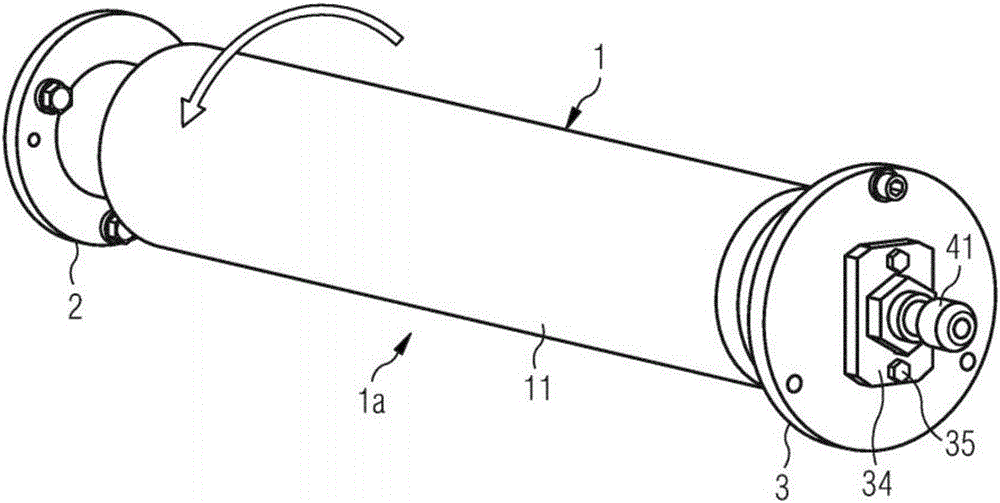

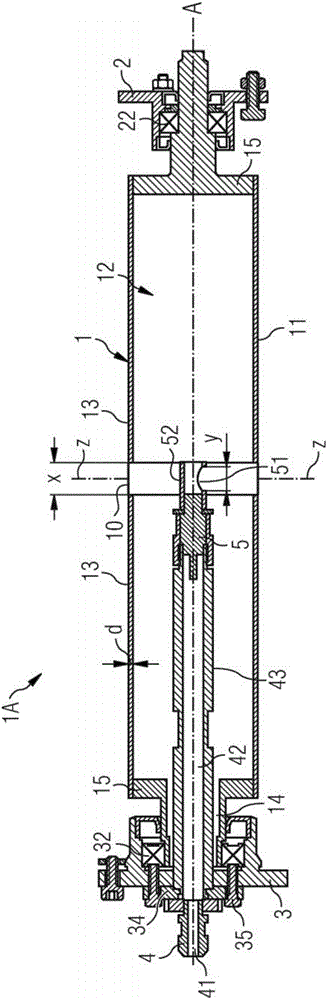

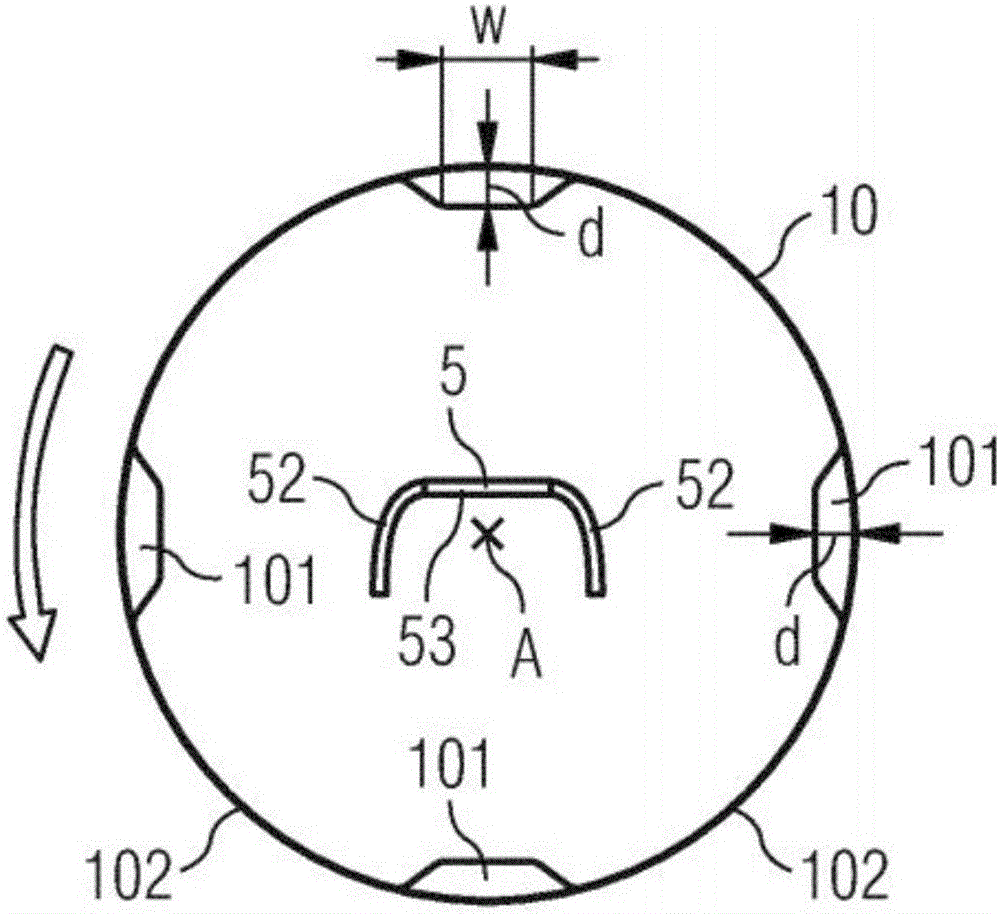

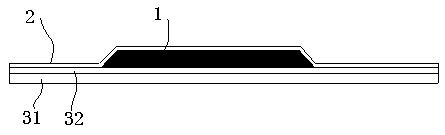

Roller device comprising temperature sensor for sensing temperature of packaging material

ActiveCN106164633AStable temperatureGuaranteed evaporationWrapping material feeding apparatusSensing radiation from moving bodiesBiomedical engineeringTemperature measurement

A sensor arrangement for temperature measurement of a material comprises a roller device (1) with a sheathing (11) configured such that the material can be rolled upon the sheathing. The sheathing comprises a first circumferential portion (13) and a second portion (10), wherein the thickness of the sheathing in the first circumferential portion is greater than the thickness of the sheathing in the second portion. A temperature sensor (5) is arranged in a cavity inside the sheathing in proximity of the second portion.

