Photo-thermal body device for solar steam generation and manufacturing and application thereof

A solar steam and photothermal technology, applied in the field of seawater desalination, can solve the problems of solid salt removal, loss, and inhibition of utilization efficiency, and achieve the effect of ensuring water vapor evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

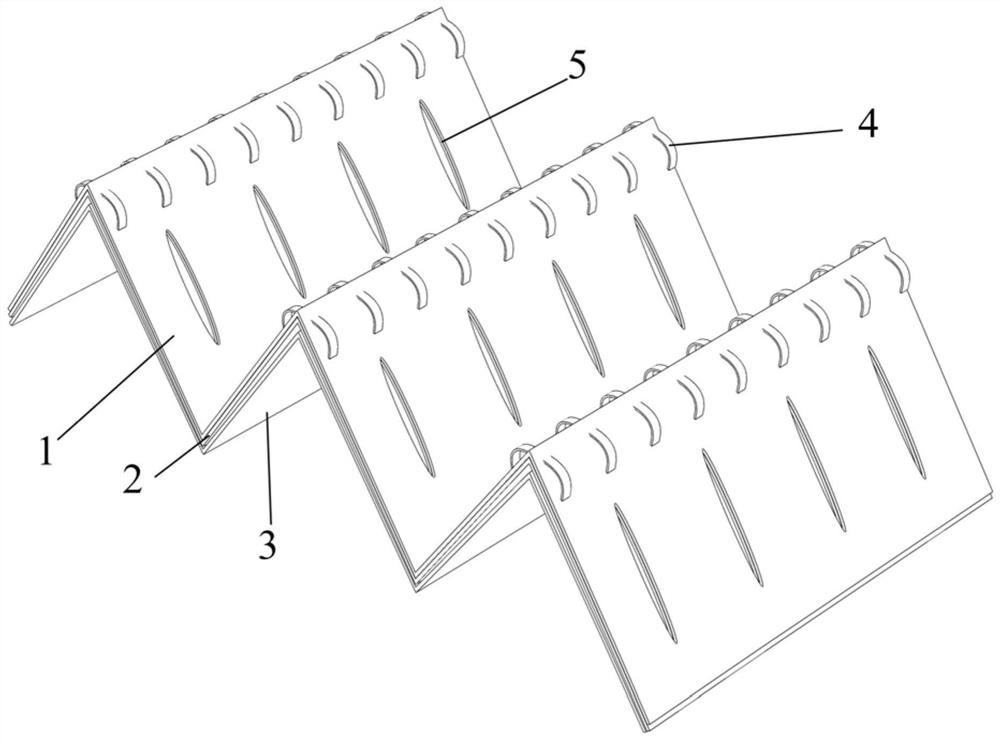

[0046] A method for manufacturing a photothermal device for solar steam generation, the steps are as follows:

[0047] (1) Preparation of photothermal layer: the wicking speed made by weaving carbon fiber is 90mm / 10min and the weight is 200g / m 2 Woven fabric (photothermal layer);

[0048] Preparation of plastic-coated wire mesh: use plastic-coated copper wire with a diameter of 1.6mm as raw material, set the warp density and weft density to 0.8 wires / cm, and make a woven structure mesh; fold the mesh to form plastic-coated wire Net, the horizontal projection of the plastic-coated wire mesh is a rectangle I, the side projection is a rectangle II, and the front projection is a broken line, each line segment of the broken line is equal (length is 1.1m), and the line segments at intervals are parallel to each other; The height of the plastic-coated wire mesh is the distance between the top of the folded line and the bottom of the folded line, and the height of the plastic-coated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com