Processing method of shiitake mushroom crispy chips

A processing method and technology for shiitake mushrooms, applied in the field of food processing, can solve problems such as poor taste, poor color and loss of nutrients, and achieve the effects of enhancing permeability, reducing frying time, and reducing absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

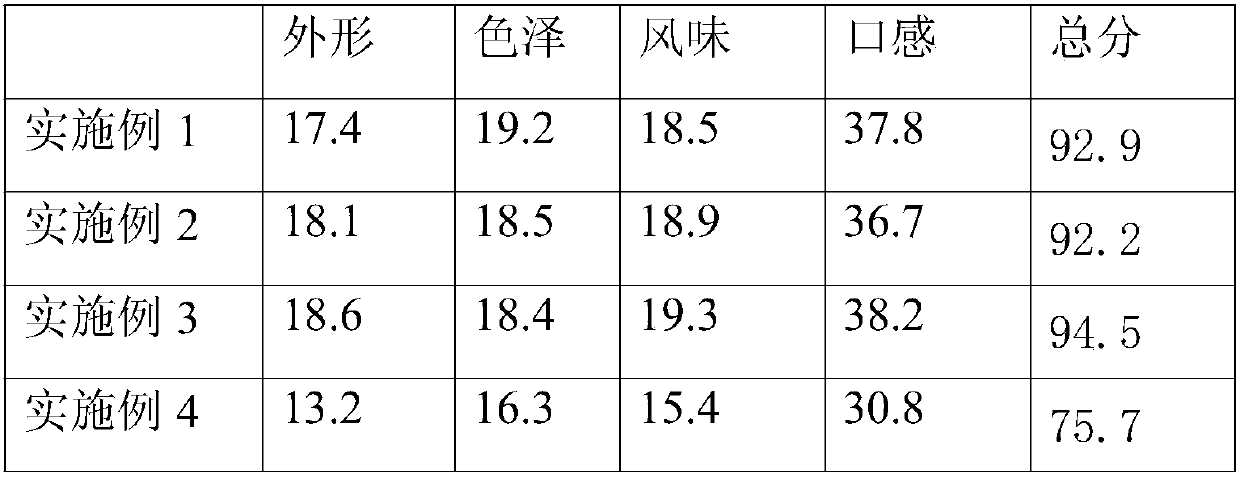

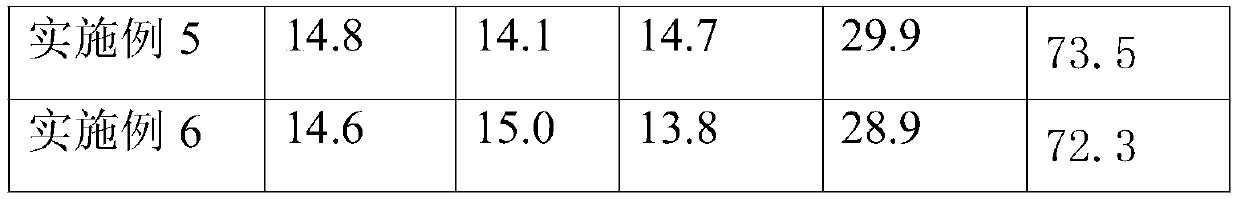

Examples

Embodiment 1

[0029] A method for processing shiitake mushroom chips includes the following steps:

[0030] 1) Preparation: Choose fresh shiitake mushrooms, clean them, and slice them for later use;

[0031] 2) Color protection: mix the shiitake mushrooms with the color protection liquid at a mass ratio of 3:1.2;

[0032] 3) Maturation: The shiitake mushroom slices obtained in step 2) are matured in solution 1 at a temperature of 85°C for 5 min;

[0033] 4) Dipping: Place the matured mushrooms in the spice liquid, the mass ratio of the mushrooms to the spice is 3:0.3, and place it at 40°C for 30 minutes;

[0034] 5) Quick freezing: Treat the shiitake mushrooms processed in step 4) at -20°C for 2h;

[0035] 6) Vacuum frying: Put the quick-frozen shiitake mushroom slices into vacuum frying;

[0036] 7) De-oiling: De-oil the shiitake mushroom slices obtained in step 6).

[0037] The color protection liquid includes the following components by mass: 20 g of hawthorn, 10 g of mint, 10 g of Bletilla striata, ...

Embodiment 2

[0049] A method for processing shiitake mushroom chips includes the following steps:

[0050] 1) Preparation: Choose fresh shiitake mushrooms, clean them, and slice them for later use;

[0051] 2) Color protection: mix the shiitake mushrooms with the color protection liquid at a mass ratio of 4:1.5;

[0052] 3) Maturation: The shiitake mushroom slices obtained in step 2) are matured in solution 1 at a temperature of 87°C for 8 min;

[0053] 4) Dipping: Place the matured mushrooms in the spice liquid, the mass ratio of the mushrooms to the spice is 4:0.4, and place it at 41°C for 35 minutes;

[0054] 5) Quick freezing: Treat the mushrooms processed in step 4) at -22°C for 2.3 hours;

[0055] 6) Vacuum frying: Put the quick-frozen shiitake mushroom slices into vacuum frying;

[0056] 7) De-oiling: De-oil the shiitake mushroom slices obtained in step 6).

[0057] The color protection liquid includes the following components by mass: 21 g of hawthorn, 13 g of mint, 11 g of Bletilla striata, an...

Embodiment 3

[0069] A method for processing shiitake mushroom chips includes the following steps:

[0070] 1) Preparation: Choose fresh shiitake mushrooms, clean them, and slice them for later use;

[0071] 2) Color protection: mix the shiitake mushrooms with the color protection liquid at a mass ratio of 5:1.7;

[0072] 3) Maturation: The shiitake mushroom slices obtained in step 2) are matured in solution 1, at a temperature of 90°C, and matured for 10 minutes;

[0073] 4) Dipping: Place the matured mushrooms in the spice liquid, the mass ratio of the mushrooms to the spice is 5:0.5, and place them at 45°C for 40 minutes;

[0074] 5) Quick freezing: Treat the mushrooms processed in step 4) at -25°C for 3 hours;

[0075] 6) Vacuum frying: Put the quick-frozen shiitake mushroom slices into vacuum frying;

[0076] 7) De-oiling: De-oil the shiitake mushroom slices obtained in step 6).

[0077] The color protection liquid includes the following raw materials in parts by mass: 23 g of hawthorn, 15 g of min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com