Owner:TETRA LAVAL HLDG & FINANCE SA

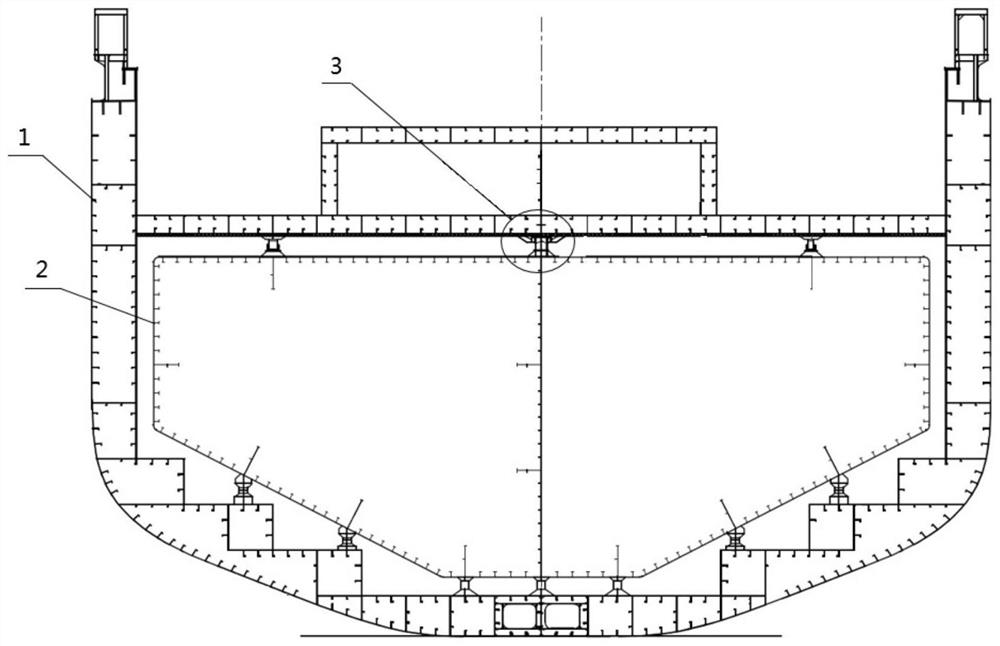

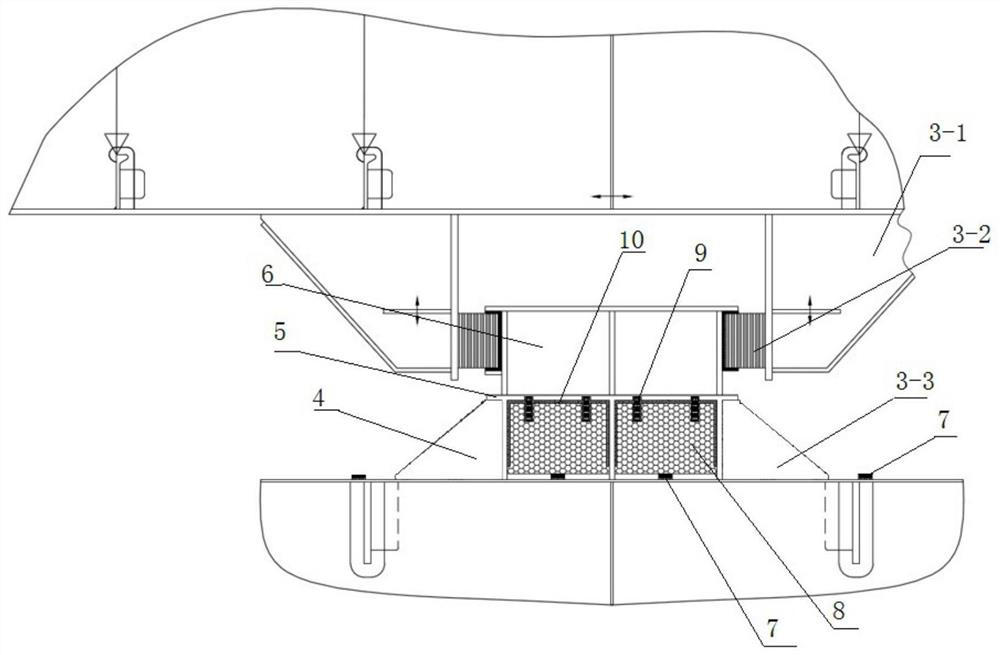

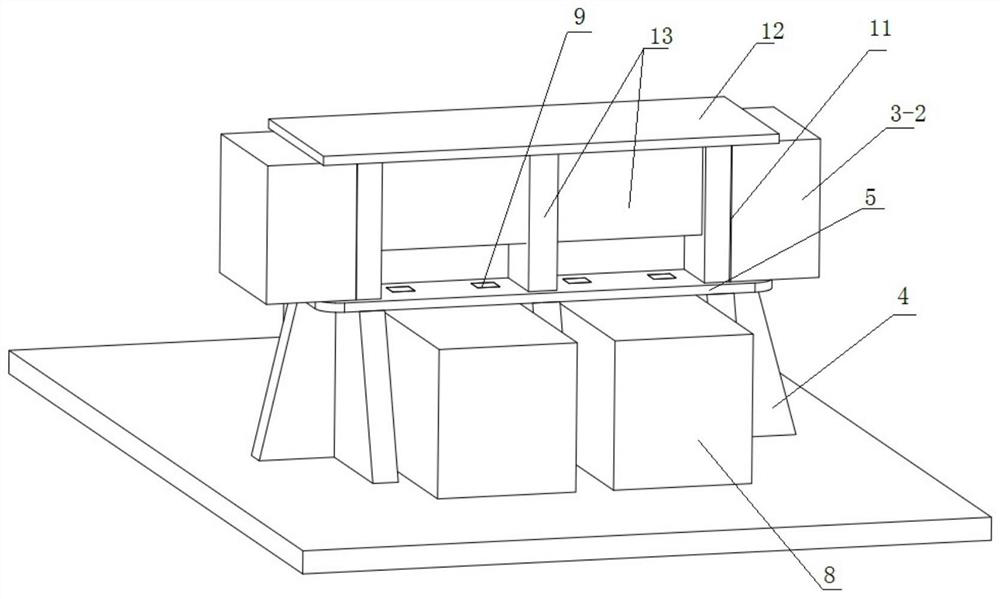

Top rolling stopping support structure for B-type independent liquid cargo tank

PendingCN113682431AImprove structural strengthReduce evaporationFor bulk goodsBody rollStructural engineering

