Bi-dodecyl double quaternary ammonium salt iodine attached bactericide preparation method

A technology of bactericide and iodophor, which is applied in the field of preparation of bactericide, can solve the problems of incomplete compounding of iodine, loss of iodine, inability to supplement stirring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

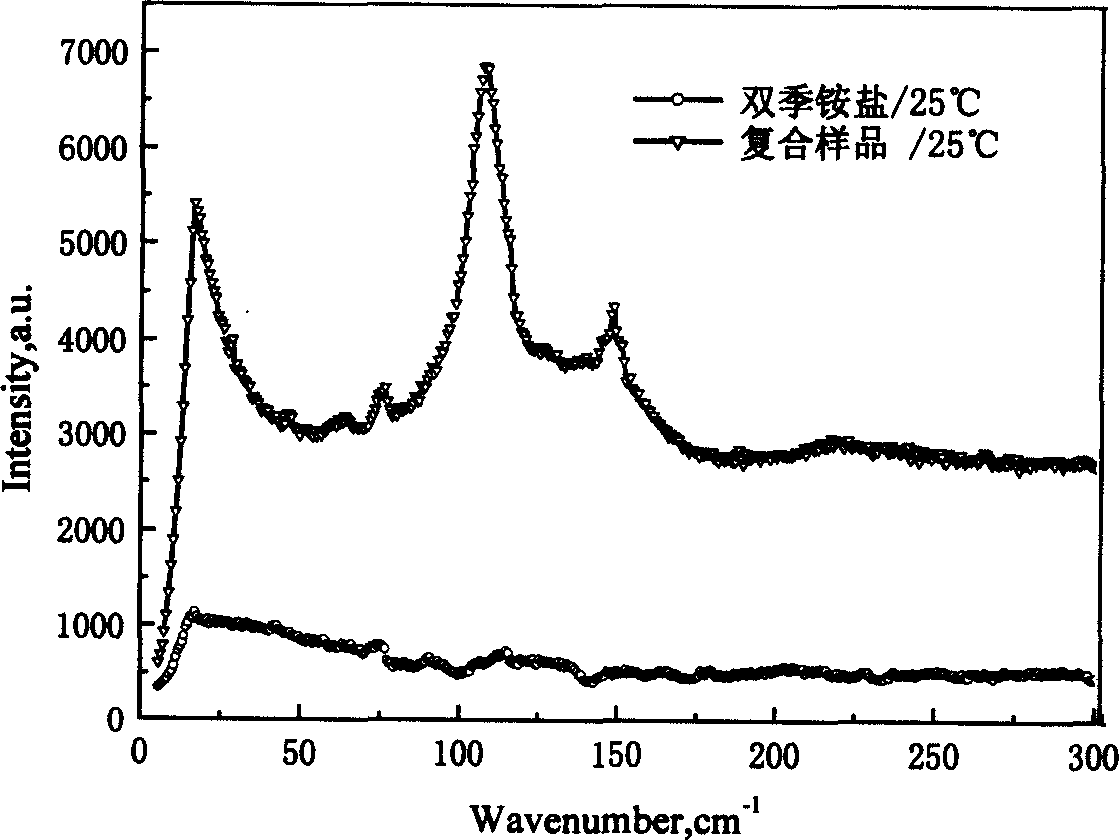

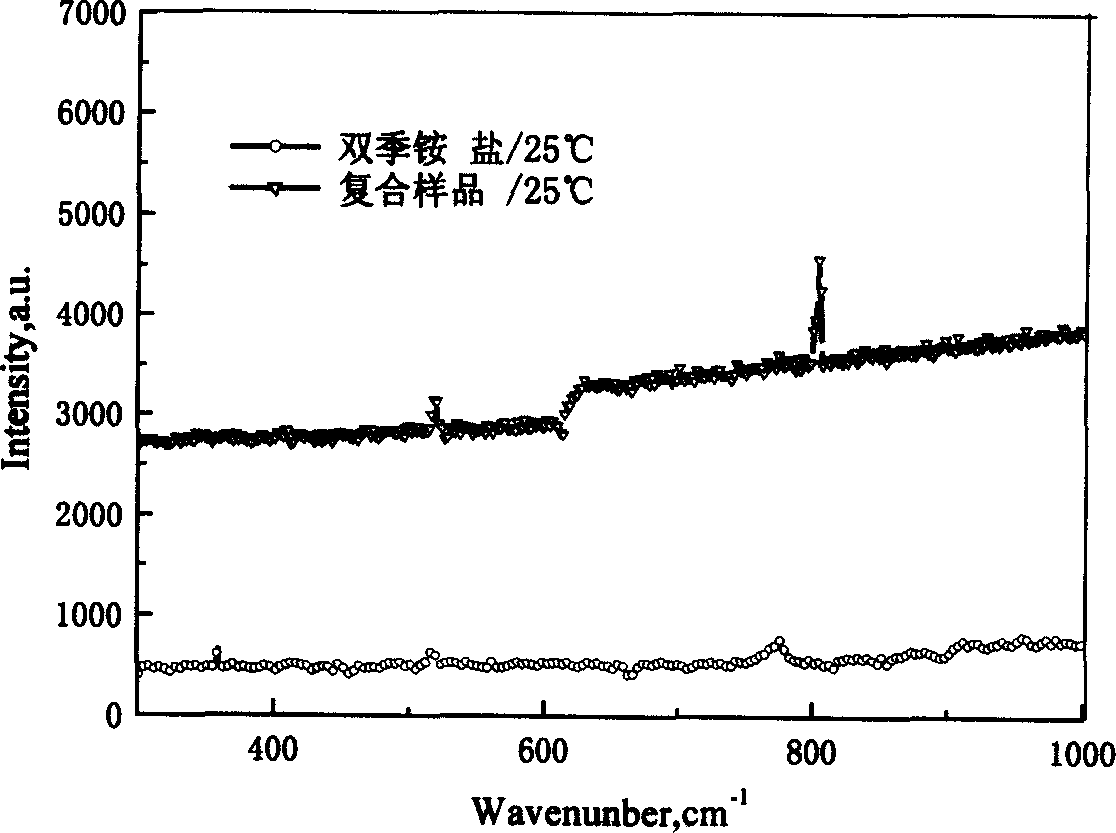

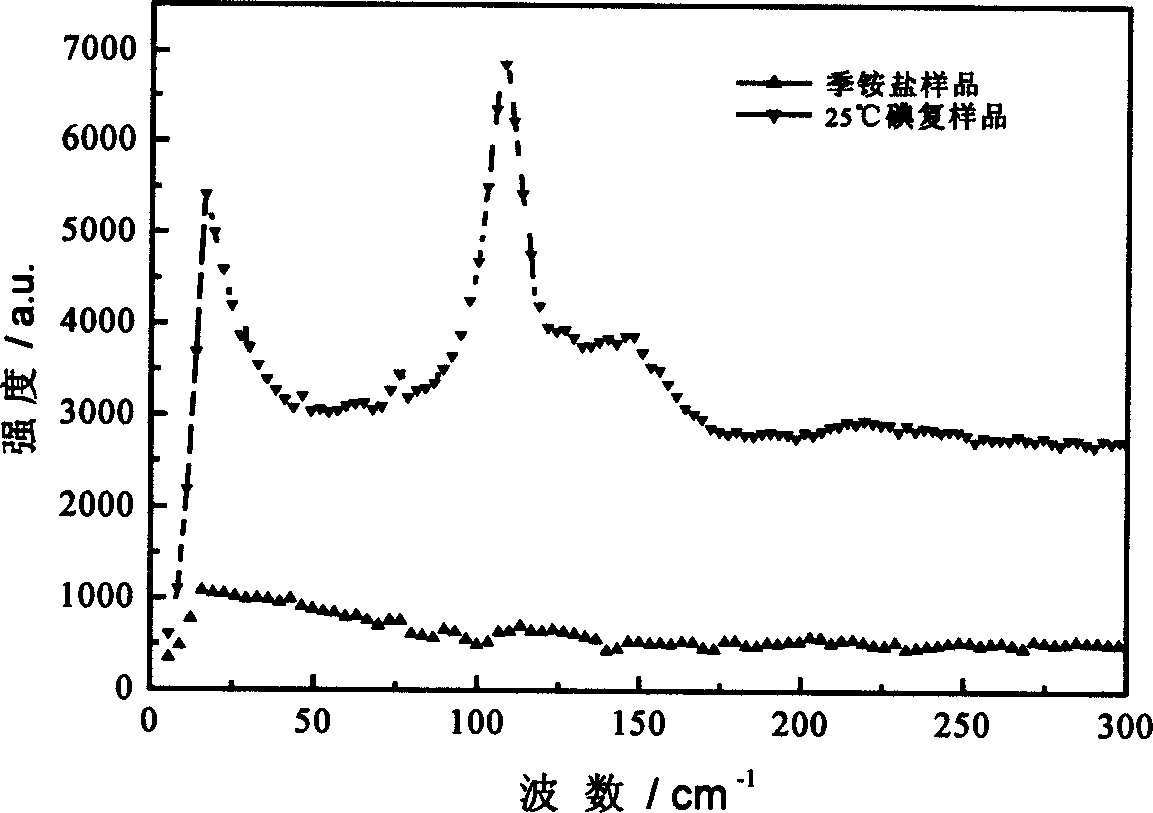

Image

Examples

specific Embodiment approach 1

[0007] Specific embodiment one: present embodiment is realized in this way: a, Gemini and 1 2 Pour it into the solvent with a mass ratio of 10: (2~5), the amount of solvent used is 8~10L / Kg Gemini; b. Dissolve iodine at 30~50°C, and then heat to 50~60°C for constant temperature reaction 3 ~5h; c, then pour the solution into a rotary evaporator, control the temperature < 40 ° C, vacuumize and evaporate the solvent to obtain a viscous brown liquid; d, put the liquid in a vacuum drying oven, Dry for 10-13 hours under the condition of -0.08~-0.09MPa, and finally obtain a tan solid.

specific Embodiment approach 2

[0008] Specific embodiment two: this embodiment is different from specific embodiment one in that it also includes step e: dissolving the tan solid in ethanol and heating at 60-100°C for 10-14 hours, then adding 20-50ml of distilled water, vacuum After suction filtration, heat at 60-80°C for 10-14 hours to obtain a purified product. Other process conditions and steps are the same as those in Embodiment 1.

specific Embodiment approach 3

[0009] Specific embodiment three: what this embodiment is different from specific embodiment one and two is that Gemini and I 2 The mass ratio is 10:2.5. Other process conditions and steps are the same as those in Embodiments 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com