The invention relates to a top rolling stopping support structure for a B-type independent liquid cargo tank, which structurally comprises an upper ship body rolling stopping support, laminated wood and a lower liquid cargo tank rolling stopping support, the lower liquid cargo tank rolling stopping support is mounted at the top of the B-type independent liquid cargo tank, and the laminated wood is fixed on two sides, close to the upper end, of the lower liquid cargo tank rolling stopping support. The upper ship body rolling stopping supports are arranged on the two sides of the laminated wood on the two sides of the lower liquid cargo tank rolling stopping supports in a clamped mode. According to the top rolling stopping support for the B-type independent liquid cargo tank, the transverse displacement of the B-type independent liquid cargo tank is limited, meanwhile, the structural rigidity of the rolling stopping support due to the large transverse acceleration load of a ship body can be reduced, and the structural strength of the rolling stopping support is improved through the design of the cross plate.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

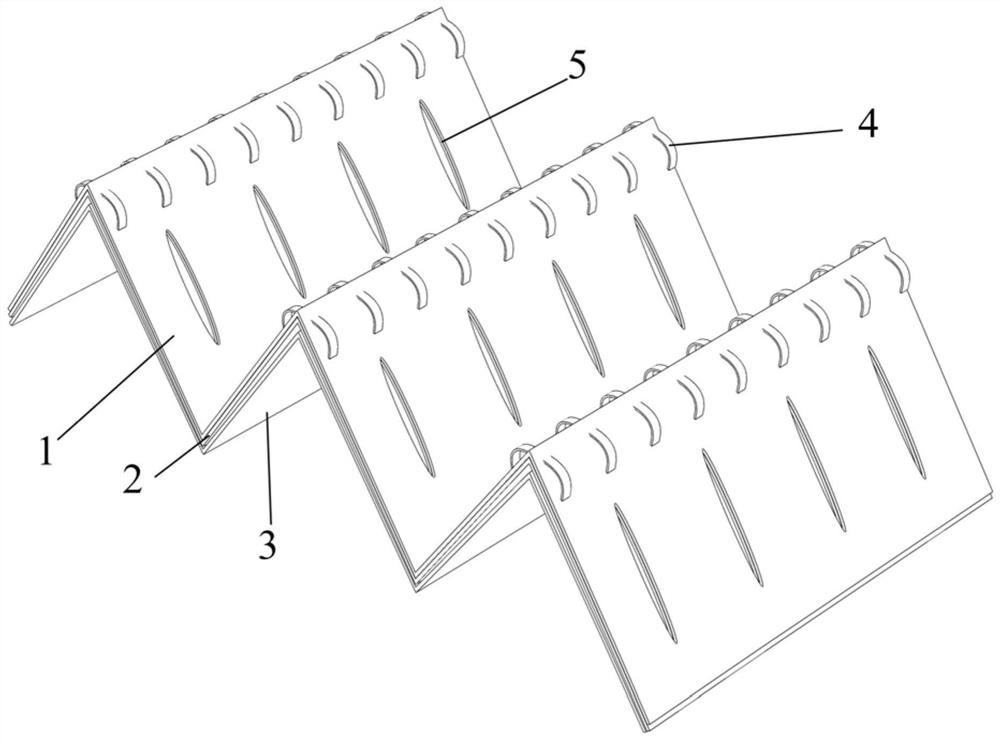

Photo-thermal body device for solar steam generation and manufacturing and application thereof

ActiveCN112624239AGuaranteed evaporationRealize the effect of no salt precipitationSolar heating energyGeneral water supply conservationWire rodThermodynamics

The invention discloses a photo-thermal body device for solar steam generation as well as manufacturing and application thereof. The method comprises the following steps: firstly, carrying out transparent super-hydrophobic coating treatment on a single side surface of a photo-thermal layer; combining one end of a hydrophilic wire rod to the photo-thermal layer, and overlapping the other end of the hydrophilic wire rod to a hydrophobic layer to obtain a double-sided different-effect fabric; fastening and connecting the double-sided different-effect fabric and a plastic-coated metal wire mesh at a lower inflection point of a broken line shape; the prepared photo-thermal body device comprises the plastic-coated metal wire mesh and the double-sided different-effect fabric attached to the plastic-coated metal wire mesh. The front projection of the plastic-coated wire mesh is in a broken line shape; wherein the cloth surface tension of the double-sided different-effect fabric is 50-80 cN; the hydrophilic wire rod is located at the upper inflection point of the broken line shape of the plastic-coated wire mesh, the wicking speed is larger than 150 mm / 10 min, and the wicking speed of the photo-thermal layer is larger than 80 mm / 10 min; the water contact angle of the hydrophobic layer is greater than 155 degrees; the photo-thermal body device is immersed into seawater, wherein the depth of the photo-thermal body device immersed into the seawater is 1 / 20-1 / 15 of the height of the plastic-coated wire mesh; under standard simulated sunlight (1kw / m<2>), the evaporation capacity of water vapor is 1.25-1.43 kg / (m<2>.H); no solid salt is separated out in the evaporation process.

Owner:JIANGSU HENGLI CHEM FIBER

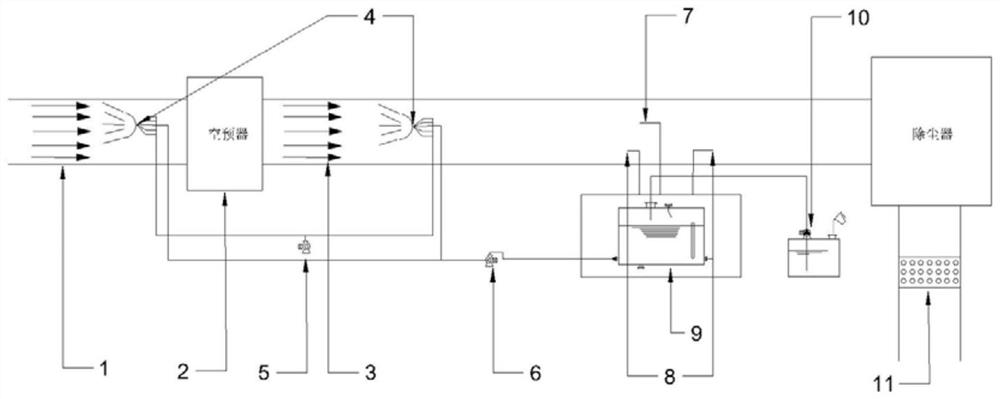

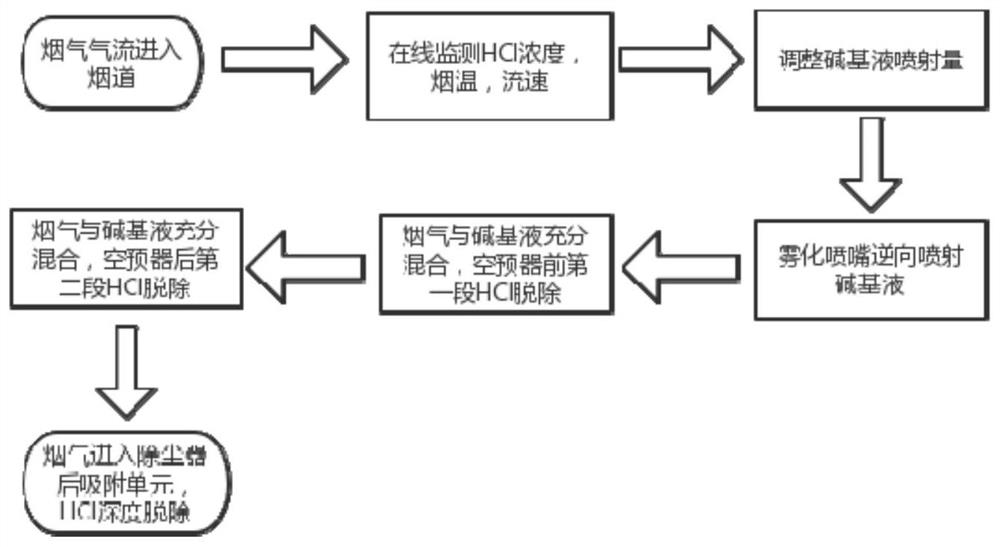

Two-section flue gas alkali spraying and adsorption combined dechlorination system

PendingCN113634099AImprove removal efficiencyLow costGas treatmentDispersed particle separationFlueSource reduction

The invention discloses a two-section flue gas alkali spraying and adsorption combined dechlorination system. The system comprises an air pre-heater front flue, an air pre-heater, a dust remover front flue, a dust remover, a base solution dosing box and two atomizing nozzles; the air pre-heater front flue is communicated with an inlet of the dust remover through the air pre-heater and the dust remover front flue, the two atomizing nozzles are arranged in the air pre-heater front flue and the dust remover front flue respectively, and the system can achieve source reduction of desulfurization waste water and reduce the cost of a follow-up zero discharge system.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION

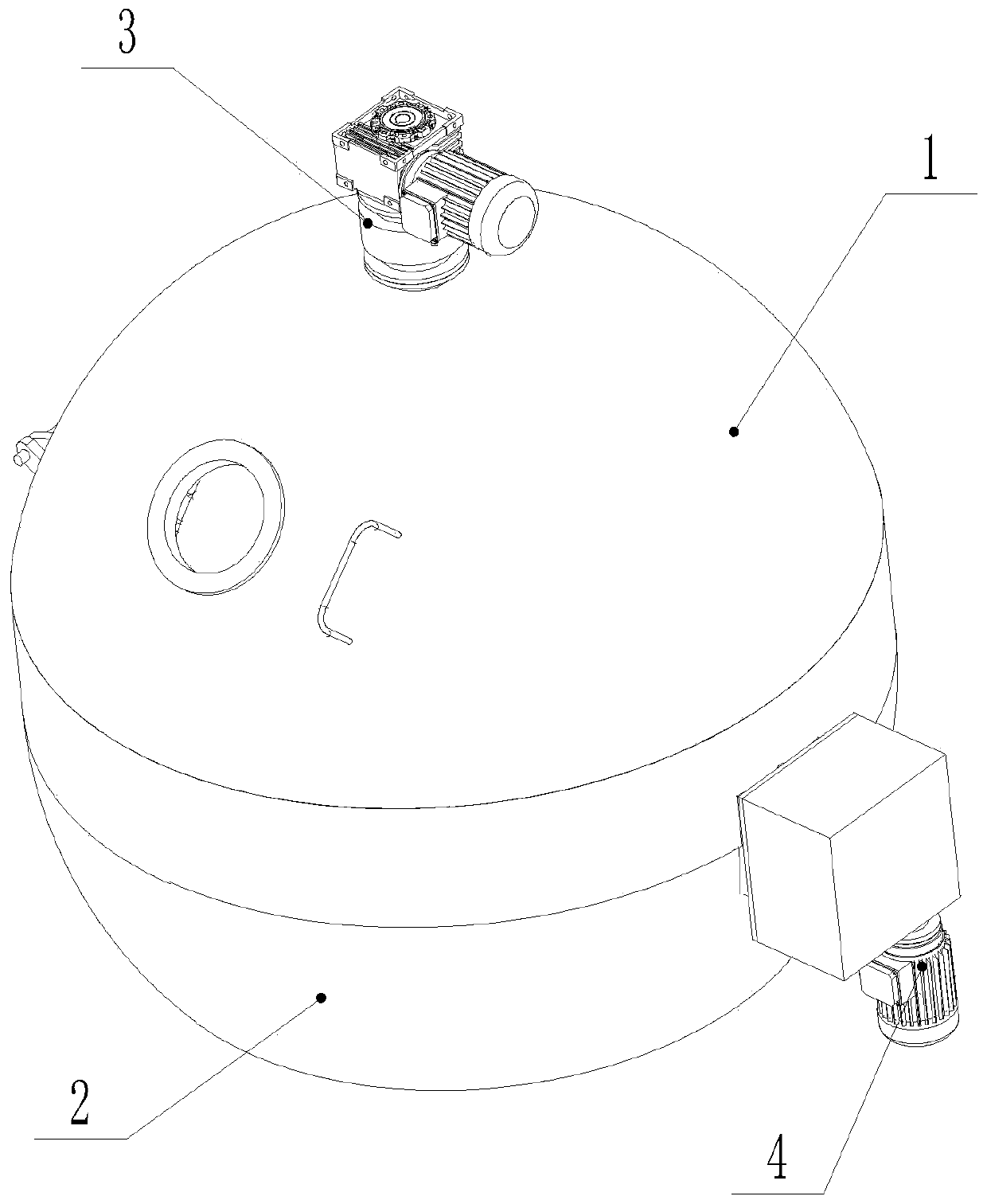

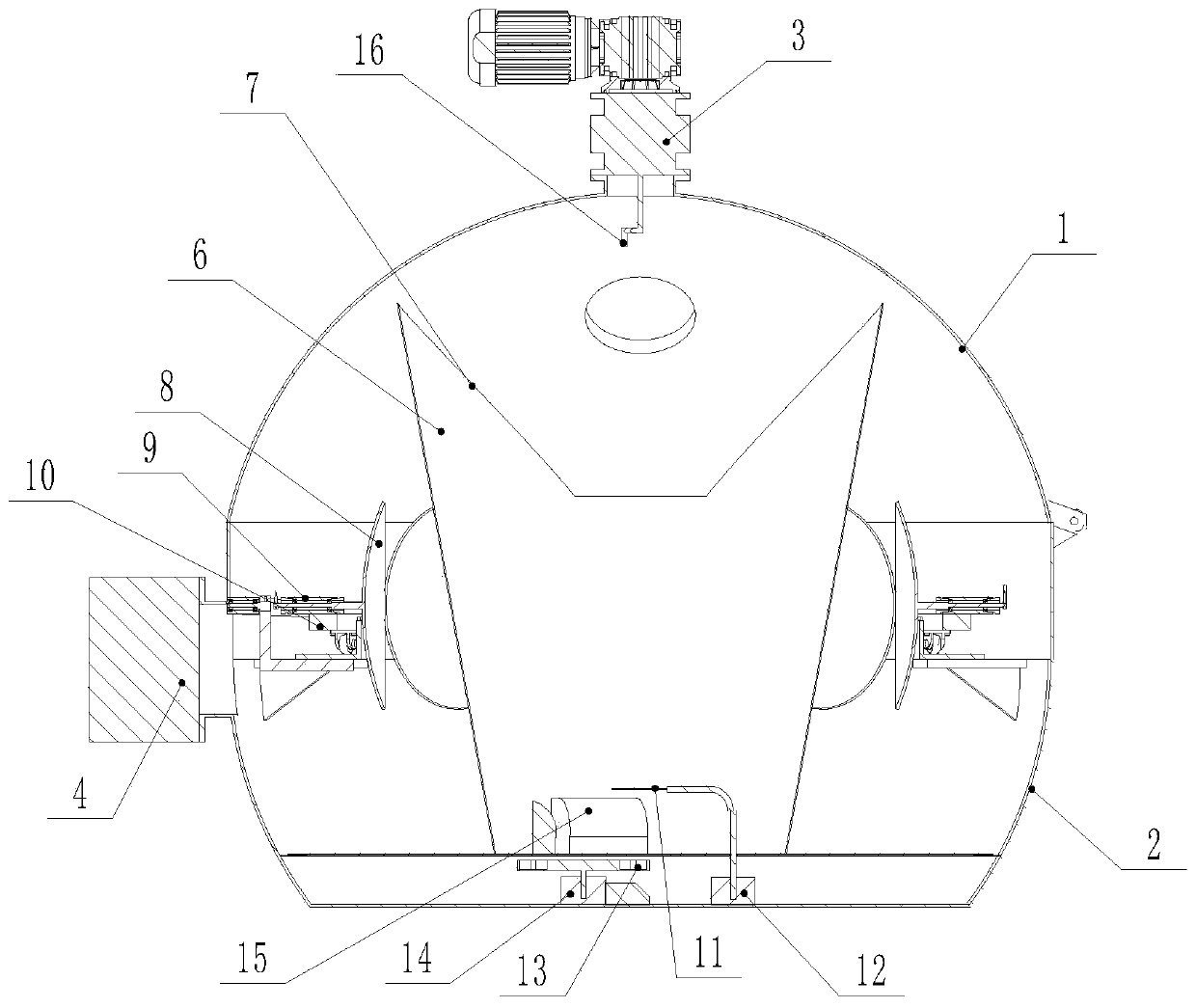

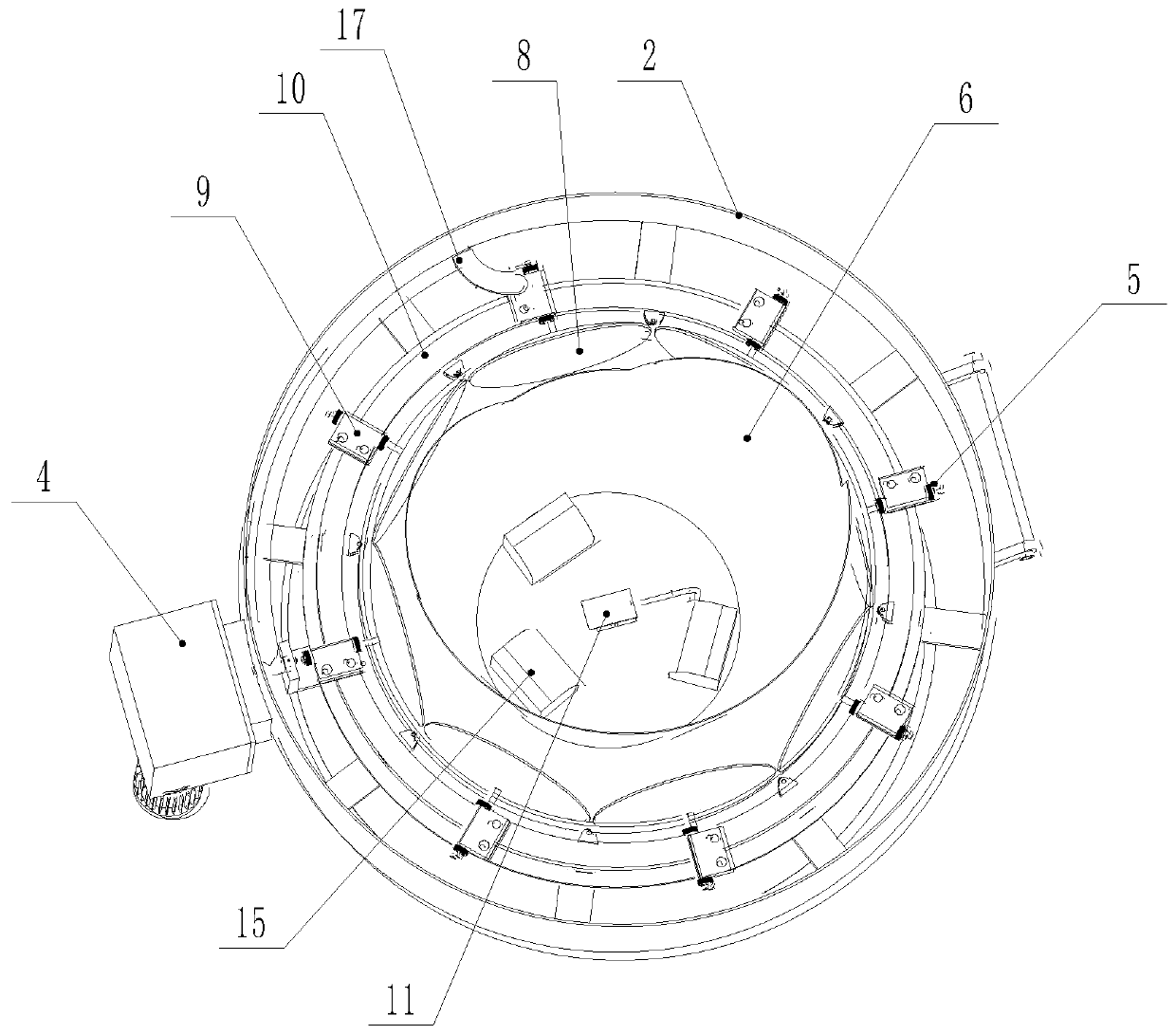

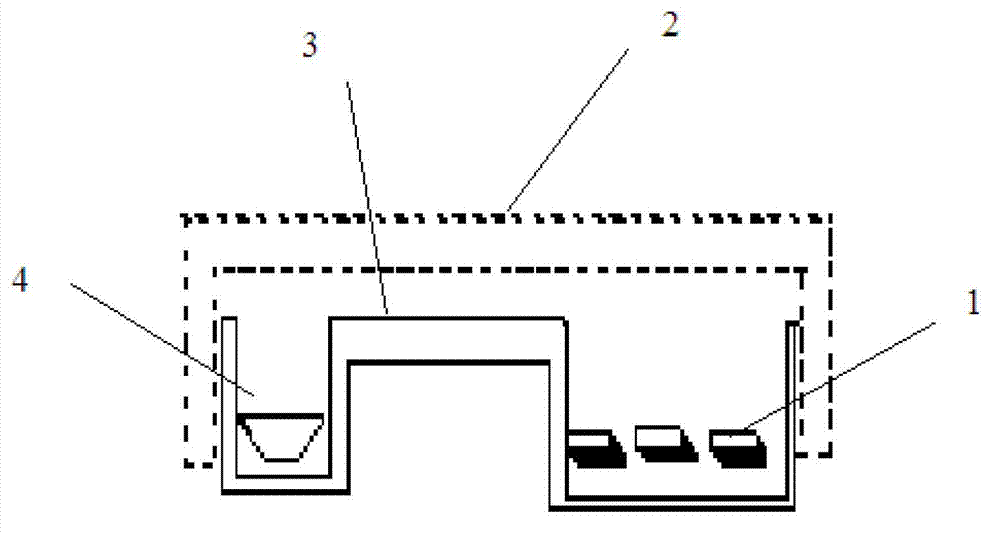

Evaporating method of revolution type semiconductor evaporation table

ActiveCN110643949AHigh evaporation precisionImprove evaporation efficiencyVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

The invention discloses an evaporating method of a revolution type semiconductor evaporation table. The evaporating method comprises the steps that S1, previous preparations of equipment are made, wherein S11, the revolution type evaporation table is provided; and S12 a vacuumizing device is started to vacuumize the interior of an evaporation cavity; S2, a taking arm deviates to take a slide coveroff from a rotary ring; S3, the taking arm deviates by 90 degrees to move the slide cover to an evaporation station; S4, the slide cover on the evaporation station rotates; S5, an electron beam generating device is started to generate high-energy electron beams, and metal in a crucible is heated to heated to evaporate; S6, after slide cover evaporation is completed, the taking arm reversely deflects by 90 degrees, and the slide cover obtained after evaporation is completed is placed on the rotary ring; S7, the rotary ring rotates to rotate another slide cover to a cover taking station; S8, the steps 2 to 6 are repeated until evaporation of all the slide covers on the rotary ring is completed. According to the evaporating method, evaporation on multiple slide covers can be completed crucible, the evaporation efficiency is improved, the evaporation precision is improved, and the vacuumizing time is shortened.

Owner:苏州华楷微电子有限公司

Apparatus and method for carrying out selenylation treatment on CIGS (copper indium gallium selenide) thin films and CIGS thin-film device

InactiveCN103088301BReduce leakageHigh Selenization EfficiencyVacuum evaporation coatingSputtering coatingIndiumThermal insulation

The invention relates to an apparatus and a method for carrying out selenylation treatment on CIGS (copper indium gallium selenide) thin films and a CIGS thin-film device. The apparatus comprises a quartz tube, a selenylation unit is arranged in the quartz tube, the selenylation unit comprises a selenium source groove and a CIGS thin-film groove which are connected through a thermal insulation material, a protective cover is arranged above the two grooves, and a confined space is formed among the protective cover and the two grooves. A solid selenium source and a CIGS thin film are respectively placed in the selenium source groove and the CIGS thin-film groove, and then operations of vacuumizing, heating and selenylation treatment are sequentially performed. The apparatus and the method disclosed by the invention have the advantages of less selenium vapor leakage, high selenylation efficiency, and capability of simultaneously treating multiple samples, and the like, and the stability and the batch preparation of CIGS thin-film solar cell devices are facilitated.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

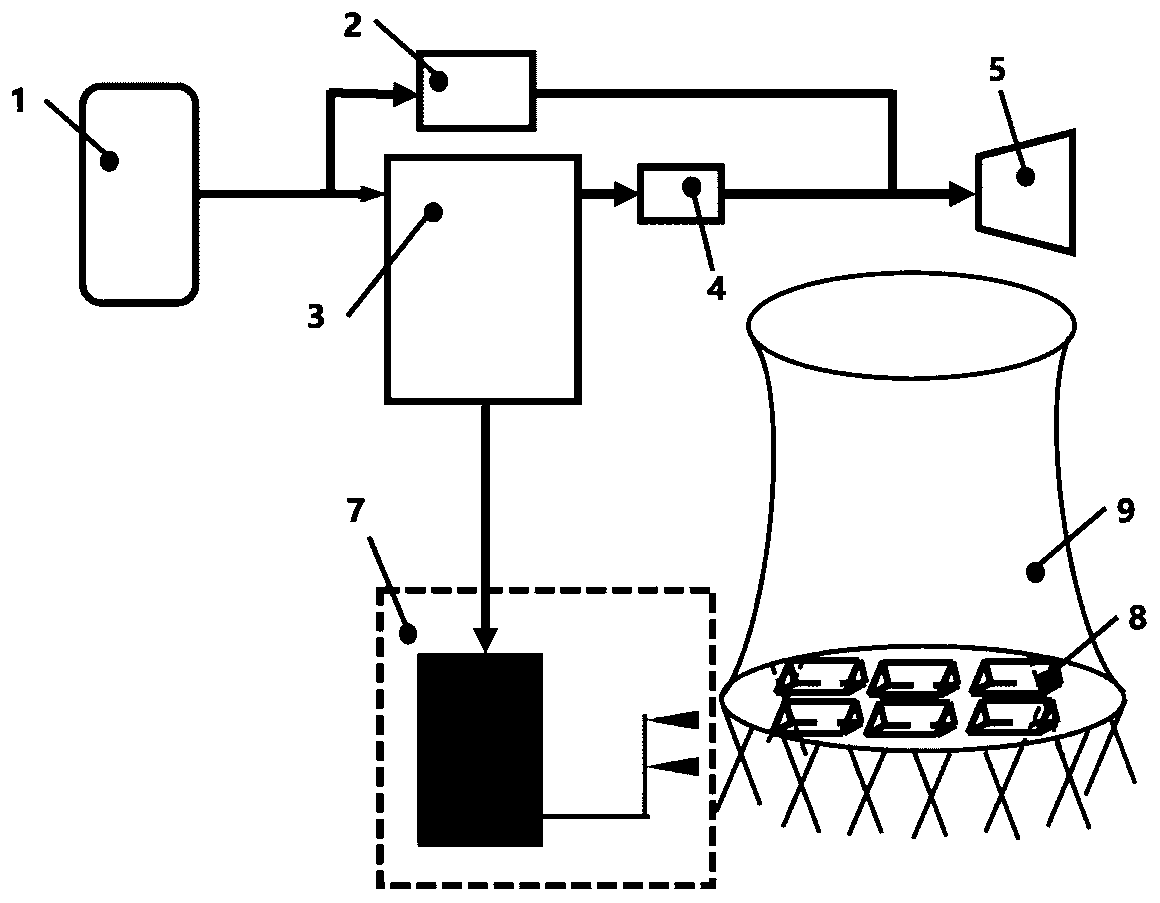

System of using LNG cold energy in spray cooling of air cooling tower

PendingCN110274416AImprove heat transfer effectReduce the temperatureDomestic cooling apparatusTrickle coolersWater storage tankEngineering

The invention discloses a system of using LNG cold energy in spray cooling of an air cooling tower. The system comprises an LNG gasifying system, an LNG cold energy utilization system and an air cooling tower spray cooling system. The LNG gasifying system is arranged next to an LNG storage tank, is connected to the LNG cold energy utilization system in a parallel manner, and comprises a high pressure water bath type gasifier. When the LNG cold energy is utilized, part of LNG enters into the high pressure water bath type gasifier to be gasified as a fuel entering into a gas turbine; the LNG cold energy utilization system recovers cold energy of LNG gasification through a two-stage heat exchange system and part of cold energy is used for reducing the water temperature of external water, and the cooled cold water enters into a spray water storage tank of the air cooling tower spray cooling system; the air cooling tower spray cooling system feeds spray water in the spray water storage tank into optimally arranged nozzles. By means of spray cooling, spray is evaporated fully without corroding an air cooling heat dissiaptor in the air cooling tower. The system disclosed by the invention is suitable for a combined-cycle power plant which takes LNG as the fuel and the air cooling tower as a cooling system.

Owner:XIAN THERMAL POWER RES INST CO LTD

SCR denitration reducing agent preparation device with flue gas heating system and method

PendingCN112774436ASave spacePrevent leakageTransportation and packagingDispersed particle separationFlueChemistry

The invention discloses an SCR denitration reducing agent preparation device with a flue gas heating system and a method. The preparation of an SCR denitration reducing agent is completed by utilizing the flue gas heating system. A reducing agent solution is directly sprayed into a high-temperature flue of a flue gas heating system, ammonia gas evaporated from high-temperature flue gas is mixed with the high-temperature flue gas and then fed into an original flue gas flue through the high-temperature flue to be mixed with original flue gas, a reducing agent required by denitration is provided, and the reducing agent solution can be ammonia water or a urea solution. Compared with a traditional SCR denitration reducing agent preparation system, an evaporator, an ammonia-air mixer, a dilution fan, a dilution air heating device, an ammonia spraying grid and the like do not need to be arranged, and the system has the advantages of being simple, easy to control, small in investment and the like.

Owner:BEIJING SHOUGANG INT ENG TECH

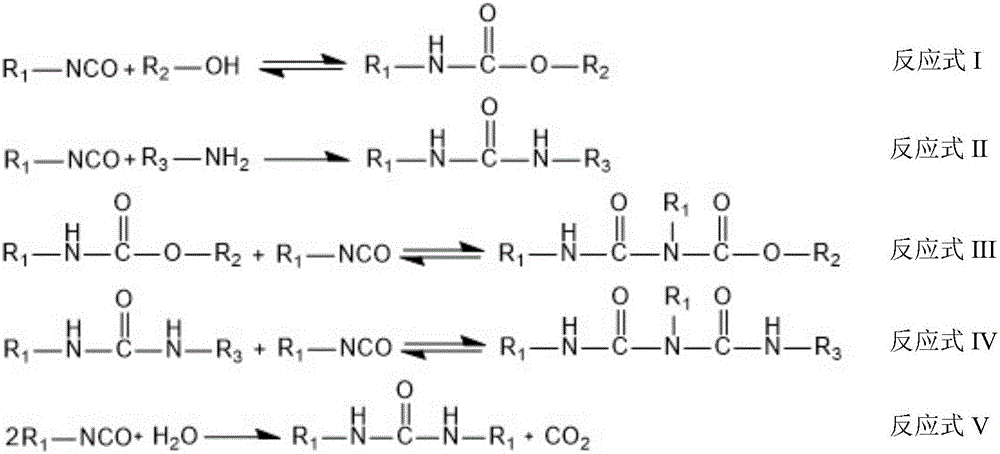

Analysis method of cross-linking degree of moisture-curable polyurethane

ActiveCN106644813AGuaranteed evaporationGuaranteed SolubilityWeighing by removing componentPolyurethane adhesiveMoisture cure polyurethane

The invention relates to an analysis method of the cross-linking degree of moisture-curable polyurethane. The method comprises the following steps: feeding a moisture-curable polyurethane sample into a net-shaped covering object and sealing to obtain a testing sample; putting the obtained testing sample into an extraction device filled with a solvent; extracting the testing sample at a first temperature range of 60 DEG C to 90 DEG C, a second temperature range of 100 DEG C to 110 DEG C, a third temperature range of 120 DEG C to 130 DEG C and a fourth temperature range of 140 DEG C to 260 DEG C; after extracting, drying the testing sample and weighing; calculating the cross-linking degree of the testing sample according to an equation C=(m2-m0) / (m1-m0). According to the analysis method, the testing sample is extracted under the four different temperature ranges and is calculated, so that a cross-linking type and a ratio in the moisture-curable polyurethane are analyzed, and furthermore, performances of the moisture-curable polyurethane are analyzed; the analysis method has certain guidance meanings on formula, process and utilization condition selection of a moisture-curable polyurethane adhesive product.

Owner:GUANGZHOU BAIYUN CHEM IND

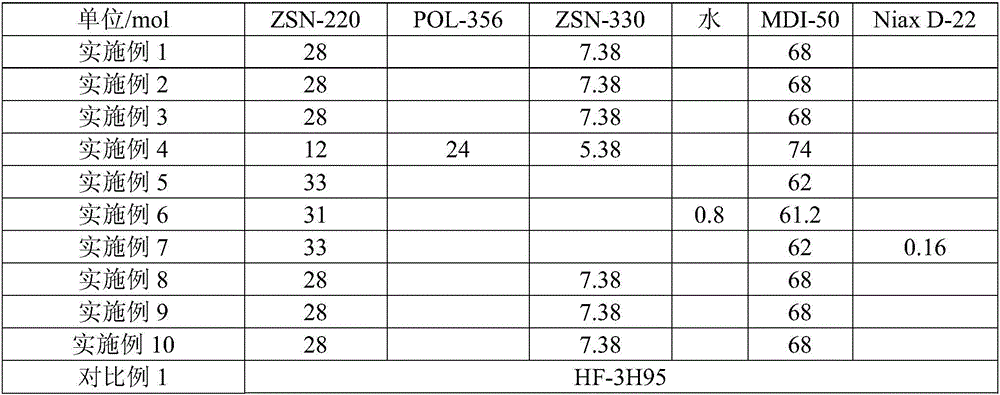

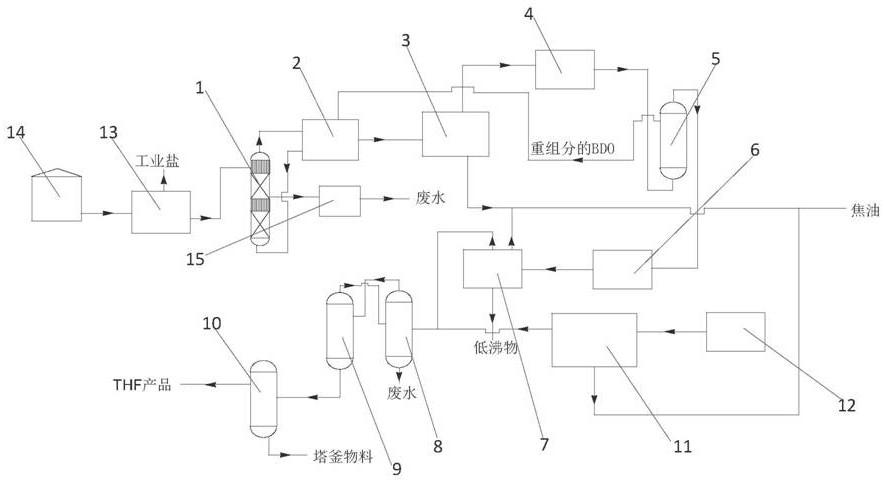

Tetrahydrofuran preparation system and use method thereof

The invention provides a tetrahydrofuran preparation system and a use method thereof, and relates to the technical field of chemical engineering. The system comprises a BDO treatment device and a THF treatment device connected with the BDO treatment device, the THF treatment device comprises a BDO reactor connected with the BDO treatment device, a THF dehydrating tower connected with the BDO reactor, a THF pressurizing tower connected with the THF dehydrating tower, a THF decolorizing tower which is connected with the THF pressurizing tower and produces a tetrahydrofuran finished product from the middle part, and a PTMEG reactor connected with the THF dehydrating tower. The system can be used for preparing high-purity tetrahydrofuran.

Owner:张雅坚

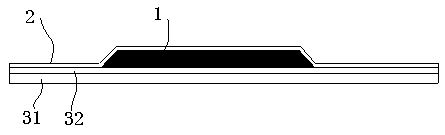

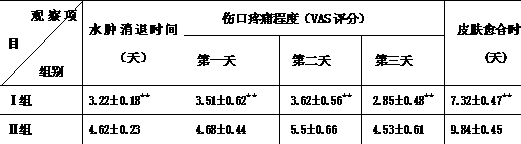

Magnesium sulfate dressing plaster capable of relieving pain and scars

The invention relates to a magnesium sulfate dressing plaster capable of relieving pain and scars, wherein the magnesium sulfate dressing plaster includes a pasting adhesive tape, an isolation film adhering to the pasting adhesive tape and an inner liner layer arranged between the pasting adhesive tape and the isolation film, and the inner liner layer contains a 50% magnesium sulfate solution. Themagnesium sulfate dressing plaster can effectively plays roles in reducing swelling, relieving pain, reducing inflammatory response and promoting wound healing.

Owner:向军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com